Beruflich Dokumente

Kultur Dokumente

Ecb SD CTG 00 Ga03 01

Hochgeladen von

Ahmad Nabil ElsharkawyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ecb SD CTG 00 Ga03 01

Hochgeladen von

Ahmad Nabil ElsharkawyCopyright:

Verfügbare Formate

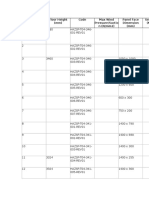

PLAN +11.

300

5014 W14X90

5035 W14X109

5034 W14X109

5025 W14X109

5034 W14X109

5764 W14X109

5016 W14X109

5036 W14X109

5003 W14X211

5029 W14X211

5017 W14X109

5767 W14X211

5038 W14X120

5732 W14X120

5733 W14X120

5732 W14X120

5732 W14X120

5007 W14X120

5762 W14X90

5737 W14X90

5766 W14X90

5738 W14X90

5737 W14X90

5012 W14X90

5033 W14X90

5033 W14X90

5026 W14X109

5028 W14X211

5007 W14X120

5037 W14X145

5031 W14X90

D.9

5033 W14X90

5015 W14X90

D.4

5015 W14X90

5015 W14X90

5015 W14X90

5033 W14X90

5736 W14X145

5001 W14X120

C.3

5002 W14X176

5018 W14X145

B.7

5008 W14X120

5765 W14X90

5013 W14X90

5023 W14X90

5024 W14X90

5735 W14X90

5000 W14X145

5019 W14X145

5739 W14X90

5419 W8X18

5539 W14X30

5419 W8X18

5420 W8X18

5419 W8X18

5419 W8X18

5440 W14X30

5419 W8X18

5539 W14X30

5151 W14X30

5419 W8X18

5022 W14X90

5763 W14X90

5027 W14X120

5030 W14X145

5070 W30X90

NOTES:1)- ALL HOLES ARE 24 mm DIA U.N.O.

2)- ALL DIMENSIONS ARE IN mm.

3)- STEEL GRADE A36 FOR ANGLES SECTIONS , CHANNEL SECTIONS AND TOE PLATES.

4)- ALL GRADE OF W-SECTIONS ARE ASTM A572 / A992 - G50

5)-ALL PLATES USED FOR BUILT UP SECTION AND GUSSET PLATE ARE S355JR

6)- ALL MATERIALS FOR HANDRAILS AND GUARDRAILS PIPES ARE CONFORM TO ASTM A53

7)- ALL BOLTS 5/8 " ARE A307 FULLY THREADED, WASHERS F436 AND NUT A194-2H.

8)- ALL BOLTS 7/8 " ARE A325 FULLY THREADED, WASHERS F436 & F959 AND NUT A194-2H.

9)- ALL BOLTS 1 1/4 " ARE A490 FULLY THREADED, WASHERS F436 & F959 AND NUT A194-2H.

10)- VERTICAL & HORIZONTAL BRACING, CRANE TRACK GRIDERS CONNECTIONS

AND COLUMN SPLICES ARE SLIP CRITICAL CONNECTIONS.

11)- WELD SIZE S= MINIMUM WELDED THICKNESS U.N.O.

12)- WELDING SHALL BE DONE USING LOW HYDROGEN ELCTRODES

IN ACCORDANCE WITH AWS D1.1 (I.E. 70 SERIES FOR WELDING OF ASTM A36).

13)- FOR WELDING DETAILS REFER TO WELDING MAP.

14)- THE SHEAR STUDS SHALL BE: 19 mm DIA X 100 mm.

FOR 200 mm SLAB THICKNESS SITE WELDED

15)- FOR STUDS QTY. (R-SS) R: INDICATES NUMBER OF ROWS OF STUDS, SS:

INDICATES THE TOTAL NUMBER OF EQUALLY SPACED.

16)- COATINGS OF HANDRAILS & TOE PLATES ARE HOT DIP GALVANIZED

ACCORDING TO ASTM A123.

7.7

9.1

5541 W14X30

5420 W8X18

5587

X20

WT6

5420 W8X18

5541 W14X30

5543 W14X30

5419 W8X18

5419 W8X18

5420 W8X18

5031 W14X90

5419 W8X18

5021 W14X120

5753 W30X90

5734 W14X90

5005 W14X145

5754 W30X90

5419 W8X18

5440 W14X30

5542 W14X30

5151 W14X30

A.1

5031 W14X90

5419 W8X18

5411 W14X30

WT6

X20

5540 W14X30

5324

5419 W8X18

Tekla structures

5032 W14X90

5542 W14X30

5755 W30X90

5411 W14X30

5039 W14X159

5030 W14X145

9.9

10

11

12

12.1

12.9

13

14

01

REV.

19-03-2012

MWS

DATE

ISSUED FOR APPROVAL

Dr A. B.

AUTHOR CHECKED

S. L.

DETAILS OF MODIFICATION

AGREED

CAIRO ELECTRICITY PRODUCTION COMPANY

GIZA NORTH POWER PLANT

1500 MW COMBINED CYCLE POWER PROJECT

CIVIL WORKS

TYPE OF DOCUMENT:-

SHOP DRAWING

ECB

SD

CTG

00

ORIGINATOR

DOC.TYPE

LOCATION

S-LOC.

CONTRACTOR CODE

NUMBER:

DRAWING TITLE:-

GA03

DWG NO.

01

REV.

SHEET: 1 OF 1

SCALE:

CONTRACT NUMBER: 10063-CP-102

99999-9-3SS-S000-0001

REFERENCE SPECIFICATION (S):

ISSUED BY:-

CONTRACTOR:-

ECB Engineering Consulting Bureau

BESIX

Dr. ABDEL-RAHIM BADAWY Dr. AMR I.I. HELMY

CONSTRUCTION INDUSTRIES

2A Kamal Hasan Ali Street,Sheraton Heliopolies,Cairo,Egypt

Tel/Fax: 2 02 268 2772

E-Mail: aeaeng@link.net

FOR CONTRACTOR:NAME: SHERIF LABIB

PGESCo CODE No. :

ENGINEER ACTION:

NTS

COMBUSTION TURBINE AREA MODULE-1

GENERAL LAYOUT LEVEL 11300

SIGNATURE:

DATE:

19-03-2012

Das könnte Ihnen auch gefallen

- Rad 1/2 D: 001 C/D M88 DB-950006 00Dokument1 SeiteRad 1/2 D: 001 C/D M88 DB-950006 00raobabar21Noch keine Bewertungen

- ULTRX®, Type 4XDokument6 SeitenULTRX®, Type 4XselocaNoch keine Bewertungen

- Snow EquipDokument80 SeitenSnow EquipfghjkljuNoch keine Bewertungen

- Duct Size Air Flow SL - No Sections L/M W/M H/M L/S CFMDokument8 SeitenDuct Size Air Flow SL - No Sections L/M W/M H/M L/S CFMDofly ShakeNoch keine Bewertungen

- 500 EXC USA 2012: Spare Parts Manual: EngineDokument28 Seiten500 EXC USA 2012: Spare Parts Manual: EnginecharlesNoch keine Bewertungen

- Spare Parts Catalogue: ZF Do Brasil LtdaDokument46 SeitenSpare Parts Catalogue: ZF Do Brasil LtdaLeonardo Almeida100% (3)

- The Shape and Future of Modular Shielding: Interior Design PackageDokument11 SeitenThe Shape and Future of Modular Shielding: Interior Design PackageJose Luis ChapasNoch keine Bewertungen

- Re 500Dokument15 SeitenRe 500mazmamrefNoch keine Bewertungen

- Toshiba Conditioner PDFDokument73 SeitenToshiba Conditioner PDFIgor StefanetNoch keine Bewertungen

- Sorted Projects - DATA ENTRYDokument8 SeitenSorted Projects - DATA ENTRYAyman_Elmasry_9107Noch keine Bewertungen

- Tank Drawing ExampleDokument2 SeitenTank Drawing Examplejuanchocazon78100% (1)

- Inertia Dynamic TypeFO SpecsheetDokument3 SeitenInertia Dynamic TypeFO SpecsheetElectromateNoch keine Bewertungen

- BRC Price List 2007Dokument12 SeitenBRC Price List 2007Adam LimNoch keine Bewertungen

- Spare Parts Catalogue: ZF Do Brasil LtdaDokument45 SeitenSpare Parts Catalogue: ZF Do Brasil LtdaWillNoch keine Bewertungen

- Notes: P.T. Badak N.G.L. Bontang L.N.G. PlantDokument10 SeitenNotes: P.T. Badak N.G.L. Bontang L.N.G. PlantAdidtya Budhi SaputraNoch keine Bewertungen

- Gutter SizingDokument11 SeitenGutter Sizingsnikkirose17Noch keine Bewertungen

- Steinel Helicalfjedre EngDokument7 SeitenSteinel Helicalfjedre Engsmhea123Noch keine Bewertungen

- Husaberg Fe 550-E 2007 MotorDokument28 SeitenHusaberg Fe 550-E 2007 Motorjinxy06Noch keine Bewertungen

- 312 Curtain WallDokument78 Seiten312 Curtain WallkalidindivenkatarajuNoch keine Bewertungen

- Grounding DetailsDokument5 SeitenGrounding DetailsAnonymous vcadX45TD7Noch keine Bewertungen

- Manna House: IndexDokument8 SeitenManna House: IndexroshancherryNoch keine Bewertungen

- InertiaDynamics ClutchCplng310s SpecsheetDokument2 SeitenInertiaDynamics ClutchCplng310s SpecsheetElectromateNoch keine Bewertungen

- Foundation Plan - Level 1: 2'-0" SLAB TOS - 5'-4" BOS - 7'-6"Dokument1 SeiteFoundation Plan - Level 1: 2'-0" SLAB TOS - 5'-4" BOS - 7'-6"Godino ChristianNoch keine Bewertungen

- Zurn Roof DrainsDokument50 SeitenZurn Roof DrainsAbdul Hakkim100% (1)

- Schletter Product Component ListDokument39 SeitenSchletter Product Component ListKirsten HernandezNoch keine Bewertungen

- Spare Parts CatalogueDokument46 SeitenSpare Parts Catalogueعبدالغني القباطيNoch keine Bewertungen

- Impact Sockets: Fractional Hexagon Metric HexagonDokument26 SeitenImpact Sockets: Fractional Hexagon Metric HexagonPieter van der WaltNoch keine Bewertungen

- 8ss1688 DownblastVentGuideDokument12 Seiten8ss1688 DownblastVentGuideoopman2002Noch keine Bewertungen

- Section E: EnclosuresindexDokument32 SeitenSection E: EnclosuresindexNMETETRNoch keine Bewertungen

- Multi-Nozzle Ceiling DiffuserDokument13 SeitenMulti-Nozzle Ceiling DiffuserLTE002Noch keine Bewertungen

- B O Q Summ 26-05-15Dokument275 SeitenB O Q Summ 26-05-15Nadim JilaniNoch keine Bewertungen

- Z Purlins TigerDokument9 SeitenZ Purlins TigerabuthahirNoch keine Bewertungen

- Fischer FBN AnchorsDokument23 SeitenFischer FBN AnchorsIstván SzékelyNoch keine Bewertungen

- One Steel ReoDataDokument40 SeitenOne Steel ReoDatapete0980100% (1)

- 250 SXS-F 2007: Spare Parts Manual: ChassisDokument28 Seiten250 SXS-F 2007: Spare Parts Manual: ChassischarlesNoch keine Bewertungen

- Spare Parts Manual: Engine: ART - NO.: 3CM089550MENDokument28 SeitenSpare Parts Manual: Engine: ART - NO.: 3CM089550MENcharlesNoch keine Bewertungen

- Taparia Hand ToolsDokument16 SeitenTaparia Hand ToolsshivaramNoch keine Bewertungen

- Mission S and W Dims and Curve Chart PDFDokument28 SeitenMission S and W Dims and Curve Chart PDFcaballero_tigreNoch keine Bewertungen

- Section PropertiesDokument4 SeitenSection PropertiesOng George SammyNoch keine Bewertungen

- Inertia Dynamic TypeFSB SpecsheetDokument4 SeitenInertia Dynamic TypeFSB SpecsheetElectromateNoch keine Bewertungen

- F#1203 SUNLITE Installation 5-06Dokument16 SeitenF#1203 SUNLITE Installation 5-06wolvewolverineNoch keine Bewertungen

- What's ?: Greenheck Quick Delivery Greenheck Quick DeliveryDokument136 SeitenWhat's ?: Greenheck Quick Delivery Greenheck Quick DeliveryAffendy KolotNoch keine Bewertungen

- 200 XC-W USA 2013: Spare Parts Manual: ChassisDokument36 Seiten200 XC-W USA 2013: Spare Parts Manual: ChassischarlesNoch keine Bewertungen

- Manual Instalare VAM - FADokument24 SeitenManual Instalare VAM - FAValentin MalihinNoch keine Bewertungen

- UntitledDokument4 SeitenUntitledAdam KnottNoch keine Bewertungen

- Perimeter Fence System Components Index: Page Date Naams Codes DescriptionDokument39 SeitenPerimeter Fence System Components Index: Page Date Naams Codes DescriptionjessicaNoch keine Bewertungen

- 2007 250SXFDokument43 Seiten2007 250SXFMartin ValderramaNoch keine Bewertungen

- York Fan Coil UnitDokument16 SeitenYork Fan Coil Unitjaja100% (3)

- Telephone Cabinet, Type 1: See Also AccessoriesDokument2 SeitenTelephone Cabinet, Type 1: See Also AccessoriesKevin Steven AsistinNoch keine Bewertungen

- Installation and Operating Instructions: Ventilated Silos D5.3 AND D7.5Dokument28 SeitenInstallation and Operating Instructions: Ventilated Silos D5.3 AND D7.5red patriotNoch keine Bewertungen

- Da 950068 002 PDFDokument1 SeiteDa 950068 002 PDFpremNoch keine Bewertungen

- 11 - 0 - Leaflet Z en C Profielen Version 2 - 4Dokument31 Seiten11 - 0 - Leaflet Z en C Profielen Version 2 - 4Amalia BistriteanuNoch keine Bewertungen

- Ex Junction BoxDokument26 SeitenEx Junction BoxMiky MooseNoch keine Bewertungen

- 250 XCF-W USA 2007: Spare Parts Manual: ChassisDokument28 Seiten250 XCF-W USA 2007: Spare Parts Manual: ChassischarlesNoch keine Bewertungen

- 250 XCF-W USA 2007: Spare Parts Manual: ChassisDokument47 Seiten250 XCF-W USA 2007: Spare Parts Manual: ChassisAndevha WygaNoch keine Bewertungen

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PVon EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNoch keine Bewertungen

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionVon EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNoch keine Bewertungen

- British Commercial Computer Digest: Pergamon Computer Data SeriesVon EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNoch keine Bewertungen

- The Environment in Which BA Is ConductedDokument17 SeitenThe Environment in Which BA Is ConductedAhmad Nabil ElsharkawyNoch keine Bewertungen

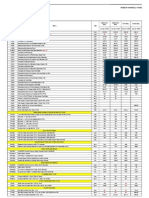

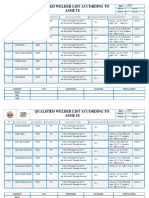

- Welder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Dokument1 SeiteWelder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Ahmad Nabil ElsharkawyNoch keine Bewertungen

- 01 Qulaity Control Plan - Asf QC QCP 001Dokument8 Seiten01 Qulaity Control Plan - Asf QC QCP 001Ahmad Nabil ElsharkawyNoch keine Bewertungen

- Plant Layout & Piping Design: PL L1 Basic MeduleDokument11 SeitenPlant Layout & Piping Design: PL L1 Basic MeduleAhmad Nabil ElsharkawyNoch keine Bewertungen

- 2019 Price List: Inspector (CAWI, CWI, SCWI) Certified Welding Educator (CWE)Dokument1 Seite2019 Price List: Inspector (CAWI, CWI, SCWI) Certified Welding Educator (CWE)Ahmad Nabil ElsharkawyNoch keine Bewertungen

- NDT - BookDokument142 SeitenNDT - BookAhmad Nabil ElsharkawyNoch keine Bewertungen

- Qualified Welder List According To Asme IxDokument5 SeitenQualified Welder List According To Asme IxAhmad Nabil ElsharkawyNoch keine Bewertungen

- Hindustan Petroleum Corporation Limited Tender: Piping Works Gresham HouseDokument6 SeitenHindustan Petroleum Corporation Limited Tender: Piping Works Gresham HouseAhmad Nabil ElsharkawyNoch keine Bewertungen

- Item # 11.1Dokument1 SeiteItem # 11.1Ahmad Nabil ElsharkawyNoch keine Bewertungen

- Moustafa C VDokument4 SeitenMoustafa C VAhmad Nabil ElsharkawyNoch keine Bewertungen

- 10 MT% 10 MT %: For Modification at Area Fe21Dokument1 Seite10 MT% 10 MT %: For Modification at Area Fe21Ahmad Nabil ElsharkawyNoch keine Bewertungen

- Ahmed Saeed Abd El-Mawgod AshoushDokument2 SeitenAhmed Saeed Abd El-Mawgod AshoushAhmad Nabil ElsharkawyNoch keine Bewertungen

- Top Coat Surface Preparation: Sigma Oil Services Surface Preparation and Painting ReportDokument3 SeitenTop Coat Surface Preparation: Sigma Oil Services Surface Preparation and Painting ReportAhmad Nabil ElsharkawyNoch keine Bewertungen

- Cristal E309L: MMA Electrodes Stainless and Heat Resistant SteelsDokument1 SeiteCristal E309L: MMA Electrodes Stainless and Heat Resistant SteelsAhmad Nabil ElsharkawyNoch keine Bewertungen

- GMAW of Stainless SteelDokument50 SeitenGMAW of Stainless SteelAhmad Nabil ElsharkawyNoch keine Bewertungen

- Elements Welding Symbol PierredostieDokument1 SeiteElements Welding Symbol PierredostieAhmad Nabil ElsharkawyNoch keine Bewertungen

- Java RingDokument22 SeitenJava Ringkanthu3Noch keine Bewertungen

- Technical Bulletin: Service Action: Incontrol Touch Pro Software UpdatesDokument11 SeitenTechnical Bulletin: Service Action: Incontrol Touch Pro Software UpdatesGheorghe OlarescuNoch keine Bewertungen

- 4 Embedded SystemsDokument49 Seiten4 Embedded SystemsAhmad AfzaalNoch keine Bewertungen

- B+V Manual - BVES-750 Hydr - 710000-Y-H-D Rev 002Dokument42 SeitenB+V Manual - BVES-750 Hydr - 710000-Y-H-D Rev 002Alan MaidaNoch keine Bewertungen

- Untitled DocumentDokument7 SeitenUntitled DocumentManikant PandeyNoch keine Bewertungen

- Unit-II Verilog HDLDokument62 SeitenUnit-II Verilog HDLsivneshvenkatesan01Noch keine Bewertungen

- PowerProtect DD - Data Domain Field Component Replacement-DD6400Dokument175 SeitenPowerProtect DD - Data Domain Field Component Replacement-DD6400Ra YuthNoch keine Bewertungen

- 883 MKII Illustrated Parts Catalog Revision 2Dokument311 Seiten883 MKII Illustrated Parts Catalog Revision 2Herdre Van Niekerk100% (1)

- Byte Con Fiden Tial Don Otc Opy: Model Name: Ga-H77M-D3HDokument34 SeitenByte Con Fiden Tial Don Otc Opy: Model Name: Ga-H77M-D3HAdi copycenterNoch keine Bewertungen

- Msi MS-7137 - Rev 1.3Dokument33 SeitenMsi MS-7137 - Rev 1.3Mauro CamiloNoch keine Bewertungen

- Microprocessor Systems & Interfacing EEE-342: Comsats UniversityDokument10 SeitenMicroprocessor Systems & Interfacing EEE-342: Comsats UniversityBilal HabibNoch keine Bewertungen

- Ovation Select OverviewDokument10 SeitenOvation Select OverviewMikeNoch keine Bewertungen

- 3 - Iet Progressa Software Upgrade InstructionsDokument12 Seiten3 - Iet Progressa Software Upgrade Instructionshoangphuc28497Noch keine Bewertungen

- Dokumen - Tips Acer h61h2 Am Manual h61h2 Amzip p5kpl Am Se 101grar Motherboard PC SchematicDokument2 SeitenDokumen - Tips Acer h61h2 Am Manual h61h2 Amzip p5kpl Am Se 101grar Motherboard PC SchematicM Nur Hatta100% (2)

- Wireless 3 Axis Magnetic Field Sensor Manual PS 3221Dokument6 SeitenWireless 3 Axis Magnetic Field Sensor Manual PS 3221djossNoch keine Bewertungen

- NXP Tech Session - Create Redundant Networks With TSN 802.1CBDokument14 SeitenNXP Tech Session - Create Redundant Networks With TSN 802.1CBMohammed AbuibaidNoch keine Bewertungen

- Appendix H (VR1250 Added)Dokument31 SeitenAppendix H (VR1250 Added)Nestor CamachoNoch keine Bewertungen

- MB Manual Ga-970a-Ds3 v.3.x eDokument44 SeitenMB Manual Ga-970a-Ds3 v.3.x eCristian CiobanuNoch keine Bewertungen

- Qualcomm® Qcs410/610 Socs For Iot: HighlightsDokument2 SeitenQualcomm® Qcs410/610 Socs For Iot: HighlightsPhú ĐỗNoch keine Bewertungen

- Comparison of Microsoft SurfaceDokument3 SeitenComparison of Microsoft SurfaceNurul FarahinNoch keine Bewertungen

- Catalog KeyboardDokument29 SeitenCatalog KeyboardRCINoch keine Bewertungen

- Reenry An Orbital Simulator Game ManualDokument40 SeitenReenry An Orbital Simulator Game ManualRandom PersonNoch keine Bewertungen

- Application Note Fan4213Dokument8 SeitenApplication Note Fan4213Matheus FalcãoNoch keine Bewertungen

- VTU ACA 6,7,8 Important QuestionsDokument2 SeitenVTU ACA 6,7,8 Important QuestionsReshma BJNoch keine Bewertungen

- Thank You For Watching This Video This Is A Short Review About Four of Best Laptop ComputersDokument11 SeitenThank You For Watching This Video This Is A Short Review About Four of Best Laptop ComputerskhalidkhanafridiNoch keine Bewertungen

- LG TV 2022 Product Profile - v1Dokument2 SeitenLG TV 2022 Product Profile - v1Quazi Anzer Shadani AbbasiNoch keine Bewertungen

- (HOWTO) Using GRUB As Bootloader (Second Stage After U-Boot)Dokument6 Seiten(HOWTO) Using GRUB As Bootloader (Second Stage After U-Boot)Soukous LoverNoch keine Bewertungen

- Buffering & SpoolingDokument5 SeitenBuffering & SpoolingPrasad ShitoleNoch keine Bewertungen

- Embedded Systems Nov 2022Dokument8 SeitenEmbedded Systems Nov 2022prasannasaimanasa jamiNoch keine Bewertungen

- Class 10icse Programming of String Function and If CaseDokument24 SeitenClass 10icse Programming of String Function and If CaseAryan KumarNoch keine Bewertungen