Beruflich Dokumente

Kultur Dokumente

Poka Yoke

Hochgeladen von

selvaganapathy1992Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Poka Yoke

Hochgeladen von

selvaganapathy1992Copyright:

Verfügbare Formate

TVS - MOTOR CO.

Poka Yoke

llhll

PED - DESIGN CENTER

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

A Strategy for Performance Excellence

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TO ACHIEVE

ZERO DEFECT

ZERO WASTE

ZERO DELAY

TVS - MOTOR CO.,

The Approach

Elimination of

wastes

KAIZEN

Continuous

Improvement

Poka Yoke

PED - DESIGN CENTER

The Strategy

One piece flow

SMED

Visual Controls

Workplace

Organization

Kanban

Standard Work

Process Control

TPM

Poka-Yoke

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

What.?

Why.?

Who.?

Where.?

When.? How.?

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Let us discuss some

day to day life examples

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

How to insert a floppy in a computer

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

In which way it has to be inserted

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

What will happen if we insert in

the wrong way

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Wrong loading is not possible

How ?

Poka Yoke

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Iron box

The lady is watching her child

during ironing a cloth ?

What would have happened.

TVS - MOTOR CO.,

Poka Yoke

Iron box

PED - DESIGN CENTER

Cloths burnt due to overheating

How to avoid ?

TVS - MOTOR CO.,

Poka Yoke

Iron box

PED - DESIGN CENTER

Provide auto off when overheated.

How ?

Poka Yoke

TVS - MOTOR CO.,

Poka Yoke

Hair drier

PED - DESIGN CENTER

Switch

If you forget to switch off

What will happen?

Energy loss , Motor overheat ,

life is reduced

How to avoid ?

TVS - MOTOR CO.,

Poka Yoke

Hair drier

PED - DESIGN CENTER

Limit switch trigger

Auto off after keeping on holder

Poka Yoke

Poka Yoke

TVS - MOTOR CO.,

PED - DESIGN CENTER

Story

Letter delivered to wrong person

To

To

Rajesh

M/s R.K Industry

Bangalore - 35

How to avoid ?

R. Suresh

D.No-86 II nd cross ,

M.G Road,

Hosur - 635109

Poka Yoke

TVS - MOTOR CO.,

Post cover

PED - DESIGN CENTER

Provide Window cover for address

Avoids wrong posting , time saving.

To

R. Suresh

D.No.86, II nd cross ,

M.G Road,

Hosur - 635109

Poka Yoke

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Wash basin

Blockage in the main drain.

If you forget to close the tap. What will happen ?

Water over flow and spills on floor

How to avoid ?

TVS - MOTOR CO.,

Poka Yoke

Wash basin

PED - DESIGN CENTER

Over flow hole provided

to avoid dropping on floor

Poka Yoke

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

CAR PARKING

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

CAR PARKING

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Think Simple

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Use Sensors to Prevent

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

POKA YOKE CHUTE

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Simple Design change

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Make Symmetry

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Make Asymmetry

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TOPIC

INTRODUCTION

POKA YOKE

QUALITY AND PRODUCTIVITY

USER & PRODUCER

DEFECT & ERRORS

CAUSE AND EFFECT

STANDARD,EFFECTIVE STANDARD,STANDARDISATION

5 LEVERL OF QUALITY ASSURANCE

3 ZEROS

POKA YOKE- WHAT?WHY?WHEN?HOW? WHERE?WHO? TYPE?

TYPE OF ERRORS

EXPLANTION WITH EXAMPLES

GEMBA VISIT AND END OF SESSION

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

POKA YOKE

POKA means INADVERTENT ERRORS

YOKE means TO AVOID

POKA -YOKE TO AVOID INADVERTENT

ERRORS

TERM COINED BY Dr. SHIGEO SHINGO

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

QUALITY AND PRODUCTIVITY

IMPROVEMENTS ARE EVRYBODYS

RESPONSIBILITY.

THESE WILL HAPPEN

ONLY WHEN EMPLOYEES GET DIRECTLY

INVOLVED IN THE PROCESS OF

CONTINUOUS IMPROVEMENT THAT

ELIMINATES/SOLVES PROBLEM

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

USER & PRODUCER

THE BEST DISCOVERER OF DEFECTS IS THE USER

THE BEST EXPERT IN CREATING DEFECTS IS THE PRODUCER.

1-10-100 Rule

The 1-10-100 rule states that as a product or service moves through

the production system, the cost of correcting An error multiplies by

10.

Activity

Cost

Order entered correctly

Rs. 1

Error detected in billing

Rs. 10

Error detected by customer

Rs. 100

Rs.1000

Dissatisfied customer shares the experience with others the costs is

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

DEFECTS AND ERRORS

DEFETS ARE RESULTS

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

DEFECTS AND ERRORS

ERRORS ARE THE CAUSES OF THESE

RESULTS

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

CAUSE AND EFFECT

MANAGING CAUSE MEANS,

MANAGING EFFECT-EVEN BEFORE IT HAPPENS.

IF WE SHIFT FROM

MANAGING OF DEFECTS

TO

MANAGING OF CAUSE

OUR FIREFIGHTING DAYS ARE OVER.

Poka Yoke

TVS - MOTOR CO.,

STANDARD

A STANDARD

= ?

PED - DESIGN CENTER

Poka Yoke

TVS - MOTOR CO.,

PED - DESIGN CENTER

STANDARD

A STANDARD

=

A WORK METHOD OR PROCEDURE

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

EFFECTIVE STANDARD

AN EFFECTIVE STANDARD = ?

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

EFFECTIVE STANDARD

AN EFFECTIVE STANDARD =

A RELIABLE METHOD

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

STANDARISATION

STANDARDISATION =

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

STANDARISATION

STANDARDISATION = TO IMPROVEMENT.

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

PREVENTION AND DETECTION

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

PREVENTION AND DETECTION

PREVENTION

PREVENTION IS BETTER THAN CURE

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

DETECTION

DETECTION IS A CERTIFICATE AFTER

DEATH

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

PROCESS AND RESULT

CURE THE CAUSE-NOT THE SYMPTOM

CONTROL PROCESS TO ACHIEVE

DESIRED RESULT CONSISTANTLY

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

HOW MISTAKE IS HAPPENED?

IS IMPORTANT !

NOT

WHO HAS DONE THIS???

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TO DAYS ..!!!!!!!! Our production process are.

DIFFERENT PROCESS!!!

MANY VENDORS!!!

DIFFERNCE IN OUT SIDE COMPONENTS!!!

DIFFERENT TYPE OF MACHINES.!!!

NO. OF PERSON INVOLVEMENT.!!!

VERY BIG COMPANY.!!!

HIGH PRODUCTION..!!!

SO,

DEFECT IS NOT POSSIBLE TO AVOIDE ! SOME % WILL BE THERE !!!

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

MAN Vs DEFECTS/ERRORS

FIRST VIEW.

IF MAN IS THERE MISTAKE WILL BE THERE !

NO OTHER WAY!

WE HAVE TO BARE THIS!

NOT POSSIBLE TO AVOIDE 100%!

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

MAN Vs DEFECTS/ERRORS

POSITIVE ATTITUDE

TO ERR IS HUMAN!

WHILE TO ERR IS HUMAN, THE ABILITY TO PREVENT

ERRORS FROM LEADING TO DEFECTS IS ALSO HUMAN

POSITIVE ATTITUDE

Training

Discipline

POKA YOKE

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

WHAT IS CALLED A DEFECT FREE PORDUCT?

A PRODUCT AGAINST WHICH EVEN ONE

CUSTOMER IS UNABLE TO FIND

A SMALL ERROR.

WHAT IS CALLED A HIGH QUALITY PRODUCT?

A PRODUCT WHICH IS FULLY ACCEPTED

BY ALL CUSTOMERS.

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

5 LEVELS OF QUALITY ASSURANCE ACHIEVEMENT

1. FACTORY DISPATCH DEFECTIVE PRODUCTS

2. DESPATCH DEFECT FREE PRODUCTS(RETAIN THE

DEFECTIVE PRODUCTS)

3. REDUCING DEFECTS

4. PROCESS CONTROL (DEFECTIVES DO NOT GET

PASSED ONTO THE NEXT PROCESS)

5. PROCESS DO NOT CREATE WASTE (WHEN AN ERROR

OCCURS, THE PROCESS DOES NOT PRODUCE

DEFECTIVES)

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TO ACHIEVE BEST LEVELS OF QUALITY ASSURANCE

i.e,

To Achieve 3 Zeros

ZERO DEFECT

ZERO WASTE

ZERO DELAY

Learn and understand about Quality,Productivity,

User,Producer,Defect,Cause,Prevention,Detection,Error etc.,

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

1. WHAT IS POKA YOKE?

2. WHY POKA YOKE IS ESSENTIAL?

3. WHERE TO IMPLEMNT POKA-YOKE?

4. WHEN TO IMPLEMENT POKA - YOKE?

5. HOW TO IMPLEMENT POKA - YOKE?

6. WHO HAS TO IMPLEMENT POKA YOKE?

7. TYPES OF POKA - YOKE?

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

WHAT IS POKA YOKE CONCEPT?

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

POKA YOKE

POKA means INADVERTENT ERRORS

YOKE means TO AVOID

POKA -YOKE TO AVOID INADVERTENT

ERRORS

TERM COINED BY Dr. SHIGEO SHINGO

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

(what?)

POKA YOKE ..CONCEPT

POKA-YOKE System is a Technique

to achieve zero Defect in the Product.

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

WHAT IS POKA YOKE CONCEPT?

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

OTHER NAMES..

POKA YOKE..?

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

(what?)

FORMER (OTHER) NAMES OF

POKA YOKE

1. FOOL PROOFING SYSTEM

2. MISTAKE PROOFING SYSTEM

3. FAIL SAFING SYSTEM

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

POKA YOKE OTHER NAMES?

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

WHY..?

POKA YOKE..

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

(what?)

POKA YOKE ..CONCEPT

Process with Zero Defects

Detect Error

Feedback/Corrective

Action

1. POKA-YOKE is to achieve ideal

Production System.

2. To carry out 100% inspection and

immediate feedback in system.

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

(why?)

POKA YOKE ..CONCEPT

1. Detect Errors & Eliminate Before they Become

Defects.

2. Install a system / Device which detects Errors

forgotten by the Producer, Thereby Preventing Defects

from occurring.

TVS - MOTOR CO.,

Poka Yoke

WHY POKA YOKE ?

PED - DESIGN CENTER

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

HOW TO IMPLEMENT POKA YOKE?

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

HOW TO IMPLEMENT POKA YOKE?

PROBLEM LIST

ANALYSIS

RESPONSE

IDENTIFICATION FOR POKA YOKE

ACTION

RESULT

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

HOW TO ANALYSIS..?????

HOW TO RESPONSE..?????

IN WHAT STAGE..?????

WHERE..?????

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

HOW TO ANALYSIS..?????

TO IDENTIFY THE

ROOT CAUSE OR ERROR

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

DEFECTS AND CAUSES(Errors)

ELEMENTS AT GEMBA (4M & I)

Errors

MAN

MACHINE

MATERIAL

METHOD

INFORMATION

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

ALL THE CAUSES ARE RELATED WITH VARIOUS FACTORS.

THE MAIN FACTORS ARE GIVEN IN THE DIAGRAM

DEFECTIVE PRODUCT

MAN

MACHINE

METHOD

PROCESSING

MATERIAL INFORMATION

WE HAVE TO AVOID DEFECTS BY ELIMINATING THE

ERRORS IN ALL THE ABOVE FACTORS.

Poka Yoke

TVS - MOTOR CO.,

PED - DESIGN CENTER

TYPES OF ERRORS CAUSED BY PROCESSING

(MACHINE + METHOD)

DEFECTIVE PRODUCT

PROCESSING ERROR

PRIMARY DEFECT

MACHINE + METHOD

MACHINE + METHOD

OPN. OMITTED

= PROCESSING

ERROR

OPN. ERROR

SECONDARY DEFECT

ADJUSTMENT

ERROR

WORK-PIECE

SETUP ERROR

OPERATIING WRONG

WORK PIECE

INCORRECT

EQUIPMENT SETUP

IMPROPER

TOOLS AND JIGS

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TYPES OF ERRORS CAUSED BY INFORMATION

DEFECTIVE PRODUCT

INFORMATION ERROR

WRONG

INFORMATION

INADEQUATE

INFORMATION

VERY

COMPLICATED

INFORMAITON

NO

INFORMATION

INFORMATION ERROR

INFORMATION

NOT CLEAR

TO UNDERSTAND

NO

STANDARDS

IN

INFORMATION

INFORMATION

NOT VISIBLE

INADEQUATE

INFORMATION

Poka Yoke

TVS - MOTOR CO.,

PED - DESIGN CENTER

TYPES OF ERRORS CAUSED BY MATERIAL

DEFECTIVE PRODUCT

MATERIAL ERROR

MATERIAL ERROR

PRIMARY DEFECT

MACHINE + METHOD

WRONG PARTS

MISSING PARTS

SECONDARY DEFECT

BLOW

HOLES

POROSITY

ONE PART

MISS IN SUB

-ASSEMBLY

ONE PART

WRONG IN SUBASSEMBLY

MATERIAL

SHORTAGE

WRONG

WRONG B. O.

MATERIAL COMPONENTS

Poka Yoke

TVS - MOTOR CO.,

PED - DESIGN CENTER

TYPES OF ERRORS CAUSED BY HUMAN ERRORS

DEFECTIVE PRODUCT

HUMAN ERROR

FORGETFULNESS

ERRORS DUE

TO MISUNDERSTANDING

ERROR DUE TO

SLOWNESS

HUMAN ERROR

ERRORS IN

IDENTIFICATION

ERROR DUE

TO LACK OF

STANDARDS

ERRORS MADE BY

AMATEURS

SURPRISE

ERROR

WILLFUL

ERRORS

INTENTIONAL ERROR

INADVERTENT

ERROR

Poka Yoke

TVS - MOTOR CO.,

PED - DESIGN CENTER

TO PREVENT THESE ERRORS

i.e,

MAN ERROR

MACHINE ERROR

MATERIAL ERROR

METHOD ERROR

&

INFORMATION ERROR

POKA YOKE SYSTEM .

Poka Yoke

TVS - MOTOR CO.,

PED - DESIGN CENTER

THREE POINT TO RESPONSE

URGENCY

DIFFICULTY

COUNTERMEASURE

Total points = Urgency x Difficulty x Countermeasure Method

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

HOW TO ANALYSIS.

HOW TO RESPONSE..

IN WHAT STAGE..?????

WHERE..?????

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

IN WHAY STAGE?.WHERE.?

POKA YOKE ?

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

THE BASIC FUNCTIONS OF

POKA YOKE

DEFECTS ARE EXISTING IN TWO STAGES:ABOUT TO OCCUR

IN THE NEXT PROCESS

- CALLED AS PREDICTION

STAGES OF

DEFECTS

ALREADY OCCURRED IN

THE PREVIOUS PROCESS

- CALLED AS DETECTION

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

THE BASIC FUNCTIONS OF

POKA YOKE

POKA YOKE HAS THREE BASIC FUNCTIONS TO USE

AGAINST DEFECTS

SHUT DOWN

BASIC

FUNCTIONS

CONTROL

WARNING

Poka Yoke

TVS - MOTOR CO.,

A

1

PREDICTION

PREVENTION

PED - DESIGN CENTER

SHUT DOWM

CONTROL

WARNING

POKA YOKE

A

DETECTION

SHUT DOWM

B

CONTROL

II

C

WARNING

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

WHAT ARE BEST POKA YOKE ?

TO AVOID DEFECTS CAUSED BY

HUMAN ERRORS

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

FIVE BEST POKA YOKE TO AVOID

DEFECTS CAUSED BY HUMAN ERRORS

FIVE EXAMPLES OF POKA YOKE FOR DETECTING OR AVOIDING DEFECTS

CAUSED BY HUMAN ERRORS

1.

GUIDE PINS OF DIFFERENT SIZES

2.

ERROR DETECTION AND ALARMS AUTOMATICALLY BY A

MISIC/SOUND OR BY A LIGHT

3.

LIMIT SWITCHES

4.

D AUTOMATIC COUIGITALNTER

5.

CHECK LIST

TVS - MOTOR CO.,

1.

Poka Yoke

GUIDE PINS OF DIFFERENT SIZES

PED - DESIGN CENTER

TVS - MOTOR CO.,

2.

Poka Yoke

PED - DESIGN CENTER

ERROR DETECTION AND ALARMS AUTOMATICALLY BY A

MISIC/SOUND OR BY A LIGHT

TVS - MOTOR CO.,

3.

Poka Yoke

LIMIT SWITCHES & SENSORS

PED - DESIGN CENTER

Poka Yoke

TVS - MOTOR CO.,

PED - DESIGN CENTER

Energy Sensors

These devices work by

using energy to detect

whether or not an defect

has occurred.

Fiber optic

Vibration

Photoelectric

TVS - MOTOR CO.,

4.

Poka Yoke

DIGITAL AUTOMATIC COUNTER

PED - DESIGN CENTER

TVS - MOTOR CO.,

5.

CHECK LIST

Poka Yoke

PED - DESIGN CENTER

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

POKA YOKE Practical Examples

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

02 - 03

Wk. 3

Eliminate Outer tube scrap due to axle bracket

miss location

Axle

bracket

Axle

bracket

Fixture accepts

wrong loading

Fixture will not

accept wrong

loading

Qty in nos

Outer tube scrap due to axle bracket

miss location

Axle bracket located wrongly in the

fixture

SS,MSR,PP,PR,CC

Wk. 3

20

10

0

Before

After

Not applicable

Provide Stopper to avoid wrong loading scrap

Ju

l

ay

M

No stopper provided

ar

Fixture accepts wrong loading

Poka Yoke

TVS - MOTOR CO.,

Equipment failure loss

PED - DESIGN CENTER

Fab-1

JH

02 - 03

Wk. 36

Eliminate Oil fork production loss due to torch

damage

Wk. 36

Torch

Damage

SS,MSR,PP,PR,CC

Production loss due to torch damage

eliminated

Sensor

Provide Proper sensor interlock

ar

Not applicable

No interlock

After

Ja

n

Axle bkt locating pin not removed after

clamping

15

10

5

0

Before

No

v

Torch hit on axle bkt locating pin in

auto cycle

Break down in hr

Oil fork rotary torch damage

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

01 - 02

Wk. 39

Eliminate Oil fork scrap due to Outer tube miss

location in Reaming

SS,MSR,PP,PR,CC

Wk. 39

Oil fork scrap due to Outer tube miss

Fork tube Position OK

Fixture

Position NOT Anchor bracket

OK

Fork tube Position OK

Anchor

bracket

Fixture

Oil fork scrap due to outer tube miss

location

Fixture accepts wrong loading

Qty in nos

Component loaded wrongly in fixture

Pokayoke

stopper

Before

After

4

3

Not applicable

2

1

0

No pokayoe stopper

Provide Proper Pokayoke stopper

location in Reaming is eliminated

Nov

Dec

Jan

Feb

Mar

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

01 - 02

Wk. 19

Eliminate Oil fork scrap due to Outer tube

length oversize

Fork tube

Length

oversize

Fixture

SS,MSR,PP,PR,VNSR

Wk. 20

End stopper

Fork tube

Oil fork scrap due to Outer tube length

Oversize problem eliminated

Fixture

Outer tube scrap due to length oversize

Defective Component loaded in fixture

Fixture accepts defective component

Qty in nos

50

Before

After

40

30

Not applicable

20

10

0

No pokayoe stopper

Provide Proper Pokayoke stopper

Jun

Jul

Aug

Sep

Oct

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

01 - 02

Wk. 39

Eliminate Oil fork scrap due to Outer tube miss

location inRotary

Stabilizer mtg bkt

Fork tube

MSR,PP,PR,VNSR,SSK

Wk. 39

Stabilizer mtg bkt

OK

position

Oil fork scrap due to Outer tube miss

OK

position

location in Rotary operation is eliminated

Poka yoke

topper

NOT OK

position

Fork tube

Oil fork scrap due to outer tube miss

location

12

Before

After

Fixture accepts wrong loading

Qty in nos

10

Component loaded wrongly in fixture

8

6

Not applicable

4

2

0

No pokayoe stopper

Provide Proper Pokayoke stopper

Aug

Sep

Oct

Nov

Dec

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

01 - 02

Wk. 6

Eliminate fuel tank scrap due to wrong

loading at inlet hole piercing

Wk. 6

MSR,PP,PR,VNSR,SSK

Fuel tank scrap due to wrong loading at

inlet hole piercing is eliminated

Punch

Punch

Outer assy

No

stopper

Die

Outer assy

Stopper

provided

Component loaded wrongly in press tool

Qty in nos

Outer assy scrap in

inlet hole piercing due to miss location

20

10

0

Die

Before

After

Introduced in sport model

Provide Stopper to avoid wrong loading scrap

Ju

l

ay

M

No stopper provided

ar

Press tool accepts miss location

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

01 - 02

Wk. 6

Eliminate fuel tank Outer scrap at adopter hole

piercing stage

Die

Outer

Wk. 6

Die

Outer

Clamp

MSR,PP,PR,VNSR,SSK

Clamp

Pot magnet provided

Possibility of slipping

from location

Component loaded wrongly in press tool

Qty in nos

Outer assy scrap in

inlet hole piercing due to miss location

40

20

0

Before

After

Introduced in sport model

Provide Stopper to avoid wrong loading scrap

Ju

l

ay

M

No stopper provided

ar

Press tool accepts miss location

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

02 - 03

Wk. 3

Eliminate Outer tube scrap due to axle bracket

miss location

Axle

bracket

Axle

bracket

Fixture accepts

wrong loading

Fixture will not

accept wrong

loading

Qty in nos

Outer tube scrap due to axle bracket

miss location

Axle bracket located wrongly in the

fixture

SS,MSR,PP,PR,CC

Wk. 3

20

10

0

Before

After

Not applicable

Provide Stopper to avoid wrong loading scrap

Ju

l

ay

M

No stopper provided

ar

Fixture accepts wrong loading

Poka Yoke

TVS - MOTOR CO.,

Equipment failure loss

PED - DESIGN CENTER

Fab-1

JH

02 - 03

Wk. 36

Eliminate Oil fork production loss due to torch

damage

Wk. 36

Torch

Damage

SS,MSR,PP,PR,CC

Production loss due to torch damage

eliminated

Sensor

Provide Proper sensor interlock

ar

Not applicable

No interlock

After

Ja

n

Axle bkt locating pin not removed after

clamping

15

10

5

0

Before

No

v

Torch hit on axle bkt locating pin in

auto cycle

Break down in hr

Oil fork rotary torch damage

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

01 - 02

Wk. 39

Eliminate Oil fork scrap due to Outer tube miss

location in Reaming

SS,MSR,PP,PR,CC

Wk. 39

Oil fork scrap due to Outer tube miss

Fork tube Position OK

Fixture

Position NOT Anchor bracket

OK

Fork tube Position OK

Anchor

bracket

Fixture

Oil fork scrap due to outer tube miss

location

Fixture accepts wrong loading

Qty in nos

Component loaded wrongly in fixture

Pokayoke

stopper

Before

After

4

3

Not applicable

2

1

0

No pokayoe stopper

Provide Proper Pokayoke stopper

location in Reaming is eliminated

Nov

Dec

Jan

Feb

Mar

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

01 - 02

Wk. 19

Eliminate Oil fork scrap due to Outer tube

length oversize

Fork tube

Length

oversize

Fixture

SS,MSR,PP,PR,VNSR

Wk. 20

End stopper

Fork tube

Oil fork scrap due to Outer tube length

Oversize problem eliminated

Fixture

Outer tube scrap due to length oversize

Defective Component loaded in fixture

Fixture accepts defective component

Qty in nos

50

Before

After

40

30

Not applicable

20

10

0

No pokayoe stopper

Provide Proper Pokayoke stopper

Jun

Jul

Aug

Sep

Oct

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

01 - 02

Wk. 39

Eliminate Oil fork scrap due to Outer tube miss

location inRotary

Stabilizer mtg bkt

Fork tube

MSR,PP,PR,VNSR,SSK

Wk. 39

Stabilizer mtg bkt

OK

position

Oil fork scrap due to Outer tube miss

OK

position

location in Rotary operation is eliminated

Poka yoke

topper

NOT OK

position

Fork tube

Oil fork scrap due to outer tube miss

location

12

Before

After

Fixture accepts wrong loading

Qty in nos

10

Component loaded wrongly in fixture

8

6

Not applicable

4

2

0

No pokayoe stopper

Provide Proper Pokayoke stopper

Aug

Sep

Oct

Nov

Dec

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

01 - 02

Wk. 6

Eliminate fuel tank scrap due to wrong

loading at inlet hole piercing

Wk. 6

MSR,PP,PR,VNSR,SSK

Fuel tank scrap due to wrong loading at

inlet hole piercing is eliminated

Punch

Punch

Outer assy

No

stopper

Die

Outer assy

Stopper

provided

Component loaded wrongly in press tool

Qty in nos

Outer assy scrap in

inlet hole piercing due to miss location

20

10

0

Die

Before

After

Introduced in sport model

Provide Stopper to avoid wrong loading scrap

Ju

l

ay

M

No stopper provided

ar

Press tool accepts miss location

Poka Yoke

TVS - MOTOR CO.,

Defect and rework loss

PED - DESIGN CENTER

Fab-1

HH

01 - 02

Wk. 6

Eliminate fuel tank Outer scrap at adopter hole

piercing stage

Die

Outer

Wk. 6

Die

Outer

Clamp

MSR,PP,PR,VNSR,SSK

Clamp

Pot magnet provided

Possibility of slipping

from location

Component loaded wrongly in press tool

Qty in nos

Outer assy scrap in

inlet hole piercing due to miss location

40

20

0

Before

After

Introduced in sport model

Provide Stopper to avoid wrong loading scrap

Ju

l

ay

M

No stopper provided

ar

Press tool accepts miss location

POKA-YOKE STEPS IN TVS-M

PED - DESIGN CENTER

Poka Yoke

TVS - MOTOR CO.,

POKA-YOKE

Existing Process

New Process, Machines

Process Design - PFMEA

Problem list

(Ensure provision of necessary Poka-Yoke in process by

existing problem,customer complaint.) TSPS NO:003

Analysis

New Machine Enquiry

(Poka-Yoke check list sent with enquiry) TSPS NO:003

Identification for

POKA-YOKE

Action

New Machine Ordering

(Poka-Yoke check list sent with ordering) TSPS NO:003

Machine Design DFMEA/DAP TSPS NO:003

(Ensure provision of necessary Poka-Yoke in design)

In house fixture and gauges

(Poka-Yoke check list for Design Fixtures and Gauges)

Result

Machine Trials at supplier end

(Check effectiveness of Poka-Yoke provided

and necessity of new Poka-Yoke) TSPS NO:003

Standardisation

Productionising Trials (EJO) Check sheet

(Check effectiveness of Poka-Yoke provided

and necessity of new Poka-Yoke identification in GEMBA

ISSUED BY :E.Tamilselvan PED/TDO Ex: Ph:No:2808

YOUR SUGGESTION FOR IMPROVING THIS ARE WELCOME.

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

PED - DESIGN CENTER

Poka

Yoke

POKA YOKE : IMROVEMENT IN UPSTREAM PROCESSES

TVS - MOTOR CO.,

Practice

Up Stream Process

Present

Fixture/Gauge Design

POKA YOKE thought by Designer but not listed.

Bought out Machine DAP Approval

POKA YOKE Discussed with M/c Supplier but not listed.

Process FMEA

Machine Trials

POKA YOKE is not a specific step.

POKA YOKE checking is not Recorded Meticulously.

To be changed to

* List

POKA YOKES Provided in Drawing.

List

POKAS Identified but Yoke not provided.

*

* List

Poka Yokes Considered.

* List

Pokas identified and yoke not provided.

* List

Poka Yokes provided.

* List

Pokas identified but Yoke not possible.

* Check

Effectiveness of Poka-Yokes.

* Identify any new Pokas required to be found.

* List

QP Trial

NO List of POKA YOKE.

and check effectiveneess of POKA

YOKES provided in earch machine.

* Identy any new pokas/ or declare as 100%

Poka Yoke station.

Review of Shop Floor POKA YOKE

Kaizens by PED

Not Systematically done.

* Review

More insight into Defects - Causes &

appropriate Poka yoke solution.

Issued by: E.Tamilselvan ph : 2808

and revise the check list.

* New

list of possible defects/causes/yoke

provided to design engineers and methods

engineers.

YOUR SUGGESTION FOR IMPROVING THIS ARE WELCOME

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

ZERO DEFECT

JUST IN TIME

IS IT POSSIBLE

ONLY IN

JAPAN.?

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TVS TEAM WILL ACHIEVE

TVS - MOTOR CO.,

Poka Yoke

ANY DOUBT?

PED - DESIGN CENTER

TVS - MOTOR CO.,

Poka Yoke

THANK YOU

PED - DESIGN CENTER

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Dont make the

mistake of thinking that the concept can only be applied to manufacturing it

applies to all functions and processes in a business: sales, marketing,

distribution, R & D, manufacturing, warehousing, billing, and customer service.

Trough which

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

TVS - MOTOR CO.,

Poka Yoke

PED - DESIGN CENTER

Das könnte Ihnen auch gefallen

- SMED – How to Do a Quick Changeover?: Toyota Production System ConceptsVon EverandSMED – How to Do a Quick Changeover?: Toyota Production System ConceptsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Operational Excellence A Complete Guide - 2019 EditionVon EverandOperational Excellence A Complete Guide - 2019 EditionBewertung: 1 von 5 Sternen1/5 (1)

- Poka Yoke Best Presentation.....Dokument39 SeitenPoka Yoke Best Presentation.....DebashishDolonNoch keine Bewertungen

- Presentation Guidelines: Case Study - Zero Defect Drive by Laxmikant MishraDokument28 SeitenPresentation Guidelines: Case Study - Zero Defect Drive by Laxmikant MishrapiyushNoch keine Bewertungen

- Error Proofing TechniquesDokument140 SeitenError Proofing TechniquesThe Informative Corner हिंदीNoch keine Bewertungen

- Cost of Poor QualityDokument24 SeitenCost of Poor Qualityrrvalero0% (1)

- Poka Yoke or Error ProofingDokument9 SeitenPoka Yoke or Error Proofingiforcett100% (2)

- Poka YokeDokument22 SeitenPoka YokeAnonymous I7dJ0lmdNoch keine Bewertungen

- 8DDokument117 Seiten8DLokesh NarasimhaiahNoch keine Bewertungen

- Lean Training New PDFDokument93 SeitenLean Training New PDFRagu RamsinghNoch keine Bewertungen

- Failure Mode AND Effect Analysis: TPM Secretariat - Orai FactoryDokument27 SeitenFailure Mode AND Effect Analysis: TPM Secretariat - Orai FactorySunilNoch keine Bewertungen

- Six Sigma - Reduction of Downtime - RE Mill-2 - NewDokument76 SeitenSix Sigma - Reduction of Downtime - RE Mill-2 - NewKiruthiga VelmuruganNoch keine Bewertungen

- IATF ManualDokument62 SeitenIATF ManualqualityNoch keine Bewertungen

- Yazaki - 9.0 Mistake Proofing NYS Training - V4 2011Dokument44 SeitenYazaki - 9.0 Mistake Proofing NYS Training - V4 2011magudeeshNoch keine Bewertungen

- MT QM PillarDokument71 SeitenMT QM Pillarazadsingh1Noch keine Bewertungen

- Kaizen KobetDokument19 SeitenKaizen KobetShubham SharmaNoch keine Bewertungen

- Black Belt Training - Module 2 - Day 1Dokument89 SeitenBlack Belt Training - Module 2 - Day 1haythemNoch keine Bewertungen

- Design Review Based On Failure Mode 1-Day Workshop by TetrahedronDokument2 SeitenDesign Review Based On Failure Mode 1-Day Workshop by TetrahedrontetrahedronNoch keine Bewertungen

- 8D Corrective Action & Root Cause AnalysisDokument95 Seiten8D Corrective Action & Root Cause AnalysisRawendrraw KuriNoch keine Bewertungen

- SPC PresentationDokument116 SeitenSPC Presentationmatsuka79Noch keine Bewertungen

- 01 - MsaDokument80 Seiten01 - MsaMohit SinghNoch keine Bewertungen

- QC StoryDokument146 SeitenQC Storyselvaganapathy199290% (39)

- 02 TVS Motor Co. LTDDokument127 Seiten02 TVS Motor Co. LTDRaj Rudrapaa100% (1)

- Kaizen - Group 5 Present ItDokument46 SeitenKaizen - Group 5 Present ItreezcoolrizNoch keine Bewertungen

- Design FMEA 2-Day Workshop by TetrahedronDokument2 SeitenDesign FMEA 2-Day Workshop by TetrahedrontetrahedronNoch keine Bewertungen

- 5 S and Six SigmaDokument19 Seiten5 S and Six SigmaAnandraj004Noch keine Bewertungen

- TWI PresentationDokument25 SeitenTWI Presentationlegecy100% (1)

- Basic TPM Workshop (Rev1)Dokument138 SeitenBasic TPM Workshop (Rev1)Ahmad FirdausNoch keine Bewertungen

- Work Instruction For Error ProofingDokument4 SeitenWork Instruction For Error ProofingBALAJI100% (1)

- Welcome To Potential Failure Modes AND Effect Analysis Process FMEA-4 EditionDokument68 SeitenWelcome To Potential Failure Modes AND Effect Analysis Process FMEA-4 EditionSundaramoorthy ArumugamNoch keine Bewertungen

- QC - Story - Format JBM GroupDokument28 SeitenQC - Story - Format JBM GroupAshish GuptaNoch keine Bewertungen

- DFMEA Sample For A PenDokument3 SeitenDFMEA Sample For A PenVinay GowdaNoch keine Bewertungen

- FMEA Facilitator Thought-Starter QuestionsDokument5 SeitenFMEA Facilitator Thought-Starter QuestionsvikeshmNoch keine Bewertungen

- New Supplier Quality Manual Training ModuleDokument119 SeitenNew Supplier Quality Manual Training ModuleMohit Singh100% (1)

- Zero Defect PresentationDokument4 SeitenZero Defect PresentationRanjith Kumar100% (1)

- 5 9 Ravichandran Slides PDFDokument26 Seiten5 9 Ravichandran Slides PDFss2mrattriNoch keine Bewertungen

- SMEDDokument26 SeitenSMEDSAURAV KUMARNoch keine Bewertungen

- 8d Problem SolvingDokument117 Seiten8d Problem SolvingChan Kok Khan100% (1)

- Poka YokeDokument41 SeitenPoka Yokefaja2004Noch keine Bewertungen

- 6 Sigma Project Selection GuidelinesDokument7 Seiten6 Sigma Project Selection Guidelineschteo1976Noch keine Bewertungen

- APQP 1st Phase Input and OutputDokument1 SeiteAPQP 1st Phase Input and OutputSunilNoch keine Bewertungen

- Fmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123Dokument5 SeitenFmea Methodology For Quality Improvement in Sheet Metal Industry IJERTV5IS010123DanistergladwinNoch keine Bewertungen

- Week 10 - Autonomous Defects Control (Pokayoke Jidoka)Dokument43 SeitenWeek 10 - Autonomous Defects Control (Pokayoke Jidoka)Nguyễn Ngọc Minh Quân100% (1)

- VDA 6.3 Management: R. Dan ReidDokument61 SeitenVDA 6.3 Management: R. Dan ReidAlpha Excellence consultingNoch keine Bewertungen

- Poka Yoke TrainingDokument44 SeitenPoka Yoke TrainingMaurício PalmeiraNoch keine Bewertungen

- Kaizen PdcaDokument32 SeitenKaizen PdcamfernandNoch keine Bewertungen

- Problem Solving Tools: Training Module OnDokument46 SeitenProblem Solving Tools: Training Module Onmiso73Noch keine Bewertungen

- NCM DB - 8D Problem Solving Training Ver 1.1Dokument24 SeitenNCM DB - 8D Problem Solving Training Ver 1.1Memo Gonzalez Aleman100% (1)

- OEE PresentationDokument33 SeitenOEE PresentationRoshan YaduwanshiNoch keine Bewertungen

- Training Programme - On POKA YOKE - 12th March 2010Dokument93 SeitenTraining Programme - On POKA YOKE - 12th March 2010ranydi0% (2)

- Shainin Vs Six SigmaDokument4 SeitenShainin Vs Six Sigmabaro4518Noch keine Bewertungen

- 5j GM1927 84 Drill Deep Worksheet 12 Oct 04Dokument2 Seiten5j GM1927 84 Drill Deep Worksheet 12 Oct 04jesusmemNoch keine Bewertungen

- Muda Mura Muri CompletoDokument9 SeitenMuda Mura Muri CompletoXochiquetzal AstudilloNoch keine Bewertungen

- Difference Between Rework & Repair As Per IATF 16949?: by - Arun Kumar SharmaDokument19 SeitenDifference Between Rework & Repair As Per IATF 16949?: by - Arun Kumar SharmaDanang Widoyoko100% (1)

- Poka-Yoke The Art of Fool ProofingDokument32 SeitenPoka-Yoke The Art of Fool ProofingJoram Roman100% (1)

- Difference Between Rework Repair PDFDokument19 SeitenDifference Between Rework Repair PDFRavichandranNoch keine Bewertungen

- Shainin AmeliorDokument40 SeitenShainin AmeliorOsman Tig100% (1)

- Error Proofing For EMSDokument48 SeitenError Proofing For EMSsaleemanisaleemaniNoch keine Bewertungen

- Hydrodynamic Modelling of Hulls Using RANSE Codes: José Luis Ortín MontesinosDokument75 SeitenHydrodynamic Modelling of Hulls Using RANSE Codes: José Luis Ortín Montesinosselvaganapathy1992Noch keine Bewertungen

- TQM Brief 1Dokument39 SeitenTQM Brief 1selvaganapathy1992100% (1)

- QC StoryDokument146 SeitenQC Storyselvaganapathy199290% (39)

- QC StoryDokument146 SeitenQC Storyselvaganapathy199290% (39)

- 7QC Tools NokiaDokument91 Seiten7QC Tools Nokiaselvaganapathy1992Noch keine Bewertungen

- Over Speed Fuel CutoffDokument3 SeitenOver Speed Fuel Cutoffselvaganapathy1992Noch keine Bewertungen

- 500-600 Forklifts & Buckmaster: Parts CatalogDokument281 Seiten500-600 Forklifts & Buckmaster: Parts CatalogRoberto Mariano100% (2)

- 701.ssvseat 1.04Dokument2 Seiten701.ssvseat 1.04Cosmin MuscaluNoch keine Bewertungen

- BD+ CD+ XD+ - tcm833-3534072Dokument20 SeitenBD+ CD+ XD+ - tcm833-3534072MisterMMNoch keine Bewertungen

- CH 4 Data CommDokument4 SeitenCH 4 Data CommHenna ShainaNoch keine Bewertungen

- Delhi Public School Bangalore North ACADEMIC SESSION 2021-2022 Ut2 Revision Work Sheet TOPIC: Sorting Materials Into Group Answer KeyDokument6 SeitenDelhi Public School Bangalore North ACADEMIC SESSION 2021-2022 Ut2 Revision Work Sheet TOPIC: Sorting Materials Into Group Answer KeySumukh MullangiNoch keine Bewertungen

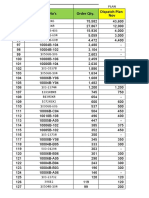

- Order Qty Vs Dispatch Plan - 04 11 20Dokument13 SeitenOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNoch keine Bewertungen

- Ammonia Production From Natural Gas-Haldor Topsoe ProcessDokument22 SeitenAmmonia Production From Natural Gas-Haldor Topsoe ProcessYash BhimaniNoch keine Bewertungen

- Slope Stability in Slightly Fissured Claystones and MarlsDokument25 SeitenSlope Stability in Slightly Fissured Claystones and MarlsrullyirwandiNoch keine Bewertungen

- AquaCal Tropical Brochure PDFDokument2 SeitenAquaCal Tropical Brochure PDFJC ParedesNoch keine Bewertungen

- Tharmal Analysis BasicsDokument56 SeitenTharmal Analysis BasicsNetoNoch keine Bewertungen

- TDS Sadechaf UVACRYL 2151 - v9Dokument5 SeitenTDS Sadechaf UVACRYL 2151 - v9Alex MacabuNoch keine Bewertungen

- 1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliDokument29 Seiten1.1 General: "Processes and Environmental Management" at SUEZ LTD, BWSSB, TK HalliYogeesh B ENoch keine Bewertungen

- PNR90 PNR510 PNR91 PNR515 PNR92 PNR520: Manual of - Installation - Operating - Maintenance Heavy Oil Burners TypeDokument28 SeitenPNR90 PNR510 PNR91 PNR515 PNR92 PNR520: Manual of - Installation - Operating - Maintenance Heavy Oil Burners Typec_lucian2004Noch keine Bewertungen

- 2019 All PDFDokument27 Seiten2019 All PDFvishesh bhatiaNoch keine Bewertungen

- Feasibility Study of Solar Photovoltaic (PV) Energy Systems For Rural Villages of Ethiopian Somali Region (A Case Study of Jigjiga Zone)Dokument7 SeitenFeasibility Study of Solar Photovoltaic (PV) Energy Systems For Rural Villages of Ethiopian Somali Region (A Case Study of Jigjiga Zone)ollata kalanoNoch keine Bewertungen

- The Right Stuff PDFDokument4 SeitenThe Right Stuff PDFNeelank Tiwari100% (1)

- Build-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACDokument18 SeitenBuild-A-Bard ABB - RFQ-807683Reaprovechamiento Relaves - SR For Cotejado 010A - HVACchristianNoch keine Bewertungen

- Experiment 5 DACDokument3 SeitenExperiment 5 DACABHISHEK SHARMANoch keine Bewertungen

- Manual PC Soundcard Scope 1.4.5Dokument17 SeitenManual PC Soundcard Scope 1.4.5NatashaKillerNoch keine Bewertungen

- TD Quintolubric 888 68Dokument2 SeitenTD Quintolubric 888 68Haitham YoussefNoch keine Bewertungen

- Korantin PPDokument4 SeitenKorantin PPteddy garfieldNoch keine Bewertungen

- WDU 2.5 enDokument14 SeitenWDU 2.5 enAhmadBintangNegoroNoch keine Bewertungen

- Measurement Advisory Committee Summary - Attachment 3Dokument70 SeitenMeasurement Advisory Committee Summary - Attachment 3MauricioICQNoch keine Bewertungen

- Sec VlanaclsDokument10 SeitenSec VlanaclsTry FajarmanNoch keine Bewertungen

- Fiber Optic Trainer/ Fiber & OSP TechnicianDokument7 SeitenFiber Optic Trainer/ Fiber & OSP Technicianapi-78570706Noch keine Bewertungen

- Ultra Petronne Interior Supply Corp.: Manufacturer of Light Metal FramesDokument1 SeiteUltra Petronne Interior Supply Corp.: Manufacturer of Light Metal Framesjun vincint geleraNoch keine Bewertungen

- FL-02-01 PM SheetDokument12 SeitenFL-02-01 PM SheetBikas SahaNoch keine Bewertungen

- Oil & Gas Asset Integrity IssuesDokument15 SeitenOil & Gas Asset Integrity Issuesyogolain100% (2)