Beruflich Dokumente

Kultur Dokumente

Straight Joint

Hochgeladen von

dillehCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Straight Joint

Hochgeladen von

dillehCopyright:

Verfügbare Formate

500

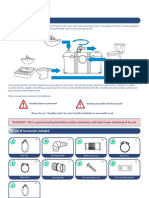

STEP 1

min

>

STEP 4

Cut

Yellow/brown

Connector

mastic

Cut

OVERLAP CABLES BY 500mm MINIMUM, MARK CENTRE LINE AND CUT AS PER DIAGRAM.

CLEAN CABLE SURFACES AND COVER WITH PLASTIC WRAP ABOUT 1.5m EACH SIDE OF THE CENTRE LINE.

PVC Tape

Fill all gaps

>

STEP 2

PVC Tape

WET WIRE BRUSH (ie UNDER A LIGHT FILM OF JOINTING COMPOUND) THE CONDUCTORS.

Screen wires

JOIN CONDUCTORS WITH THE APPROPRIATE CONNECTOR AND DIE, REMOVE ANY BURRS, AND THOROUGHLY

CLEAN OFF EXCESS GREASE FROM CONNECTOR AND CABLE INSULATION.

Screen wires

THOROUGHLY CLEAN THE CABLE INSULATION (SEE INSTRUCTION ON DRAWING S2-2-2-20) USING THE

Remove swellable tape to here

A

CLEANING PADS SUPPLIED IN THE JOINT KIT. DONT RE-USE PADS.

150

Remove swellable

DONT HANDLE THE INSULATION FROM NOW ON!

tape to here

400 sq.mm 11kV

CABLE

35 sq.mm 11kV

USING THE YELLOW/BROWN MASTIC TAPE, STRETCHING IT TO HALF ITS ORIGINAL WIDTH, FILL THE GAPS

95 sq.mm 11kV

240 sq.mm 11kV

35 sq.mm 22kV

120 sq.mm 22kV 240 sq.mm 22kV

BETWEEN THE CONNECTOR AND CABLE INSULATION, CONTINUING OVER THE CONNECTOR AND OVERLAPPING THE

CABLE INSULATION AT EACH END BY 5mm. DONT TOUCH THE MASTIC AFTER ITS APPLIED! DO NOT USE

DIM A mm

TERMIMESH SIPE

275

1000x250

325

275

325

1000x280

1100x300

TOO MUCH MASTIC. IF THE CONNECTOR DIAMETER IS GREATER THAN THE INSULATION DIAMETER ONLY A THIN

LAYER IS NEEDED. IF THE CONNECTOR DIAMETER IS SMALLER THEN USE ONLY SUFFICIENT TO MATCH THE

1100x320

CABLE DIAMETER. A SMEAR OF SILICONE GREASE ON YOUR FINGERS WILL PREVENT THEM FROM STICKING TO

REMOVE OUTER SHEATH, NYLON AND INNER SHEATH TO A DISTANCE A FROM THE CENTRE LINE OF THE LH

THE MASTIC.

CABLE, AND A + 150mm FROM THE CENTRE LINE OF THE RH CABLE.

BEND BACK THE LONG SCREEN WIRES OF THE LH CABLE AND SECURE WITH A SPIRAL WRAP OF PVC TAPE.

CHECK THAT ALL SURFACES ARE CLEAN (LOOK UNDERNEATH!) AND THAT NO DIRT OR MOISTURE CAN

DONT TAPE THE BEND DOWN - IT WONT STRAIGHTEN EASILY LATER. REMOVE WATER SWELLABLE TAPE.

CONTAMINATE THE INSIDE OF THE TUBES.

ON THE RH CABLE MARK THE SCREEN WIRES WITH A TEXTA AT A DISTANCE A FROM THE CENTRE LINE AND

CUT THE WIRES WITH SIDE CUTTERS. REMOVE WATER SWELLABLE TAPE. PVC TAPE OVER THE ENDS OF THE

WIRES.

STEP 5

PLACE THE LARGE OUTER HEAT SHRINK TUBE OVER THE LH CABLE. TEMPORARILY PLASTIC WRAP THE

SEMI-CON AND SCREEN WIRES ON THE RH CABLE AND CAREFULLY PARK THE INNER JOINT SLEEVE SET.

>

COVER THE PARKED TUBES WITH PLASTIC WRAP UNTIL NEEDED.

STEP 3

>

A

90

A

X

90

Stress control

tube(black)

Large outer tube

Inner joint

PLACE THE BLACK STRESS CONTROL TUBE CENTRALLY OVER THE JOINT. STARTING AT THE CENTRE SHRINK THE

sleeve set

TUBE TOWARDS ONE END AND THEN TOWARDS THE OTHER END UNTIL FULLY SHRUNK. APPLY HEAT EVENLY

CUT CABLES AT THE CENTRE LINE.

THROUGHOUT THE PROCESS.

CAREFULLY REMOVE SEMI-CONDUCTIVE SCREEN (SEE INSTRUCTION ON DRAWING S2-2-2-21) FROM BOTH

WHEN COMPLETED ADHESIVE WILL FLOW FROM THE ENDS, WIPE OFF EXCESS.

CABLES TO THE DIMENSIONS SHOWN.

Dont stop for smoko now!

REMOVE INSULATION FROM CONDUCTORS FOR A DISTANCE X EQUAL TO HALF THE CONNECTOR LENGTH +

5mm. CUT A 3mm (MAX) BEVEL ON THE INSULATION ENDS.

1

NO

JOINT KIT STOCK CODES - REFER DRAWING S2-1-2-3

COMPRESSION LINKS

FOR STEPS 6-11 SEE DRG S2-2-2-24

SUPERSEDED

DESCRIPTION

AMENDMENTS

A.T. DEC12 B.C. B.C.

DRN

DATE

CKD

APPD

NORTHERN TERRITORY

DES

DRN

J.A.L.

CKD

A.T.

APPD

P.J.D.

SCALE

N.T.S.

ISSUED

DEC95

ALL DIM. IN mm

- REFER DRAWING S2-2-2-17

POWER STANDARD DRAWING

CABLE JOINTING & TERMINATIONS

SIGMAFORM JOINTING INSTRUCTIONS (SHEET 1 OF 2)

11/22kV XLPE CABLE

A3

DRAFTING STANDARD TO A.S.1100

DRAWING

NUMBER

S02-2-2-23

CAD PRODUCT - DO NOT AMEND MANUALLY

1

AMDT

Das könnte Ihnen auch gefallen

- Weatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundVon EverandWeatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundNoch keine Bewertungen

- DTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionDokument10 SeitenDTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionMuhammad Lathieful HaqNoch keine Bewertungen

- ISTRCSSJ25ENGDokument6 SeitenISTRCSSJ25ENGHector Vidal Rodriguez ValdezNoch keine Bewertungen

- Method Statement For 33 KV Cable Termination Size 3x300sqDokument3 SeitenMethod Statement For 33 KV Cable Termination Size 3x300sqbutunsona60% (10)

- Method of Statement For Cable TerminationDokument2 SeitenMethod of Statement For Cable TerminationNagaraj Vj100% (1)

- WEC SensorInstructions PDFDokument14 SeitenWEC SensorInstructions PDFthouche007Noch keine Bewertungen

- Installation Instructions UTERMKIT Mk3Dokument4 SeitenInstallation Instructions UTERMKIT Mk3aleloc2000Noch keine Bewertungen

- De Pura DoraDokument53 SeitenDe Pura DoraKenneth BlackNoch keine Bewertungen

- 33kV Jointing Manual Section 4Dokument84 Seiten33kV Jointing Manual Section 4Egbodor PeterNoch keine Bewertungen

- Drain Pipe Work of Indoor UnitDokument24 SeitenDrain Pipe Work of Indoor UnitMiguel AbuegNoch keine Bewertungen

- Cl20702 705 Manual Mup HiDokument33 SeitenCl20702 705 Manual Mup HiRamadan RashadNoch keine Bewertungen

- Assembly Instructions For Cable Gland: 755 32R4: Connection SolutionsDokument4 SeitenAssembly Instructions For Cable Gland: 755 32R4: Connection Solutionspvalverdea2014Noch keine Bewertungen

- Split Air Conditioner Wall Mounted Type Service Manual: AUS-07C (H) 53R010Lx AUS-07C (H) 53R150Lx AUS-09C (H) 53R150LxDokument42 SeitenSplit Air Conditioner Wall Mounted Type Service Manual: AUS-07C (H) 53R010Lx AUS-07C (H) 53R150Lx AUS-09C (H) 53R150Lxanon_226950787Noch keine Bewertungen

- Stratco Gutters Overflow SolutionsDokument8 SeitenStratco Gutters Overflow SolutionsMoamar TaratinganNoch keine Bewertungen

- How The PVI - Pro Video Instruments Makes Their HDMI COAX Modulators - Made in USA ScamDokument60 SeitenHow The PVI - Pro Video Instruments Makes Their HDMI COAX Modulators - Made in USA ScamTrue SeekerNoch keine Bewertungen

- Installation Instructions: Full Size Tumble Action WashersDokument12 SeitenInstallation Instructions: Full Size Tumble Action WashersGabriel Alexandru GhitaNoch keine Bewertungen

- Cac Buoc Lam Dau Cap Trung TheDokument12 SeitenCac Buoc Lam Dau Cap Trung ThevuhalongNoch keine Bewertungen

- Installation Instructions: Lower Termination Instructions For LTERMKIT-Mk3 For HVSC PlusDokument3 SeitenInstallation Instructions: Lower Termination Instructions For LTERMKIT-Mk3 For HVSC PlusWelmi AfdalNoch keine Bewertungen

- En Maflowrap Application GuidelinesDokument2 SeitenEn Maflowrap Application Guidelinesnilanga123Noch keine Bewertungen

- Owner'S Guide: Hayward Pool Products, IncDokument2 SeitenOwner'S Guide: Hayward Pool Products, IncASHRAFELZONFOLYNoch keine Bewertungen

- This Paper Elaborates On The Various Methods of Cable Laying and The Advantages and Disadvantages of The SameDokument15 SeitenThis Paper Elaborates On The Various Methods of Cable Laying and The Advantages and Disadvantages of The SamesamsungloverNoch keine Bewertungen

- US-EZ Culligan ManualDokument7 SeitenUS-EZ Culligan ManualCarliko FafernerNoch keine Bewertungen

- BMT 963 Cleaning InstructionsDokument2 SeitenBMT 963 Cleaning InstructionsBİROL ÖTERNoch keine Bewertungen

- Esp Running ProceduresDokument12 SeitenEsp Running ProceduresAhmedMohsenNoch keine Bewertungen

- Instruction C02 78.3Dokument4 SeitenInstruction C02 78.3ВиталийКрутиковNoch keine Bewertungen

- 55 Watt Gas CO2 Laser TubeDokument66 Seiten55 Watt Gas CO2 Laser TubeFitzwalter100% (1)

- Instructions Guide To InstallationDokument4 SeitenInstructions Guide To InstallationIvan BriscoeNoch keine Bewertungen

- PAL - Construction GuidelinesDokument28 SeitenPAL - Construction GuidelinesCarew Mohammed AbayomiNoch keine Bewertungen

- Terminal Con Copa 3M Cold Shrink QT-III 769X-S-4 KitsDokument20 SeitenTerminal Con Copa 3M Cold Shrink QT-III 769X-S-4 KitsEnrique G.Noch keine Bewertungen

- Methodology For PSC GirdersDokument5 SeitenMethodology For PSC GirdersvnilNoch keine Bewertungen

- 11 KV 92-Ogxxx-3 Pilc To PilcDokument5 Seiten11 KV 92-Ogxxx-3 Pilc To PilcRa'fat HerzallahNoch keine Bewertungen

- Jointing Instructions Dec 20123Dokument2 SeitenJointing Instructions Dec 20123Gabi CristacheNoch keine Bewertungen

- Model: DWF-5510/5511 5520/5521 6010/6011 6020/6021: Instruction ManualDokument17 SeitenModel: DWF-5510/5511 5520/5521 6010/6011 6020/6021: Instruction Manualvio99usNoch keine Bewertungen

- 2010 11-05-14 STOPAQ Training PresentationDokument21 Seiten2010 11-05-14 STOPAQ Training Presentationalfreddieick1Noch keine Bewertungen

- Esd 4873 Au 5 - 09 PDFDokument13 SeitenEsd 4873 Au 5 - 09 PDFGeorge IstrateNoch keine Bewertungen

- Jointing Manual: XLPE CablesDokument21 SeitenJointing Manual: XLPE CablesGustavo OliveiraNoch keine Bewertungen

- Empalme 750 MCMDokument6 SeitenEmpalme 750 MCMEfren Rosales SarabiaNoch keine Bewertungen

- Method Statement - Cable Joint LVDokument4 SeitenMethod Statement - Cable Joint LVanuraj arackal60% (5)

- CMP TMCX Installation Fitting Instructions FI280 Issue 6 0210Dokument18 SeitenCMP TMCX Installation Fitting Instructions FI280 Issue 6 0210raviNoch keine Bewertungen

- Strip Coupon HolderDokument2 SeitenStrip Coupon Holderwhah11Noch keine Bewertungen

- Metcal MX DS1 User GuideDokument70 SeitenMetcal MX DS1 User GuideGameBooy2020Noch keine Bewertungen

- Manual Daewoo 5510Dokument18 SeitenManual Daewoo 5510Ioan LiviuNoch keine Bewertungen

- Lý thuyết màng thẩm thấu ngược (tiếng Anh)Dokument111 SeitenLý thuyết màng thẩm thấu ngược (tiếng Anh)BajaminhNoch keine Bewertungen

- AI316Dokument4 SeitenAI316pvalverdea2014Noch keine Bewertungen

- CM 132Dokument22 SeitenCM 132Leo HiddenValleyNoch keine Bewertungen

- Side Entry Sub: AdvantagesDokument2 SeitenSide Entry Sub: AdvantagesDaniel GuerrreroNoch keine Bewertungen

- Cassette: Sunline HydroDokument8 SeitenCassette: Sunline HydrojesNoch keine Bewertungen

- Andrew Coaxial Cable Installation Instructions-Bulletin 17800BDokument8 SeitenAndrew Coaxial Cable Installation Instructions-Bulletin 17800BMike FixNoch keine Bewertungen

- SanibestDokument8 SeitenSanibesth8banksNoch keine Bewertungen

- Auya30lblu - Aoya30lbtl - InstallDokument2 SeitenAuya30lblu - Aoya30lbtl - InstallpepondeAvilesNoch keine Bewertungen

- Trane Mini Split Normal InstalacionDokument12 SeitenTrane Mini Split Normal InstalacionAnonymous ApjtcZ6YT6100% (1)

- Methodology For Stressing of PSC Girders (C)Dokument2 SeitenMethodology For Stressing of PSC Girders (C)HegdeVenugopalNoch keine Bewertungen

- Methodology For Stressing of PSC Girders (C)Dokument2 SeitenMethodology For Stressing of PSC Girders (C)VB665Noch keine Bewertungen

- Sewage Disposal Works: Their Design and ConstructionVon EverandSewage Disposal Works: Their Design and ConstructionNoch keine Bewertungen

- Ultimate Guide: Wiring, 8th Updated EditionVon EverandUltimate Guide: Wiring, 8th Updated EditionBewertung: 3.5 von 5 Sternen3.5/5 (4)

- System Model in ViewDokument5 SeitenSystem Model in ViewdillehNoch keine Bewertungen

- BI Simulation QNDokument2 SeitenBI Simulation QNdillehNoch keine Bewertungen

- Power Flow Through A Transmission Line - EEEGUIDEDokument8 SeitenPower Flow Through A Transmission Line - EEEGUIDEdillehNoch keine Bewertungen

- 27 Atco Electric - Harmonic StudyDokument29 Seiten27 Atco Electric - Harmonic StudydillehNoch keine Bewertungen

- Mastering Excel To Save Precious TimeDokument33 SeitenMastering Excel To Save Precious TimedillehNoch keine Bewertungen

- Lecture 03 PS OLDiagramDokument23 SeitenLecture 03 PS OLDiagramdillehNoch keine Bewertungen

- Catalogo BT 2011 ENG PDFDokument258 SeitenCatalogo BT 2011 ENG PDFAhmad HamoudaNoch keine Bewertungen

- 12 SDMS 01rev3Dokument16 Seiten12 SDMS 01rev3Dipak VaghelaNoch keine Bewertungen

- Pushrod Cable Retermination Guide enDokument60 SeitenPushrod Cable Retermination Guide enMatias Alfredo Contreras Köbrich100% (1)

- Instrumentation For Concrete StructuresDokument306 SeitenInstrumentation For Concrete StructuresAsier Castaño100% (1)

- Fibre OpticDokument16 SeitenFibre OpticJoanna BaileyNoch keine Bewertungen

- Pfisterer Inner Cone PlugsDokument80 SeitenPfisterer Inner Cone PlugsayemyothantNoch keine Bewertungen

- SSP 646 - EN - Audi A4 (Type 8W) - Vehicle Electrics and ElectronicsDokument72 SeitenSSP 646 - EN - Audi A4 (Type 8W) - Vehicle Electrics and ElectronicsIngwarNoch keine Bewertungen

- Jupiter TP Series Connectors PDFDokument26 SeitenJupiter TP Series Connectors PDFSid Io100% (1)

- SAE J1939-15-1999.Reduced Physical Layer, 250kbit UTPDokument21 SeitenSAE J1939-15-1999.Reduced Physical Layer, 250kbit UTPАлександр Кукушкин100% (1)

- Raychem Saudi Arabia Ltd. High Voltage, Medium Voltage & Low Voltage Cable Joints, Termination Kits & Heat Shrinkable TubingDokument4 SeitenRaychem Saudi Arabia Ltd. High Voltage, Medium Voltage & Low Voltage Cable Joints, Termination Kits & Heat Shrinkable TubingGIBUNoch keine Bewertungen

- Trusted Technology, Reliable Protection and Insulation.: 3M Heat Shrink Tubing and DevicesDokument48 SeitenTrusted Technology, Reliable Protection and Insulation.: 3M Heat Shrink Tubing and DevicesJan sandi FloresNoch keine Bewertungen

- 12-SDMS-01 Cable Joints, Terminations, And. Accessories PDFDokument16 Seiten12-SDMS-01 Cable Joints, Terminations, And. Accessories PDFMehdi SalahNoch keine Bewertungen

- Heat Shrink Selection Guide hssg02Dokument5 SeitenHeat Shrink Selection Guide hssg02prashanth kandulaNoch keine Bewertungen

- Illustrated Assembly Manual k4040 Rev1Dokument28 SeitenIllustrated Assembly Manual k4040 Rev1Gabriel TanaseNoch keine Bewertungen

- Underground Secondary Cable & ConnectionsDokument33 SeitenUnderground Secondary Cable & ConnectionsAnonymous hRePlgdOFrNoch keine Bewertungen

- Battery & Array Cables & ConnectorsDokument4 SeitenBattery & Array Cables & ConnectorsSteven BurnsNoch keine Bewertungen

- 8W - 01 Wiring Diagram InformationDokument14 Seiten8W - 01 Wiring Diagram InformationPunchis PanchisNoch keine Bewertungen

- Jeep XJ Cherokee 1998 System Wiring DiagramsDokument582 SeitenJeep XJ Cherokee 1998 System Wiring DiagramsRafael Pertile Carneiro71% (7)

- Coil Gun Object Detect MethodDokument46 SeitenCoil Gun Object Detect MethodshawnleegabrielNoch keine Bewertungen

- 3m Elecrical Full Line CatalogueDokument84 Seiten3m Elecrical Full Line Cataloguevivek jayswalNoch keine Bewertungen

- 3M Electrical Scotch Tapes BrochureDokument12 Seiten3M Electrical Scotch Tapes BrochureKatamba RogersNoch keine Bewertungen

- Cold Shrink Technology For CablesDokument8 SeitenCold Shrink Technology For Cablesnitin369Noch keine Bewertungen

- Astm10 1002Dokument6 SeitenAstm10 1002Jean CarlosNoch keine Bewertungen

- Chrysler Voyager Town Country 1997 Wiring DiagramDokument20 SeitenChrysler Voyager Town Country 1997 Wiring Diagramcatherine100% (40)

- Heat-Shrinkable Tubing (WCSM) : Heavy Low Voltage Insulation and Outer Sealing TubingsDokument2 SeitenHeat-Shrinkable Tubing (WCSM) : Heavy Low Voltage Insulation and Outer Sealing TubingshenriquezrsNoch keine Bewertungen

- Steinel - Heat Gun HandbookDokument14 SeitenSteinel - Heat Gun HandbookHewa PCNoch keine Bewertungen

- Electrical Wiring Material List With PicturesDokument140 SeitenElectrical Wiring Material List With PicturesMuhammad AzriNoch keine Bewertungen

- Pico Wireing CatalogDokument64 SeitenPico Wireing CatalogSheaNoch keine Bewertungen

- Instruction Manual Pygmy Current Meter Model Oss-Pc1: Hyquest Solutions Pty LTDDokument17 SeitenInstruction Manual Pygmy Current Meter Model Oss-Pc1: Hyquest Solutions Pty LTDTomás Londoño GarcíaNoch keine Bewertungen

- Electronic Mainternance 1981Dokument180 SeitenElectronic Mainternance 1981Hoa Nguyen VanNoch keine Bewertungen