Beruflich Dokumente

Kultur Dokumente

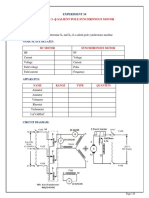

Electrical Power Systrem

Hochgeladen von

Sagar ThotaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Electrical Power Systrem

Hochgeladen von

Sagar ThotaCopyright:

Verfügbare Formate

M9920102

2010 11/09

4.12 The three-phase synchronous machine of Problem

4.9 is to be moved to an application which

requires that its operating frequency be reduced

from 60 to 50Hz. This application requires that ,

for the operating condition considered in Problem

4.8, the Vrms generated voltage equal 13.0 kV

line-to-line. As a result, the machine armature

must be rewound with a different number of

turns. Assuming a winding factor of Kw=0.928,

calculate the required number of series turns per

phase.

Solution 4.12

4.18 A two-pole, 60 Hz, three-phase, laboratory-size synchronous

generator has a rotor radius of 5.71 cm, a rotor length of 18.0 cm,

and an air-gap length of 0.25 mm. The rotor filed winding consists

of 264 turns with a winding factor of kr = 0.95. The Y-connected

armature winding consists of the 45 turns per phase with a

winding actor kw = 0.93.

a. Calculate the flux per pole and peak fundamental air-gap flux

density which will result in an open-circuit, 60-Hz armature

voltage of 120 V rms / phase (line-to-neutral).

b. Calculate the dc field current required to achieve the operating

condition of part (a).

c. Calculate the peak values of the field-winding to armature-

phase winding mutual inductance.

Solution 4.18

4.20 A four-pole, 60Hz synchronous generators has a

rotor length of 5.2 m, diameter of 1.24 m, and air-

gap length of 5.9 cm. The rotor winding consists of

a series connection of 63 turns per pole with a

winding factor of Kr = 0.91. The peak values of the

fundamental air-gap flux density is limited to 1.1 T

and the rotor winding current to 2700 A. Calculate

the maximum torque (N.m) and power output

(MW) which can be supply by this machine.

Solution 4.20

Thank you

Very much!!

Das könnte Ihnen auch gefallen

- High Voltage Direct Current Transmission: Converters, Systems and DC GridsVon EverandHigh Voltage Direct Current Transmission: Converters, Systems and DC GridsNoch keine Bewertungen

- Numerical Problems Synchronous MachinesDokument3 SeitenNumerical Problems Synchronous MachinestusharNoch keine Bewertungen

- Synchronous Machine DesignDokument35 SeitenSynchronous Machine DesignvietnhuNoch keine Bewertungen

- Practical ExamDokument2 SeitenPractical ExamIrfan AliNoch keine Bewertungen

- Chapter3 InductionmachineDokument25 SeitenChapter3 InductionmachineAbhijitNoch keine Bewertungen

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsVon EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNoch keine Bewertungen

- 6 +ok+MEASURE+MENT+OF+SEQUENCE+REACTANCES+OF+SALIENT+POLE+SYNCHRONOUS+MACHINEDokument3 Seiten6 +ok+MEASURE+MENT+OF+SEQUENCE+REACTANCES+OF+SALIENT+POLE+SYNCHRONOUS+MACHINEaissmsNoch keine Bewertungen

- Integration of Green and Renewable Energy in Electric Power SystemsVon EverandIntegration of Green and Renewable Energy in Electric Power SystemsNoch keine Bewertungen

- Static and Dynamic Characteristics ofDokument7 SeitenStatic and Dynamic Characteristics ofAman SinghNoch keine Bewertungen

- Solid State Drives Short BookDokument48 SeitenSolid State Drives Short BookGomathi Raja MNoch keine Bewertungen

- International Refereed Journal of Engineering and Science (IRJES)Dokument8 SeitenInternational Refereed Journal of Engineering and Science (IRJES)www.irjes.comNoch keine Bewertungen

- Control Structures of Power Electronics For DPGSDokument23 SeitenControl Structures of Power Electronics For DPGSAnna Maria BanicaNoch keine Bewertungen

- Electrical Machines I Lab Twisted QuestionsDokument4 SeitenElectrical Machines I Lab Twisted QuestionsPranav MenonNoch keine Bewertungen

- Torsion Testing MachineDokument5 SeitenTorsion Testing Machinegosaye desalegnNoch keine Bewertungen

- Steady-State Analysis of DC MotorsDokument24 SeitenSteady-State Analysis of DC MotorsUsama RaoNoch keine Bewertungen

- Static Excitation System Stage-I. 2docDokument28 SeitenStatic Excitation System Stage-I. 2docraghavendran raghu100% (1)

- Tutorial 1 (Transformers)Dokument5 SeitenTutorial 1 (Transformers)Vishal GaurNoch keine Bewertungen

- Questions 1Dokument11 SeitenQuestions 1anvithaNoch keine Bewertungen

- Experiment No.5-Determination of XD and XQ of Synchronous Machine by Slip TestDokument3 SeitenExperiment No.5-Determination of XD and XQ of Synchronous Machine by Slip Test61EEPrabhat PalNoch keine Bewertungen

- Slip Test On Salient Pole MachineDokument3 SeitenSlip Test On Salient Pole Machinedeepak reddyNoch keine Bewertungen

- Control System Lab ManualDokument62 SeitenControl System Lab ManualVenkata Subramanian0% (1)

- Generator Controls Voltage StabilityDokument13 SeitenGenerator Controls Voltage StabilityhhipowerNoch keine Bewertungen

- Analysis of Chopper Fed D.C. Drive With PWM & Hysteresis Current Control SchemeDokument8 SeitenAnalysis of Chopper Fed D.C. Drive With PWM & Hysteresis Current Control SchemeS Bharadwaj ReddyNoch keine Bewertungen

- Publication 1 19208 6043Dokument13 SeitenPublication 1 19208 6043Stephen Velasco Villaruz0% (1)

- Acdc - Synchronous Motor - Lecture Notes 9Dokument19 SeitenAcdc - Synchronous Motor - Lecture Notes 9Cllyan Reyes100% (1)

- Steady-State Stability Limit Studies Using Matlab SimulationDokument12 SeitenSteady-State Stability Limit Studies Using Matlab SimulationPius OdabaNoch keine Bewertungen

- Rotor Flux Based MRASDokument6 SeitenRotor Flux Based MRASMastan ReddyNoch keine Bewertungen

- SMPC NotesDokument98 SeitenSMPC NotesHarsha Anantwar100% (1)

- Optimization Techniques For Power System ProblemsDokument12 SeitenOptimization Techniques For Power System ProblemsAhsan SaleemNoch keine Bewertungen

- Chapter 1 DC Drives Part2Dokument75 SeitenChapter 1 DC Drives Part2Mohammad MunzirNoch keine Bewertungen

- VT Guard Pro - Technical ArticleDokument4 SeitenVT Guard Pro - Technical ArticleAdemir DzanicNoch keine Bewertungen

- A New Method For Online Thyristor Conduction Monitoring Based On Thyristor Current Waveform Recording in Static Excitation SystemDokument6 SeitenA New Method For Online Thyristor Conduction Monitoring Based On Thyristor Current Waveform Recording in Static Excitation SystemR0B0T2013Noch keine Bewertungen

- EE360 - Synchronous MachinesDokument85 SeitenEE360 - Synchronous MachinesAliAl-jaziriNoch keine Bewertungen

- Transformer FaultsDokument11 SeitenTransformer FaultsMusembiNoch keine Bewertungen

- DC MachinesDokument52 SeitenDC MachinesArun Kumar100% (1)

- Electrical Engineering QUESTION BANKDokument7 SeitenElectrical Engineering QUESTION BANKMATHANKUMAR.S100% (1)

- Synchronous Machine: Generator MotorDokument14 SeitenSynchronous Machine: Generator Motorhafiz_jaaffar100% (1)

- Asynchronous and Synchronous Machines (EL-208) (IV SEM EL Session 2017-18) Tutorial Sheet 1 (Dated 08.01.2018) (3 Phase Induction MotorsDokument10 SeitenAsynchronous and Synchronous Machines (EL-208) (IV SEM EL Session 2017-18) Tutorial Sheet 1 (Dated 08.01.2018) (3 Phase Induction MotorsKushagra BhatiaNoch keine Bewertungen

- 1.AC DC InteractionDokument26 Seiten1.AC DC Interactionpvenky_kkdNoch keine Bewertungen

- Unit 1: The Power System Overview and ModelingDokument8 SeitenUnit 1: The Power System Overview and ModelingIhuhwa Marta TauNoch keine Bewertungen

- Frog Leg WindingDokument9 SeitenFrog Leg WindingAbhijeet RedekarNoch keine Bewertungen

- PQ Unit 1Dokument21 SeitenPQ Unit 1Ezhiln 0328sNoch keine Bewertungen

- Two Marks - UNIT IV - 28.10.2022Dokument13 SeitenTwo Marks - UNIT IV - 28.10.2022G.L. Jai Purushotham RajNoch keine Bewertungen

- Drives Manual Final EeeDokument60 SeitenDrives Manual Final EeenandhakumarmeNoch keine Bewertungen

- Design of A Driver IC IR2110 For MOSFETDokument21 SeitenDesign of A Driver IC IR2110 For MOSFETAyoub RajawiNoch keine Bewertungen

- Introduction To Power Systems (Eceg-3176) : Addis Ababa University Addis Ababa Institute of Technology (Aait)Dokument38 SeitenIntroduction To Power Systems (Eceg-3176) : Addis Ababa University Addis Ababa Institute of Technology (Aait)DANIEL ABERANoch keine Bewertungen

- Synchronous Machines Question BankDokument10 SeitenSynchronous Machines Question BankelecenggNoch keine Bewertungen

- Indian Institute of Engineering Science and Technology, Shibpur Department of Electrical EngineeringDokument4 SeitenIndian Institute of Engineering Science and Technology, Shibpur Department of Electrical EngineeringKool PrashantNoch keine Bewertungen

- Ems PDFDokument99 SeitenEms PDFSathish DevNoch keine Bewertungen

- IEEE Transactions On Magnetics Volume 22 Issue 5 1986 (Doi 10.1109 - Tmag.1986.1064466) Sebastian, T. Slemon, G. Rahman, M. - Modelling of Permanent Magnet Synchronous MotorsDokument3 SeitenIEEE Transactions On Magnetics Volume 22 Issue 5 1986 (Doi 10.1109 - Tmag.1986.1064466) Sebastian, T. Slemon, G. Rahman, M. - Modelling of Permanent Magnet Synchronous MotorsmauricetappaNoch keine Bewertungen

- Tutorial On Single Phase Induction MotorDokument1 SeiteTutorial On Single Phase Induction MotorHimanshu Saini0% (1)

- Power System Control and OperationDokument3 SeitenPower System Control and OperationSantosh ThapaNoch keine Bewertungen

- Power System Stabliser: A ReviewDokument71 SeitenPower System Stabliser: A ReviewPiyush AgnihotriNoch keine Bewertungen

- Doubly Fed Induction Generator For Wind Energy ConversionDokument32 SeitenDoubly Fed Induction Generator For Wind Energy Conversionanujayan0% (1)

- PCEG 403 Lab No. 1 Title: Simulation of Single Phase Half Wave Converter DC DriveDokument5 SeitenPCEG 403 Lab No. 1 Title: Simulation of Single Phase Half Wave Converter DC DriveJanup PokharelNoch keine Bewertungen

- Design of Electrical Machine Unit 1 2 MarksDokument6 SeitenDesign of Electrical Machine Unit 1 2 MarksVel MuruganNoch keine Bewertungen

- Government Polytechnic Muzaffarpur: Name of The Lab: Power Electronics & DrivesDokument18 SeitenGovernment Polytechnic Muzaffarpur: Name of The Lab: Power Electronics & DrivesVK DNoch keine Bewertungen

- Ratios and ProportionDokument10 SeitenRatios and ProportionSagar ThotaNoch keine Bewertungen

- VI CLASS MATHEMATICS 130 Perimeter and A PDFDokument14 SeitenVI CLASS MATHEMATICS 130 Perimeter and A PDFSagar ThotaNoch keine Bewertungen

- Water Bodies Class 6Dokument3 SeitenWater Bodies Class 6Sagar ThotaNoch keine Bewertungen

- Control System Objective Type QuestionsDokument18 SeitenControl System Objective Type QuestionsVinod MuruganNoch keine Bewertungen

- Electrical Hazard Awareness Study GuideDokument49 SeitenElectrical Hazard Awareness Study GuideKARAM ZAKARIANoch keine Bewertungen

- CBSE Class 5 Maths Revision Worksheets (1) - 0Dokument3 SeitenCBSE Class 5 Maths Revision Worksheets (1) - 0Rajeev KaushikNoch keine Bewertungen

- Ee Gate 2010Dokument16 SeitenEe Gate 2010Sekhar ChallaNoch keine Bewertungen

- Control Systems (OBJ) - G.K.Debbe PDFDokument99 SeitenControl Systems (OBJ) - G.K.Debbe PDFSagar ThotaNoch keine Bewertungen

- Power Distribution SystemDokument120 SeitenPower Distribution SystemSagar ThotaNoch keine Bewertungen

- Electrical Distribution SystemDokument30 SeitenElectrical Distribution SystemSagar Thota0% (1)

- Galgotia Question Bank in Electrical and Eelectronics Engineering Bby RaiDokument895 SeitenGalgotia Question Bank in Electrical and Eelectronics Engineering Bby RaiSagar Thota71% (59)

- Recommendations For Students With High Functioning AutismDokument7 SeitenRecommendations For Students With High Functioning AutismLucia SaizNoch keine Bewertungen

- II 2022 06 Baena-Rojas CanoDokument11 SeitenII 2022 06 Baena-Rojas CanoSebastian GaonaNoch keine Bewertungen

- 5c3f1a8b262ec7a Ek PDFDokument5 Seiten5c3f1a8b262ec7a Ek PDFIsmet HizyoluNoch keine Bewertungen

- Problem Set-02Dokument2 SeitenProblem Set-02linn.pa.pa.khaing.2020.2021.fbNoch keine Bewertungen

- Broken BondsDokument20 SeitenBroken Bondsapi-316744816Noch keine Bewertungen

- School of Mathematics 2021 Semester 1 MAT1841 Continuous Mathematics For Computer Science Assignment 1Dokument2 SeitenSchool of Mathematics 2021 Semester 1 MAT1841 Continuous Mathematics For Computer Science Assignment 1STEM Education Vung TauNoch keine Bewertungen

- IKEA SHANGHAI Case StudyDokument5 SeitenIKEA SHANGHAI Case StudyXimo NetteNoch keine Bewertungen

- Electro Fashion Sewable LED Kits WebDokument10 SeitenElectro Fashion Sewable LED Kits WebAndrei VasileNoch keine Bewertungen

- Developing Paragraphs: Test Section - Writing Task 2Dokument11 SeitenDeveloping Paragraphs: Test Section - Writing Task 2Cengizhan AkdağNoch keine Bewertungen

- Working Capital in YamahaDokument64 SeitenWorking Capital in YamahaRenu Jindal50% (2)

- Washing Machine: Service ManualDokument66 SeitenWashing Machine: Service ManualFernando AlmeidaNoch keine Bewertungen

- An Exploration of The Ethno-Medicinal Practices Among Traditional Healers in Southwest Cebu, PhilippinesDokument7 SeitenAn Exploration of The Ethno-Medicinal Practices Among Traditional Healers in Southwest Cebu, PhilippinesleecubongNoch keine Bewertungen

- The Construction of Optimal Portfolio Using Sharpe's Single Index Model - An Empirical Study On Nifty Metal IndexDokument9 SeitenThe Construction of Optimal Portfolio Using Sharpe's Single Index Model - An Empirical Study On Nifty Metal IndexRevanKumarBattuNoch keine Bewertungen

- Outdoor Air Pollution: Sources, Health Effects and SolutionsDokument20 SeitenOutdoor Air Pollution: Sources, Health Effects and SolutionsCamelia RadulescuNoch keine Bewertungen

- GT-N7100-Full Schematic PDFDokument67 SeitenGT-N7100-Full Schematic PDFprncha86% (7)

- Chapter 1 To 5 For Printing.2Dokument86 SeitenChapter 1 To 5 For Printing.2Senku ishigamiNoch keine Bewertungen

- 1.technical Specifications (Piling)Dokument15 Seiten1.technical Specifications (Piling)Kunal Panchal100% (2)

- TIMO Final 2020-2021 P3Dokument5 SeitenTIMO Final 2020-2021 P3An Nguyen100% (2)

- The Magic DrumDokument185 SeitenThe Magic Drumtanishgiri2012Noch keine Bewertungen

- AnticyclonesDokument5 SeitenAnticyclonescicileanaNoch keine Bewertungen

- Ito Na Talaga Yung FinalDokument22 SeitenIto Na Talaga Yung FinalJonas Gian Miguel MadarangNoch keine Bewertungen

- Oracle Forms & Reports 12.2.1.2.0 - Create and Configure On The OEL 7Dokument50 SeitenOracle Forms & Reports 12.2.1.2.0 - Create and Configure On The OEL 7Mario Vilchis Esquivel100% (1)

- Lesson 5 Designing and Developing Social AdvocacyDokument27 SeitenLesson 5 Designing and Developing Social Advocacydaniel loberizNoch keine Bewertungen

- Talking Art As The Spirit Moves UsDokument7 SeitenTalking Art As The Spirit Moves UsUCLA_SPARCNoch keine Bewertungen

- Companyprofil E: Erfanconstructionsolut IonDokument14 SeitenCompanyprofil E: Erfanconstructionsolut IonNurin AleesyaNoch keine Bewertungen

- Role of Personal Finance Towards Managing of Money - DraftaDokument35 SeitenRole of Personal Finance Towards Managing of Money - DraftaAndrea Denise Lion100% (1)

- Heterogeneity in Macroeconomics: Macroeconomic Theory II (ECO-504) - Spring 2018Dokument5 SeitenHeterogeneity in Macroeconomics: Macroeconomic Theory II (ECO-504) - Spring 2018Gabriel RoblesNoch keine Bewertungen

- LEIA Home Lifts Guide FNLDokument5 SeitenLEIA Home Lifts Guide FNLTejinder SinghNoch keine Bewertungen

- Ricoh IM C2000 IM C2500: Full Colour Multi Function PrinterDokument4 SeitenRicoh IM C2000 IM C2500: Full Colour Multi Function PrinterKothapalli ChiranjeeviNoch keine Bewertungen

- DC 7 BrochureDokument4 SeitenDC 7 Brochures_a_r_r_yNoch keine Bewertungen