Beruflich Dokumente

Kultur Dokumente

Howard Terzigni Presentation and Handouts PDF

Hochgeladen von

Miguel MancillaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Howard Terzigni Presentation and Handouts PDF

Hochgeladen von

Miguel MancillaCopyright:

Verfügbare Formate

HVAC DUCT CONSTRUCTION

STANDARDS

March, 2010

Presented by:

Eli Howard

Executive Director

Technical Services

Mark Terzigni

Project Manager

Technical Services

HVAC DUCT CONSTRUCTION

STANDARDS METAL AND FLEXIBLE

Information Required for Duct Construction

1. A comprehensive duct layout indicating

sizes, design airflows, pressure class,

and routing of the duct system.

2. The types of fittings to be used based

on the designer's calculations of fitting

losses (i.e., square versus 45

entry

taps, conical versus straight taps, etc.).

Information Required for Duct Construction

3. Use of turning vanes or splitter vanes.

4. Location of access doors.

5. Location and type of control and

balancing dampers.

6. Location and types of diffusers.

7. Requirements for duct insulation.

Information Required for Duct Construction

8. Location and types of any fire

protection device including fire

dampers, smoke dampers, combination

fire/smoke dampers, and ceiling

dampers. Building codes require this

information to be shown on the design

documents submitted for building

permit.

Information Required for Duct Construction

9. Details of offsets required to route

ductwork around obstructions (columns,

beams, etc.).

CONTRACTOR

Construction Considerations:

Pressure Class

(as specified)

Panel Thickness (Gage)

Panel Width/Height

J oint Type/Spacing

Intermediate

Reinforcement

Type/Spacing

ENGINEER

Design Considerations:

CFM

Static Pressure

Duct Size

Fitting Type

Construction

Pressure Class

Information Required for Duct Construction

DEPENDENT VARIABLES

Rectangular Transverse J oints

Rectangular

Figure 2-1

Pages 2.6-2.9

Rectangular Transverse J oints

Rectangular Transverse J oints

Rectangular Transverse J oints

Rectangular Transverse J oints

Rectangular Transverse J oints

Rectangular Transverse J oints

Rectangular Transverse J oints

Rectangular Transverse J oints

Rectangular Transverse J oints

Figure 2-16 Corners not required up to

2 in. w.g.

Corners are required

above 2 in. w.g.

Figure 2-17

Longitudinal Seams

Rectangular

Figure 2-17

Page 2.10

Longitudinal Seams

Longitudinal Seams

Longitudinal Seams

Intermediate Reinforcement

Figure 2-3

Page 2.12

Rectangular

Intermediate Reinforcement

Basic Duct Construction Process

Verify pressure class

Check corresponding table

Start with the larger side first

Determine reinforcement spacing options

Check joint reinforcement tables

Check intermediate reinforcement tables

if applicable (tie rod options)

Repeat for the short side

Guide Summary (P 2.5)

Circles are column

numbers

Number in box is the

minimum gage

First letter is minimum

reinforcement class

required.

Second letter is

downsized reinforcement

when used with tie rod

Xt t means tie rod is

required

In Words

If the box in the table shows H-20G

The minimum panel gage is 20

The reinforcement required is class H at the

spacing noted at the top of the column (this can

be a joint or intermediate reinforcement)

You can use G instead of H if you use a tie rod

as well. (If to achieve a class G you are already

required to use a tie rod then you can not use

this option)

Rectangular Duct Reinforcement

Rectangular Duct Reinforcement

Rectangular Duct Reinforcement

Rectangular Duct Reinforcement

Rectangular Duct Reinforcement

J oint Reinforcement

Table 2-31

Starts on page 2.74

Covers all transverse

joints that qualify as

reinforcement except

T-1 drive slip

For T-1 drive slip see

Table 2-48 on page

2.110

J oint Reinforcement

J oint Reinforcement

The (R) means use with a tie rod The (+) means use for positive

pressure application only

Table 2-48

Example 1

Pressure class is positive 1/2 in. w.g.

Dimensions are 20 in. x 12 in.

5 ft. joint spacing (longer if possible)

Preferred joint type plain Slip and Drive

Example 1

Page

2.14

Example 1 Table 2-48

Not Accepted

Page

2.110

Example 1 Solutions

Option 1

Use 24 gage

No reinforcement required either side

Option 2

Use 26 gage

T-1 (plain drive) on the 20 in. side at a max

spacing of 10 ft

No reinforcement required on the 12 in. side

Intermediate Reinforcement

Table 2-29

Starts on page 2.70

Covers typical

intermediate

reinforcement types.

For struts see Table

2-30 on page 2.72

Intermediate Reinforcement

Intermediate Reinforcement

H denotes Hot formed

C denotes Cold formed

Example 2

Pressure Class is 2 in. w.g.

Dimensions are 60 in. x 26 in.

5 foot joint spacing

TDC or TDF joint

No internal reinforcement

The Right Table (Pressure Class)

Page

2.18

The Right Table (Pressure Class)

Page

2.18

The Right Table (Pressure Class)

Page

2.18

J oint Reinforcement

Page

2.76

J oint Reinforcement

Page

2.76

Intermediate Reinforcement

Page

2.70

Intermediate Reinforcement

Page

2.70

Intermediate Reinforcement

The Right Table (Pressure Class)

Page

2.18

J oint Reinforcement

Page

2.76

Example 2 Solution

Duct gage is 20

J oint spacing is 5 feet (56 in.)

TDC/TDF for transverse joint

Intermediate reinforcement (2 feet)

G class

Angle 1 x 1 x 1/8

Not required on the 26 in. side

Intermediate External Reinforcement

Reinforcement Intervals do not need to

coincide

At 4 in. positive pressure and above

reinforcements must be tied

Must be fastened to the duct within 2 in.

from the corner (unless tied)

Maximum fastener spacing is 12 in.

Reinforced on Two Sides

Reinforced on Two Sides

Reinforced on Four Sides

Reinforced on Four Sides

Reinforced on Four Sides

Reinforcement Attachment

Tie Rods

Steel Rod

Threaded (all thread) or partial

Plain

Conduit

RC

EMT (most common type)

Steel Pipe

Steel Strap (positive pressure only)

1 in. x 1/8 in.

Angles (rare)

Tie Rod Attachment

Figure 2-5

Page 2.82

Tie Rod Attachment

Figure 2-5

Page 2.82

Tie Rod Attachment

Figure 2-6

Page 2.83

Tie Rod Attachment

Figure 2-6

Page 2.83

Tie Rod Layout p 2.98

Mid-Panel Tie Rods

Do not use in underground/slab apps

Do not use if air velocity > 2500 fpm

Do not use where grease or condensation can

collect

Unless no penetration is made

Or penetration is sealed water tight

If tie rods occur in 2 directions in the same

vicinity they must: (applies to J TR and MPT)

Be prevented from touching

Or be permanently attached

Example 3

Pressure class is positive 4 in. w.g.

Dimensions are 36 in. x 24 in.

5 ft. joint spacing

Transverse joint TDC/TDF

Use tie rod(s) where possible

The Right Table (Pressure Class)

Page

2.22

The Right Table (Pressure Class)

Page

2.22

J oint Reinforcement

Page

2.76

J oint Reinforcement

Page

2.76

J oint Reinforcement

Page

2.76

Mid Panel Tie Rod Schedule

Page

2.100

Tie Rod Load

Page

2.106

Table

2-46

Mid Panel Tie Rod Size

EMT conduit positive pressure

in. 900 lbs

in. 1,340 lbs

1 in. 1,980 lbs

HVAC DCS p2.80 S1.19.4

The Right Table (Pressure Class)

Page

2.22

J oint Reinforcement

Page

2.76

Example 3 Solution

Duct gage is 22

J oint spacing is 5 feet (56 in.)

TDC/TDF for transverse joint

Intermediate reinforcement (2 feet)

1 MPT

in. EMT Conduit

Not required on the 24 in. side

Could use 20 gage and J TR also

Mid Panel Tie Rods

Negative pressure

uses special tables

Concern is buckling

Table 2-38 in HVAC

DCS for EMT

P 2.91

Mid Panel Tie Rods Neg. Pressure

Page

2.91

Tie Rod Loads

Table 2-46 p. 2.100 is for mid panel tie

rods (100% load)

Table 2-34 p. 2.84 is for tie rods used to

back up joints or external reinforcement

(75% Load)

1 in. w.g. = 5.2 lbf/ft

2

Tie Rod Loads

Given information:

48wide, RS = 28(TDC/TDF) @ 4 in. w.g.

Area = 48x 28= 1344 in

2

Convert to ft

2

1344/144 = 9.33 ft

2

4 in. w.g. x 5.2 lbs/ft

2

/in. w.g. x 9.33 ft

2

194 lbf

If backing up a joint or external

reinforcement 194 lbf x .75 = 146 lbf

An Easier Way?

Newest addition are the TDC/TDF tables

Tables based on

Pressure class

J oint length

Example 3 (revisited)

4 in. w.g.

TDC/TDF

5 ft. joint spacing

36 in. x 24 in.

Table 2-19 HVAC DCS

Example 3 (revisited)

Page

2.50

Table 2-19 HVAC DCS

Example 3 (revisited)

Page

2.50

Table 2-19 HVAC DCS

Example 3 (revisited)

Page

2.50

Example 3 (revisited) Solution

Option 1

20 gage

J TR on 36 in. side

No additional reinforcement on 24 in. side

Option 2

22 gage

MPT for 36 in. side

No additional reinforcement on 24 in. side

Example 3 (revisited) Solution

Option 3

20 gage

(2) E class reinforcements at the joints for 36 in. side

No additional reinforcement on 24 in. side

Option 4

22 gage

F class reinforcement at the mid-panel for 36 in. side

No additional reinforcement on 24 in. side

Duct over 120 inches

Figure 2-13 in HVAC

DCS

Use standard tables

for sizes < 120 in.

P 2.117

Duct over 120 inches

Page

2.117

Duct over 120 inches

Page

2.117

Example 4

Duct is 140 x 70 inches at negative 2 in.

w.g.

Duct over 120 inches

Page

2.117

You need 2 tie rods across the width at

every joint and at every reinforcement.

140/60 = 2.33 (round down) to 2

Need 3 at widths beyond 180

140/(2+1) = 140/3 = 46 5/8spacing

The joint length will be 5 ft. (56 inches

using TDC/TDF) and the reinforcement

spacing will be 2 ft (28 inches using

TDC/TDF).

Duct over 120 inches

Determine the tie rod load:

Tip- You can figure the load on a duct of

half of the width using Table 2-46 and

then double the load.

140/2 = 70 inches

RS = 28 inches

Duct over 120 inches

Duct over 120 inches

Page

2.106

The load is 146 lbs (load for 70 inches) x

2 = 292 lbs for 140 inches

The load per tie rod is 292 lbs/2 = 146 lbs

(75% - Rule)

What size does the tie rod need to be?

If we use EMT conduit check Table 2-38

What size reinforcement is a class I

Check Tables 2-29 or 2-30

Duct over 120 inches

Mid Panel Tie Rods Neg. Pressure

Page

2.91

Example 4 mid-panel reinforcement

Page

2.70

Check the short side using the tables for

duct less than 120 inches.

In this case since we are using TDC/TDF

we can use those specific tables.

Table 2-17 on page 2.46

Duct over 120 inches

Duct over 120 inches

Page

2.46

Example 4 mid-panel reinforcement

Page

2.70

Example 4 solution

The duct will be 18 gage

The joints will be TDC/TDF

The joint length is 56 inches

The 140 inch side will be supported by 1EMT

conduit spaced 46 5/8across the width and will

be at each side of the joint and backing up the

mid-panel reinforcement.

The mid-panel reinforcement for the 140 inch

side will be 2 x 2 x 1/8 and will be tied

using 1 x 1 x 12 gage

Example 4 solution

The 70 inch side will be reinforced using

only external reinforcement

The reinforcement will be 2 x 2 x 1/8 and

installed on both sides of each joint

This reinforcement will not be tied

No mid-panel reinforcement is required

Example 4 solution

Page

2.117

Example 5 Round Duct

Positive 10 in. w.g.

24 in. diameter

Long seam or spiral

Table 3-5 in HVAC DCS

Applies to positive pressure up through 10 in.

w.g.

Example 3 Round Duct

Table 3-5 Page 3.8

Unreinforced Round Duct to Positive 10 in. w.g.

Example 3 Round Duct

Table 3-5 Page 3.8

Unreinforced Round Duct to Positive 10 in. w.g.

Example 6 Round Duct

Negative 10 in. w.g.

24 in. diameter

Long seam Spiral

Table 3-9 in HVAC DCS for long seam

Table 3-13 in HVAC DCS for spiral

Example 4 long seam

Longitudinal Seam

Page 3.16

Example 4 Spiral

Spiral Seam

P 3.24

Round Reinforcement

Tables in the HVAC

DCS

3-2 Reinforcement

3-3 Attachment

Schedule

3-4 Rings Used as

Companion Flanges

P 3.6

Round Reinforcement

Page 3.6

Round Reinforcement

Page 3.6

Oval Duct

Approved for positive pressure only

Can be used for negative pressure with

special designs

Table 3-15 for gage

Reinforce like rectangular

Based on the flat span

Flat span = major minor

Based on reinforcement spacing

Use at least one tie rod (Figure 3-7 p 3.32)

Oval Duct

Page 3.28

Example 7 Oval Duct

Flat Oval Duct 20x 46@+10 in. w.g.

Major dimension = 46

Minor dimension = 20

Flat span (Major Minor) = 26 (46- 20)

First step determine gage

Use Table 3-15

Use Major dimension

Example 7 Oval Duct

Page 3.28

Example 7 Oval Duct

Next determine the reinforcement

Based on the flat span (26)

Use the correct rectangular table

Pick reinforcement spacing

Determine reinforcement class

Example 7 Oval Duct

Page 2.26

Example 7 Oval Duct Solution

Using spiral duct

Build the duct from 22 gage material

Reinforce the duct every 5 feet

Use a G class reinforcement

1 x 1 x 1/8 angle

Use either type 1 or type 2 option for tie rod

Figure 3-7 page 3.32

Questions?

Technical Inquiries:

www.smacna.org

Click on technical services (left side)

Click on technical inquiries (center)

http://www.smacna.org/technical/index.cfm?fuseaction=inquiry

Das könnte Ihnen auch gefallen

- Hvac Duct Constrction Examples: Ashrae January 26, 2009 Mark Terzigni Project Manager SmacnaDokument54 SeitenHvac Duct Constrction Examples: Ashrae January 26, 2009 Mark Terzigni Project Manager SmacnaAdhanom G.Noch keine Bewertungen

- Cooke Ductwork ManualDokument37 SeitenCooke Ductwork Manualquantum 46bNoch keine Bewertungen

- Metal Duct WorkDokument9 SeitenMetal Duct WorkSyed Waqas HussainNoch keine Bewertungen

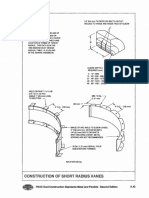

- Short Radius VanesDokument1 SeiteShort Radius VanesblahblahNoch keine Bewertungen

- Types and Functions of Wood Joints: Loft, "Purely A System of Joints" Was A Customary Part of A Bride'sDokument27 SeitenTypes and Functions of Wood Joints: Loft, "Purely A System of Joints" Was A Customary Part of A Bride'sAlin GhitoiuNoch keine Bewertungen

- Catalog 21Dokument940 SeitenCatalog 21Daniel Quijada LucarioNoch keine Bewertungen

- The Mortise and Tenon Joint: Best Results Come Directly From Chisel and SawDokument6 SeitenThe Mortise and Tenon Joint: Best Results Come Directly From Chisel and SawAdrian Cocis100% (1)

- Energy PlusDokument6 SeitenEnergy PlusSwapnil JainNoch keine Bewertungen

- Design of Duct For A Two Storey Retail Shop 30-1-2017Dokument5 SeitenDesign of Duct For A Two Storey Retail Shop 30-1-2017Mir Aqueel AliNoch keine Bewertungen

- حصر الصاجDokument4 Seitenحصر الصاجSaber Elkassas100% (1)

- Operation Manual: Duct Air Leakage Tester Model DALT 6900Dokument27 SeitenOperation Manual: Duct Air Leakage Tester Model DALT 6900karimakkiNoch keine Bewertungen

- PVC Duct DesignDokument10 SeitenPVC Duct DesigncitramuaraNoch keine Bewertungen

- Air Filter Grades PDFDokument2 SeitenAir Filter Grades PDFMMMOH200Noch keine Bewertungen

- City of Houston IdmDokument272 SeitenCity of Houston IdmKevin MillsNoch keine Bewertungen

- Vertical Tiling Guide1 PDFDokument60 SeitenVertical Tiling Guide1 PDFArchitecture AdbiaNoch keine Bewertungen

- Duct Loop and VAVDokument10 SeitenDuct Loop and VAVengomar76Noch keine Bewertungen

- Titus Engineering GuideDokument23 SeitenTitus Engineering Guideteri-scribdNoch keine Bewertungen

- PalDuct PIR Datasheet ME en 10 16Dokument2 SeitenPalDuct PIR Datasheet ME en 10 16fahad0% (1)

- 4 Egg Crate Grills PDFDokument6 Seiten4 Egg Crate Grills PDFMUHAMMED SHAFEEQNoch keine Bewertungen

- Air Conditioner: The BasicsDokument14 SeitenAir Conditioner: The BasicsNikki AmuraoNoch keine Bewertungen

- ElectricManual-7 00Dokument406 SeitenElectricManual-7 00datacrime7Noch keine Bewertungen

- Hdpsychart Generic ManualDokument87 SeitenHdpsychart Generic Manualwalnasp1Noch keine Bewertungen

- 1-Room Air DistributionDokument30 Seiten1-Room Air DistributionSatwinder SinghNoch keine Bewertungen

- Air Distribution SystemDokument21 SeitenAir Distribution SystemRohit JainNoch keine Bewertungen

- Dr. Fixit Newcoat 105 1 PDFDokument3 SeitenDr. Fixit Newcoat 105 1 PDFmohdrashidNoch keine Bewertungen

- Rotary Damper Actuator: Standard 2 NM / 5 NM 2 Point and 3 Point ControlDokument4 SeitenRotary Damper Actuator: Standard 2 NM / 5 NM 2 Point and 3 Point ControlZay Min HtetNoch keine Bewertungen

- 1 - Rectangular Duct (Single & Double Wall)Dokument40 Seiten1 - Rectangular Duct (Single & Double Wall)Tariq AsgharNoch keine Bewertungen

- Liquid Process Piping - Part 1 General Piping Design PDFDokument33 SeitenLiquid Process Piping - Part 1 General Piping Design PDFnitin guptaNoch keine Bewertungen

- Contam User GuideDokument340 SeitenContam User GuidehuyenilpNoch keine Bewertungen

- Duct Design For "Super" SupermarketDokument47 SeitenDuct Design For "Super" Supermarketkevin_thian_1100% (4)

- Holyoake Engineering DataDokument24 SeitenHolyoake Engineering DataSantiago J. ramos jr100% (1)

- Lokring I Single Ring 01.07.2013Dokument58 SeitenLokring I Single Ring 01.07.2013Sandra Mabel Leguizamon100% (1)

- Hvac Duct Air Leakage 9 12 19Dokument7 SeitenHvac Duct Air Leakage 9 12 19Marinos GounaridisNoch keine Bewertungen

- F 1090 - 87 R97 - Rjewota - PDFDokument4 SeitenF 1090 - 87 R97 - Rjewota - PDFFreddy AlmeidaNoch keine Bewertungen

- 346N No06 HVAC Cooling LoadDokument33 Seiten346N No06 HVAC Cooling LoadmartinqNoch keine Bewertungen

- Moisture Control Part 4Dokument36 SeitenMoisture Control Part 4Karthik RajendrenNoch keine Bewertungen

- UPONOR Technical Guidelines Industrial UfhDokument32 SeitenUPONOR Technical Guidelines Industrial Ufhbadmike71Noch keine Bewertungen

- 093 Paint Booth VentDokument3 Seiten093 Paint Booth VentFajar Hadi CrisnamurtiNoch keine Bewertungen

- Humidity ControlDokument16 SeitenHumidity ControlHanan SFNoch keine Bewertungen

- Topic3 Ventilation Part 2Dokument51 SeitenTopic3 Ventilation Part 2Anisha AdzihanNoch keine Bewertungen

- Ae892 PDFDokument32 SeitenAe892 PDFSyafmi KarotNoch keine Bewertungen

- Duct Construction ManualDokument110 SeitenDuct Construction Manualenjoylife0290Noch keine Bewertungen

- Act 2 2 3 Heat Loss GainDokument4 SeitenAct 2 2 3 Heat Loss Gainapi-2474370040% (1)

- Grilles Registers Diffusers Catalogs 15819Dokument808 SeitenGrilles Registers Diffusers Catalogs 15819Anibal VpNoch keine Bewertungen

- General Description: Click For Detailed Diagram Collection and Mixing of Outdoor Air and Air From The BuildingDokument16 SeitenGeneral Description: Click For Detailed Diagram Collection and Mixing of Outdoor Air and Air From The BuildingGiftson ImmanuelNoch keine Bewertungen

- Thermal Conductivity of Some Common Materials and GasesDokument11 SeitenThermal Conductivity of Some Common Materials and GasesPragasti Nilam SariNoch keine Bewertungen

- Typical Multi-Zone VAV SystemDokument12 SeitenTypical Multi-Zone VAV SystemEldin Jelec100% (1)

- ChillerDokument3 SeitenChillerSajib Chandra RoyNoch keine Bewertungen

- Chilled BeamDokument16 SeitenChilled BeamDEVIKA ANILNoch keine Bewertungen

- Course M-2059 Hydraulic Design of Fire Water Sprinkler Systems Containing Typical Branch LinesDokument62 SeitenCourse M-2059 Hydraulic Design of Fire Water Sprinkler Systems Containing Typical Branch LinesAhmed NabilNoch keine Bewertungen

- Method Statement For Galvanized Sheet Metal Duct WorkDokument5 SeitenMethod Statement For Galvanized Sheet Metal Duct WorkMamado099Noch keine Bewertungen

- Heat Wheel Technical HandbookDokument29 SeitenHeat Wheel Technical Handbooksripriya01Noch keine Bewertungen

- Duct ConstructionDokument75 SeitenDuct ConstructionJavier VespaNoch keine Bewertungen

- 10) Api 510 Day 2Dokument206 Seiten10) Api 510 Day 2hamedNoch keine Bewertungen

- SIS BOOK 2 - 3rd RevisionDokument201 SeitenSIS BOOK 2 - 3rd RevisionHamza Alam100% (1)

- HVAC - Duct ConstructionDokument75 SeitenHVAC - Duct ConstructionGaapchu100% (2)

- ANSI-SMACNA 2006 HvacDuctStandardsDokument64 SeitenANSI-SMACNA 2006 HvacDuctStandardsErica MorrisonNoch keine Bewertungen

- DuctHeaters CatalogDokument12 SeitenDuctHeaters Catalogjohnking5555Noch keine Bewertungen

- EBT730 731 ManualDokument80 SeitenEBT730 731 ManualMiguel MancillaNoch keine Bewertungen

- Product Dimensions: SDV Basic UnitDokument1 SeiteProduct Dimensions: SDV Basic UnitMiguel MancillaNoch keine Bewertungen

- Airflow Testing Accuracy in The Field: Ben LipscombDokument40 SeitenAirflow Testing Accuracy in The Field: Ben LipscombMiguel MNoch keine Bewertungen

- Performance Rating of Water - Chilling Packages Using The Vapor Compression CycleDokument36 SeitenPerformance Rating of Water - Chilling Packages Using The Vapor Compression CyclesamuraivickyNoch keine Bewertungen

- Tate Airflow Directaireal24indatasheetDokument1 SeiteTate Airflow Directaireal24indatasheetMiguel MancillaNoch keine Bewertungen

- 37.621 Vortex 4-12 SubmittalDokument1 Seite37.621 Vortex 4-12 Submittaloemolina25Noch keine Bewertungen

- HVAC OutdoorAirVentilationStandard - PDDokument5 SeitenHVAC OutdoorAirVentilationStandard - PDIbrahim SirpiNoch keine Bewertungen

- BAC Tab OpenCoolingTowers ENv00Dokument2 SeitenBAC Tab OpenCoolingTowers ENv00Miguel MancillaNoch keine Bewertungen

- SGGWGDokument5 SeitenSGGWGAu NguyenNoch keine Bewertungen

- 2006 - Chapter 4-Ventilation PDFDokument4 Seiten2006 - Chapter 4-Ventilation PDFMiguel MancillaNoch keine Bewertungen

- EngData 203 Internet PDFDokument16 SeitenEngData 203 Internet PDFMiguel MancillaNoch keine Bewertungen

- PGAG Solarban 60-70XL (7123)Dokument2 SeitenPGAG Solarban 60-70XL (7123)Miguel MancillaNoch keine Bewertungen

- Varitrac Changeover Bypass VavDokument52 SeitenVaritrac Changeover Bypass VavMiguel MancillaNoch keine Bewertungen

- 2006 - Chapter 4-Ventilation PDFDokument4 Seiten2006 - Chapter 4-Ventilation PDFMiguel MancillaNoch keine Bewertungen

- Autocad 2015 What Is New Guide PDFDokument47 SeitenAutocad 2015 What Is New Guide PDFLuis Carlos Ayllón EscobarNoch keine Bewertungen

- Autocad 2015 Tips and Tricks Booklet 1Dokument23 SeitenAutocad 2015 Tips and Tricks Booklet 1Ruben RedondoNoch keine Bewertungen

- AutoCAD Electrical 2015 Productivity Study PDFDokument12 SeitenAutoCAD Electrical 2015 Productivity Study PDFMiguel MancillaNoch keine Bewertungen

- Featuremanager Design Tree: External References Status IndicatorsDokument4 SeitenFeaturemanager Design Tree: External References Status IndicatorscecepscribdNoch keine Bewertungen

- Acadmechanical15 Study PDFDokument15 SeitenAcadmechanical15 Study PDFMiguel MancillaNoch keine Bewertungen

- AutoCAD 2015 Brochure PDFDokument4 SeitenAutoCAD 2015 Brochure PDFMiguel MancillaNoch keine Bewertungen

- HVAC Systems Duct DesignDokument39 SeitenHVAC Systems Duct Designsardarmkhan100% (2)

- VRF-EM-BH-002-US 013D17 MVIII EngManual 20130426131551Dokument264 SeitenVRF-EM-BH-002-US 013D17 MVIII EngManual 20130426131551lopesinho2010Noch keine Bewertungen

- Howard Terzigni Presentation and HandoutsDokument129 SeitenHoward Terzigni Presentation and HandoutsMiguel MancillaNoch keine Bewertungen

- Air Distribution Selection For SchoolsDokument55 SeitenAir Distribution Selection For SchoolsMiguel MancillaNoch keine Bewertungen

- Ag Ufad 02Dokument9 SeitenAg Ufad 02Miguel MancillaNoch keine Bewertungen

- 08.08.26 VariableAirHVACPresentationDokument62 Seiten08.08.26 VariableAirHVACPresentationMiguel MancillaNoch keine Bewertungen

- Ag LeedDokument10 SeitenAg LeedMiguel MancillaNoch keine Bewertungen

- Ag Ufad 02Dokument9 SeitenAg Ufad 02Miguel MancillaNoch keine Bewertungen

- Air Balancing - AG - 2014Dokument8 SeitenAir Balancing - AG - 2014Miguel MancillaNoch keine Bewertungen

- Single DualDokument38 SeitenSingle DualMiguel MancillaNoch keine Bewertungen