Beruflich Dokumente

Kultur Dokumente

LOTO Case Packer Example PDF

Hochgeladen von

Daniel GhersiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

LOTO Case Packer Example PDF

Hochgeladen von

Daniel GhersiCopyright:

Verfügbare Formate

Developed by Reviewed by Revised by

ESC ESC

Revn: 0 Date: N/A Origin Date: 3/13/2013

ID Source Device

1

Electrical

480V

Padlock

1

Pneumatic

Inlet - 110 PSI

Ball valve

device

1

Pneumatic

Inlet - 110 PSI

Ball valve

device

Potential Energy

Gravity - 300 LBS

Thermal Energy

300 F

Kinetic Energy

1000 RPM

LOCKOUT-TAGOUT PROCEDURE

OSHA CFR 1910.147

Visually verify zero

pressure status.

Turn valve to closed position.

Lock out.

Isolation point on West

side of unit.

Equipment #: 866.773.7541 Description: Case Packer

Isolation Points to be

Locked and Tagged

Location: Packaging Room

Check

Attempt restart at

CP-1.

Confined Space. Obtain proper permits and follow confined space procedure prior to entering.

Sharp blades and pinch points. Take precautions and wear proper PPE when servicing. Shut

off adjacent equipment prior to servicing.

Isolation point on South

side of unit.

Location

3

Move disconnect to off.

Lock out.

Method

ALWAYS PERFORM A MACHINE STOP BEFORE LOCKING OUT DISCONNECTS

DANGER

Area: Building 5

Isolation point on West

side of unit.

Turn valve to closed position.

Lock out.

Visually verify zero

pressure status.

Any machine modifications must be shown in procedure. Contact safety department to update procedure.

Saf et y I s Your Responsi bi l i t y!

OPENING A GUARD DOES NOT CONSTITUTE A LOCKOUT

Be sure to lower all parts to lowest position or install blocks in raised position before

attempting to service machine.

Be sure to wait until heat has dissipated from machine until cool to touch before

servicing. Wear proper PPE before beginning work.

Be sure to wait until all moving parts have come to a complete stop. If necessary,

use a block or chain to prevent equipment from moving while servicing.

E-1

NEXT AUDIT DUE

MAR 2014

NEXT AUDIT DUE

MAR 2015

NEXT AUDIT DUE

MAR 2016

NEXT AUDIT DUE

MAR 2017

P-1

CP-1

866-773-7541

West Side View West Side View Southeast Side View

E-1

P-1

P-2

P-2

Page 1 of 1 LOTO - Case Packer Example

Das könnte Ihnen auch gefallen

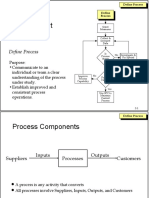

- Basics of Defining ProcessesDokument18 SeitenBasics of Defining ProcessesFaried Putra SandiantoNoch keine Bewertungen

- Risk Assessment Register: Prepared By: Toolpusher / Hse AdvisorDokument1 SeiteRisk Assessment Register: Prepared By: Toolpusher / Hse Advisorcmrig74Noch keine Bewertungen

- Reinforcement Cutting Bending JSA HSE ProfessionalsDokument1 SeiteReinforcement Cutting Bending JSA HSE ProfessionalsNoval FebriNoch keine Bewertungen

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Dokument3 SeitenHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Wealth OSIOBENoch keine Bewertungen

- Toolbox Meeting - Health Safety and Environment Underpass ProjectDokument1 SeiteToolbox Meeting - Health Safety and Environment Underpass ProjectDe' OvaNoch keine Bewertungen

- MS KPI Trend - Management System Compliance - November 2023Dokument1 SeiteMS KPI Trend - Management System Compliance - November 2023DUSTIN AYEN KERBY DEALOLANoch keine Bewertungen

- SOP For Handling Complaint Received - VertexDokument5 SeitenSOP For Handling Complaint Received - Vertexحافظ عبدالحسیب طارقNoch keine Bewertungen

- Trouble Shooting Injection Molding ProcessDokument16 SeitenTrouble Shooting Injection Molding ProcessKaya Eralp AsanNoch keine Bewertungen

- Safety Inspection ChecklistDokument6 SeitenSafety Inspection ChecklistVel MuruganNoch keine Bewertungen

- RCA SampleDokument2 SeitenRCA Sampleedward tagarino100% (1)

- Jsa GRIT BLASTINGDokument3 SeitenJsa GRIT BLASTINGPrajnay ShettyNoch keine Bewertungen

- UntitledDokument6 SeitenUntitledAnkit SinghNoch keine Bewertungen

- Control MeasuresDokument4 SeitenControl MeasuresCharlie Dela RosaNoch keine Bewertungen

- Proposal of Risk Register1Dokument21 SeitenProposal of Risk Register1Mohammad FaisalNoch keine Bewertungen

- Hazardous Material Weekly InspectionDokument1 SeiteHazardous Material Weekly InspectionYexiong YIALENGNoch keine Bewertungen

- Job Safety Analysis FormDokument9 SeitenJob Safety Analysis FormBhagat DeepakNoch keine Bewertungen

- Oilfield Inspection Services: Method Statement: Forklift Tubular & General Cargo HandlingDokument6 SeitenOilfield Inspection Services: Method Statement: Forklift Tubular & General Cargo HandlingDheeraj MenonNoch keine Bewertungen

- First Aid - Sample ProcedureDokument5 SeitenFirst Aid - Sample ProcedureARSHI ASLAMNoch keine Bewertungen

- Control of Nonconforming Outputs ProcessDokument18 SeitenControl of Nonconforming Outputs Process124th EAGLECOM KimJaveroNoch keine Bewertungen

- Small Business Safety Checking Out Your Workplace Checklist 1284Dokument8 SeitenSmall Business Safety Checking Out Your Workplace Checklist 1284Farra CartoumNoch keine Bewertungen

- DMN-8D Report: Target Date: Actual DateDokument1 SeiteDMN-8D Report: Target Date: Actual DateFudu KhichNoch keine Bewertungen

- Bench GrinderDokument6 SeitenBench GrinderGaurav KhamkarNoch keine Bewertungen

- Incident / Injury Report Form: o o o o oDokument2 SeitenIncident / Injury Report Form: o o o o ostjohn300100% (1)

- 3 3bb0aDokument7 Seiten3 3bb0aEleandro JoaquimNoch keine Bewertungen

- Quality Plan Dyeing FinishingDokument3 SeitenQuality Plan Dyeing FinishingITOPS TeamNoch keine Bewertungen

- Ehs Committee - NewDokument4 SeitenEhs Committee - NewNand KumarNoch keine Bewertungen

- Fire Extinguisher Check SheetDokument5 SeitenFire Extinguisher Check SheetSafety DeptNoch keine Bewertungen

- Osha 300 FormDokument12 SeitenOsha 300 FormGaharu Nisaa100% (1)

- Environmental Management SystemDokument145 SeitenEnvironmental Management Systemmohamed ibrahimNoch keine Bewertungen

- CP-SS BLK-01Dokument5 SeitenCP-SS BLK-01yogesh WakchaureNoch keine Bewertungen

- Crane Inspection ChecklistDokument2 SeitenCrane Inspection ChecklisttatonyNoch keine Bewertungen

- Crane Inspection ChecklistDokument2 SeitenCrane Inspection ChecklisttatonyNoch keine Bewertungen

- Wind Power Plant Testing and CommissioningDokument27 SeitenWind Power Plant Testing and CommissioningyoonghmNoch keine Bewertungen

- Risk Assessment Checklist For New and Expectant MothersDokument2 SeitenRisk Assessment Checklist For New and Expectant MothersDave NalugonNoch keine Bewertungen

- 5s Checklist OperationDokument1 Seite5s Checklist OperationDian PeshevNoch keine Bewertungen

- IEC 61400-3 EdDokument17 SeitenIEC 61400-3 EdDaniel Ghersi0% (4)

- Unloader Check ListDokument1 SeiteUnloader Check ListAnonymous ahdhFMaNoch keine Bewertungen

- R1937-JSA-003 Job Safety Analysis For TrenchingDokument5 SeitenR1937-JSA-003 Job Safety Analysis For TrenchingVineet AgrawalNoch keine Bewertungen

- First Aid Safety Meeting TopicsDokument79 SeitenFirst Aid Safety Meeting TopicsSrikanth BammhideNoch keine Bewertungen

- Project Management PresentationDokument4 SeitenProject Management PresentationSam ChauhanNoch keine Bewertungen

- 5 S - A PresentationDokument38 Seiten5 S - A Presentationpbalawin43900% (1)

- JSA EmployeesDokument2 SeitenJSA EmployeesburhanNoch keine Bewertungen

- IMS 138-DSTI Checklist Rev05Dokument2 SeitenIMS 138-DSTI Checklist Rev05victor100% (2)

- Contigency PlanDokument1 SeiteContigency Planapi-510150665Noch keine Bewertungen

- 108 Iyappan Sarana Gosham in TamilDokument5 Seiten108 Iyappan Sarana Gosham in TamilSudhagarNoch keine Bewertungen

- Die Inward Inspection ReportDokument2 SeitenDie Inward Inspection ReportRahul DevkateNoch keine Bewertungen

- Annexure-1 Respiratory Hazard Inventory and Employee Fitness RecordDokument6 SeitenAnnexure-1 Respiratory Hazard Inventory and Employee Fitness RecordAshok PatelNoch keine Bewertungen

- Questions For Root Cause Analysis Participants (Job Titles)Dokument4 SeitenQuestions For Root Cause Analysis Participants (Job Titles)paul_aldNoch keine Bewertungen

- PCP & FmeaDokument4 SeitenPCP & FmeaDaniela AscolaniNoch keine Bewertungen

- CF 601 1 Purchasing Quality Assurance RequirementsDokument3 SeitenCF 601 1 Purchasing Quality Assurance RequirementsTrent CockerhamNoch keine Bewertungen

- B515 TempDokument4 SeitenB515 TempubraghuNoch keine Bewertungen

- PT Jawa Tirtamarin Form Keselamatan, Kesehatan Kerja Dan Perlindungan Lingkungan Statistik Keselamatan Dan Kesehatan KerjaDokument1 SeitePT Jawa Tirtamarin Form Keselamatan, Kesehatan Kerja Dan Perlindungan Lingkungan Statistik Keselamatan Dan Kesehatan Kerjaimam santosoNoch keine Bewertungen

- SOP For Handling of Expired ProductsDokument3 SeitenSOP For Handling of Expired ProductsMuhammad NisarNoch keine Bewertungen

- Appendix 10 Waste Matrix Attachment A 092203Dokument14 SeitenAppendix 10 Waste Matrix Attachment A 092203droffilcz27Noch keine Bewertungen

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDokument4 SeitenJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- Cost of Poor QualityDokument17 SeitenCost of Poor QualityrajaNoch keine Bewertungen

- Design Validation Plan - DVPR Template PDFDokument5 SeitenDesign Validation Plan - DVPR Template PDFsiva sankarNoch keine Bewertungen

- Procedure Personal Protective EquipmentDokument3 SeitenProcedure Personal Protective EquipmentNas KacangNoch keine Bewertungen

- Sop Hydraulic Punch and ShearDokument1 SeiteSop Hydraulic Punch and ShearBorislav VulićNoch keine Bewertungen

- HSE Inspection Checklist: 1 Safety PromotionDokument4 SeitenHSE Inspection Checklist: 1 Safety PromotionRanjan PrNoch keine Bewertungen

- Corp 9-17-10Dokument26 SeitenCorp 9-17-10John AndersonNoch keine Bewertungen

- P18HP Air Conditioning ManualDokument15 SeitenP18HP Air Conditioning ManualRicardo EdwardoNoch keine Bewertungen

- Fan Assy 2Dokument7 SeitenFan Assy 2chandrarazor18Noch keine Bewertungen

- Lowe's #0461679 20 Gallon (20-Gal) Portable Air Compressor Blue Hawk Model #0132055 User's Guide Manual (461679.pdf)Dokument36 SeitenLowe's #0461679 20 Gallon (20-Gal) Portable Air Compressor Blue Hawk Model #0132055 User's Guide Manual (461679.pdf)BanditoX100% (1)

- JKBench InstallDokument2 SeitenJKBench InstallWashington BobadillaNoch keine Bewertungen

- GoodGame RulesDokument3 SeitenGoodGame RulesDaniel GhersiNoch keine Bewertungen

- Cmstorm TrooperDokument26 SeitenCmstorm TrooperDaniel GhersiNoch keine Bewertungen

- PigDokument20 SeitenPigWidar Eko WaspodoNoch keine Bewertungen

- Design of Chute SpillwayDokument33 SeitenDesign of Chute SpillwayBhaskar ReddyNoch keine Bewertungen

- Gmail - PruebaDokument2 SeitenGmail - PruebaDaniel GhersiNoch keine Bewertungen

- QBR FebruaryDokument2 SeitenQBR FebruaryDaniel GhersiNoch keine Bewertungen

- Cupisnique Social and Environmental Reporting FebruaryDokument6 SeitenCupisnique Social and Environmental Reporting FebruaryDaniel GhersiNoch keine Bewertungen

- Credito VehicularDokument9 SeitenCredito VehicularDaniel GhersiNoch keine Bewertungen

- 01 - EESA Petty Cash 02 Ene To 10Dokument7 Seiten01 - EESA Petty Cash 02 Ene To 10Daniel GhersiNoch keine Bewertungen

- Credito VehicularDokument9 SeitenCredito VehicularDaniel GhersiNoch keine Bewertungen

- Modelo Safety AlertDokument2 SeitenModelo Safety AlertDaniel GhersiNoch keine Bewertungen

- STG UAT Single Line Diagram Rev.3Dokument1 SeiteSTG UAT Single Line Diagram Rev.3Daniel GhersiNoch keine Bewertungen