Beruflich Dokumente

Kultur Dokumente

Pilgrim Nut

Hochgeladen von

Jitendra KumarOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pilgrim Nut

Hochgeladen von

Jitendra KumarCopyright:

Verfügbare Formate

o

PILGRIM NUT

Assembly

Propeller bedded to tailshaft and jacked up to usual shop mark. The Pilgrim nut is then screwed on the shaft

with the loading ring against the prop boss. With the lever operated, high pressure grease gun, grease is pumped

into the inner tube inside the nut at around 600 bar, ( w.p. stamped on nut, not to be eceeded!, the prop will be

pushed sufficientl" up the taper to give the re#uired frictional grip. The pressure is then released and the nut is

rotated until it is hard up against the aft face of the prop hub and locked, fair water cone then fitted.

Removal

$fter removal of fair water cone and the locking plate, the pilgrim nut is removed, reversed and together with a

loose shock ring is screwed back onto the shaft. $ strong back is fitted and secured with studs to the prop boss.

%rease is now inserted to the s"stem epanding the inner tube forcing the loading ring, strongback, withdrawal

studs and prop aft.

Advantages

Precise tightening working on a measured applied load

Adequate interference fit

no heat used

Simple and safe to operate

No shock loads applied

Considerable saving in man power and time

Das könnte Ihnen auch gefallen

- Common Rail Fuel Injection Technology in Diesel EnginesVon EverandCommon Rail Fuel Injection Technology in Diesel EnginesNoch keine Bewertungen

- Meo Class 4Dokument55 SeitenMeo Class 4adam shaneNoch keine Bewertungen

- Southern Marine Engineering Desk Reference: Second Edition Volume IiVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNoch keine Bewertungen

- Steering Gear From Marineengg Uk Site PDFDokument32 SeitenSteering Gear From Marineengg Uk Site PDFPratham SinghNoch keine Bewertungen

- Operational Information The Two Stroke Crosshead Engine The Stuffing BoxDokument6 SeitenOperational Information The Two Stroke Crosshead Engine The Stuffing BoxAbhishek Singh ChauhanNoch keine Bewertungen

- Exhaust Valve Overhaul (Two Stroke Engine)Dokument19 SeitenExhaust Valve Overhaul (Two Stroke Engine)غازي عليNoch keine Bewertungen

- Marine Main Engine ComponentsDokument117 SeitenMarine Main Engine ComponentsNandakishore Pradeep100% (1)

- Purifier Manual DesludgeDokument1 SeitePurifier Manual Desludgesubscru100% (1)

- Batch PurificationDokument4 SeitenBatch PurificationthirdNoch keine Bewertungen

- Meo Class 4 QuestionsDokument13 SeitenMeo Class 4 QuestionsAthulRKrishnanNoch keine Bewertungen

- Puncture ValveDokument1 SeitePuncture ValveAnkit DedhiyaNoch keine Bewertungen

- Cargo Oil Pump Turbine Operating Instructions: StartingDokument4 SeitenCargo Oil Pump Turbine Operating Instructions: StartingSaratkumar RatnalaNoch keine Bewertungen

- Thrust BlockDokument2 SeitenThrust Blockkyaw yaNoch keine Bewertungen

- November 2016: SECTION - 1: Answer at Least TWO Questions SECTION - 2: Answer at Least TWO QuestionsDokument2 SeitenNovember 2016: SECTION - 1: Answer at Least TWO Questions SECTION - 2: Answer at Least TWO QuestionsArun SNoch keine Bewertungen

- Compressor SafetiesDokument2 SeitenCompressor Safetiesvic.barca2012Noch keine Bewertungen

- Fuel Pump Overhauling DismantlinDokument5 SeitenFuel Pump Overhauling DismantlinAnoop Vijayakumar100% (1)

- CoC Oral Exam Preparation (Part - 16) - CO2 Flooding System - Marine StudyDokument6 SeitenCoC Oral Exam Preparation (Part - 16) - CO2 Flooding System - Marine StudyShaip Sankar100% (1)

- July - Aug 2016 Marine Engineering at Operational Level Function 4BDokument4 SeitenJuly - Aug 2016 Marine Engineering at Operational Level Function 4Brajish2014Noch keine Bewertungen

- 15 PPM Bilge AlarmDokument9 Seiten15 PPM Bilge AlarmIgnacio SantanaNoch keine Bewertungen

- Bow ThrusterDokument19 SeitenBow ThrusterAnakin SkywalkerNoch keine Bewertungen

- Handout Deck Machinery PDFDokument20 SeitenHandout Deck Machinery PDFMalik ForbesNoch keine Bewertungen

- Fun 3 & 6 Q & A UpdatedDokument173 SeitenFun 3 & 6 Q & A Updatedrajesh kumarNoch keine Bewertungen

- Raising Steam From A Cold ConditionDokument3 SeitenRaising Steam From A Cold ConditionbadpplNoch keine Bewertungen

- 001 Bearing FailureDokument1 Seite001 Bearing FailureHiddenDNoch keine Bewertungen

- Latest Oral Questions MEO Class 4 Mumbai MMDDokument23 SeitenLatest Oral Questions MEO Class 4 Mumbai MMDanon_322442463Noch keine Bewertungen

- 6 Checking and Adjustment of Exhaust Cam LeadDokument8 Seiten6 Checking and Adjustment of Exhaust Cam LeadJomari Saligan100% (1)

- Section - 1: Meo Class 4 - Electrical Oral Questions With AnswersDokument81 SeitenSection - 1: Meo Class 4 - Electrical Oral Questions With AnswersHelna joseph JOSENoch keine Bewertungen

- Boiler Maintenance Checklist: Inspection and Safety Checks To Marine Steam BoilerDokument9 SeitenBoiler Maintenance Checklist: Inspection and Safety Checks To Marine Steam BoilerChriscarl De LimaNoch keine Bewertungen

- Types Liner Material Problems in Liner Liner Inspection Liner Calibration Difference Between MAN B&W and SULZER LinersDokument7 SeitenTypes Liner Material Problems in Liner Liner Inspection Liner Calibration Difference Between MAN B&W and SULZER LinersRicardo Garing100% (2)

- Safety Meo Class 4Dokument18 SeitenSafety Meo Class 4Bhargav Krsna GayanNoch keine Bewertungen

- MT VICTORY Report On Decarbonization of Auxiliary EnginesDokument3 SeitenMT VICTORY Report On Decarbonization of Auxiliary Engineskailash behera100% (1)

- Class 4 Frequent Asked Qs Shashwat000Dokument168 SeitenClass 4 Frequent Asked Qs Shashwat000Lovy Singh100% (1)

- REEDS - BOILERS - PAGES 01 To 40Dokument40 SeitenREEDS - BOILERS - PAGES 01 To 40Narendra niranjan MathiyarasuNoch keine Bewertungen

- Slide Fuel ValvesDokument2 SeitenSlide Fuel ValvesSpasoje100% (1)

- Crank Case Inspection ProcedureDokument6 SeitenCrank Case Inspection ProcedureSid ACHARYANoch keine Bewertungen

- Stern Tubes PDFDokument8 SeitenStern Tubes PDFrajishrrr100% (1)

- Accommodation Ladder NewDokument9 SeitenAccommodation Ladder NewBrian Voyd RebitoNoch keine Bewertungen

- Ram Steering Gear - OperationsDokument8 SeitenRam Steering Gear - Operationsnarendra rathoreNoch keine Bewertungen

- The Air Start ValveDokument5 SeitenThe Air Start ValveRejoGevargheseRajan100% (1)

- Stuffing BoxDokument2 SeitenStuffing BoxMeghali Borle67% (3)

- BB. Docking Indent (Repair) Pioneer. 13th Feb.20Dokument11 SeitenBB. Docking Indent (Repair) Pioneer. 13th Feb.20Thiet PhamNoch keine Bewertungen

- Mehr OtraDokument13 SeitenMehr OtraThomas JoseNoch keine Bewertungen

- Main Engine (S) Unit 6 OverhaulDokument4 SeitenMain Engine (S) Unit 6 OverhaulMocanu MarianNoch keine Bewertungen

- FWGDokument8 SeitenFWGSWASTIK MISHRANoch keine Bewertungen

- 2 Stroke Diesel EngineDokument5 Seiten2 Stroke Diesel EngineJims Cudinyerah100% (1)

- Assorted QuestionsDokument17 SeitenAssorted QuestionsRohit MishraNoch keine Bewertungen

- 4th Class Orals: Return To Cadets HomeDokument9 Seiten4th Class Orals: Return To Cadets HomeJJK112Noch keine Bewertungen

- Some Test About RuddersDokument2 SeitenSome Test About RuddersVaibhav DesaiNoch keine Bewertungen

- BADA (BADA Heavy Industries) - CatalogDokument24 SeitenBADA (BADA Heavy Industries) - CatalogSholeh KhuddinNoch keine Bewertungen

- An Introduction To Vibration Aspects of Two-Stroke Diesel Engines I, N ShipsDokument11 SeitenAn Introduction To Vibration Aspects of Two-Stroke Diesel Engines I, N Shipshpss77100% (1)

- Class 4 2018 Kolkata MMD QuestionsDokument155 SeitenClass 4 2018 Kolkata MMD QuestionsAbhinandan ChandraNoch keine Bewertungen

- Safety Meo Class 4 CocDokument16 SeitenSafety Meo Class 4 CocROSHANNoch keine Bewertungen

- Indicator Diagrams of Diesel EnginesDokument5 SeitenIndicator Diagrams of Diesel EnginesAbdul Anis67% (3)

- FRAMO SYSTEM Drain and VentDokument3 SeitenFRAMO SYSTEM Drain and VentjoelandrewpintoNoch keine Bewertungen

- Auxillary Engine TroubleshootingDokument4 SeitenAuxillary Engine Troubleshootingneo_nitinNoch keine Bewertungen

- Mep Oral AnswersDokument28 SeitenMep Oral AnswersAshjo Gamer100% (1)

- Mounting WhitepaperDokument7 SeitenMounting WhitepaperSamik MukherjeeNoch keine Bewertungen

- Haynes Pump 6500 ManualDokument8 SeitenHaynes Pump 6500 Manualhiram avilaNoch keine Bewertungen

- Packer Setting MechanismDokument3 SeitenPacker Setting MechanismYougchu Luan67% (3)

- AsasasasasasasDokument1 SeiteAsasasasasasasmateoNoch keine Bewertungen

- Overall Arrangement: Description of The Salient PartsDokument6 SeitenOverall Arrangement: Description of The Salient PartsJitendra KumarNoch keine Bewertungen

- Increasing Propulsive EfficiencyDokument6 SeitenIncreasing Propulsive EfficiencyJitendra KumarNoch keine Bewertungen

- PID TuningDokument4 SeitenPID TuningJitendra Kumar100% (1)

- Oxygen AnalysersDokument2 SeitenOxygen AnalysersJitendra KumarNoch keine Bewertungen

- Oil WhirlDokument2 SeitenOil WhirlJitendra KumarNoch keine Bewertungen

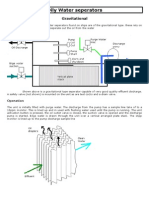

- Oily Water SeperatorsDokument2 SeitenOily Water SeperatorsJitendra KumarNoch keine Bewertungen

- Navigation LightingDokument1 SeiteNavigation LightingJitendra KumarNoch keine Bewertungen

- Motor Ship Steam Plant ControlDokument1 SeiteMotor Ship Steam Plant ControlJitendra KumarNoch keine Bewertungen

- Motor Ship Steam Plan1Dokument3 SeitenMotor Ship Steam Plan1Jitendra KumarNoch keine Bewertungen

- Tooth Design: Forces Acting On Spur GearsDokument77 SeitenTooth Design: Forces Acting On Spur GearsJitendra KumarNoch keine Bewertungen

- LNG Containment DesignsDokument3 SeitenLNG Containment DesignsJitendra KumarNoch keine Bewertungen

- Hydraulic SystemsDokument4 SeitenHydraulic SystemsJitendra KumarNoch keine Bewertungen

- Lifting Using Accessories: Calculation of LoadDokument2 SeitenLifting Using Accessories: Calculation of LoadJitendra KumarNoch keine Bewertungen

- Liquified Gas CargoesDokument2 SeitenLiquified Gas CargoesJitendra KumarNoch keine Bewertungen

- Jacket Water SystemDokument2 SeitenJacket Water SystemJitendra KumarNoch keine Bewertungen

- Mechanical GovernorsDokument1 SeiteMechanical GovernorsJitendra KumarNoch keine Bewertungen

- LiftingDokument5 SeitenLiftingJitendra KumarNoch keine Bewertungen

- Holding Down ArrangementsDokument3 SeitenHolding Down ArrangementsJitendra KumarNoch keine Bewertungen

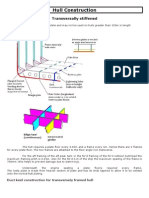

- Hull ConstructionDokument4 SeitenHull ConstructionJitendra KumarNoch keine Bewertungen

- Hydraulic GovernorsDokument6 SeitenHydraulic GovernorsJitendra KumarNoch keine Bewertungen

- Halon 1301 Bromotrichlhoromethane CF3BrDokument2 SeitenHalon 1301 Bromotrichlhoromethane CF3BrJitendra Kumar0% (1)