Beruflich Dokumente

Kultur Dokumente

Evaporation: Chemical Engineering Series

Hochgeladen von

kmrosarioOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Evaporation: Chemical Engineering Series

Hochgeladen von

kmrosarioCopyright:

Verfügbare Formate

CHEMICAL ENGINEERING SERIES

EVAPORATION

Compilation of Lectures and Solved Problems

CHEMICAL ENGINEERING SERIES 2

EVAPORATION

EVAPORATION

A unit operation that involves the concentration of a solution consisting of a non-volatile solute

and a volatile solvent

It is conducted by vaporizing a portion of the solvent to produce a concentrated solution of thick

liquor.

It differs with other unit operations in such a way that:

1. Distillation: in evaporation vapor is usually a single component

2. Drying: in evaporation, residue is liquid, sometimes a highly viscous one

3. Crystallization: focus is on concentrating a solution rather than forming crystals

Calculations for the Different Methods of Operations of Evaporators:

1. Single Effect Evaporators used when the required capacity of operation is relatively small

and/or cost of steam is relatively cheap compared to the evaporator cost.

Vapor, V

where:

TV

- Mass flow rates of feed,

HV

PV

vapor, and steam

respectively

- Temperatures of feed,

product and vapor,

respectively

P

Steam, S

I

TS

- Liquid enthalpy of feed

S

and product, respectively

Condensate

- Vapor enthalpy

TS2

TI

- Operating temperature

Feed, F

- Operating pressure

xF

TF

- Mass fraction of solute in

hF

Product, P

feed and product

CP, F

xP

respectively

TP

hP

Over-all Material Balance:

Solute Balance:

Enthalpy Balance:

Heat Balance:

must be evaluated at

or

If vacuum pressure is given,

CHEMICAL ENGINEERING SERIES 3

EVAPORATION

2. Forward Feed Multiple Effect Evaporators fresh feed is added to the first effect and flows

to the next in the same direction as the vapor flow. This is used when the feed is hot or when

the final concentrated product might be damaged at high temperatures

VI

Steam, S

VII

VIII

P1, T1

P2 ,T2

P 3 , T3

TI

TII

TIII

LII

LI

3. Backward Feed Multiple Effect Evaporators fresh feed enters the last and coldest effect

and continues until the concentrated product leaves the first effect. This is used when the

fresh feed is cold. This type of evaporation would requires liquid pump for each effect since

flow is from low to high pressure

VI

Steam, S

VII

VIII

P1, T1

P2 ,T2

P 3 , T3

TI

TII

TIII

LI

LII

4. Mixed Feed Multiple Effect Evaporators fresh feed enters any of the available effects and

continues not necessarily to the effect next to it.

5. Parallel Feed Multiple Effect Evaporators involves the adding of fresh feed and the

withdrawal of concentrated product from each effect. The vapor from each effect is still used

to heat the next effect. This method is used mainly when the feed is almost saturated and

solid crystals are the product, as in the evaporation of brine to make salt.

CHEMICAL ENGINEERING SERIES 4

EVAPORATION

Performance Evaluation of Steam-Heated Evaporators

1. Capacity number of kilograms of water vaporized per hour

Evaporator Capacity

Where:

-

Rate of heat transfer through the heating

surface of an evaporator

Over-all heat transfer coefficient

Heat transfer surface area

Over-all temperature drop

2. Steam Economy number of kilograms vaporized per kilogram of steam fed to the unit

Boiling point Evaluation (BPE) of a solution is the increase in boiling point over that of water

1. Small for dilute solutions and organic colloids solution

2. Large enough for concentrated solutions of inorganic salts; BPE can be estimated using

th

Figure 11-124 (CHE HB 8 edition)

Dhrings Rule the boiling point of a given solution is a linear function of the boiling point of

th

pure water at the same pressure. Figure 16.3 (Unit Operations 7 edition by McCabe and

Smith)

For solutions with BPE:

(

CHEMICAL ENGINEERING SERIES 5

EVAPORATION

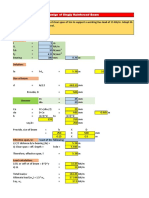

PROBLEM # 01:

A triple effect forward feed evaporator is being used to evaporate a sugar solution containing 5 wt

% solids to a concentrated solution of 80 %. The boiling point rise of the solutions (independent

2

of pressure) can be estimated from BPR C = 1.78x + 6.22x , where x is wt fraction of sugar in

solution. Saturated steam at 205.5 kPa (121.1C saturation temperature) is being used. The

pressure in the vapor space of the third effect is 13.4 kPa. The feed rate is 10,000 kg/h at

26.7C. The heat capacity of the liquid solutions is 4.19 2.35x, kJ/kgK. The heat of solution is

considered to be negligible. The coefficients of heat transfer have been estimated as U 1 = 3123,

2

U2 = 1987, and U3 = 1136 W/m K. if each effect has the same surface area, calculate the area,

the steam rate used and the steam economy.

SOLUTION:

V1

Steam, S

V2

V3

P1, T1

P2 ,T2

P 3 , T3

TI

TII

TIII

L1

L2

Step 1:

rd

From steam table, at 13.4 kPa (pressure of the vapor space at 3 effect)

From the given:

rd

For the 3 effect with x = 0.80

(

)

(

)

(

(

)

Step 2:

Consider solute balance around the system:

(

)(

Over-all material balance around the system

L3

CHEMICAL ENGINEERING SERIES 6

EVAPORATION

Where:

Assume , initially equal rate of evaporation in each effect

(

st

For the 1 effect:

)(

For the 2

nd

effect:

)(

Step 3:

st

nd

To solve for BPR for the 1 and 2 effects:

st

1 effect:

(

)

(

)

(

)

nd

2 effect:

(

)

(

)

(

)

Estimate T for each effect using equation 8.5-6

)*

)*

)*

Calculate actual boiling point of solution for each effect using the estimated T

CHEMICAL ENGINEERING SERIES 7

EVAPORATION

Step 4: Heat Balance with 0C as datum

st

For 1 effect:

(

)

(

)

(

From steam table, steam at 121.1C

From steam table, H(vapor enthalpy) at

(

(

For 2

)(

nd

)(

effect:

)

(

)

)(

)(

From steam table, at TV1 = 109C

From steam table, H(vapor enthalpy) at

(

(

)(

)(

( )(

)(

)

)(

rd

For 3 effect:

(

)

)

(

From steam table, at TV2 = 89.89C

CHEMICAL ENGINEERING SERIES 8

EVAPORATION

(

From steam table, H(vapor enthalpy) at

(

(

)(

(

Equate

)(

)(

(

)

)(

( )(

) (

)

)(

and

Step 5:

Solve for heat transfer area for each effect:

st

For 1 effect:

(

*(

*(

(

For 2

nd

*

)

effect:

*(

*

*(

rd

For 3 effect:

(

*(

(

*

*(

Since areas are not close, then another trial should be done

TRIAL 2:

Conduct new material balance using the computed L values

CHEMICAL ENGINEERING SERIES 9

EVAPORATION

)(

)

)(

)

st

To solve for BPR for the 1 and 2

st

1 effect:

(

)

(

)

(

nd

2 effect:

(

)

(

)

(

nd

effects:

)

)

Average Area from trial 1:

For the new

)(

)(

)(

Adjust to attain total T of 63.53

(

)(

)(

Calculate actual boiling point of solution for each effect using the estimated T

Step 4: Heat Balance with 0C as datum

st

For 1 effect:

(

)

(

)

CHEMICAL ENGINEERING SERIES 10

EVAPORATION

(

From steam table, steam at 121.1C

From steam table, H(vapor enthalpy) at

(

(

For 2

)(

nd

)(

effect:

)

(

)

)(

)(

From steam table, at TV1 = 103.94C

From steam table, H(vapor enthalpy) at

(

(

)(

)(

( )(

)(

)

)(

rd

For 3 effect:

(

)

(

From steam table, at TV2 = 87.61C

From steam table, H(vapor enthalpy) at

CHEMICAL ENGINEERING SERIES 11

EVAPORATION

(

)(

(

Equate

)(

)(

)

)(

( )(

) (

)

)(

and

Step 5:

Solve for heat transfer area for each effect:

st

For 1 effect:

(

*(

*

*(

(

For 2

nd

effect:

*(

*

*(

rd

For 3 effect:

(

*(

(

*

*(

Areas are almost equal, therefore new assumptions are valid:

ANSWERS:

Area of each effect:

Steam Requirement

Steam Economy:

CHEMICAL ENGINEERING SERIES 12

EVAPORATION

PROBLEM # 02:

A solution with a negligible boiling point rise is being evaporated in a triple effect evaporator using

saturated steam at 121.1C. The pressure in the vapor of the last effect is 25.6 kPa abs. The

2

heat transfer coefficients are U1 = 2840, U2 = 1988, and U3 = 1420 W/m K and the areas are

equal. Estimate the boiling point in each of the evaporators.

(Source: Transport Processes and Separation Processes, Geankoplis)

SOLUTION:

VI

Steam, S

121.1 C

T2

T3

TI

TII

TIII

LI

Using the heat transfer area equation:

Assume equal heat transfer flux for each effect

( )

( )

From steam table,

VIII

T1

( )

VII

LII

p3 = 25.6

kPa abs

CHEMICAL ENGINEERING SERIES 13

EVAPORATION

)(

)(

)(

CHEMICAL ENGINEERING SERIES 14

EVAPORATION

PROBLEM # 03:

A

forced-circulation

evaporator

is

to

concentrate 60,000 kg/h of 44 percent NaOH to

65 percent using steam at 3 atm pressure. The

feed temperature and the condensing

temperature are both 40C. The density of the

3

feed solution is 1,450 kg/m . If the over-all

2

heat transfer coefficient is 2,000 W/m C,

calculate (a) the steam requirement, in kg/h; (b)

the heat transfer area required.

(Source: Unit Operations of Chemical

th

Engineering, 7 edition, McCabe and Smith)

SOLUTION:

Consider solute balance (NaOH balance)

(

)(

Consider Over-all material Balance:

Consider enthalpy balance:

From figure 16.6

(

From figure 16.3 (McCabe and Smith)

For

the corresponding boiling point of solution at 65% conc,

From figure 16.6, at 65% concentration and 101.67C

For the superheated vapor, assume Cp of steam is 0.45 BTU/lbF

(

)

From steam table at 40C, HV, To = 1106.72 BTU/lb

CHEMICAL ENGINEERING SERIES 15

EVAPORATION

[

*(

*(

*(

)]

*(

*

At 3 atm, from steam table,

( )

(

)(

CHEMICAL ENGINEERING SERIES 16

EVAPORATION

PROBLEM # 04:

A triple-effect evaporator of the long-tube is to be used to concentrate 35,000 gal/h of a 17%

solution of dissolved solids to 38% dissolved solids. The feed enters at 60Fand passes through

three tube-and-shell heaters, a, b, and c, in series and then through the three effects in order II,

III,I. Heater a is heated by vapor taken from the vapor line between the third effect and the

condenser, heater b with vapor from the vapor line between the second and the third effects,

and heater c with vapor from the line between the first and the second effect. In each heater the

warm end temperature approach is 10F. Other data are given below:

Steam to I

230F, dry and saturated

Vacuum on III

28 in (referred to a 30-in barometer)

Condensates leave steam chests at condensing temperatures

Boiling point elevations

1F in II, 5F in III, 15F in I

2

Coefficients, in BTU/hft F, corrected for BPE - 450 in I, 700 in II, 500 in III

All effects have equal areas of heating surface

Concentration,

% solids

Specific

gravity

Specific heat,

BTU/lbF

10

20

30

35

40

1.02

1.05

1.10

1.16

1.25

0.98

0.94

0.87

0.82

0.75

Calculate (a) the steam required in lb/h; (b) heating surface per effect; (c) economy in lb per lb of

steam; and (d) the latent heat to be removed in the condenser

th

(Source: Unit Operations of Chemical Engineering, 7 edition, McCabe and Smith)

SOLUTION:

II

c

P

xP= 0.38

III

CONDENSER

a

F= 35,000 gal/h

xF = 0.17

TF = 60 F

CHEMICAL ENGINEERING SERIES 17

EVAPORATION

Consider solute balance:

At 17% concentration, sp. gr = 1.041

)(

Consider over-all material balance:

Assume equal evaporation in each effect:

(

Material Balance for each effect:

For second effect:

Over-all material balance:

Solute balance:

(

)(

For third effect:

Over-all material balance:

Solute balance:

(

)(

For first effect:

To check:

Over-all material balance:

CHEMICAL ENGINEERING SERIES 18

EVAPORATION

Solute balance:

(

)(

TEMPERATURE DISTRIBUTION

rd

rd

Temperature of vapor leaving the 3 effect corresponds to the pressure in the 3 effect

From steam table, at 2 in Hg

Theres a need to assume values of T 1, T2, T3

(

)(

)(

(

)

)(

(

)(

)

)

( )

( )

STREAM

DESIGNATION

TEMPERATURE,

F

st

1 Effect

Steam Feed to E-I

Liquor from E-III

Vapor to E-II

Product

230

106

172

187

nd

2 Effect

Feed from H- c

Vapor to E-III

Liquor to E-III

162

144

145

rd

3 Effect

Vapor to condenser

Liquor to E-I

101

106

Feed

Feed to b

Feed to c

60

91

134

CHEMICAL ENGINEERING SERIES 19

EVAPORATION

st

Consider heat balance around 1 effect:

(

)

For x = 0.2692, Cp = 0.89156 BTU/lbF

From steam table, at T1 = 172 F, = 995 BTU/lb; at Ts = 230F, = 958.8 BTU/lb

)(

)(

)

(

)

(

)

Consider heat balance around the second effect and heater c

st

nd

Note that the vapor coming from 1 effect will be used to heat the heater and the 2 effect

(

)

(

)

(

)

For x = 0.17, Cp = 0.952 BTU/lbF

From steam table, at T2 = 144 F, = 1011.64 BTU/lb

(

) (

)(

)(

)

Consider heat balance around the third effect and heater b

nd

rd

Note that the vapor coming from 2 effect will be used to heat the heater and the 3 effect

(

)

(

)

For x = 0.2084, Cp = 0.9341 BTU/lbF

From steam table, at T3 = 101 F, = 1036.44 BTU/lb

)

(

) (

)(

)(

(

)(

)(

)

Equate

Substitute

(

and

and

)

CHEMICAL ENGINEERING SERIES 20

EVAPORATION

From equation

(

)

(

*(

*(

(

(

*(

*(

*(

*(

*(

*(

*(

*(

)

*

Since surface of each effect is not the same, therefore, previous assumptions need to be readjusted

To adjust T:

Assume constant q and U

(

)

(

)

(

)(

)(

)(

CHEMICAL ENGINEERING SERIES 21

EVAPORATION

SECOND TRIAL:

Recompute using the adjusted T:

STREAM

DESIGNATION

TEMPERATURE,

F

st

1 Effect

Steam Feed to E-I

Liquor from E-III

Vapor to E-II

Product

230

106

170

185

nd

2 Effect

Feed from H- c

Vapor to E-III

Liquor to E-III

160

143

144

rd

3 Effect

Vapor to condenser

Liquor to E-I

101

106

Feed

Feed to b

Feed to c

60

91

133

st

Consider heat balance around 1 effect:

(

)

For x = 0.2692, Cp = 0.89156 BTU/lbF

From steam table, at T1 = 170 F, = 996.2 BTU/lb; at T s = 230F, = 958.8 BTU/lb

)(

)(

)

(

)

(

)

Consider heat balance around the second effect and heater c

st

nd

Note that the vapor coming from 1 effect will be used to heat the heater and the 2 effect

(

)

(

)

(

)

For x = 0.17, Cp = 0.952 BTU/lbF

From steam table, at T2 = 143 F, = 1012.23 BTU/lb

(

) (

)(

)(

)

CHEMICAL ENGINEERING SERIES 22

EVAPORATION

Consider heat balance around the third effect and heater b

nd

rd

Note that the vapor coming from 2 effect will be used to heat the heater and the 3 effect

(

)

(

)

For x = 0.2084, Cp = 0.9341 BTU/lbF

From steam table, at T3 = 101 F, = 1036.44 BTU/lb

)

(

) (

)(

)(

(

)(

)(

)

Equate

and

Substitute

(

and

)

From equation

(

)

(

*(

*(

(

(

*(

*(

*(

(

(

)

*(

*(

*(

*(

)

*

CHEMICAL ENGINEERING SERIES 23

EVAPORATION

*(

Since surface of each effect is not the same, therefore, previous assumptions need to be readjusted

To adjust T:

Assume constant q and U

(

)

(

)

(

)(

)(

)(

Since there will be no change in Ts, therefore, assumptions are correct:

( )

( )

ECONOMY:

( )

(

(

)

*(

*(

From steam table, at T3 = 101 F, = 1036.44 BTU/lb

(

*(

*

( )

CHEMICAL ENGINEERING SERIES 24

EVAPORATION

PROBLEM # 05:

A single effect evaporator concentrates 1 MT of

10% wt sucrose solution to 50%. The feed

enters the evaporator at 20C and has a

specific heat of 1.0.

The evaporator is

maintained at a vacuum of 800 mm Hg against

a barometric reading of 760 mm Hg. The heat

2

is provided by saturated steam at 8.8 kg/cm

gage. Assuming that no sensible heat is

recovered in the evaporator, calculate the

weight of heating steam, in kg, needed for

concentrating the sucrose solution.

Vapor, V

Steam, S

8.8 kg/cm2 gage

Sucrose Soln

F= 1 MT

xP = 0.10

TF= 20 C

Sp ht = 1.0

T1

TI

(Source: CHE BP May 1990)

SOLUTION:

Consider sucrose balance

(

)(

Consider Over-all material Balance:

Consider heat balance:

Since system involves solution of non-electrolytes, assume negligible BPE

(

From the steam table, @ 160 mm Hg,

)(

*(

From steam table at 160 mm Hg,

(

)(

From steam table at 8.8 kg/cm gage

(

)

*

+

pvacuum = 600 mm Hg

Pbarometric= 760 mm Hg

P

xP = 0.50

CHEMICAL ENGINEERING SERIES 25

EVAPORATION

PROBLEM # 06:

A solution of organic colloids is to be concentrated

from 20 to 65% wt solids in an evaporator.

Saturated steam is available at 172 kPa absolute

and the pressure in the condenser is 61.07

vacuum. The feed enters at 25C and its specific

heat is 4.0 J/gC. The solution has a negligible

2

elevation in boiling point. OHTC is 1,000 W/m C

and the evaporator must evaporate 9,000 kg/h.

a) Determine the steam consumption, kg/h

b) How many square meters of heating surface

are required?

c) What is the steam economy?

Vapor,

V = 9,000 kg/h

pvacuum = 61.07 cm

Steam, S

172 kPa abs

Organic Colloid

F

xF = 0.20

TF= 25 C

sp ht = 4.0 J/g C

SOLUTION:

Consider sucrose balance

(

Consider Over-all material Balance:

Consider heat balance:

(

)

(

From the steam table, @ 460 mm Hg,

*(

*(

From steam table at 460 mm Hg,

(

)(

T1

TI

P

xP = 0.65

CHEMICAL ENGINEERING SERIES 26

EVAPORATION

From steam table at 172 kPa abs

( )

)(

( )

CHEMICAL ENGINEERING SERIES 27

EVAPORATION

PROBLEM # 07:

An evaporator is to concentrate 10% wt caustic

soda solution to 50% wt. Feed enters at 100F.

Steam is available saturated at 50 psig and the

evaporator can be operated at 9.96 psi vacuum.

2

OHTC of the evaporator is 500 BTU/hft F.

d) Determine the heating area required for the

production of 10,000 lb/h of the 50% wt NaOH.

e) What is the steam economy?

Vapor,

V

pvacuum = 9.96 psi

Steam, S

50 psig

NaOH soln

F

xF = 0.100

TF= 100 F

T1

TI

P = 10,000 lb/h

xP = 0.50

SOLUTION:

Consider NaOH balance

(

)(

Consider Over-all material Balance:

Consider enthalpy balance:

Since solution is an electrolyte, it can be expected that there will be BPE

Solve for TI for a vacuum pressure of 9.96 psi vacuum (evaporator pressure)

From steam table,

From figure 16.3 (McCabe and Smith), for 50% NaOH solution and T I of 159.95F

From steam table at 87F,

(

)

(

)(

From figure 16.6 (McCabe and Smith),

At 100F and 10% NaOH

At 159.95 F and 50% NaOH

*(

*(

*(

CHEMICAL ENGINEERING SERIES 28

EVAPORATION

)

For steam at 50 psig

*(

)

( )

( )

CHEMICAL ENGINEERING SERIES 29

EVAPORATION

PROBLEM # 08:

A 10% wt NaOH at 80 F is to be concentrated in a

single effect evaporator to 40% wt. Steam is

supplied at 20 psig and the vacuum pressure of the

barometric condenser is 26 in Hg. 100 gpm of water

is fed to the condenser and the water leaving the

condenser (including the condensate) is at 100 F.

2

OHTC of evaporator is 200 BTU/hft F. Calculate

the heating surface required for the evaporator.

(Source: CHE BP May 1984)

tB =T =

100 F

Vapor,

V

pvacuum = 26Hg

Steam, S

20 psig

NaOH soln

F

xF = 0.10

TF= 80 F

T1

tA = 70 F

100 gpm

TI

P

xP = 0.40

SOLUTION:

Consider heat balance around the condenser:

(

)(

*(

(

)

Assume barometric pressure of 1 atm or 29.921 in Hg

From steam table, at 3.921 in Hg,

The vapor will be condensed first before lowering to 100F, thus, Cp of the liquid water

should be used

(

)(

For the evaporator

Consider NaOH balance

(

Consider Over-all material Balance:

CHEMICAL ENGINEERING SERIES 30

EVAPORATION

Consider enthalpy balance:

Since solution is an electrolyte, it can be expected that there will be BPE

From figure 16.3 (McCabe and Smith), for 40% NaOH solution and T 1 of 124.37F

From steam table at 124.37F,

(

)

(

)(

From figure 16.6 (McCabe and Smith),

At 80F and 10% NaOH

At 170 F and 40% NaOH

*(

)

For steam at 20 psig

*(

*(

*(

CHEMICAL ENGINEERING SERIES 31

EVAPORATION

PROBLEM # 09:

4,500 kg/h of a 10% wt sugar solution is to be concentrated to 30% wt. Feed enters at 21C.

Saturated steam at 110C is available and the temperature in the condenser is 43C. Specific

heat of the solutions may be taken as constant at 4 J/gC. Determine (a) heating surface

required, (b) steam consumption, and (c) steam economy, for each of the following cases:

2

I.

II.

III.

Single effect, OHTC = 2,840 W/m C

2

Double effect, forward feed; U1 = 2,270, U2 = 1,700 W/m C

2

Double effect, backward feed; U1 = 2,270, U2 = 1,700 W/m C

SOLUTION:

Consider sugar balance

(

)(

Consider Over-all material Balance:

CASE I: SINGLE EFFECT

Vapor,

V

T1 = 43 C

Steam, S

110 C

Sugar soln

F=4,500 kg/h

xF = 0.10

TF= 21 C

T1

TI

P

xP = 0.30

Consider heat balance:

Since solution is non electrolyte, BPE is negligible

Temperature of vapor leaving the evaporator is the same as the condenser temperature

(

(

)

*(

*(

CHEMICAL ENGINEERING SERIES 32

EVAPORATION

From steam table, at 43C

*(

)(

From steam table, at 110C,

CASE II: DOUBLE EFFECT, FORWARD FEED

CHEMICAL ENGINEERING SERIES 33

EVAPORATION

VI

VII

T2 = 43 C

Steam, S

110 C

T1

T2

TI

TII

Sugar soln

F=4,500 kg/h

xF = 0.10

TF= 21 C

PI

Initial Assumptions:

Assume equal evaporation rates

*

st

Consider material balance around the 1 effect

Solve for the temperature distribution; to assume Ts

Assume equal heat flux

( )

( )

( )

( )

P

xP = 0.30

CHEMICAL ENGINEERING SERIES 34

EVAPORATION

Ts = 110 C

TI

)(

TI

*

)

TII

TII = 43 C

)(

(

nd

Enthalpy balance around the 2

effect:

st

Enthalpy balance around the 1 effect:

(

Equate

and

(

(

)

)

)(

)(

From steam table;

CHEMICAL ENGINEERING SERIES 35

EVAPORATION

)(

)(

(

)

(

(

)(

( )

Equate

and

*(

)(

)(

)

)

CHEMICAL ENGINEERING SERIES 36

EVAPORATION

Since AI = AII, therefore original assumptions are correct

(

CASE III: DOUBLE EFFECT, BACKWARD FEED

VI

VII

T2 = 43 C

Steam, S

110 C

T1

T2

TI

TII

PI

P

xP = 0.30

Initial Assumptions:

Assume equal evaporation rates

st

Consider material balance around the 1 effect

Sugar soln

F=4,500 kg/h

xF = 0.10

TF= 21 C

CHEMICAL ENGINEERING SERIES 37

EVAPORATION

Solve for the temperature distribution; to assume Ts

Assume equal heat flux

( )

( )

( )

( )

Ts = 110 C

TI

TI

TII

TII = 43 C

nd

st

effect:

Enthalpy balance around the 1 effect:

and

(

(

)

)

*

)

)(

(

Enthalpy balance around the 2

Equate

)(

*

*

CHEMICAL ENGINEERING SERIES 38

EVAPORATION

)(

)(

From steam table;

)

(

)(

( )

Equate

and

*(

)(

)(

)(

CHEMICAL ENGINEERING SERIES 39

EVAPORATION

)(

Since AI = AII, therefore original assumptions are correct

(

CHEMICAL ENGINEERING SERIES 40

EVAPORATION

PROBLEM # 10:

Glycerine is to be concentrated from 12% to 72% in a single-effect evaporator. The inlet steam

used is at 25 psig and comes out at 170F. The vapor space in the evaporator has 25 inches Hg

vacuum. Ten metric tons of glycerine per hour are fed at 85F. The concentrated product is at

125F. Calculate the amount of water evaporated in kg/h.

(Source: MRII Reviewer)

SOLUTION:

Vapor,

V

P = 25 Hg vac

Steam, S

25 psig

F=10 MT/h

xF = 0.12

TF= 85 F

TI

170 F

P

xP = 0.72

TF= 125 F

Consider solute balance:

(

)(

Consider over-all material balance:

CHEMICAL ENGINEERING SERIES 41

EVAPORATION

PROBLEM # 11:

A feed of 4,535 kg/h of a 2.0 % wt salt solution at 311 K enters continuously a single effect

evaporator and is being concentrated to 3%. The evaporation is at atmospheric pressure and the

2

area of the evaporator is 69.7 m . Saturated steam at 383.2 K is supplied for heating. Since the

solution is dilute, it can be assumed to have the same boiling point as water. The heat capacity

of the feed can be taken as Cp = 4.10 kJ/kgK. Calculate the amounts of vapor and liquid product

and the over-all heat transfer coefficient.

(Source:

Principles of Transport Processes and Separation Processes, 4

Geankoplis)

SOLUTION:

Vapor,

V

P = 1 atm

Steam, S

383.2 K

F=4535 kg/h

xF = 0.02

TF= 311 K

TI

P

xP = 0.03

Consider solute balance:

(

)(

Consider over-all material balance:

Consider heat balance:

th

edition, by

CHEMICAL ENGINEERING SERIES 42

EVAPORATION

Since the evaporator operates at 1 atm, operating temperature will be the the

temperature corresponding to 1 atm or water boiling point (373 K)

(

(

)

*(

*(

From the steam table at 373 K,

*(

)

(

)(

CHEMICAL ENGINEERING SERIES 43

EVAPORATION

PROBLEM # 12:

2

An evaporator having an area of 83.6 m and U = 2270

2

W/m K is used to produce distilled water for a boiler feed.

Tap water having 400 ppm dissolved solids at 15.6 C is fed

to the evaporator operating at 1 atm pressure abs.

Saturated steam at 115.6C is available for use. Calculate

the amount of distilled water produced per hour if the outlet

liquid contains 800 ppm solids.

Vapor,

V

xF = 0.04

TF= 15.6 C

(Source: Principles of Transport Processes and Separation

th

Processes, 4 edition, by Geankoplis)

SOLUTION:

Assume that the boiling point of the solution is 100C (1 atm operating pressure)

(

)

)(

)(

Consider solute balance:

(

Consider over-all material balance:

Consider heat balance:

(

)

For water, Cp = 4.1868 kJ/kgC

(

)(

*(

From the steam table at 100C,

( )(

P = 1 atm

Steam, S

115.6 C

TI

P

xP = 0.08

CHEMICAL ENGINEERING SERIES 44

EVAPORATION

PROBLEM # 13:

A single effect evaporator is concentrating a feed of 9,072 kg/h

of a 10 wt % solution of NaOH in water to a product of 50 %

solids. The pressure of saturated steam used is 42 kPa (gage)

and the pressure in the vapor space of the evaporator is 20

kPa (abs). The over-all heat transfer coefficient is 1,988

2

W/m K. Calculate the steam used, the steam economy in kg

vaporized/kg steam, and the area for the following feed

conditions:

a) Feed temperature of 288.8 K

b) Feed temperature of 322.1 K

Vapor,

V

PV = 20 kPa (abs)

Steam, S

42 kPa (gage)

NaOH soln

F=9,072 kg/h

xF = 0.10

TF

TI

(Source: Principles of Transport Processes and Separation

th

Processes, 4 edition, by Geankoplis)

SOLUTION:

Consider NaOH balance:

(

)(

Consider over-all material balance:

For 20 kPa evaporator vapor space pressure, the temperature of the vapor (from steam table)

Since system is NaOH, it is expected to have BPE

From figure 8.4-2 (Geankoplis), for 50% NaOH concentration and T V = 333.06 K (60.06C)

)]

From steam table, at 60.06C,

P

xP = 0.50

CHEMICAL ENGINEERING SERIES 45

EVAPORATION

(

*[

)(

)]

A. For feed temperature of 288.8 K

Consider enthalpy balance:

From steam table, at 42 kPa gage,

From figure 8.4-3 (Geankoplis)

*(

*(

(

*(

)(

)(

)

)

*(

CHEMICAL ENGINEERING SERIES 46

EVAPORATION

B. For feed temperature of 322.1 K

Consider enthalpy balance:

From steam table, at 42 kPa gage,

From figure 8.4-3 (Geankoplis)

*(

*(

(

*(

)(

)(

)

)

*(

CHEMICAL ENGINEERING SERIES 47

EVAPORATION

PROBLEM # 14:

In order to concentrate 4,536 kg/h of an NaOH solution

containing 10 wt % NaOH to a 20 wt % solution, a single

2

effect evaporator is being used with an area of 37.6 m .

The feed enters at 21.1 C. Saturated steam at 110 C is

used for heating and the pressure in the vapor space of

the evaporator is 51.7 kPa abs. Calculate the kg/h of

steam used and the over-all heat transfer coefficient.

(Source: Principles of Transport Processes and

th

Separation Processes, 4 edition, by Geankoplis)

Vapor,

V

PV = 51.7 kPa (abs)

Steam, S

110 C

NaOH soln

F=4,536 kg/h

xF = 0.10

TF = 21.1 C

TI

P

xP = 0.20

SOLUTION:

Consider NaOH balance:

(

)(

Consider over-all material balance:

For 51.7 kPa evaporator vapor space pressure, the temperature of the vapor (from steam table)

Since system is NaOH, it is expected to have BPE

From figure 8.4-2 (Geankoplis), for 20% NaOH concentration and T V = 82.06C

)]

From steam table, at 82.06C,

(

*[

)(

,

)]

CHEMICAL ENGINEERING SERIES 48

EVAPORATION

Consider enthalpy balance:

From steam table, at 110C,

From figure 8.4-3 (Geankoplis)

*(

(

(

)

)

*(

(

*(

)(

)(

)

*(

CHEMICAL ENGINEERING SERIES 49

EVAPORATION

PROBLEM # 15:

An evaporator is concentrating F kg/h at 311 K of a 20 wt %

solution of NaOH to 50%. The saturated steam for heating

is at 399.3 K. The pressure in the vapor space of the

evaporator is 13.3 kPa abs. The over-all heat transfer

2

2

coefficient is 1,420 W/m K and the area is 86.4 m .

Calculate the feed rate F of the evaporator.

Vapor,

V

PV = 13.3 kPa (abs)

Steam, S

399.3 K

NaOH soln

F

xF = 0.20

TF = 311 K

(Source: Principles of Transport Processes and Separation

th

Processes, 4 edition, by Geankoplis)

TI

P

xP = 0.50

SOLUTION:

Consider NaOH balance:

(

)( )

Consider over-all material balance:

For 13.3 kPa evaporator vapor space pressure, the temperature of the vapor (from steam table)

Since system is NaOH, it is expected to have BPE

From figure 8.4-2 (Geankoplis), for 50% NaOH concentration and T V = 51.39C

)]

From steam table, at 51.39C,

(

)[

Consider enthalpy balance:

)(

,

)]

CHEMICAL ENGINEERING SERIES 50

EVAPORATION

From steam table, at 399.3 K,

From figure 8.4-3 (Geankoplis)

(

(

)(

( )(

)(

)(

CHEMICAL ENGINEERING SERIES 51

EVAPORATION

PROBLEM # 16:

A single effect evaporator is concentrating a feed

solution of organic colloids from 5 to 50 wt %. The

solution has a negligible boiling point elevation. The

heat capacity of the feed is Cp= 4.06 kJ/kgK and the

feed enters at 15.6C. Saturated steam at 101.32 kPa

is available for heating, and the pressure in the vapor

space of the evaporator is 15t.3 kPa. A total of 4,536

kg/h of water is to be evaporated. The over-all heat

2

transfer coefficient is 1,988 W/m K. What is the

2

required surface area in m

and the steam

consumption?

Vapor,

V = 4,536 kg/h

PV = 15.3 kPa (abs)

Steam, S

101.32 kPa

F

xF = 0.05

TF = 15.6 C

TI

P

xP = 0.50

(Source: Principles of Transport Processes and

th

Separation Processes, 4 edition, by Geankoplis)

SOLUTION:

Consider NaOH balance:

(

)( )

Consider over-all material balance:

For 15.3 kPa evaporator vapor space pressure, the temperature of the vapor (from steam table)

For steam at 101.32 kPa

Since no BPE

Consider heat balance:

(

CHEMICAL ENGINEERING SERIES 52

EVAPORATION

*(

*(

*(

)(

Das könnte Ihnen auch gefallen

- EvaporationDokument36 SeitenEvaporationPaul Andrew MadlangbayanNoch keine Bewertungen

- Evaporation CalculationsDokument57 SeitenEvaporation CalculationsHarsha94% (101)

- Single effect evaporator heat and mass balancesDokument9 SeitenSingle effect evaporator heat and mass balancesJahre El Leonard Tañedo100% (2)

- Study of A Single Effect EvaporatorDokument11 SeitenStudy of A Single Effect Evaporatormahbub133267% (6)

- Evaporator EfficiencyDokument15 SeitenEvaporator EfficiencySanjaySinghAdhikariNoch keine Bewertungen

- HumidificationDokument29 SeitenHumidificationClark Ivan Torres100% (3)

- Gas Absorption PDFDokument42 SeitenGas Absorption PDFKim GojoCruz90% (29)

- Distillation: Sample ProblemsDokument7 SeitenDistillation: Sample ProblemsZeny Naranjo100% (1)

- Evaporation Sample Solved ProblemsDokument19 SeitenEvaporation Sample Solved ProblemsZeny Naranjo100% (2)

- CRYSTALLIZATION PROCESS OPTIMIZATIONDokument42 SeitenCRYSTALLIZATION PROCESS OPTIMIZATIONKTINE0894% (16)

- SEPARATIONSDokument13 SeitenSEPARATIONSR ZoNoch keine Bewertungen

- Distillation 2Dokument3 SeitenDistillation 2roxetteNoch keine Bewertungen

- Separation Process 1Dokument86 SeitenSeparation Process 1hanisshi50% (4)

- Mass Transfer PartDokument37 SeitenMass Transfer Partoctoviancletus63% (8)

- Gas AbDokument14 SeitenGas AbJackielyn EugenioNoch keine Bewertungen

- Gas Absorption Lecture NotesDokument11 SeitenGas Absorption Lecture NotesMark Guevarra0% (1)

- Problems in Mass TransferDokument3 SeitenProblems in Mass TransferAngelica Joyce BenitoNoch keine Bewertungen

- Solved Problems PDFDokument6 SeitenSolved Problems PDFMayank PrasadNoch keine Bewertungen

- Drying: Chemical Engineering SeriesDokument54 SeitenDrying: Chemical Engineering Serieskmrosario67% (21)

- GATE Previous Years Solved Papers: Chemical Reaction EngineeringDokument31 SeitenGATE Previous Years Solved Papers: Chemical Reaction EngineeringSandeep CharanNoch keine Bewertungen

- Separation ProcessesDokument57 SeitenSeparation ProcessesAngelo X0% (1)

- LT2 2Dokument7 SeitenLT2 2Lin Xian XingNoch keine Bewertungen

- Separation Process Compilation of Problem SetDokument60 SeitenSeparation Process Compilation of Problem SetKaye Fabros100% (5)

- Separation Process Compilation of Problem SetDokument55 SeitenSeparation Process Compilation of Problem Setjames100% (1)

- Constant Underflow Leaching SolutionDokument8 SeitenConstant Underflow Leaching SolutionFran LeeNoch keine Bewertungen

- Batch Drying Problem With SolutionsDokument11 SeitenBatch Drying Problem With SolutionsKorina_Gomez_274494% (17)

- Sample Problem #11Dokument6 SeitenSample Problem #11Dozdi100% (4)

- Evaporation: By: Allie E. Fuentebella-Pomperada, Che, Mengr, PHDTMDokument49 SeitenEvaporation: By: Allie E. Fuentebella-Pomperada, Che, Mengr, PHDTMjantskie100% (2)

- Sample Problem #3Dokument1 SeiteSample Problem #3DozdiNoch keine Bewertungen

- COMPIDokument129 SeitenCOMPIJeanne Roselle Dulatre CortezNoch keine Bewertungen

- Single Effect Evaporator 2Dokument22 SeitenSingle Effect Evaporator 2Shailesh Lohare100% (1)

- 8-Heat Transfer-2016 - Ans Key-Master FileDokument12 Seiten8-Heat Transfer-2016 - Ans Key-Master FileLourdes Cagungun100% (2)

- 4single Effect Evaporators ProblemsDokument24 Seiten4single Effect Evaporators Problemsananth2012100% (4)

- ChE Calculations 2: Sulfur and Its CompoundsDokument22 SeitenChE Calculations 2: Sulfur and Its CompoundsJeyemar Roge100% (2)

- Lab Report (Distillation)Dokument10 SeitenLab Report (Distillation)najihahNoch keine Bewertungen

- Crystallizations QuestionsDokument4 SeitenCrystallizations Questionsengr2021Noch keine Bewertungen

- Sample Problem #2Dokument2 SeitenSample Problem #2Dozdi67% (3)

- Distillation Exercises2013Dokument23 SeitenDistillation Exercises2013Zakaria Elhammoumi0% (1)

- Evaporator DesignDokument5 SeitenEvaporator DesignSaurab DevanandanNoch keine Bewertungen

- R14 - Steam Power Cycles PDFDokument10 SeitenR14 - Steam Power Cycles PDFnotoriousneal12Noch keine Bewertungen

- Carnotrankineandsteampowercycles 140217011629 Phpapp01Dokument10 SeitenCarnotrankineandsteampowercycles 140217011629 Phpapp01Mohd ShajiNoch keine Bewertungen

- ERT 209 Heat and Mass Transfer For Bioprocess Engineering EvaporatorDokument50 SeitenERT 209 Heat and Mass Transfer For Bioprocess Engineering EvaporatorSreenivasNoch keine Bewertungen

- Peb Evaporation PDFDokument23 SeitenPeb Evaporation PDFmessy munozNoch keine Bewertungen

- EvaporationDokument50 SeitenEvaporationRajNoch keine Bewertungen

- 1 EvaporationDokument36 Seiten1 EvaporationDoaa Badarneh100% (1)

- Double Effect EvaporatorDokument9 SeitenDouble Effect EvaporatorVaidh Prakash ChoudharyNoch keine Bewertungen

- EVAPORATORDokument50 SeitenEVAPORATORnur irfana mardiyah100% (1)

- Triple-Effect Evaporator DesignDokument8 SeitenTriple-Effect Evaporator DesignHajra AamirNoch keine Bewertungen

- EvaporationDokument2 SeitenEvaporationdanena88100% (1)

- TA-FE-2_231219_080052Dokument45 SeitenTA-FE-2_231219_080052MAI NGUYỄN TRẦN THANHNoch keine Bewertungen

- Heat and MassDokument13 SeitenHeat and MassMohammed AliraqiNoch keine Bewertungen

- Group Membersid - No 1.meseret Tekie ATR/3016/06 2. Abduljelil Abdurhman ATR/4505/06Dokument6 SeitenGroup Membersid - No 1.meseret Tekie ATR/3016/06 2. Abduljelil Abdurhman ATR/4505/06yohannes lemiNoch keine Bewertungen

- HMTDokument16 SeitenHMTfreakameNoch keine Bewertungen

- Evaporation 2Dokument18 SeitenEvaporation 2Kuma Gloria100% (1)

- Climbing Film EvaporatorDokument8 SeitenClimbing Film EvaporatorPelin Yazgan BirgiNoch keine Bewertungen

- Evaporation (Lab Report)Dokument5 SeitenEvaporation (Lab Report)Ynno0% (1)

- المراجل البخاريةDokument8 Seitenالمراجل البخاريةmuhammed atallaNoch keine Bewertungen

- EvaporationDokument49 SeitenEvaporationYOSEF BUDIMANNoch keine Bewertungen

- CL405 2021 End Term ExaminationDokument4 SeitenCL405 2021 End Term ExaminationArpit GuptaNoch keine Bewertungen

- CHEDROcc 2Dokument21 SeitenCHEDROcc 2kmrosarioNoch keine Bewertungen

- Sample Answer SheetDokument1 SeiteSample Answer SheetkmrosarioNoch keine Bewertungen

- Civil Service Exam Complete Reviewer Philippines 2017Dokument46 SeitenCivil Service Exam Complete Reviewer Philippines 2017JJ Torres84% (434)

- Compressed HydrogenDokument12 SeitenCompressed Hydrogenkmrosario100% (1)

- 03 Catalyst CharacterizationDokument39 Seiten03 Catalyst CharacterizationMegan TorresNoch keine Bewertungen

- Extraction OilDokument49 SeitenExtraction OilmoshejamNoch keine Bewertungen

- Batch Manufacture of Propylene GlycolDokument24 SeitenBatch Manufacture of Propylene Glycoloption2010100% (1)

- Analytic Geometry 2014 - 20151Dokument1 SeiteAnalytic Geometry 2014 - 20151kmrosarioNoch keine Bewertungen

- Lecture 19 Propylene GlycolDokument5 SeitenLecture 19 Propylene GlycolkmrosarioNoch keine Bewertungen

- Kiln SystemsDokument60 SeitenKiln Systemskmrosario0% (1)

- Computer Application (Introduction To MATLAB)Dokument29 SeitenComputer Application (Introduction To MATLAB)kmrosarioNoch keine Bewertungen

- Lecture 1 - Chemical KineticsDokument25 SeitenLecture 1 - Chemical KineticsRooth AdajetNoch keine Bewertungen

- CRYSTALLIZATION PROCESS OPTIMIZATIONDokument42 SeitenCRYSTALLIZATION PROCESS OPTIMIZATIONKTINE0894% (16)

- Drying: Chemical Engineering SeriesDokument54 SeitenDrying: Chemical Engineering Serieskmrosario67% (21)

- HumidificationDokument29 SeitenHumidificationClark Ivan Torres100% (3)

- Basic Principles & Calculations in Chemical Engineering 7th Ed Solution Manual (C)Dokument454 SeitenBasic Principles & Calculations in Chemical Engineering 7th Ed Solution Manual (C)kmrosario100% (2)

- Aws CatalogDokument43 SeitenAws CatalogDesmond Chin100% (1)

- PACCAR MX Engine Reference Sheet PDFDokument2 SeitenPACCAR MX Engine Reference Sheet PDFMalique ChamauneNoch keine Bewertungen

- 2 - Seismic Waves and Their MeasurementDokument29 Seiten2 - Seismic Waves and Their MeasurementDuy PhướcNoch keine Bewertungen

- Models 69NT40-511-300 To 309, 69NT40-511-311 To 399Dokument117 SeitenModels 69NT40-511-300 To 309, 69NT40-511-311 To 399cloviskrelling100% (2)

- Rizal Tech SMAW Module 2 Welding ResponsibilitiesDokument10 SeitenRizal Tech SMAW Module 2 Welding ResponsibilitiesMclawrence SaquingNoch keine Bewertungen

- 207ACBH-2-SS Parker Brass FittingDokument24 Seiten207ACBH-2-SS Parker Brass FittingMROstop.comNoch keine Bewertungen

- Earthquake DescriptorsDokument13 SeitenEarthquake DescriptorsDiane Demariano Torcuator60% (5)

- AVK Dams - Reservoirs - HydroPower BrochureDokument15 SeitenAVK Dams - Reservoirs - HydroPower Brochureindra putraNoch keine Bewertungen

- Reciprocating Compressor Trouble Shooting GuidesDokument3 SeitenReciprocating Compressor Trouble Shooting GuidesRahul ChandrawarNoch keine Bewertungen

- Training ProjectDokument43 SeitenTraining ProjectlokeshkrkushwahaNoch keine Bewertungen

- Caseih Serie 20Dokument1.267 SeitenCaseih Serie 20Fernando Sabino100% (2)

- Conprint 3DDokument30 SeitenConprint 3DManu S NadesanNoch keine Bewertungen

- Fracturing Engineering Manual - 4243456 - 02Dokument903 SeitenFracturing Engineering Manual - 4243456 - 02Pablo Antezana100% (2)

- RCC Is Provision NotesDokument4 SeitenRCC Is Provision NotessameerNoch keine Bewertungen

- Test 924G, 1. General Testing and AdjustingDokument7 SeitenTest 924G, 1. General Testing and Adjustingmijael1393100% (1)

- Oil Reservoir Fluids Properties ExercisesDokument2 SeitenOil Reservoir Fluids Properties ExercisesRafraf Ezdine100% (1)

- Multi - Choice Question Paper (MSR-WI-2)Dokument8 SeitenMulti - Choice Question Paper (MSR-WI-2)Karit Hawichit100% (1)

- M10S Ball Valve DN " To DN2 ": Full BoreDokument4 SeitenM10S Ball Valve DN " To DN2 ": Full BoreTsion GtatiosNoch keine Bewertungen

- Computational Study of Effects of Jet Fans On The Ventilation of A Highway PDFDokument9 SeitenComputational Study of Effects of Jet Fans On The Ventilation of A Highway PDFZine ModelsNoch keine Bewertungen

- TRX2319 Crane Escorts Parts BookDokument383 SeitenTRX2319 Crane Escorts Parts BookRaghavendra Mestha100% (5)

- Syphon For Pressure Measuring Instruments Model 910.15: ApplicationsDokument4 SeitenSyphon For Pressure Measuring Instruments Model 910.15: Applicationsluis carlos martin contrerasNoch keine Bewertungen

- Vibration PDFDokument48 SeitenVibration PDFtruva_kissNoch keine Bewertungen

- Singly Reinforced Beam ExcelDokument3 SeitenSingly Reinforced Beam ExcelVEERKUMAR100% (3)

- Lecture 2Dokument30 SeitenLecture 2hania dogar0% (1)

- Tutorial 5Dokument6 SeitenTutorial 5Mohammad Asri ChristopherNoch keine Bewertungen

- Wire Rope Inspection Checklist FormDokument1 SeiteWire Rope Inspection Checklist FormРашад ИбрагимовNoch keine Bewertungen

- Adjustable Type EAZ SeriesDokument8 SeitenAdjustable Type EAZ SeriesVimalendra SinghNoch keine Bewertungen

- Safe Work Method Statement For Welding of Pipes WPS PQR PDFDokument3 SeitenSafe Work Method Statement For Welding of Pipes WPS PQR PDFDeepak RajanNoch keine Bewertungen

- AS4041 PresurecontainmentDokument5 SeitenAS4041 PresurecontainmentJOHNKNoch keine Bewertungen

- NED Booklet 2015 ENDokument120 SeitenNED Booklet 2015 ENElena JursinaNoch keine Bewertungen