Beruflich Dokumente

Kultur Dokumente

1908 - June 23

Hochgeladen von

Tom Bates0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

5 Ansichten9 Seitenpower plant book from june 1908

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenpower plant book from june 1908

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

5 Ansichten9 Seiten1908 - June 23

Hochgeladen von

Tom Batespower plant book from june 1908

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 9

Tune 23, 1968

POWER AND THE ENGINEER.

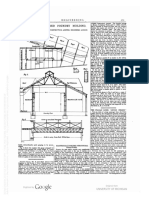

A Simple Turbine Plant in New England

‘A Decidedly Interesing Installation in Which the Turbines Are

Practically the Only Apparatus to Be Seen in the Engine Room

‘The remark that has been made of some

turbine installations, that “it is hard to

find the turbine among the auxiliaries,”

certainly does not apply to the Curtis in

sallation atthe mills of the Nashua Man-

tfacturing Company, at Nashua, N. H.

The relative levels of the canal and river

are such that water will flow tothe barom-

frie condenser without pumping, while

the condenser head is far enough sbove

“This set i also run at night for maintain-

ing veatchman’s lights throughout the

factory and for lighting the boiler and

engine rooms. Through the day excita-

tion is furnished by the as-kilowatt induc-

tion-motor generator set, shown at the

ght in Fig. 2 and in the foreground in

Fig. 3

Fig. 4 is a view in the basement, show-

jing the 18-inch exhaust main leading

the step, the surplus oil being by-passed.

Contintity of operation is therefore not

endangered by a possible slowing down of

the pump to a point where it might stp.

With this arrangement and the duplicate

pump ready for immediate service, the

probability of interruption to the supply

fof oil to the step is so remote that in the

opinion of Charles H. Austin, the designer

fof the plant, the accumulator would be

the river to give the fall required for i

discharge against atmospheric pressure.

‘The only auxiliary required, therefore, is

the step-pump, which is located in the

basement, leaving in the turbine room

nothing but the turbines, the two ex-

citers and the switchboard.

‘The turbine sets consist of two s00-kilo-

watt Goo-volt three-phase anits, shown

from different positions in Figs.'r and 2

‘The later figure shows also in the fore-

‘ground the 25-kilowatt Curtis turbine

driven exciter set need in starting. up.

ont from the turbine to the condenser,

‘which stands outside the wall toward

Which the camera was pointed when this

View was taken, and which is shown from

the outside in Fig. 5

‘The turbines stand upon substantial

brick foundations, circular in form. The

step-pumps occupying the center of Fig.

4 are Worthington duplex pumps of the

pot-valve type, installed in duplicate. No

sccumulator is used, nor automatic regula

tion for the pumps, which are run at a

speed greater than that required to feed

an unwarranted complication of a beauti-

fully simple outfit

The oil-cooling and ‘fitering tank is

shown in the background of Fig. 4 while

fon the brick pier at the right are the

theostat grids operated by shafts from the

Switchboard immediately above,

The condenser is a Manning-Bulkley,

No des-vacwsm pump is used, nor any

special provision ‘made for expelling the

air, but a vacuum of between 28 and 29

inches is easily maintained. The canal

level ig 7 feet Below the neck of the con-

POWER AND THE ENGINEER.

Jane 23, 1908

FIG, 3. SHOWING SWITCHBOARD AND MOTOR-GENERATOR IN NASHUA PLANT

denser, and the hot-well is 34 feet below

the neck, with a fall of about § feet from

‘the hotwell to the river.

‘The initial installation of one turbine

wwas made between two and three years

ago and proved s0 satisfactory that it

was duplicated to meet the increasing de-

mand for power. The first unit-was taken

apart and examined after being in service

for two and a half years, running ten

hours per day, and was found in excellent

condition, no signs of corrosion or erosion

‘ia, 5, VIEW oP CONDENSER

‘upon the blades, although the

steam is not superheated

fies considerable: mois

Tune 23, 1908.

Power Plants for Sawmills

By W. J. Buckwun

‘The choice now open to the proprietors

‘of sawmill, as to what power they shall

buy, is a very perplexing one, and often

Aeads to disappointment. So’ many men

are ready to fornish details of what they

‘can do with certain plants and of what

Title power is needed to drive certain ma-

chines, that not only are sawmill proprie-

tors led into dificulties, but engineers are

also led astray a8 to the requirements of

‘woodworking machinery.

For instance, take two sawmills; there

‘may be the same number of machines in

‘each, but the probability is that the power

taken by each mill varies by some 30 per

‘cent, oF in another case a mill in which

the machines are worked lightly will con-

POWER AND THE ENGINEER.

question as to whether it would be best

to drive a ie

Waren Power Paacricatty ELrnerearea

In England the question of water power

does not come into the problem: in Amer~

iea itis now almost a matter of whether

the mills are required for season work,

fr throughout the year. In most eases,

though, even in the States, the power of

the sawmill if now confined to either

steam, suction gas or electricity

Tt may be said that this problem of

power is the same in every industry, and

that in four mills, factories and other

places, the proprietors are seriously de-

ating as to which it the most reliable

and cheapest power. The sawmill, how-

fever, is distinetly diferent, as very few

industries make’ suficlent, refuse from

their work to supply them with the neces-

sary fuel for producing’ power. This does

‘sume about half the power needed in one

‘which is hard-driven

All this was of no importance a few

years ago. The engineer could make a

‘ough estimate of the power required by

the machines and allow a good margin for

any excess; then order a power plant

which would cover all these requirements

‘This was straightforward sailing, and the

‘worty of underestimating did ‘not enter

{nto the calevlation of the engineer

Today, things In most

‘cates the sa

‘power plant which

Hee is not eager to have any excess or re

‘serve power. If he intends to arrange for

fature development of his business, he

proposes to put down other power.

‘Take the case of a man stating a mil

‘The engineer is ealled upon to say what

it shall be. What are the advantages of

Steam, reciprocating or turbine, or both?

“What are the advantages of a suction-gas

‘plant for a sawmill? "Then the ever ready

(4 VIEW IN BASEMENT, SHOWING STEE-PUMES AND I8-INCH EXHAUST MAIN

rot mean that a sawmill must of necessity

be driven by steam, but only as 2 result

of the working of the mill there must be

refuse which is good fuel and should be

used if it does not cost t00 much for its

collection,

‘At present, then the three powers which

are competing for the driving of a saw-

‘mill are: Steam, gas and elects

‘The steam engine holds its place in

many cases because it was installed be-

fore the gas engine was an ecient power

producer, and because it was in the mill

before the days of electricity. The en-

sine and boiler have perhaps worn un

equally. The engine has been completely

overhauled; then a new boiler took the

place of the old one; then the engine was

replaced by a new-one, so that the mill

will then have a new engine and a boiler

half worn out. So it may be continued

indefinitely. This is no “fairy story.” but

many engineers have had just such ex-

periences

os

Such concems which are owned by men

‘who will not scrap half-worn-out tools to

replace them with a new set, can never be

expected to be entirely up-to-date. Their

tools will always be a generation behind.

With a gas engine this half renewal of

1 plant would not occur; all of it would be

removed if old and unserviceable, and the

power plant could then be made modern.

‘These little details, which are often un

noticed, tend to make the gas engine

fuch a serious rival to steam and elec-

tricity.

Evecrncry

‘The reverse of those feelings which

prompt a man never to renew his plant

luntil it ie condemned actuates the owner

who is keenly alive and desirous of mov-

ing with the times to want electricity.

Electricity isin the ai, and is sign that

the owner of a mill driven by electricity -

tas no second-rate, obsolete machines, but

i right up-to-date. This has been the

‘ase in many instances, and some of these

sawmill proprietors, in. gratifying. theit

whims for “up-to-dateness," have been

badly burnt

Electricity has its advocates as well as

gas and steam, and it would be wrong to

Say that itis not a capital power for some

sawmills, Tt is, but in many cases it is

fot. Fitst and foremost, it depends on

what you have to pay for electricity, and

What kind of work you intend to do in the

vil

‘The engineer who rashes in and advises

the sawmill proprietor to use electricity

because it will save power lost in trans-

mission, because it will enable him to

place the machine regardless of any Tine

fof shaftng, is not counting all the costs,

and is not fully aware of all the facts of

the ease

To understand fully when and why

electricity should be’ recommended, it

Would be best to state a case in which it

would be possible to get good results from

this power. Take a saw or joinery mill in

which the power is used in various build-

ings placed considerable distances apart.

Most of the machines are used but for

lite time, and there is power required

the piling and stacking yards. In this

case electricity can be “used advanta-

‘geously. It would save an enormous amount

of shafting, and would also save an enor-

mous amount of power which. would be

required to tura this shafting. Unless an

elaborate system of grouping is planned,

and in many mills planning is the excep-

tion and not the rule, electricity would

sive good results compared with other

powers. A cable carrying the current is

better than revolving shafting, and only

power used would be charged for. This

is the ideal condition for electricity as a

power for driving a mill; the reverse

would be a8 follows:

‘Ail in which there is but a short line

of shafting, and from this is driven heavy

sawmill machinery which is kept hard at

974

work. If the machines were driven by

cleetricity, the number of units consumed

would be enormous, much more than

either steam or gas. "Here, then, the con

tice with regard to the powers that could

bbe economically used, would be between

the steam or gat engine, Before pro-

ceeding, it should be recognized that when

electricity is mentioned, it does not apply

to such as ean be obtained at Niagar

with its phenomenally cheap electricity,

bout to ordinary towns where electricity is

sold from 154 to 4 cents per unit for

power.

‘When asked for his decision as to the

best power for a proposed mill, the frst

thing’ for the engineer to ascertain is the

value of trade refuse in that particular

town, In some cases the refuse in «mill

will more than pay the fuel bill

Gas Powes

For cleanliness and to lessen the risk

of fire, series of gas engines is by far

the best outit for 2 sawmill, It is poor

economy to make a large-sized mill de-

‘pend upon one power producer. A hitch,

perhaps, in some insignificant part and the

whole plant is idle for hours. Besides, it

5 not possible with a single large gas en-

sine to obtain that grouping of machin-

cry which gives the best results.

Without going into detail, it might be

mentioned that the shafting can be driven

by separate engines, arranged so that they

canbe easily connected by means of

clutches. “A gas engine is almost as self-

contained as an electric motor, and it does

not require continuous watching. A litle

skilful planning would soon effect a way

by which these engines could be arranged

to work separately or conjointly. Indeed,

this problem is one sehich ean be so easily

solved that it need not enter into com-

sideration

There is another problem, however,

which may present itself to the engineer

who has to arrange power for a sawmill,

It is presumed that the owner isi favor

cof a gas plant; that modem gxs producers

and engines ate to be installed; then it is

remembered that a drying kiln for dry-

ing timber will require steam for heaters.

[At once the questions are raised: Why

have two distinct powers in the mill? Why

have a boiler for the kiln and gas for the

‘engines? Here is a possibility of further

the power of the engines. There

are several apparates upon the market for

utilizing the waste gases from the engines

to raise suficient steam for use in a dry

ing kiln. Here, then, is the answer to the

‘questions. The gas engines work the mill,

and the exhaust gases raise sficient

steam for the drying kiln. This arrange-

ment is satisfactory in those ills in

Which the trade refuse is sold or cleared

away: where it is not, then the great

Argument in favor of ‘steam power has

mach weight. Te should also. beim

Pressed upon gas-engine makers how this

fefuse from mills prevents. the sawmill

“answered,

POWER AND THE ENGINEER.

trade from giving universal support to

the gascengine people.

One or to gas-engine makers adver-

tise that their suction-gas plants can be

fed with chips and sawdust, and a short

time ago a French firm was very jubilant

over the fact that they had solved the

problem of successfully using mill refuse

for suction-gas plants. Still the results

were not published in any timber trade

paper, and the results of the experiments

have up to the present been kept 2 great

secret. Tt should be along the lines of

‘tiling wood waste in the production of

fas that the gas-engine maker should de-

Yelop his product, s0 that the fuel cost to

the sawmill ovener will be practically nil

Apvavracss oF Steaw: Power

‘Taking steam a5 a power for sawmills,

this result of obtaining power at the cost

fof upkeep and supérvision of the plant is

boeing realized, There are many mills which

are being run solely upon the fuel ob-

tained from the mill The waste from the

machines is sufficient, not only to. pro=

Vide efficient power, but also reserve

power. In this ese, the question of which

fs the cheapest power for a sawmill, is

Te is steam, when itis properly

‘made and utilized,

‘The question of which gives the highest

percentage of power, the steam oF gas en

kine, does not enter into consideration,

‘The gas engine may have the high per-

centage of 17 and the steam only 11, still

the fact remains that under existing’ cob-

ditions chips and sawdust will give the

percentage of 11 at a nominal cost. With

4 gas engine the chips and sawdust are

not available for power production, s0

the high percentage of 17 per cent. has

to be made by other fuel, and the mill

‘owner is still left with his waste.

Tt is often pointed out that many mills

are run by steam, sell the waste, and still

the cost of upkeep exceeds that of a gas-

driven plant.” This often ocedrs, and the

cause it not far to seek. The engines

land boilers are not the best of their type,

and they do not have all the auxiliaries

recessary to obtain the best results from

a steam plant

A savenll which isto be run at « nomi:

1 low cost for power, must have boil-

ers with large-areas of heating surface and

high-pressure steam and. condensing en-

ines. The furnaces must be arranged t0

that there is a minimum of Jabor attached

to feeding them, and. special appliances

used if the wood chips or dust are wet or

green. This would mean that an arti-

ficial draft apparatus must be used, but

with ordinary wood, chips or dust this is

fot at all necessar:

Given ample furnace room, or for that

matter one of the many patent furnaces

for burning wood waste there should be

no diffieslty in obtaining plenty of power

for driving the engine. A necessary addi

tion to this plant isan installation for cot-

lectin the 2 waste from the ma

Jue 23, 1908,

chines and blowing them into the furnace.

All hese appliances are necessary to thor-

‘oughly equip a mill so that its power cost

is simpy that of attendance and upkeep

‘Taking all the powers into consideration

and examining ‘the various conditions

tunder which they may be worked, steam

is by far the cheapest and the most re-

Table of the three powers for this indus

tty. But it requires every essential for

obtaining the greatest. power from the

fuel, and it is necessary that the collec-

tion of the waste does not cost more than

the interest of the money invested in the

collecting apparatus.

The Water Powers of the World

‘The Reve Electrigue has just published

summary of the water powers of the

world. The possible horse-power of

France is estimated at 4500000, of which

‘only Sooo00 is utilized. The region

fof the Alps is the most abundant. About

fan equal amount of power is available in

italy, but only 300200 horse-power

atid. Falls of 10000 horse-power are

abundant. ‘The estimate for Switzerland

is incomplete. About 300000 horse-power

js in use. Germany has 700000 horse

power available, with 109000 applied. Nor

‘way has g20900 horse-power available,

with a large part already developed. In

Sweden there is 763000 horse-power

available, but mostly at a considerable dis-

tance from any industrial center. In

Great Britain there is 79000 horse-power

already utilized, and an equal amount in

Spain, The resources of Russia are esti-

rated 48 11,000,000 horse-power, of which

fso00 has been developed. The United

States i credited with 1300000 horse

power utilzable, Japan has 1,000,000, of

‘which 70000 has been exploited and inthe

Indies "so000.horse-power has already

been developed

American Institute of Electrical

Engineers’ Convention

‘The twenty-fifth annual convention of

the American Institate of Electrical Engi-

neers will be held at Atlantic City, N. J,

Jane 29 to July 2. The headquarters will

ibe at the Hotel Traymore. A reception

and dance will be given at that hotel

Monday evening, June 29, and a tea at the

Atlantic City Golf Club, Tuesday after-

rnoon. These will be the only format

functions of the convention,

‘The United States Civil Service Com-

Imizsion announces an examination on

July 8 to secure eligibles for the postion

‘of engineer in the mint at Denver, Colo,

at $425 per day. Application forms 1600

land 1093 will be required

Jane 23, 1908.

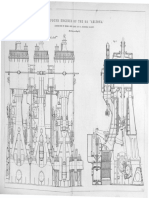

‘A Southem Railway Plant

By Jawes F. Muss

Until recently the citizens of the old-

cat city in the United States have not had

the convenience of electric light and trans-

portation. ‘The St. Johns Light and

Power Company, of St. Augustine, Fla,

hhas recently completed at that ety an up-

to-date power plant, the dimensions of the

rain building being 97 by 87 feet. This

‘of concrete and

piling for foundations driven

walls, engines, boilers and stack.

ion,

for all

Enaie-roow Equiraent

‘The equipment of the engine room is

‘One r2xaj-ineh Reliance

POWER AND THE ENGINEER.

ric. 1. St, JOHNS LIGHT AND POWER PLANT

é f

Corliss engine diect-connested to a 100"

Kilowatt Bullock railway generator, re-

volving at 1s revolutions per minute;

‘one 18x30-inch engine directconnected to

a 2gprkilowatt, 2300-volt, Go-ycle, three-

phate Bullock alternator with speed of 120

evolutions per minute; one. 18x36x30-

inch Reliance eross-compound engine, di-

ctconnected to a agokilowatt, 2300+

volt, 6o-cycle, three-phase Bullock alter-

nator at 120 revolutions per minute, and

‘one go-kilowatt motor-generator set. There

is alsor a foundation for a. 3g0-kilowatt

cross-compound unit to be installed in the

future. Excitation of alternators is ob-

tained from separate direct-current gene-

‘ators belted from the main shafts

Tn the engine-room basement is a 2400-

foot surface condenser, and one 12x20x18-

finch vacuum pump and a 16-inch G. M.

Davis automatic relief valve gives free

exhaust

densing outit. Condensing water is sup-

7s

plied by a to-inch main from an artesian

well 535 feet deep, with a 12-pound pres-

Sure and a flow of 3.000000 gallons in 24

hours. With condensed steam returned

to the hot well at 120 degrees Fahrenheit,

26 inches of vacuum is easily maintained.

Each engine has a Cochrane separator

and Davis traps discharging condensation

to the hot-well

‘The switchboard is of white marble,

and was erected and wired by the Allie.

‘Chalmers Company. Generators are de-

signed to run in parallel, and the switch-

board is equipped with the necessary

instruments for their control.

Bowen Roo

In the boiler room are three 2schorse-

power Stirling boilers, with a foundation

for a fourth. The boilers were given a

cold-water test of 287 pounds per square

inch. From the hot-wel, the feed-water

flows to an open exhaust heater, thence is

taken by one of two toxGxi2-isth duplex

‘outside-packed plunger pumps, and forced

through a Green improved economizer to

he temperature of feed-water

ves 260 degrees Fahrenheit at

‘The entire piping system was designed

and erected by the writer, formerly with

the Boston Elevated Railway Company. The

‘main header and all fittings were supplied

by the Crane Company, of Chicago, and

are extra heavy malleable, no cast iron

being used in the plant. ‘The header is

supported on roller” brackets, bolted

through the center wall, and condensation

is drained through a Wright emergency

trap.

‘The main header is 12 inches, and the

‘auxiliary header for the pumps is 4 inches,

both being 76 feet long. The header is

sade up on the unit system, so that any

fone unit ean be repaired, while others are

in service, and both end units must be out

fof service at the same time before the

feed-pumps are disabled. For the feed-

Fic. 3. MAIN GENERATING UNITS AND stetrcMMDARD

ed

water the line is of extra-heavy sold-brass

Constructgn. The entire system has been

funder pressure for a year and the sound

fof steam cannot be heard.

‘Pumps are #0 piped that they may take

water from the exhaust heater, city water,

rtesian well, and rain-water tanks, of

‘hich there ‘are two of 100,000 gallons

Capacity, which Keep the plant supplied

‘vith all water losses. Pumps can also be

‘sed for supplying several hydrants about

the plant for fire protection.

‘The main damper is controlled by a

Lawrence regulator, and the ash-pit doors

‘by a Straight Line regulator. The stack,

go feet high, was built by the Alphons

Custodis Company, of New York City

Fuel used is hard. pine, or by the local

fname, "light wood” It is first passed

through a “hoa” driven by a. so-horse~

power induction motor, then steamed in

Petorts, where the turpentine is extracted,

after which process itis even better for

fuel than the natural wood, making a very

hot and clean fire

‘The Safe and Effective Use of the

Entropy Diagram

By Prop. S.A. Reeve

It is only within recent years that the

‘engineering world has come into the habit

‘of using the entropy diagram for portray-

ng, and even for “thinking,” its problems

land a very good habit it is. But while the

‘entropy diagram portrays excellently well

thermal action which is already wnder-

stood, yet for portraying that which is not

fundersiood—for “thinking out” obscure

Situations —it is a dangerous weapon. Its

‘fiectiveness compares with that of the

{indicator diagram mach as does that of

gunpowder with the bow and arrow; for

Hf not properly handled it is equally de-

structive 10 the user,

For the safe and effective use of the en-

‘copy diagram the prime essential is an

lccurate idea of the nature of entropy.

‘This statement is axiomatic. The ac-

cepted attitude of the profession upon this

point, to which the writer has hitherto

Consttuted himself a Tonely and lonesome

‘rception, may be expressed in two sim-

ple statements, viz:

(a) There is no physical reality to

entropy.

(2). As a mathematical abstraction it

was completely and accurately deined by

its originator, Professor Clausits. All

that is necessary for its complete and efi-

cent use is to memorize this defcition,

Briefly quoted, this definition is that

ecairayy > 42,

wherein the sign of equality refers to *re-

Yersible” processes and that of inequality

to “irreversible” ones, And as all natoral

processes are more or less “irreversible.”

POWER AND THE ENGINEER.

in the sense contemplated by Professor

Glausius, Professor» Zeuner concluded

from this equation that “the entropy of

the universe is steadily on the increase.”

‘This broad fact Lord. Kelvin broadened

into the general principle that the avail-

ability of the energy of the universe for

transformation is dying ovt. In other

‘words, the universe is Hike some great

clock, which was wound up “originally”

‘once ‘and for all, and is now engaged in

fgradually running down

Tn contemplating this aspect of our uni-

verse the imagination ie staggered, not #0

much by the picture of the ultimate wni

versal stagnation, ruin and desolation

‘which must be the result of the “degrada-

tion” of all availability and the end of all

‘energy transformation—no motion, 90

(perceptible) heat, no light, no life, any-

whereas il is by the attempt to grasp

what mast have been the terife condition

Of the mainspring of the heavens when

“originally” wound up tight. For cer-

tainly, for two billion billion years in the

past, and perhaps for a few weeks more,

i has already been engaged in ranning

down, ‘The writer breathes more easily

to feel that what of cold-blooded mathe-

matical philosophy he has yet been able

to master indicates rather an eternity,

past and fature, of indestructible, unde-

gradable availability of energy, with its

ternal conservation ofall the present life,

light and happiness of the world, beyond

the peradventure of any imaginable heay-

cenly catastrophe to diminish it, rather

than this pessimistic degradation theory.

ust see what problems are kindled by

a lite equation, of only six symbols, if it

bbe inaccurate or incomplete!

For the equation fails to answer two

questions, viz:

(1) What is meant. by reversibility

and iereversbiity?

(2) What is meamt by €Q?

‘The frst of these questions need not be

discussed here. It sufices to say that, 0

the author at least, the terms. reversible

and irreversible, after years of study of

them, remain virtually meaningless. In

so far as they mean anything they class

themselves with such quantities as clas

ticity and inelastcty, vie, a8 things which

always occor together and everywhere,

there being no. instance where either

occurs alone

‘As to dQ, that is universally defined as

any “addition of heat" That is how itis

Gefined in Professor Heck’s textbook, and

in every other also, so far as Tam aware.

But if thie is the sole necessary definition.

then the equation stated above easily

transforms into

Saozfran.

This equation, applied to the entropy

diagram rhich i ieelf nothing But a

fraphial means for illustrating the def

ition of entropy), enfoees the concusion

That iv ony care where a heal process ts

Tune 23, 1908,

Portrayed by © curve on an entropy dioe

{gram the “heat added” is measured by the

‘rea beneath the curve. And since the

definition of entropy is a simple, funda-

‘mental fact, this conclusion must rank as

2 fundamental principle

Now comes the trouble. Two familiar

engine-room processes give the denial to

this “fundamental principle” First, in

wire-drawing occurs a rapid increase in

entropy; yet there is no. “addition of

heat.” ‘This trouble has been dodged by

the writer, in the past, by the explana-

tion that dQ meant the addition of heat

from anything externel to the molecule;

for the later is the thermal unit. Thus,

aven the inner surface of a steam pipe

fof throttle valve must be considered as

fextemal to the steam, Hence frition

Against these surfaces engenders heat,

which heat is immediately thereafter

“added” to the steam, to the increase of

its entropy. And this fresh entropy is

just as able to do work, hammer-head

fashion, a8 is any received from the fur-

nace heat

Indeed, this wirexdrawing process re-

minds one much of the test of a canvas-

trough fire escape which once occurred in

4 mukiple-storied public school. Appar

‘ently the builders had a definite quantity

‘of pupils to lower safely from each floor

But in practice they had not. The boys

first down from the top floor found shoot-

ing the chutes in the canvas trough so

enjoyable that they re-entered the build

ing, climbed to the floor beneath the top,

there joined the paniestricken multitude

awaiting chances to escape and so gained

Additional slides, Nominally cach pupil

tmbodied only one unit of “extent” of

sliding energy, just as each bit of entropy

rominally embodies only a certain poten:

Kiality for work performance as it drops in

femperature. But let a given mass of en-

tropy drop one degeee, in wire-drawing

fashion, and it will make of itself addi-

tional recruits for dropping the next de-

tree, schoolboy fashion.

"And herein dQ has picked up an add

tional meaning to that frst stated It must

be re-defined as the “sddition of heat and

work.” The word work may not be

‘omitted just beeause, in the particular ease

cited, the work happens to have come

Originally from the steam eat itsel

jn another instance of growing familiarity,

the compression of air by turbo-compres

sots, the increase in entropy comes froin

work which never was a part ofthe body's

and of heat at all” The ease is purely an

increase of entropy by the addition of un-

disguised work

‘This is the shoe that fits the Knoblauch

experiments Tf dQ=heat plus work

Addition, then the heat addition must be

4Q minus the work addition; and all is

fs plain sailing a5 Dr. Heck’s article

‘would indicate

But now again comes trouble from the

other sie. How about adiabatic com

pression? There work is added, yet ro

June 23, 1908.

increase in entropy occurs. The quantity

4Q remains zero. Nor will the writer

agree to crawl out of this quandary by the

“irreversibility” knot hole. It is too small.

‘The wire-drawing process is just a8 re-

versible as is any other, though it be too

long a story, just now, to prove it

Yet the distinction is easily stated.

Adiabatic compressive or expansive work

performance (with dQ and dN equal to

zero) can occur only sehen motion occur

normal 10 the body's surface. On the

other hand, entropy-begetting work (with

44Q and dN positive quantities) can be

done only when motion occurs parallel

with the body's surface

Here isthe foundation, then

(2) As fong as the hot body remains

at rest relatively to its surroundings, dQ

is heat addition, and heat addition only.

Such, for instance, is the case inthe

‘eam boiler.

(2) When the hot body moves rela

tively to its surroundings, if the motion

bbe normal tthe surface the above still

holds true. Such, for instance, is the ease

fof the steam piston engine.

(3) But when the hot body moves

relatively to is surroundings and the mo

POWER AND THE ENGINEER.

tion is parallel to the surface, then d Q is

hheat addition plus work addition. Such,

for instance, occurs in turbo-compres:

sors, ete

In other words, radial motion relatively

to the hot body (imagining it sphere, for

instance) has nothing to do with en-

tropy, oF the “extent” of heat, as T have

called it in my textbook, but only with

temperature ofits "intensity." Tangential

motion, on the other hand, has nothing to

do with intensity of heat, but everything

with its extent. These two pairs of terms

wrradial action with intensity of energy,

and tangential motion with “extensity” of

fenergy-—will be found to compass the un-

derstanding of heat, as well as of other

forms of energy.

Yet is the task of defining dQ com-

plete, even now? To meet the condi-

tions already known to him, the writer

several years ago formulated a definition

‘of the sources of dQ, a8 follows:

(1) Thermal conduction,

(2) Absorption of radiation,

(3)_Bxothermic chemical action, such

as combustion,

(4) Electrical resistance and

”

(5) Work performance parellel with

the surface; but distinetly excluding

(6) Work performance normal to the

surface

But whether this definition be correct

for complete of not, for all the problems

‘which engineers may meet, a8 well as for

those which they have already not only

met, but tumbled over, the writer cannot

say. Only the professional physicists

and chemists can answer this ques-

tion. But these gentlemen pay litle atten-

tion to these questions of fundamental

definitions of basic quantities, such as

heat, eneray, ete. They seem t consider

them beneath their dignity, as problems

St to entrap only the humble engineer.

‘Those who. wish to read a complete

statement of the views held by the "itre-

versiilty” school of doctrinaires will do

swell to secure a copy of James Swin-

bburne's book, “Entropy; or Thermodyna-

mies for Engineers" (igo4). It is most

frankly and clearly stated, and in a style

niost enconraging in that it finds humor

compatible with thermodynamics. If one

could only accept the monstrous doctrine

of irreversibility, with the conclusions

which it enforces, all would be well

(ALLISCCHALMERS ENGINE AND GENERATOR 18 THE MANUFACTURE OF QUAKER OATS. THE VIEW stows 1

‘ALL OVER THE WORLD. THE UNIT SHOWN 15 AN BoO-KILOWATT, 240-V0LT, 3+

tASE, OO-CVCLE

sto

POWER AND THE ENGINEER. Jane 23, 1908

Burning Oil for Power and Heating

Pertinent Discussion ofj Temperature, ‘Draft and Smoke; Proper-

ties, Possibilities and Limitations of Fuel Oil; How to Buy Oil

BY PROF WILLIAM D. ENNIS

Bunwine On Wirsour Swoxe

‘There is no dificuty in barning oil

‘without smoke, providing the furnace is

properly designed and the boiler is not

too heavily overloaded in proportion to

the capacity of the furnace. In practice,

the presence of an excess of air is more

apt to be experienced than that of smoke;

consequently it is considered good prac-

tice to diminish the air supply to such a

point that smoke just begins to appear. A

Jow temperature of the oil, or any varia-

mia. 1. mNstALLATION oF “esr” aU:

ton in its pressure or temperature is

Tiable to.result in emoke.

‘Regulation of the air supply is partic

larly easy in the case of off fuel, since

there is no fuel bed to introduce varia-

tons in the flow of air, and in view of

the essential relations of air supply to

ficiency of combustion, no pains should

bbe spared, in operation, to have this mat-

ter at all times under fall control. For

‘observations on this point, with relation

to smoke production, peep-holes should

bbe provided in the front and back wall,

and elsewhere if possible. ‘These should

bbe #0 constructed as not to result in in-

ward leakage of

‘Teurmaroms, Dear ano Evaronarion

For the reasons given, oil may be

bbumed more readily at high efficiency

than almost any other fuel. High efici- tarders in the fue the highest gas tem-

fency of combustion means high furnace perature was 484" degrees, evaporating

temperatures, usually accompanied by 388 pounds of water per square foot of

rapid deterioration of boilers. Fire cracks heating surface per hour, and showing @

fon shells near the seams, leaks at boiler efficiency close to 89 per cent.

the tube ends, and blisters on shells of “Under forced draft conditions, in marine

horizontal boilers or on tubes of watet- service, drafts as high as 9 inches of pres

tube boilers are apt to be found. sure have been maintained in the furnace

Fig. 1 shows a simple form of furnace, system, these de-

furnace of a Scotch marine boiler on the $5 high as 167 pounds, with fue tempera

represents the furnace of a locomotive Lot noes

ices eraeegiece meet nee as Seco

nes arc ce ese

ieee eat ci ce ne

626 degrees, with rates of evaporation of tion, Sulphur may be determined by

from 33 t0 44. pounds of steam per oxidation with fuming nitric acid in an

square foot of heating surface per hour, open capsule. Professor Blasdale gives

and equivalent evaporation per pound of the following results of examination of

fll of from 135 to 16 pounds. With re- eight samples of California fuel oil

Sarple No. 1

Set a ck oe

Supe “oats

Jane 23, 1908.

‘The average heating value of oil free

from

Bau. The United States Naval Liquid

Fuel Board gives the following results

from one sample of California oil: Heat-

unig Bp

ate hosing val (vg Dull’ iors)

je sbaur at 21 deg Fah

212 degrees Fahrenheit, 12:20

per cent; specific gravity, 0966; vaporiza-

tion point, 290 degrees Fahrenheit; flash

POWER AND THE ENGINEER.

and burning point, 311 degrees Fahren~

heit; ultimate analysis, C, 81.52; H, 11.01;

S, 035; N+ 0, 692; parts in too. Two

analyses of Beaumont, Texas, oil give,

{from the same source:

code

ee aS

qgee IEEE

Dower ofthe carbon la that du to gs carbon (11,828 ea), not st of sald carbon

forms a

‘thinner liquid than the Califo

and may consequently be handled an

regulated with more facility. With app

MiG 4. RURNING OIL 1H LocoMorIVE

8

ances properly adapted to the nature of

the oil, there is no. diference in the

evaporative efficiency of the two oils. The

California ol weighs almost exactly eight

pounds per gallon. Its fash point is never

Pia § Locomorne sURNER WITH 1WO

below 200 degrees. The proportion of

moisture and sediment, as the oil is now

marketed, is guaranteed not to exceed 2

per cent, and the heating value is of great

iformity. The coeficient of expansi

fs about 0.0006 per degree Fahrenheit.

‘The carbon is a litle lower, and. the

‘oxygen a litle higher than in the Texas

‘ils, and the heating value rather less.

Das könnte Ihnen auch gefallen

- 1902 - Floating DrydockDokument9 Seiten1902 - Floating DrydockTom BatesNoch keine Bewertungen

- General Arrangement Engines'J-End THE: OF Boilers OF Normandie."Dokument5 SeitenGeneral Arrangement Engines'J-End THE: OF Boilers OF Normandie."Tom BatesNoch keine Bewertungen

- 1895 - Molesey Sewage WorksDokument4 Seiten1895 - Molesey Sewage WorksTom BatesNoch keine Bewertungen

- 1894 - Marie HenrietteDokument10 Seiten1894 - Marie HenrietteTom BatesNoch keine Bewertungen

- 1890 - HMS BarhamDokument7 Seiten1890 - HMS BarhamTom BatesNoch keine Bewertungen

- 1891 - Doune CastleDokument4 Seiten1891 - Doune CastleTom BatesNoch keine Bewertungen

- 1891 - Richmond Sewage WorksDokument9 Seiten1891 - Richmond Sewage WorksTom BatesNoch keine Bewertungen

- Lli.! Llil (: Q I - M@-!!!!!!!Q!! !!!!!! EDokument10 SeitenLli.! Llil (: Q I - M@-!!!!!!!Q!! !!!!!! ETom BatesNoch keine Bewertungen

- 1921 - Giulio CesareDokument9 Seiten1921 - Giulio CesareTom BatesNoch keine Bewertungen

- 1921 - MendozaDokument16 Seiten1921 - MendozaTom BatesNoch keine Bewertungen

- 1914 - BritannicDokument28 Seiten1914 - BritannicTom Bates100% (2)

- 1880 - ArizonaDokument8 Seiten1880 - ArizonaTom BatesNoch keine Bewertungen

- 1914 - Buenos AiresDokument10 Seiten1914 - Buenos AiresTom BatesNoch keine Bewertungen

- 1916 - City of CantonDokument6 Seiten1916 - City of CantonTom BatesNoch keine Bewertungen

- 1914 - ImperatorDokument11 Seiten1914 - ImperatorTom BatesNoch keine Bewertungen

- 2 Deck ArrangementDokument1 Seite2 Deck ArrangementTom BatesNoch keine Bewertungen

- 1914 - MargaretDokument9 Seiten1914 - MargaretTom BatesNoch keine Bewertungen

- The French South American Quadruple-Screw "Lutetia.": IN LinerDokument9 SeitenThe French South American Quadruple-Screw "Lutetia.": IN LinerTom BatesNoch keine Bewertungen

- 1915 - Scotia 2Dokument9 Seiten1915 - Scotia 2Tom BatesNoch keine Bewertungen

- M1 Machinery ArrangementDokument1 SeiteM1 Machinery ArrangementTom BatesNoch keine Bewertungen

- GSD WWTP Dedication June 22, 1933 BrochureDokument11 SeitenGSD WWTP Dedication June 22, 1933 BrochureTom BatesNoch keine Bewertungen

- Driftmaster GADokument1 SeiteDriftmaster GATom BatesNoch keine Bewertungen

- BB-64 USS WisconsinDokument15 SeitenBB-64 USS WisconsinTom BatesNoch keine Bewertungen

- DD 793Dokument1 SeiteDD 793Tom BatesNoch keine Bewertungen

- MontmagnyDokument2 SeitenMontmagnyTom BatesNoch keine Bewertungen

- Leopard 1924Dokument6 SeitenLeopard 1924Tom BatesNoch keine Bewertungen

- Driftmaster GADokument1 SeiteDriftmaster GATom BatesNoch keine Bewertungen

- BBC AsiaDokument1 SeiteBBC AsiaTom BatesNoch keine Bewertungen

- 1908 - June 9Dokument8 Seiten1908 - June 9Tom BatesNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)