Beruflich Dokumente

Kultur Dokumente

Energy Balance

Hochgeladen von

Muhammad Zubair SharifOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Energy Balance

Hochgeladen von

Muhammad Zubair SharifCopyright:

Verfügbare Formate

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

1. Across Washer

Input Streams

Stream l1

m = 3333.33 kg/hr

Cp of stream:

Fiber=

0.0432 x 3.72

= 0.15509 kj/kg.K

Dissolved Solids = 0.1250 x 1.1827 = 0.1382 kj/kg.K

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/kg.K

Water

= 0.8317 x 4.18

Total Cp

= 3.7850 kj/kg.K

= 3.4765 kj/kg.K

Total Q:

T1 = 298.15K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 3333.33 x 3.7850 x (298.15 298.15) = 0 kj/kg

Stream l2

m = 350 kg/hr

Cp of stream

Energy Balance

Page 20

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Water = 4.18 x 1 = 4.18kj/kg.K

Total Q:

T1 = 298.15K

T2 = 298.15k=K

Q = mCp(T1-T2)

Q = 350 x 4.18 x (298.15 298.15) = 0 kj/kr

Output Streams

Stream l4

m = 3333.3 kg/hr

Cp of stream:

Fiber=

0.0432 x 3.72

= 0.15509 kj/kg.K

Dissolved Solids = 0.1250 x 1.1827 = 0.1382 kj/kg.K

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/kg.K

Water

= 0.8317 x 4.18

Total Cp

= 3.7850 kj/kg.K

= 3.4765 kj/kg.K

Total Q:

T1 = 298.15 K

T2 = 298.15 K

Q = mCp(T1-T2)

Q = 3333.33 x 3.7850 x (298.15 298.15) = 0 kj/hr

Stream l8

m = 350 kg/hr

Cp of stream

Water= 4.18 x 0.9962 = 4.164 kj/kg.K

Impurities = 1.1x 0.0038 = 0.00418 kj/kg.K

Total Cp = 4.17 kj/kg.K

Total Q:

Energy Balance

Page 21

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

T1 = 298.15 K

T2 = 298.15 K

Q = mCp(T1-T2)

Q = 350 x 3.7850 x (298.15K 298.15K) = 0 kj/hr

Balance:

Qin = Qout

l1 + l2 = l4 + l8

0+0=0+0

0 kj/hr = 0 kj/hr (Balanced)

2. Across Crusher

Input Streams

Stream l4

m = 3333.33 kg/hr

Cp of stream:

Fiber=

0.0432 x 3.72

= 0.15509 kj/kg.K

Dissolved Solids = 0.1250 x 1.1827 = 0.1382 kj/kg.K

Energy Balance

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/kg.K

Water

= 0.8317 x 4.18

Total Cp

= 3.7850 kj/kg.K

= 3.4765 kj/kg.K

Page 22

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Total Q:

T1 = 298.15K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 3333.33 x 3.7850 x (298.15 298.15) = 0 kj/hr

Stream l3

m = 6.66 kg/hr

Cp of stream:

Enzyme

= 0.05 x 2.26 = 0.113 kj/kg.K

Water

= 0.95 x 4.18

Total Cp

= 4.08 kj/kg.K

= 3.97 kj/kg.K

Total Q:

T1 = 303.15K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 6.66 x 3.7850 x (303.15 298.15) = 126.04 kj/hr

Output Streams

Stream l5

m = 3339.96 kg/hr

Cp of stream:

Fiber=

0.0431 x 3.72

= 0.1603 kj/kg.K

Dissolved Solids = 0.1247 x 1.1827 = 0.1474 kj/kg.K

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/kg.K

Water

= 0.8320 x 4.18

Enzyme

= 9.97 x 10-5 x 2.26 = 2.253 x 10-4 kj/kg.K

Total Cp

= 3.7859 kj/kg.K

= 3.4777 kj/kg.K

Total Q:

T1 = 303.15K

T2 = 298.15K

Energy Balance

Page 23

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Q = mCp(T1-T2)

Q = 3339.96 x 3.7859 x (303.15 298.15) = 63223.7728 kj/hr

Balance

Qin = Qout

L4 + l3 = l5

0 + 126.04 = 63223.7728

0 = 63097.7328 kj/hr

Crusher Duty = 63097.7328 kj/hr

Hot water mass = 503.17 kg/hr

3. Across With-holding Tank

Input Streams

Stream l5

m = 3339.96 kg/hr

Cp of stream:

Fiber=

0.0431 x 3.72

= 0.1603 kj/kg.K

Dissolved Solids = 0.1247 x 1.1827 = 0.1474 kj/kg.K

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/kg.K

Water

= 0.8320 x 4.18

Enzyme

= 9.97 x 10-5 x 2.26 = 2.253 x 10-4 kj/kg.K

Total Cp

= 3.7859 kj/kg.K

= 3.4777 kj/kg.K

Total Q:

Energy Balance

Page 24

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

T1 = 303.15 K

T2 = 298.15 K

Q = mCp(T1-T2)

Q = 3339.96 x 3.7859 x (303.15 298.15) = 63223.7728 kj/hr

Output Streams

Stream l6

m = 3339.96 kg/hr

Cp of stream:

Fiber=

0.0431 x 3.72

= 0.1603 kj/kg.K

Dissolved Solids = 0.1247 x 1.1827 = 0.1474 kj/kg.K

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/kg.K

Water

= 0.8320 x 4.18

Enzyme

= 9.97 x 10-5 x 2.26 = 2.253 x 10-4 kj/kg.K

Total Cp

= 3.7859 kj/kg.K

= 3.4777 kj/kg.K

Total Q:

T1 = 303.15 K

T2 = 298.15 K

Q = mCp(T1-T2)

Q = 3339.96 x 3.7859 x (303.15 298.15) = 63223.7728 kj/hr

Balance

Qin = Qout

L5 = l6

63223.7728 kj/hr = 63223.7728 kj/hr (Balanced)

Energy Balance

Page 25

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

4. Across Presses

Input Streams

Stream l6

m = 3339.96 kg/hr

Cp of stream:

Fiber=

0.0431 x 3.72

= 0.1603 kj/kg.K

Dissolved Solids = 0.1247 x 1.1827 = 0.1474 kj/kg.K

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/kg.K

Water

= 0.8320 x 4.18

Enzyme

= 9.97 x 10-5 x 2.26 = 2.253 x 10-4 kj/kg.K

Total Cp

= 3.7859 kj/kg.K

= 3.4777 kj/kg.K

Total Q:

T1 = 303.15K

T2 =298.15K

Q = mCp(T1-T2)

Q = 3339.96 x 3.7859 x (303.15 298.15) = 63223.7728 kj/hr

Output Streams

Stream p4

m = 501 kg/hr

Energy Balance

Page 26

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Cp of stream:

Fiber

0.2101 x 3.72

= 0.7815 kj/kg.K

Dissolved Solids = 0.0742 x 1.1827 = 0.0877 kj/kg.K

Water

= 0.7157 x 4.18

Total Cp

= 3.8608 kj/kg.K

= 2.9916kj/kg.K

Total Q:

T1 = 303.1484 K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 501 x 3.8608 x (303.1484 298.15) = 9668.2128 kj/hr

Stream l15

m = 2838.96 kg/hr

Cp of stream:

Fiber=

0.0136 x 3.72

= 0.0506 kj/kg.K

Dissolved Solids = 0.1336 x 1.1827 = 0.1580 kj/kg.K

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/kg.K

Water

= 0.8526 x 4.18

Enzyme

= 9.97 x 10-5 x 2.26 = 2.253 x 10-4 kj/kg.K

Total Cp

= 3.7729 kj/kg.K

= 3.5639 kj/kg.K

Total Q:

T1 = 303.15K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 2838.96 x 3.7729 x (303.15 298.15) = 53555.56 kj/hr

Balance

Qin = Qout

l6 = L15 + p4

53555.56 + 9668.2128 = 63223.7728

63223.7728kj/hr = 63223.7728 kj/hr (Balanced)

Energy Balance

Page 27

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

5. Across Heat Exchanger

Input Streams

Stream l15

m = 2838.96 kg/hr

Cp of stream:

Fiber=

0.0136 x 3.72

= 0.0506 kj/kg.K

Dissolved Solids = 0.1336 x 1.1827 = 0.1580 kj/kg.K

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/kg.K

Water

= 0.8526 x 4.18

Enzyme

= 9.97 x 10-5 x 2.26 = 2.253 x 10-4 kj/kg.K

Total Cp

= 3.7729 kj/kg.K

= 3.5639 kj/kg.K

Total Q:

T1 = 303.15 K

T2 = 298.15 K

Q = mCp(T1-T2)

Q = 2838.96 x 3.7729 x (303.15 298.15) = 53555.56 kj/hr

Stream u3

m = 48.66 kg/hr

Temperature = T2 = 393.57

Pressure = 2 bar (g)

Latent Heat = 2201 kj/kg

Energy Balance

Page 28

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Cp of steam= 2.02 kj/kg

Cp of water= 4.18 kj/kg

Total Q:

T1 = 298.15 K

T2 = 393.57 K

Q = mCpwaterdT + m.H

Q = (48.66 X 4.18 X (393.57 - 298.15)) + (48.66 X 2201) = 126731.04 kj/hr

Output Streams

Stream l17

m = 2838.96 kg/hr

Cp of stream:

Fiber=

0.0136 x 3.72

= 0.0506 kj/kg.K

Dissolved Solids = 0.1336 x 1.1827 = 0.1580 kj/kg.K

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/kg.K

Water

= 0.8526 x 4.18

Enzyme

= 9.97 x 10-5 x 2.26 = 2.253 x 10-4 kj/kg.K

Total Cp

= 3.7729 kj/kg.K

= 3.5639 kj/kg.K

Total Q:

T1 = 313.15K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 2838.96 x 3.7729 x (313.15 298.15) = 160666.68 kj/kg

Stream c1

m = 48.66

Cp of water:

Water

= 1 x 4.18

= 4.18 kj/kg.K

Total Q:

T1 = 394.15K

T2 = 298.15K

Energy Balance

Page 29

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Q = mCp(T1-T2)

Q = 48.66 x 4.18 x (394.15 298.15) = 19542.34 kj/hr

Balance

Qin = Qout

L15 + u3 = l17 + c1

53555.56 + 126731.04 = 19542.34 + 160666.6

180286.596 kj/hr = 180209.02kj/hr Difference: 77.57 kj/hr

6. Across Falling Film Evaporator

Input Streams

Stream l17

m = 2838.96 kg/hr

Cp of stream:

Fiber

0.0136 x 3.72

= 0.0506 kj/kg.K

Dissolved Solids = 0.1336 x 1.1827 = 0.1580 kj/ kg.K

Aroma

= 0.0001 x 3.0006 = 0.0003 kj/ kg.K

Water

= 0.8526 x 4.18

Enzyme

= 9.97 x 10-5 x 2.26 = 2.253 x 10-4 kj/ kg.K

Total Cp

= 3.77 kj/ kg.K

= 3.5639 kj/ kg.K

Total Q:

Energy Balance

Page 30

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

T1 = 313.15K

T2 = 298.15K

P= -0.79 bar (g)

Q = mCp (T1-T2)

Q = 2838.96 x 3.77 x (313.15 298.15) = 160543.188 kj/hr

Stream u4

m = 484.904 kg/hr

Temperature = 335.35K

Latent Heat = 2352.31 kj/kg

Total Q:

Q = mCpdT + m.H

Q = (484.904 x 4.18 (335.35- 298.15))+(484.904 x 2352.31) = 1216045.161 kj/hr

Output Streams

Stream l19

m = 2510.150 kg/hr

Cp of stream:

Fiber=

0.015381 x 3.72

= 0.0572 kj/kg.K

Dissolved Solids = 0.1511 x 1.1827 = 0.1787 kj/kg.K

Water

= 0.8330 x 4.18

= 3.4819 kj/kg.K

Enzyme

= 1.1276 x 10-4 x 2.26 = 2.540 x 10-4 kj/kg.K

Total Cp

= 3.71 kj/kg.K

Total Q:

T1 = 323.15K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 2510.150 x 3.71 x (323.15 298.15) = 232816.412 kj/hr

Stream A2

m = 328.80 kg/hr

Cp of stream:

Aroma

Energy Balance

= 8.6342 x 10-4 x 3.0006 = 2.590 x 10-3 kj/kg.K

Page 31

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Water

= 0.9991 x 4.18

Total Cp

= 4.18 kj/kg.K

= 4.1762 kj/kg.K

Total Q:

Enthalpy of aroma = 3093.11 kj/kg

T1 = 335.35K

T2 = 298.15K

Since the stream contains both aroma in vapor and water in liquid form so,

Q = mCp(T1-T2) + m.H

Q = (328.80 x 4.18 x (335.35 298.15)) + (328.80 x 3093.11) = 1068141.653 kj/kg

Stream c2

m = 484.904 kg/hr

Cp of water:

Water

= 1 x 4.18

= 4.18 kj/kgoC

Total Q:

T1 = 335.35K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 484.904 x 4.18 x (335.35 298.15) = 75400.63 kj/hr

Balance

Qin = Qout

L17 + u4 = l19 + A2 + c2

160543.188 + 1216045.161 = 232816.412 + 1068141.653 + 75400.63

1376588.349 kj/hr = 1376358.695 kj/hr Difference = 233.654 kj/hr

Energy Balance

Page 32

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

7. Across Aroma Stripping Column

Input Streams

Stream A2

m = 328.80 kg/hr

Cp of stream:

Aroma

= 8.6342 x 10-4 x 3.0006 = 2.590 x 10-3 kj/kg.K

Water

= 0.9991 x 4.18

Total Cp

= 4.18 kj/kg.K

= 4.1762 kj/kg.K

Total Q:

Enthalpy of aroma = 3093.11 kj/kg

T1 = 335.35K

T2 = 298.15K

Since the stream contains both aroma in vapor and water in liquid form so,

Q = mCp(T1-T2) + m.H

Q = (328.80 x 4.18 x (335.35 298.15)) + (328.80 x 3093.11) = 1068141.653 kj/kg

Output Streams

Stream A3

m = 0.283893 kg/hr

Cp of stream:

Aroma

Energy Balance

= 1 x 3.0006 = 3.0006 kj/kg.K

Page 33

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Total Cp

3.0006 kj/kg.K

Total Q:

T1 = 353.15K

T2 =298.15K

Q = mCp(T1-T2) + m.H + mCp(T3-T4)

Q = [0.283893 x 3 x (351.45 298.15)] + [0.283893 x 846] + [0.283893 x 2.5 x (353.15 351.45)] =

286.77 kj/kg

Stream w7

m = 328.517

Cp of stream:

Water = 4.18 x 1 = 4.18 kj/kg.K

Total Cp = 4.18 kj/kg.K

Total Q:

T1 = 373.15

T2 = 298.15

Q = mCp(T1-T2)

Q = 328.517 x 4.18 x (373.15 298.15) + (328.517 x 2270) = 848723.669 kj/kg

Balance

Qin = Qout

A2 = A3 + w7

1068141.653 kj/hr = 286.77 kj/hr + 848723.669 kj/hr

1068141.653 kj/hr = 849010.439 kj/hr

Heat needed to be removed to maintain required conditions = 219131 kj/hr

Energy Balance

Page 34

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

8. Across Aroma Condensor

Input Streams

Stream A3

m = 0.283893 kg/hr

Cp of stream:

Aroma

= 1 x 3.0006 = 3.0006 kj/kg.K

Total Cp

3.0006 kj/kg.K

Total Q:

T1 = 353.15

T2 = 298.15

Q = mCp(T1-T2) + m . H

Q = [0.283893 x 3 x (351.45 298.15)] + [0.283893 x 846] + [0.283893 x 2.5 x (353.15 351.45)] =

286.77 kj/kg

Stream w1

m = 3.432 kg/hr

Cp of pure water: 4.18 kj/kg.K

T1 = 309.95 K

T2 = 298.15 K

Total Q:

Q = mCpdT

Q = 3.432 x 4.18 x (309.95 - 298.15)

Q = 169.88 kj/hr

Energy Balance

Page 35

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Output Streams

Stream w6

m = 3.432 kg/hr

Cp of pure water: 4.18 kj/kg.K

T1 = 323.15K

T2 = 298.15K

Total Q:

Latent Heat liberated by aroma = (0.283893 x 846) = 240.17

Q = Q = mCp(T1-T2) + m.H

Q = 3.432 x 4.18 x (323.15 - 298.15) + 240.17

Q = 455.18 kj/hr

Stream A4

m = 0.283893 kg/hr

Cp of stream:

Aroma

= 1 x 3.0006 = 3.0006 kj/kg.K

Total Cp

3.0006 kj/kg.K

Total Q:

T1 = 300.15

T2 = 298.15

Q = mCp(T1-T2)

Q = [0.283893 x 3.0006 x (300.15 298.15)] = 1.7 kj/kg

Balance

Qin = Qout

A3 + w1 = w6 + A4

256.77 + 169.88 = 455.18 + 1.7

456.88 kj/hr = 456.88 kj/hr

Energy Balance

Page 36

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

9. Across Enzymatic Treatment Tank

Input Streams

Stream l19

m = 2510.156 kg/hr

Cp of stream:

Fiber=

0.015381 x 3.72

= 0.0572 kj/kg.K

Dissolved Solids = 0.1511 x 1.1827 = 0.1787 kj/kg.K

Water

= 0.8330 x 4.18

= 3.4819 kj/kg.K

Enzyme

= 1.1276 x 10-4 x 2.26 = 2.540 x 10-4 kj/kg.K

Total Cp

= 3.7180 kj/kg.K

Total Q:

T1 = 323.15K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 2510.156 x 3.7180 x (323.15 298.15) = 233319 kj/hr

Stream E1

m = 54.146 kg/hr

Cp of stream:

Energy Balance

Enzyme

= 1 x 2.26 = 2.26 kj/kg.K

Total Cp

2.26 kj/kg.K

Page 37

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Total Q:

T1 = 323.15K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 54.146 x 2.26 x (323.15 298.15) = 3059.249 kj/hr

Output Streams

Stream l22

m = 2564.804 kg/hr

Cp of stream:

Fiber=

0.01565 x 3.72

= 0.0582 kj/kg.K

Dissolved Solids = 0.14788 x 1.1827 = 0.1748 kj/kg.K

Water

= 0.81471 x 4.18

= 3.4055 kj/kg.K

Enzyme

= 0.021221 x 2.26 = 0.0480 kj/kg.K

Total Cp

= 3.6865 kj/kg.K

Total Q:

T1 = 323.15K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 2564.804 x 3.6865 x (323.15 298.15)) = 236378.249 kj/hr

Balance

Qin = Qout

L19 + l21 = l22

233319 kj/hr + 3059.249 kj/hr = 236378.249 kj/hr

236378.249 kj/hr = 236378.249 kj/hr (Balanced)

Energy Balance

Page 38

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

10.

Across Ultra filtration Unit

Input Streams

Stream l22

m = 2564.804 kg/hr

Cp of stream:

Fiber=

0.01565 x 3.72

= 0.0582 kj/kg.K

Dissolved Solids = 0.14788 x 1.1827 = 0.1748 kj/kg.K

Water

= 0.81471 x 4.18

= 3.4055 kj/kg.K

Enzyme

= 0.021221 x 2.26 = 0.0480 kj/kg.K

Total Cp

= 3.6865 kj/kg.K

Total Q:

T1 = 323.15

T2 = 298.15K

Q = mCp(T1-T2)

Q = 2564.804 x 3.6865 x (323.15 298.15) = 236378.249 kj/hr

Output Streams

Stream l23

m = 2223.2217 kg/hr

Cp of stream:

Energy Balance

Page 39

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Dissolved Solids = 0.1535 x 1.1827 = 0.1815 kj/kg.K

Water

= 0.8465 x 4.18

Total Cp

= 3.7199 kj/kg.K

= 3.5384 kj/kg.K

Total Q:

T1 = 323.15K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 2223.2217 x 3.7199 x (323.15 298.15K) = 206754.06 kj/hr

Stream l23

m = 341.5823 kg/hr

Cp of stream:

Fiber=

0.1175 x 3.72

= 0.4371 kj/kg.K

Dissolved Solids = 0.6121 x 1.1827 = 0.7239 kj/kg.K

Water

= 0.1110 x 4.18

= 0.4639 kj/kg.K

Enzyme

= 0.1593 x 2.26 = 0.3600 kj/kg.K

Total Cp

= 1.984 kj/kg.K

Total Q:

T1 = 341.85K

T2 = 298.15K

Q = mCp(T1-T2)

Q = 341.5823 x 1.984 x (341.85 298.15) = 29624.189 kj

Balance

Qin = Qout

L22 = l23 + l 23

236378.249 kj/hr = 206754.06 kj/hr + 29624.189 kj/hr

236378.249 kj/hr = 236378.249 kj/hr (Balanced)

Energy Balance

Page 40

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

11.

Across Triple Effect Evaporator

Input Streams

Stream l23

m = 2223.2217 kg/hr

Cp of stream:

Dissolved Solids = 0.1535 x 1.1827 = 0.1815 kj/kg.K

Water

= 0.8465 x 4.18

Total Cp

= 3.71 kj/kg.K

= 3.5384 kj/kg.K

Total Q:

T1 = 323.15K

T2 = T2 = 298.15K

Q = mCp(T1-T2)

Q = 2223.2217 x 3.71 x (323.15 298.15) = 205648.007 kj/hr

Stream u5

m = 767 kg/hr

Temperature = 138oC = 411.15K

Specific enthalpy of saturated steam = 2706.54 kj/kg

Total Q:

Q = m x Enthalpy

Q = (767 x 2147) + (767 x 2.17 x (411.15 - 407.15)) + (767 x 4.18 x (407.15 -298.15)) = 2002867.1

kj/hr

Energy Balance

Page 41

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Output Streams

Stream c5

m = 767 kg/hr

Temperature = 134 oC = 407.15K

Cp of water from 0 to 100 = 4.18 kj/hr

Total Q:

Q = mCpdT

Q = 767 x 4.18 x (407.15K - 298.15K) = 349460.54 kj/hr

Stream c6

m = 594.612 kg/hr

Temperature = 121oC = 394.15K

Cp of water = 4.18 kj/kg

Total Q:

Q = mCpdt

Q = 594.612 x 4.18 x (394.15 - 25) = 238605.9 kj/hr

Stream c7

M = 583.3 kg/hr

Temperature = 112.53oC = 385.68K

Cp of water = 4.18

Total Q:

Q = mCpdT

Q = 583.3 x 4.18 x (385.68 - 298.15) = 213390.73 kj/hr

Stream v1

M = 571.359 kg/hr

Temperature = 385.68K

Cp of Water = 4.18

Latent Heat of vapors = 2226.23 kj/kg

Total Q:

Energy Balance

Page 42

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Q = mCpdT + m.H = (571.359 x 4.18 x (385.68-347.25)) + (571.359 x 2226.23) = 1363758.171

kj/hr

Stream l26

M = 474 kg/hr

Cp of apple juice at 72 brix = 2.02 kj/kg

Temperature = 345.15K

Total Q:

Q = mCpdT

Q = 474 x 2.02 x (345.15 - 298.15) = 45001.56 kj/hr

Balance

Qin = Qout

l23 +u5 = c5 + c6 + c7 + l26 + v1

205648.007 + 2002867.1 = 349460.54 +238605.9 + 213390.73 + 47874 + 1363758.171

2208515.107kj/hr = 2213089.341kj/hr

Heat Capacity Estimation of Constituents

Enzyme

The value of heat capacity used is estimated from the reference given and is very near to the

heat capacity of protein as our enzyme is protein based.

Heat capacity of enzyme = 2.26 kj/kg

Fiber

The value of heat capacity used is estimated from the reference given

Heat Capacity of Fiber = 3.72 kj/kg

Aroma

The heat capacity of aroma is estimated based on the heat capacity of individual components

and their composition in aroma.

Constituents

Ethanol

Propanol

Butanol

2-Methyl Butanol

Hexanol

Ethyl Iso-Butyrate

Ethyl Butyrate

Ethyl Acetate

Energy Balance

Composition(xi)

0.495

0.016

0.046

0.014

0.015

0.097

0.064

0.010

Heat Capacity(kj/kgoC)

2.43

2.37

2.307

2.303

2.308

1.7372

1.6290

1.9200

xiCp

1.203

0.038

0.106

0.032

0.035

0.167

0.1042

0.0192

Page 43

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

Butyl Acetate

Pentyl Acetate

Ethyl Valerate

Benzaldehyde

Hexanal

Trans-2-Hexanal

Total

0.035

0.040

0.078

0.0005

0.043

0.042

1.9630

1.7667

2.1980

1.6211

2.11

2.07

0.0688

0.061

0.171

0.0081

0.9073

0.0261

3.0006 kj/kg.K

Note: The references for composition and heat capacities of constituents are provided.

Dissolved Solids

The heat capacity of dissolved solids is estimated based on the heat capacity of individual

components and their composition in dissolved solids.

Constituents

Protien

Ash

Liphids

Sucrose

Glucose

Fructose

Starch

Calcium

Iron

Magnesium

Phosphorous

Potassium

Zinc

Vitamin C

Vitmain A

Total

Composition(xi)

0.0234

0.0171

0.0153

0.1868

0.2193

0.5325

4.63 x 10-3

5.45 x 10-7

1.083 x 10-8

4.513 x 10-7

9.92 x 10-7

9.65 x 10-6

9.02 x 10-8

4.151 x 10-7

1.353 x 10-6

Heat Capacity (kj/kg.K)

2.34

1.343

2.1

1.30

0.63

1.28

1.753

0.650

0.447

1.024

0.809

0.74

0.399

1.39

1.62

xiCp

0.0548

0.0230

0.0321

0.2428

0.1382

0.6816

8.086 x 10-3

3.5198 x 10-8

4.1841 x 10-9

4.621 x 10-7

8.0253 x 10-7

7.141 x 10-6

3.5990 x 10-8

5.769 x 10-7

2.192 x 10-6

1.182 kj/kg.K

Note: The references for composition and heat capacities of constituents are provided.

Water

Heat capacity of water is taken from literature as 4.18 kj/kg.K.

Energy Balance

Page 44

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

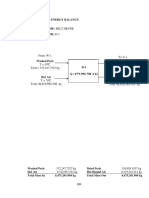

Overall Energy Balance

IN

STREAM NAME

STREAM Heat kj/hr

l1

l2

l3

63223.8182

u2 (u3+u4)

1183470.062

E1

3059.249

w1

169.88

u5

2009960.37

TOTAL Heat

3382001.794

OUT

STREAM NAME

STREAM heat kg/hr

l8

p4

9668.212

c4 (c1+c2)

100344.56

A4

1.7

Energy Balance

Page 45

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

w7

903075.79

w2

455.18

w5

29624.189

c5

350417.342

c6

238605.98

Energy Balance

Page 46

PRODUCTION OF APPLE JUICE AT LOW TEMPERATURE PROCESSING BY ULTRAFILTRATION

sc7

213415.1208

v3

1363758.1

l24

45001.56

TOTAL Heat

3350784.662

Energy Balance

Page 47

Das könnte Ihnen auch gefallen

- Heat and mass balance across washer, crusher, holding tank, presses, heat exchanger, evaporator and stripping columnDokument21 SeitenHeat and mass balance across washer, crusher, holding tank, presses, heat exchanger, evaporator and stripping columnMuhammad Zubair SharifNoch keine Bewertungen

- Energy BalanceDokument10 SeitenEnergy BalanceAadiNoch keine Bewertungen

- Saccharification Process Heat Transfer AnalysisDokument7 SeitenSaccharification Process Heat Transfer AnalysisCarol WeiNoch keine Bewertungen

- CHE 260 - Solutions, Chapter 7Dokument8 SeitenCHE 260 - Solutions, Chapter 7chemnerd2Noch keine Bewertungen

- Ejercicio para CompararDokument4 SeitenEjercicio para CompararCamila SarabiaNoch keine Bewertungen

- Chapter 3 (B) Energy Balance: 3.9 AssumptionsDokument21 SeitenChapter 3 (B) Energy Balance: 3.9 Assumptionssaur1Noch keine Bewertungen

- Calculating the efficiency of an ideal Stirling cycle engineDokument2 SeitenCalculating the efficiency of an ideal Stirling cycle engineJaniz TumambingNoch keine Bewertungen

- Sample Problems: Rankine CycleDokument12 SeitenSample Problems: Rankine CycleReiVanNoch keine Bewertungen

- Acetone Distillation Column-BalsDokument12 SeitenAcetone Distillation Column-Balsanon_926824359Noch keine Bewertungen

- ENGR 2213 Thermodynamics: F. C. Lai School of Aerospace and Mechanical Engineering University of OklahomaDokument20 SeitenENGR 2213 Thermodynamics: F. C. Lai School of Aerospace and Mechanical Engineering University of OklahomaSebastián SantarrosaNoch keine Bewertungen

- HW#1Dokument7 SeitenHW#1MahsaNoch keine Bewertungen

- Heat balance for acetic acid plant reactorDokument6 SeitenHeat balance for acetic acid plant reactormbeni0751Noch keine Bewertungen

- Calculations 2Dokument3 SeitenCalculations 2LeoNoch keine Bewertungen

- Energy Balance:: ReactionDokument7 SeitenEnergy Balance:: ReactionHarsh ShahNoch keine Bewertungen

- Multi Fuel EngineDokument12 SeitenMulti Fuel EngineNikhil DixitNoch keine Bewertungen

- Completion in Airconditioning and Ventilation System: DBT 44°CDokument6 SeitenCompletion in Airconditioning and Ventilation System: DBT 44°CJay Mark CayonteNoch keine Bewertungen

- Q and Q Calculation: Double Pipe Heat ExchangerDokument3 SeitenQ and Q Calculation: Double Pipe Heat ExchangerKiran JojiNoch keine Bewertungen

- Design of Ball Bearing and Engine PistonDokument23 SeitenDesign of Ball Bearing and Engine PistonretechNoch keine Bewertungen

- Counter Flow and Parallel Flow Heat Exchanger CalculationDokument8 SeitenCounter Flow and Parallel Flow Heat Exchanger CalculationNur' AyuniNoch keine Bewertungen

- CH 09Dokument22 SeitenCH 09hirenpatel_universalNoch keine Bewertungen

- One Minute Thermo: Freeway Driving, Propane Cylinder, Water Pump and MoreDokument15 SeitenOne Minute Thermo: Freeway Driving, Propane Cylinder, Water Pump and MoreclearcastingNoch keine Bewertungen

- Thermo ProblemsDokument8 SeitenThermo ProblemsChrister John UyNoch keine Bewertungen

- Ah SHHHHDokument44 SeitenAh SHHHHAjay RamaniNoch keine Bewertungen

- PPD - Module IDokument9 SeitenPPD - Module IJohn Babe CapiliNoch keine Bewertungen

- Chlorine Gas Compressor DesignDokument2 SeitenChlorine Gas Compressor DesignRamji MishraNoch keine Bewertungen

- Ciclo BraytonDokument17 SeitenCiclo BraytonNubia Bergamini100% (2)

- Termodinámica 28Dokument12 SeitenTermodinámica 28Ana LopezNoch keine Bewertungen

- H S S X S S HDokument4 SeitenH S S X S S HahmadskhanNoch keine Bewertungen

- Heat Exchanger Heat Accumulation 63545.31kcal/hrDokument4 SeitenHeat Exchanger Heat Accumulation 63545.31kcal/hrMuthuKumar ArunachalamNoch keine Bewertungen

- MATERIAL BALANCE TITLEDokument46 SeitenMATERIAL BALANCE TITLEG Vamsee KrishnaNoch keine Bewertungen

- Cumene Energy 2520balanceDokument13 SeitenCumene Energy 2520balanceismailchoughule50% (2)

- Assignment No. 1 in PpeDokument3 SeitenAssignment No. 1 in PpeJenny Mae PomedaNoch keine Bewertungen

- Hematra SolutionDokument7 SeitenHematra SolutionDarlene FranciaNoch keine Bewertungen

- Introduction To Chemical Processes Murphy Chapter06 SolutionsDokument94 SeitenIntroduction To Chemical Processes Murphy Chapter06 SolutionsEric Barnett29% (7)

- Chlorine Energy 2520 BalanceDokument4 SeitenChlorine Energy 2520 Balancetonzz10Noch keine Bewertungen

- CalculationsDokument2 SeitenCalculationsLeoNoch keine Bewertungen

- Blue Book PIPEDokument55 SeitenBlue Book PIPEJohnMichaelCabungcalNoch keine Bewertungen

- Detailed energy balance of belt dryer and sterilizerDokument31 SeitenDetailed energy balance of belt dryer and sterilizerkennethmsorianoNoch keine Bewertungen

- Tugas Volume Molar Dan Termo CmpuranDokument6 SeitenTugas Volume Molar Dan Termo CmpuranHeppy Yessya100% (1)

- Reactor:: Energy BalanceDokument4 SeitenReactor:: Energy BalanceSanjay KumarNoch keine Bewertungen

- Applied Thermodynamics Exam 2018 Wirh SolutionsDokument9 SeitenApplied Thermodynamics Exam 2018 Wirh SolutionsFarouk BassaNoch keine Bewertungen

- Data PengamatanDokument8 SeitenData PengamatanRaden BayuNoch keine Bewertungen

- For Water: .. .. ..: C KJ Kmol - K 2.413 KJ KG - K KJ KG - KDokument10 SeitenFor Water: .. .. ..: C KJ Kmol - K 2.413 KJ KG - K KJ KG - KanmarNoch keine Bewertungen

- PetE2106 - 17 - Gallano - Kael AaronDokument6 SeitenPetE2106 - 17 - Gallano - Kael AaronKael Aaron GallanoNoch keine Bewertungen

- THERMODokument5 SeitenTHERMOStephanie FalcatanNoch keine Bewertungen

- Ahlan Zulfakhri - 6019231001 - Tugas Individu - S2 Siskal-Sistem & Permesinan KapalDokument8 SeitenAhlan Zulfakhri - 6019231001 - Tugas Individu - S2 Siskal-Sistem & Permesinan Kapalahlan zulfakhriNoch keine Bewertungen

- Example CalculationsDokument2 SeitenExample CalculationsLisajanelollyNoch keine Bewertungen

- Anaerobic Treatment of Municipal Wastewater (10,000 Liter/Day) With A Staged Anaerobic Fluidized Membrane Bioreactor (Saf-Mbr) SystemDokument11 SeitenAnaerobic Treatment of Municipal Wastewater (10,000 Liter/Day) With A Staged Anaerobic Fluidized Membrane Bioreactor (Saf-Mbr) SystemAzam HussainNoch keine Bewertungen

- PIPE REVIEWER SOLUTIONSDokument189 SeitenPIPE REVIEWER SOLUTIONSzxzzenNoch keine Bewertungen

- Solved Problems On Mechanical Equivalent of Heat Calorimetry and Effects of HeatDokument43 SeitenSolved Problems On Mechanical Equivalent of Heat Calorimetry and Effects of HeatChristine MalibiranNoch keine Bewertungen

- Rac AssignmntDokument3 SeitenRac Assignmntlukesh singhNoch keine Bewertungen

- Foundations of Energy Past Paper 1 SolutionsDokument6 SeitenFoundations of Energy Past Paper 1 Solutionsapi-3765936Noch keine Bewertungen

- Audhea Yolandha Kania - 1955041001 - Tugas Ke-3 - TermodinamikaDokument2 SeitenAudhea Yolandha Kania - 1955041001 - Tugas Ke-3 - TermodinamikaMarida EyaNoch keine Bewertungen

- Formulas - PipeDokument34 SeitenFormulas - PipeReuben Madera DabaNoch keine Bewertungen

- Crystallization Material BalanceDokument5 SeitenCrystallization Material BalanceAron BalinesNoch keine Bewertungen

- CGB Sample TestDokument4 SeitenCGB Sample TestMuhammad Zubair SharifNoch keine Bewertungen

- Good Cip SystemDokument7 SeitenGood Cip SystemThanneeru Naga RajuNoch keine Bewertungen

- Response of SystemDokument4 SeitenResponse of SystemMuhammad Zubair SharifNoch keine Bewertungen

- Group 15 Project on Benefits of ApplesDokument74 SeitenGroup 15 Project on Benefits of ApplesMuhammad Zubair SharifNoch keine Bewertungen

- Report 3344444Dokument19 SeitenReport 3344444Muhammad Zubair SharifNoch keine Bewertungen

- Design of Condensers/Condensing ZonesDokument42 SeitenDesign of Condensers/Condensing ZonesTint Tiger100% (1)

- Industrial Microbiology Tutorial on BioreactorsDokument46 SeitenIndustrial Microbiology Tutorial on BioreactorsJasdeep KaurNoch keine Bewertungen

- Material BalanceDokument5 SeitenMaterial BalanceMuhammad Zubair SharifNoch keine Bewertungen

- Design of Ultra Filtration MembraneDokument3 SeitenDesign of Ultra Filtration MembraneMuhammad Zubair SharifNoch keine Bewertungen

- Experiment No.4 To Study The Variation of Photoelectric Effect With Intensity of LightDokument8 SeitenExperiment No.4 To Study The Variation of Photoelectric Effect With Intensity of LightMuhammad Zubair SharifNoch keine Bewertungen

- Detergent 1Dokument4 SeitenDetergent 1Muhammad Zubair SharifNoch keine Bewertungen

- FlotationDokument39 SeitenFlotationMuhammad Zubair SharifNoch keine Bewertungen

- Emerging Technologies For Food Processing and PreservationDokument10 SeitenEmerging Technologies For Food Processing and PreservationKhushbu KumariNoch keine Bewertungen

- Fiber Paper No LowDokument60 SeitenFiber Paper No Low120984Noch keine Bewertungen

- Primer Milk ProteinDokument12 SeitenPrimer Milk ProteinAmos MainaNoch keine Bewertungen

- Recovery and Purification of ProductsDokument15 SeitenRecovery and Purification of ProductsRatih Margita SariNoch keine Bewertungen

- Technip Separations PDFDokument22 SeitenTechnip Separations PDFProcess EngineerNoch keine Bewertungen

- Water System PQDokument47 SeitenWater System PQsainzb8389% (9)

- LifeSaver Bottle Instruction Manual 1Dokument13 SeitenLifeSaver Bottle Instruction Manual 1VladimirNoch keine Bewertungen

- Treatment of Waste CoolantDokument11 SeitenTreatment of Waste CoolantEdward Jones S mm15d024Noch keine Bewertungen

- Comprehensive Solutions for Water TreatmentsDokument56 SeitenComprehensive Solutions for Water TreatmentsTurinto MarjonoNoch keine Bewertungen

- Reverse Osmosis and Ultrafiltration of Corn Light Steep-Water SolublesDokument5 SeitenReverse Osmosis and Ultrafiltration of Corn Light Steep-Water SolublesMurali Krishna IndanaNoch keine Bewertungen

- Sabp A 028Dokument38 SeitenSabp A 028Abu Anas M.SalaheldinNoch keine Bewertungen

- MTPCL - WTP O&m ManualDokument62 SeitenMTPCL - WTP O&m Manualm_ganesh1983100% (4)

- 1.11 Ceramic MembranesDokument28 Seiten1.11 Ceramic Membranesfzl123007Noch keine Bewertungen

- 10 1016@j Desal 2019 114178Dokument40 Seiten10 1016@j Desal 2019 114178WAHYU DWI LESTARINoch keine Bewertungen

- UF Module Parameters ComparisonDokument8 SeitenUF Module Parameters Comparisonigo badrNoch keine Bewertungen

- Rachel Adams Jana Dengler Megan Macleod Kyla Sask Rachel Adams Jana Dengler Megan Macleod Kyla SaskDokument31 SeitenRachel Adams Jana Dengler Megan Macleod Kyla Sask Rachel Adams Jana Dengler Megan Macleod Kyla Saskbetengaan2100% (1)

- Pi Bond Collodial Silica in Power Plant Water Chemistry PDFDokument4 SeitenPi Bond Collodial Silica in Power Plant Water Chemistry PDFthanhhuyenNoch keine Bewertungen

- Treatment of Textile Dye Effluent Using A Polyamide-Based Nanofiltration MembraneDokument9 SeitenTreatment of Textile Dye Effluent Using A Polyamide-Based Nanofiltration MembraneOmaya TariqNoch keine Bewertungen

- The Hygenic Chain PDFDokument16 SeitenThe Hygenic Chain PDFstomakosNoch keine Bewertungen

- Calcium Phosphate Precipitation During Concentration by Vacuum Evaporation of Milk Ultrafiltrate and MicrofiltrateDokument9 SeitenCalcium Phosphate Precipitation During Concentration by Vacuum Evaporation of Milk Ultrafiltrate and MicrofiltrateJuank González TéllezNoch keine Bewertungen

- Suez-Mbr Planta CatalogueDokument2 SeitenSuez-Mbr Planta CatalogueEstefania CarrilloNoch keine Bewertungen

- Index: Sl. No. Topic Page NoDokument48 SeitenIndex: Sl. No. Topic Page NoSwapnil RoyNoch keine Bewertungen

- Methods of Endotoxin Removal From Biological PreparationsDokument17 SeitenMethods of Endotoxin Removal From Biological PreparationsexecNoch keine Bewertungen

- Guideline For Dialysate Quality of Spanish Society of Nephrology (Second Edition, 2015)Dokument52 SeitenGuideline For Dialysate Quality of Spanish Society of Nephrology (Second Edition, 2015)luc1902Noch keine Bewertungen

- X-Flow Aquaflex 55: Ultrafiltration MembraneDokument2 SeitenX-Flow Aquaflex 55: Ultrafiltration MembraneProjects AquariusNoch keine Bewertungen

- Inspection Guides - High Purity Water System (7 - 93) (FDA)Dokument11 SeitenInspection Guides - High Purity Water System (7 - 93) (FDA)Alejandro Carmona HenaoNoch keine Bewertungen

- Outside - in Hollow Fiber Ultrafiltration Membranes: Pure TechnologyDokument2 SeitenOutside - in Hollow Fiber Ultrafiltration Membranes: Pure TechnologyParvinder KaurNoch keine Bewertungen

- Aquafilter CatalogDokument24 SeitenAquafilter CatalogLordWaderNoch keine Bewertungen

- Using of Artificial Neural Network For Modeling of Oily Wastewater in Reverse Osmosis ProcessDokument5 SeitenUsing of Artificial Neural Network For Modeling of Oily Wastewater in Reverse Osmosis ProcessIJARP PublicationsNoch keine Bewertungen

- Stakpure OmniaTap 6 - 12 Instruction ManualDokument40 SeitenStakpure OmniaTap 6 - 12 Instruction ManualJuan Carlos CrespoNoch keine Bewertungen