Beruflich Dokumente

Kultur Dokumente

Smart CDI

Hochgeladen von

jose sousa oliveira100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

1K Ansichten22 SeitenCopyright

© © All Rights Reserved

Verfügbare Formate

PPT, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

1K Ansichten22 SeitenSmart CDI

Hochgeladen von

jose sousa oliveiraCopyright:

© All Rights Reserved

Verfügbare Formate

Als PPT, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 22

T0503F <> Issue date 01/2012 smart Training

open your mind.

T0503F <> Issue date 01/2012 smart Training

Engine variants 2007 09/2010

Engine M132(45kW) M132(52kW) M132(62kW) M132(72kW) OM660/1(33kW) OM660/2(33kW) OM660/3(40kW)

Vehicle 451mhd 451mhd 451 turbo 451 turbo 451(DPF open) 451(DPF closed) 451(DPF closed)

Model designation 132.910 132.910 132.930 132.930 660.950 660.950 660.950

Emissions standard EU4 EU4 EU4 EU4 EU4 EU4 EU5

Engine model

3 cylinder in-line

engine

3 cylinder in-line

engine

3 cylinder in-line

engine

3 cylinder in-line

engine

3 cylinder in-line engine 3 cylinder in-line engine 3 cylinder in-line engine

Installation position Rear/transverse Rear/transverse Rear/transverse Rear/transverse Rear/transverse Rear/transverse Rear/transverse

Rated output kW (HP) 45 (61) 52 (71) 62 (84) 72 (98) 33 (45) 33 (45) 40 (54)

At speed 5800 5800 5250 5500 3800 3800 3800

Torque (Nm) 89 92 120 140 110 110 130

Valves per cylinder 4 (VVT) 4 (VVT) 4 (VVT) 4 (VVT) 2 2 2

Valve assembly

Bucket tappet direct

drive

Bucket tappet direct

drive

Bucket tappet direct

drive

Bucket tappet direct

drive

Hydraulic tappet Hydraulic tappet Hydraulic tappet

Variable valve timing Manual at 100,000 Km Manual at 100,000 Km Manual at 90,000 Km Manual at 90,000 Km

Automatic

hydraulic

Automatic

Hydraulic

Automatic

hydraulic

Spark plugs per cylinder 1 1 1 1

Common-rail

direct injection

Common-rail

direct injection

Common-rail

direct injection

Displacement (cm) 999 999 999 999 799 799 799

Compression ratio 11.4:1 11.4:1 10.0:1 10.0:1 18.5:1 18.5:1 16.3:1

Camshaft DOHC/chain DOHC/chain DOHC/chain DOHC/chain OHC/chain OHC/chain OHC/chain

Stroke (mm) 81.8 81.8 81.8 81.8 79 79 79

Bore (mm) 72 72 72 72 65.5 65.5 65.5

T0503F <> Issue date 01/2012 smart Training

Engine variants as of 10/2010

Engine M132(45kW) M132(52kW) M132(62kW) M132(74kW) OM660/3(40kW)

Vehicle 451mhd 451mhd 451 turbo 451 turbo 451(DPF closed)

Model designation 132.910 132.910 132.930 132.930 660.950

Emissions standard EU5 EU5 EU5 EU5 EU5

Engine model 3 cylinder in-line engine 3 cylinder in-line engine 3 cylinder in-line engine 3 cylinder in-line engine 3 cylinder in-line engine

Installation position Rear/transverse Rear/transverse Rear/transverse Rear/transverse Rear/transverse

Rated output kW (HP) 45 (61) 52 (71) 62 (84) 75 (102) 40 (54)

At speed 5800 5800 5250 6000 3800

Torque (Nm) 89 92 120 147 130

Valves per cylinder 4 (VVT) 4 (VVT) 4 (VVT) 4 (VVT) 2

Valve assembly Bucket tappet direct drive Bucket tappet direct drive Bucket tappet direct drive Bucket tappet direct drive Hydraulic tappet

Variable valve timing Manual at 100,000 Km Manual at 100,000 Km Manual at 90,000 Km Manual at 90,000 Km

Automatic hydraulic

Spark plugs per cylinder 1 1 1 1 Common-rail direct inj.

Displacement (cm) 999 999 999 999 799

Compression ratio 11.4:1 11.4:1 10.0:1 9.9:1 16.4:1

Camshaft DOHC/chain DOHC/chain DOHC/chain DOHC/chain OHC/chain

Stroke (mm) 81.8 81.8 81.8 81.8 79

Bore (mm) 72 72 72 72 65.5

Maximum speed (km/h) 145 145 145 155 135

ECE series veh. efficiency class C C E E B

T0503F <> Issue date 01/2012 smart Training

Diesel engine generation

Engine OM660/1 OM660/2 OM660/3

Model designation OM660.950 w/o code 474 OM660.950 with code 474 OM660.951

Build period 01/2007 01/2009 02/2009 09/2009 As of 10/2009

Engin output in KW 33 33 40

Emissions standard EURO 4 EURO 4 EURO 5

Open particle filter system Yes No No

Closed particle filter system No Yes Yes

Injection pressure in bar 1600 1600 1600

Element shutoff No No No

EGR valve (actuation)

Pneumatic Pneumatic Pneumatic

EGR cooler Yes Yes Yes

Classifiied injectors Yes Yes Yes

Hot-film air mass sensor Yes Yes Yes

T0503F <> Issue date 01/2012 smart Training

open your mind.

T0503F <> Issue date 01/2012 smart Training

OM660/1

System overview:

CDI 3

Injector quantity compensation (IMA) injectors

1600 bar

33 kW

110 Nm

Euro 4

Particulate filter

Changes in comparison to OM660:

B2/ 5 Hot film mass air flow sensor

B50 Fuel temperature sensor

G3/ 2 O2 sensor upstream of CAT (wideband sensor)

Y27 Exhaust gas recirculation switchover valve (pneumatic)

Y94 Quantity control valve

Y76/ 1 Cylinder 1 injection nozzle (injector quantity compensation)

Y76/ 2 Cylinder 2 injection nozzle (injector quantity compensation)

Y76/ 3 Cylinder 3 injection nozzle (injector quantity compensation)

T0503F <> Issue date 01/2012 smart Training

Coolant circuit OM660/1

R

A

D

I

A

T

O

R

AGB

H

E

A

T

E

R

Small coolant circuit

Large coolant circuit

KP

T

H

E

N

G

I

N

E

AGB Expansion reservoir

TH Thermostat

KP Coolant pump

Pipe set

Pipe 1

Pipe 3

Pipe 2

EGR cooler

T0503F <> Issue date 01/2012 smart Training

OM660/2

Changes in comparison to OM660/ 1:

Modified exhaust system with DPF and connections for

differential pressure sensor and temp. sensor

Modified mixing chamber with integrated pressure sensor (1)

Additional throttle valve (intake air throttle) (2)

Electronically regulated vacuum control of wastegate flap

(turbocharger)

Modified engine oil pan

(oil volume +0.9 liters), refill quantity 3.6 liters

Piston with cooling gallery

Modified vacuum hoses through additional

electropneumatic pressure converter * turbocharger

Differential pressure sensor incl. lines and hoses

Oil filter module with enlarged heat exchanger

* Electropneumatic pressure converter

T0503F <> Issue date 01/2012 smart Training

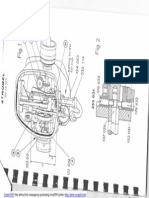

Piston with cooling gallery

OM 660/2

The modified piston is equipped with a cooling gallery,

which is supplied at the bottom with engine oil through

an oil injection nozzle in the crankshaft housing and

which is used to cool the piston crown.

Cooling gallery

T0503F <> Issue date 01/2012 smart Training

Enlarged engine oil pan

OM 660/2

The engine oil pan has been enlarged and the oil volume

increased by 0.9 liters

Refill quantity 3.6 liters

Use of low ash engine oil (Low Spash,

low-sulfur engien oil) as per Sheet 229.51

T0503F <> Issue date 01/2012 smart Training

Oil filter module

OM 660/2

The oil filter module has been given a larger heat

exchanger with greater cooling output

Heat exchanger equipped with extra heat sink

T0503F <> Issue date 01/2012 smart Training

OM 660/2

The exhaust system is differentiated externally to the open system by the two

connections of the differential pressure sensor and the temperature sensor.

Exhaust system with DPF

1. Exhaust system

2. CAT assembly

3. Monolith

4. Particulate filter

5. Suspension

6. Oxygens sensor

7. Temperature sensor

8. Short pressure line

9. Long pressure line

Differential pressure sensor

T0503F <> Issue date 01/2012 smart Training

OM 660/2

The vacuum supply for the turbochargers aneroid capsule is

electronically controlled.

This means that an additional EPT2* is required.

Vacuum supply

*Electropneumatic pressure transducer

T0503F <> Issue date 01/2012 smart Training

OM660/3

Component Change description

EGR cooler

Piston

Glow plugs + control unit

Thermostat

Control unit

Enlarged and switchable with bypass

-reduction 16.3 (piston combustion cavity) (old: 18.5:1)

Ceramics + software

Heated

Software for EU5 and OBD

Cylinder head

Crankcase

Cylinder-head bolts

Crankshaft

Connecting rod

Piston

Oil filter module

Reinforcement measures adapted to ceramic glow plugs

Screw-ion depth for cylinder head bolts to 3.2D, optimization

with regard to residual spoiling, new tool (KS company)

New length, strength restricted to upper tolerance

Metasco material

Trapezoidal conrod, actual dimension 130 128mm,

Wieland bushing

New piston recess, ring package, trapezoidal support

Oil temperature sensor

Power boost by 21 percent to 40 kW

Torque increase of 18 percent to 130 Nm

Consumption values identical with current smart fortwo cdi

Fulfills EU5 emissions standard

Offer solely with closed diesel particulate filter

T0503F <> Issue date 01/2012 smart Training

OM660/3 performance map thermostat

Advantages:

Extension of functional range through variable opening

temperature

Fast response time through possible current supply

Improved engine management for benefit of environment

Optimized compatibility for conventional thermostat

This further development offers, on the one hand, as before the option

to heat up the wax through the coolant, while on the other hand it also

offers additional electrical heating.

This combination means that the temperature difference range can be

configured to be much larger. In other words, the working element' s

electrical heating feature is actuated under certain engine load

conditions. These are defined by parameters and filed in a

characteristics map in the electronic engine management.

1 Coolant thermostat

6 Click clamps

7 Coolant return flow line

8 Coolant feed line

9 Clamp

10 Coolant line feed line

11 Bolts

B11/ 4 Coolanmt temperature sensor

Y88 Thermostatic valve

T0503F <> Issue date 01/2012 smart Training

Diagnosis of sensors/actuators OM660/3

Exercise:

Measure the internal resistance of the injector for cylinder 1 (Adapter 220589009935).

Specified value: 0.3 0.5 Actual value:

Exercise:

With the aid of current clamp KR015 connect the oscilloscope to the positive line of the cylinder 1 injector.

Record the signal of the injector with the oscilloscope and transfer the signal path and all settings to your

document.

Which circuit diagram do you need for this?

PE07.16-p-2000-97mcd

Wiring diagram for common rail diesel

injection (CDI)

T0503F <> Issue date 01/2012 smart Training

Diagnosis of sensors/actuators OM660/3

Exercise:

Measure the power supply for the rail pressure sensor B4/ 6.

Specified value: 5V Actual value:

Exercise:

Using adapter cable (166589016300) connect the oscilloscope in parallel to the rail pressure sensor.

Record the signal of the sensor with the oscilloscope and transfer the signal path and all settings to your document.

Which circuit diagram do you need for this?

pe07.16-p-2000-97mcd

Wiring diagram for common-rail diesel

injection (CDI)

T0503F <> Issue date 01/2012

Exercise:

How can you evaluate the mechanical function of the pressure regulator valve (Y74) without actually removing it?

Detach connector from pressure regulating valve Start Actual values approx. 90 bar (spring force)

with intact component or seal

Exercise:

Connect the oscilloscope in parallel to the pressure regulating valve or quantity control valve.

Record the signal of the pressure regulating valve with the oscilloscope and transfer the signal path and all settings to your

document.

Which circuit diagram do you need for this?

pe07.16-p-2000-97mcd

Wiring diagram for common-rail diesel

injection (CDI)

smart Training

Diagnosis for sensors/actuators OM660/3

T0503F <> Issue date 01/2012 smart Training

Diagnosis of sensors/actuators OM660/3

Checking the compression

Test requirement:

Battery is charged

Apply hand brake

Ignition ON

Engine not running

Note:

As from a difference in speed of more than 7 rpm

between the smallest and the largest value, it is

to perform a manual compression test and a

cylinder leak test on all cylinders to enable

the fault to be localized.

Test result: Evaluation

Cylinder 1: 299 rpm OK

Cylinder 2: 299 rpm OK

Cylinder 3: 299 rpm OK

T0503F <> Issue date 01/2012 smart Training

Diagnosis of sensors/actuators OM660/3

Check if engine runs smoothly

Test requirement:

Engine at idle

Test of compression OK

Note:

In the event of a complaint after a cold start or during

the warm-up phase, do not condition the engine for

the operating temperature, but proceed in a complaint-

specific basis.

Test result: Actual value Actual value min. Actual value max. Evaluation

Cylinder 1: -4.77mm

3

/ stroke -4.77mm

3

/ stroke -0.23mm

3

/ stroke OK

Cylinder 2: 2.43mm

3

/ stroke 0.30mm

3

/ stroke 2.64mm

3

/ stroke OK

Cylinder 3: 2.35mm

3

/ stroke -0.41mm

3

/ stroke 2.35mm

3

/ stroke OK

T0503F <> Issue date 01/2012 smart Training

6. Overall network C/A451

EPS ESP ASG

ME CDI LWS KI SAM Yaw/Rot.

KLA OBD SRS

EFH

SIH

KGZS

Alt

RLS

DZM

Horn +

inclination sensor

DWA

-C

N129

mhd

B95

LIN D

BS

T0503F <> Issue date 01/2012 smart Training

smart open your mind

open your mind.

Das könnte Ihnen auch gefallen

- Tutorial ATmega ScribDokument60 SeitenTutorial ATmega ScribCarlosOlivierNoch keine Bewertungen

- 4.0 CDI Virtual EGR SystemsDokument9 Seiten4.0 CDI Virtual EGR SystemsExtrat poisNoch keine Bewertungen

- On Board Diagnostic-OBDDokument12 SeitenOn Board Diagnostic-OBDPHÁT NGUYỄN THẾ100% (1)

- ObdtuningopelDokument3 SeitenObdtuningopelcarl robinsonNoch keine Bewertungen

- Laptop Repair Complete Guide Including Motherboard Component Level Repair!Dokument89 SeitenLaptop Repair Complete Guide Including Motherboard Component Level Repair!smooky1980100% (2)

- SM - Kymco Vitality 50 - Chapter 13 (Exhaust - Frame Covers)Dokument12 SeitenSM - Kymco Vitality 50 - Chapter 13 (Exhaust - Frame Covers)jose sousa oliveiraNoch keine Bewertungen

- BMW 3-Series (E36) 1992-1999: How to Build and ModifyVon EverandBMW 3-Series (E36) 1992-1999: How to Build and ModifyBewertung: 5 von 5 Sternen5/5 (5)

- Opel VauxhallDokument17 SeitenOpel Vauxhallmaximus3790% (2)

- Doosan g420fDokument284 SeitenDoosan g420fWalter100% (1)

- Ford Scorpio DiagramsDokument421 SeitenFord Scorpio DiagramsOctavianIancu100% (1)

- The Cosworth YB SeriesDokument6 SeitenThe Cosworth YB SeriesJameel Khan67% (3)

- 007 MeganeDokument37 Seiten007 MeganeDaniel Dario Greig SalazarNoch keine Bewertungen

- System Wiring Diagrams 1989 Volkswagen VanagonDokument33 SeitenSystem Wiring Diagrams 1989 Volkswagen VanagonAnonymous bp007p8Ws100% (1)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Von EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Bewertung: 5 von 5 Sternen5/5 (1)

- BMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesVon EverandBMW 5 & 6 Series E12 - E24 - E28 -E34 Restoration Tips and TechniquesNoch keine Bewertungen

- TRANSITDokument192 SeitenTRANSITAlexandr KachenovskyNoch keine Bewertungen

- F01 Single-Axle Air SuspensionDokument11 SeitenF01 Single-Axle Air SuspensionNyírautó-Trade Bt.100% (1)

- Citroen c3 PicassoDokument29 SeitenCitroen c3 PicassoEsteban Perez PerezNoch keine Bewertungen

- Ford Motor Company - Automotive Systems Training - Electrical SystemsDokument68 SeitenFord Motor Company - Automotive Systems Training - Electrical SystemsjevulNoch keine Bewertungen

- Digifant Engine Management SystemDokument5 SeitenDigifant Engine Management SystemSantz TechNoch keine Bewertungen

- Manitou Hydraulic System PDFDokument92 SeitenManitou Hydraulic System PDFИнж.Стефан Чавдаров100% (1)

- Body Electrical SystemDokument59 SeitenBody Electrical SystemLeonardo Gómez Berniga100% (1)

- Zafira ADokument3 SeitenZafira AElectroventica ElectroventicaNoch keine Bewertungen

- Smart Forfour 454-6Dokument1 SeiteSmart Forfour 454-6yamegNoch keine Bewertungen

- Engineering 2018 UG Admissions PolicyDokument8 SeitenEngineering 2018 UG Admissions PolicyBudes DanielNoch keine Bewertungen

- 2013fusion Steering 5Dokument58 Seiten2013fusion Steering 5Andre VPNoch keine Bewertungen

- N75 Checking Procedure - PierburgDokument2 SeitenN75 Checking Procedure - PierburgSrđan PavićNoch keine Bewertungen

- Hilux Elecrical Ewd307fDokument381 SeitenHilux Elecrical Ewd307fjose sousa oliveira75% (4)

- Infodiag 213Dokument14 SeitenInfodiag 213ArturHeiseNoch keine Bewertungen

- AGA 3 Gas Measurement Orifice PDFDokument100 SeitenAGA 3 Gas Measurement Orifice PDFmilecsaNoch keine Bewertungen

- SSP 157 - ABF Engine ManagementDokument13 SeitenSSP 157 - ABF Engine ManagementMatt DethNoch keine Bewertungen

- VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Von EverandVW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004Bewertung: 3 von 5 Sternen3/5 (1)

- Opel EngDokument26 SeitenOpel EngalmircelebicNoch keine Bewertungen

- 968 Fuse Box ChartDokument1 Seite968 Fuse Box Chartdamon wNoch keine Bewertungen

- SAF-11 Emergency Shut Down, Isolation and DepressuringDokument7 SeitenSAF-11 Emergency Shut Down, Isolation and DepressuringlukeNoch keine Bewertungen

- Engine Lubrication SystemDokument6 SeitenEngine Lubrication SystemWaqar Younas NumberdarNoch keine Bewertungen

- Generador Cat 3512bDokument4 SeitenGenerador Cat 3512bcarlucido247970Noch keine Bewertungen

- Speeduino ManualDokument118 SeitenSpeeduino ManualFreddy CamposNoch keine Bewertungen

- 196 The 1.4-ltr. 16V 55kW Engine With Roller-Type Cam Follower PDFDokument36 Seiten196 The 1.4-ltr. 16V 55kW Engine With Roller-Type Cam Follower PDFAllan CancinoNoch keine Bewertungen

- VW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Von EverandVW Transporter T4 ( Diesel - 2000-2004) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Bewertung: 1 von 5 Sternen1/5 (3)

- Passat 91-Esquema Electrico-Wiring Diagram (RADAR)Dokument11 SeitenPassat 91-Esquema Electrico-Wiring Diagram (RADAR)rafa_r0Noch keine Bewertungen

- Digifant ShopDokument51 SeitenDigifant ShopjralliartNoch keine Bewertungen

- SGS (Elgiznur Cebi)Dokument2 SeitenSGS (Elgiznur Cebi)AamirMalik100% (1)

- To The Digital Storage Oscilloscope (Dso) : A Consulab PresentationDokument28 SeitenTo The Digital Storage Oscilloscope (Dso) : A Consulab Presentationala100% (3)

- Audi A8 4e 2003 Electrical System EngDokument369 SeitenAudi A8 4e 2003 Electrical System EngNP100% (1)

- 08 - Source Rock EvaluationDokument76 Seiten08 - Source Rock EvaluationJose Prima Boang Manalu50% (2)

- Peugeot 307 1600cc E3 NfuDokument4 SeitenPeugeot 307 1600cc E3 NfuZoli BorbelyNoch keine Bewertungen

- GT900/901/902/903/904 GT905/906/907/908/909: User and Installation ManualDokument20 SeitenGT900/901/902/903/904 GT905/906/907/908/909: User and Installation ManualNuno SilvaNoch keine Bewertungen

- P&IDDokument34 SeitenP&IDHabibNoch keine Bewertungen

- Manual de Taller Skoda Fabia 2000 InglesDokument110 SeitenManual de Taller Skoda Fabia 2000 InglesVicente Alcázar Martínez100% (1)

- Engine Management System: VW SIMOS 18.1 EA888Dokument10 SeitenEngine Management System: VW SIMOS 18.1 EA888rumellemur59Noch keine Bewertungen

- 2 g4 1.9L ALH Autom TrsDokument13 Seiten2 g4 1.9L ALH Autom TrsDan Paşca100% (1)

- Catalogue BV PDFDokument132 SeitenCatalogue BV PDFKis Stiv0% (1)

- Manual Engleza Opel Signum - Vectra CDokument330 SeitenManual Engleza Opel Signum - Vectra CEmanuel Mihai100% (1)

- 1993 VW Passat Electrical Wiring SchematicDokument12 Seiten1993 VW Passat Electrical Wiring Schematicaaadmin100% (1)

- Vauxhall Engine CodesDokument2 SeitenVauxhall Engine CodesGarry BlakeNoch keine Bewertungen

- Seat Leon (Data Lines) 2005-2011Dokument4 SeitenSeat Leon (Data Lines) 2005-2011Chino PlagaNoch keine Bewertungen

- OPel Astra HDokument2 SeitenOPel Astra HAlexandru Gârniță0% (1)

- Daewoo Lanos y NubiraDokument15 SeitenDaewoo Lanos y NubiraJøta PerozoNoch keine Bewertungen

- Opel Corsa C Coolant Pump ReplacementDokument10 SeitenOpel Corsa C Coolant Pump ReplacementAndrásBakosNoch keine Bewertungen

- Diagramas Eléctricos VOLVO S40 T5 L5-2.5L TURBO VIN 68 B5254T3 2007Dokument66 SeitenDiagramas Eléctricos VOLVO S40 T5 L5-2.5L TURBO VIN 68 B5254T3 2007Christian Muñoz DuranNoch keine Bewertungen

- EpsDokument6 SeitenEpsJoselee Ramos TitoNoch keine Bewertungen

- OpelDokument8 SeitenOpelCristi NaNoch keine Bewertungen

- 1.4L Ford FigoDokument21 Seiten1.4L Ford FigoAmit Garg100% (1)

- User Manual Landirenzo Omegas SoftwareDokument10 SeitenUser Manual Landirenzo Omegas SoftwareAzhar Qureshi0% (1)

- 2006VolkswagenJettaTDI 1 PDFDokument5 Seiten2006VolkswagenJettaTDI 1 PDFArmando Carrasco100% (1)

- System of Gathering of Steams of Fuel BOSCH MEV 17.4Dokument2 SeitenSystem of Gathering of Steams of Fuel BOSCH MEV 17.4Rui MendesNoch keine Bewertungen

- Peugeot All Models Wiring Diagrams - GeneralDokument30 SeitenPeugeot All Models Wiring Diagrams - GeneralLoki_YONoch keine Bewertungen

- BMW Ewsii&III 3.2systemsDokument6 SeitenBMW Ewsii&III 3.2systemsdavidNoch keine Bewertungen

- 6-Cylinder Injection Engine 3.2LDokument201 Seiten6-Cylinder Injection Engine 3.2Lberenice togaNoch keine Bewertungen

- SaecoDokument224 SeitenSaecojose sousa oliveiraNoch keine Bewertungen

- Files Without This Message by Purchasing Novapdf PrinterDokument1 SeiteFiles Without This Message by Purchasing Novapdf Printerjose sousa oliveiraNoch keine Bewertungen

- User Instructions: DishwasherDokument17 SeitenUser Instructions: Dishwasherjose sousa oliveiraNoch keine Bewertungen

- User Instructions: DishwasherDokument17 SeitenUser Instructions: Dishwasherjose sousa oliveiraNoch keine Bewertungen

- Files Without This Message by Purchasing Novapdf PrinterDokument1 SeiteFiles Without This Message by Purchasing Novapdf Printerjose sousa oliveiraNoch keine Bewertungen

- Files Without This Message by Purchasing Novapdf PrinterDokument1 SeiteFiles Without This Message by Purchasing Novapdf Printerjose sousa oliveiraNoch keine Bewertungen

- Files Without This Message by Purchasing Novapdf PrinterDokument1 SeiteFiles Without This Message by Purchasing Novapdf Printerjose sousa oliveiraNoch keine Bewertungen

- Files Without This Message by Purchasing Novapdf PrinterDokument1 SeiteFiles Without This Message by Purchasing Novapdf Printerjose sousa oliveira100% (1)

- Files Without This Message by Purchasing Novapdf PrinterDokument1 SeiteFiles Without This Message by Purchasing Novapdf Printerjose sousa oliveiraNoch keine Bewertungen

- Files Without This Message by Purchasing Novapdf PrinterDokument1 SeiteFiles Without This Message by Purchasing Novapdf Printerjose sousa oliveiraNoch keine Bewertungen

- Files Without This Message by Purchasing Novapdf PrinterDokument1 SeiteFiles Without This Message by Purchasing Novapdf Printerjose sousa oliveiraNoch keine Bewertungen

- Files Without This Message by Purchasing Novapdf PrinterDokument1 SeiteFiles Without This Message by Purchasing Novapdf Printerjose sousa oliveiraNoch keine Bewertungen

- Files Without This Message by Purchasing Novapdf PrinterDokument1 SeiteFiles Without This Message by Purchasing Novapdf Printerjose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 15 (Rear Shocks)Dokument7 SeitenSM - Kymco Vitality 50 - Chapter 15 (Rear Shocks)jose sousa oliveiraNoch keine Bewertungen

- Refilling - Adding Anti-FreezeDokument3 SeitenRefilling - Adding Anti-Freezejose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 16 (Electrical Equipment)Dokument21 SeitenSM - Kymco Vitality 50 - Chapter 16 (Electrical Equipment)jose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 17 (Instruments - Switches - Lights)Dokument10 SeitenSM - Kymco Vitality 50 - Chapter 17 (Instruments - Switches - Lights)jose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 14 (Steering - Front Shocks)Dokument22 SeitenSM - Kymco Vitality 50 - Chapter 14 (Steering - Front Shocks)jose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 09 (Drive Pulley - Clutch - Kick Starter)Dokument18 SeitenSM - Kymco Vitality 50 - Chapter 09 (Drive Pulley - Clutch - Kick Starter)jose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 12 Carburetor)Dokument29 SeitenSM - Kymco Vitality 50 - Chapter 12 Carburetor)jose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 11 (Crankcase - Crankshaft)Dokument14 SeitenSM - Kymco Vitality 50 - Chapter 11 (Crankcase - Crankshaft)jose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 10 (Final Reduction)Dokument9 SeitenSM - Kymco Vitality 50 - Chapter 10 (Final Reduction)jose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 07 (2-Stroke Cylinder - Head - Valves)Dokument19 SeitenSM - Kymco Vitality 50 - Chapter 07 (2-Stroke Cylinder - Head - Valves)jose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 08 (A.c. Generator)Dokument6 SeitenSM - Kymco Vitality 50 - Chapter 08 (A.c. Generator)jose sousa oliveiraNoch keine Bewertungen

- SM - Kymco Vitality 50 - Chapter 06 (4-Stroke - Cylinder Head - Valves)Dokument15 SeitenSM - Kymco Vitality 50 - Chapter 06 (4-Stroke - Cylinder Head - Valves)jose sousa oliveiraNoch keine Bewertungen

- 374F - Critical Parts ListDokument5 Seiten374F - Critical Parts ListDAnielNoch keine Bewertungen

- Dual Fuel Engines Wartsila50df TrifuelDokument5 SeitenDual Fuel Engines Wartsila50df TrifuelPiero Sanguineti AcevedoNoch keine Bewertungen

- AmeronDokument4 SeitenAmerontahatekriNoch keine Bewertungen

- Ilp P.gudang PDFDokument8 SeitenIlp P.gudang PDFBlades DeeNoch keine Bewertungen

- Termicki Proracun Parnog KotlaDokument1 SeiteTermicki Proracun Parnog KotlavjakovljevicNoch keine Bewertungen

- Chem 16 Thermo ProblemsDokument2 SeitenChem 16 Thermo Problemsjessica_compuesto0% (1)

- Air Intake Systems Product Guide PDFDokument280 SeitenAir Intake Systems Product Guide PDFmehralsmenschNoch keine Bewertungen

- Ac375 SPNDokument40 SeitenAc375 SPNGonzalo ClavijoNoch keine Bewertungen

- Divya Tandon and Nivedita SharmaDokument13 SeitenDivya Tandon and Nivedita SharmaDianaElenaNoch keine Bewertungen

- MI Combined Slide Deck MDC Slides Revised PDFDokument30 SeitenMI Combined Slide Deck MDC Slides Revised PDFdinaNoch keine Bewertungen

- Volvo Tad 660ve SpecsDokument5 SeitenVolvo Tad 660ve SpecsAhmed Mostafa YoussefNoch keine Bewertungen

- Vane Type Double Pump (Bomba de Palheta) Vickers EATON V2200-S214Dokument5 SeitenVane Type Double Pump (Bomba de Palheta) Vickers EATON V2200-S214Lucas CardosoNoch keine Bewertungen

- 5 Engine Specification SheetDokument6 Seiten5 Engine Specification SheetpyrodidoNoch keine Bewertungen

- Cast Iron Foundry Melting Practices in South Asian (Autosaved)Dokument15 SeitenCast Iron Foundry Melting Practices in South Asian (Autosaved)virendrapalguptaNoch keine Bewertungen

- Stoichiometric Ratios For BiogasDokument2 SeitenStoichiometric Ratios For BiogasGovind RaoNoch keine Bewertungen

- Ta35 Ta40 Operations SafetyDokument150 SeitenTa35 Ta40 Operations Safetyjuan100% (2)

- Standard Features: Engine Doosan, P222LE-S Alternator LEROY SOMER, LSA491S4Dokument4 SeitenStandard Features: Engine Doosan, P222LE-S Alternator LEROY SOMER, LSA491S4Engine Tuning UpNoch keine Bewertungen

- DT40 PDFDokument34 SeitenDT40 PDFFrancisco Carlos TelesNoch keine Bewertungen

- Inlet Ex SystemDokument5 SeitenInlet Ex SystembejoythomasNoch keine Bewertungen

- KAPL DownstreamDokument6 SeitenKAPL DownstreamKrishna GuptaNoch keine Bewertungen

![VW Volkswagen Transporter T4 [ Powered By 1.8, 2.4 & 2.9 Diesel engines ]: Workshop Manual Diesel Models Years 2000-2004](https://imgv2-2-f.scribdassets.com/img/word_document/282876773/149x198/5fb74bd6e1/1675169638?v=1)