Beruflich Dokumente

Kultur Dokumente

Technical Spec. 3000002288

Hochgeladen von

vinay19990 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten47 Seitentechnical specification

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldentechnical specification

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

19 Ansichten47 SeitenTechnical Spec. 3000002288

Hochgeladen von

vinay1999technical specification

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 47

“AINICAL SPECIFICATION FOR PURCHASE REQUISITION

VALVES GATE VALVES

Nee Eee Deliver the Nem fo Dalvery Date

wauotten eis Nosnally Latest by

eaeuitog tego tetangel | MANGALORE REFINERY AND Sanuary 2013,

‘nly new eevised pageisissed. | PETROCHEMICALS LIMITED,

2. the mare of is wrety noed | MANGALORE, INDIA

tie deals ese ate nap

fF the roqustion The tered

pages soe pt of the rial

Fesivon sd shall be complied

| win heavy.

Rev Date By ‘Appa. Details

o | omm | aL

DESCRIPTION:

This requisition covers the supply of complete materials, inspection, testing, packing and forwarding

of valves as per the specifications, standards and applicable codes indicated / enclosed with this

specification.

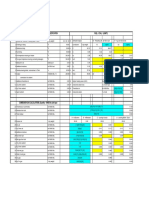

Size | Type | Rating | Body Trim Ends Special | Quantity

20° | Gate | 150# | A105 13%Cr Flanged [No | 2

Gate 1508 PAIOS | 13%Cr Flanged | Motor 1

Hea Operated

NOTES:

1. All nvateriats above to be supplied shall strictly conform to the specifications attached along-

with,

2. Inspection of all materials above shall be done by Third party inspection agencies like BIL /

Toyo / Lloyds Register / BV / DNV / TUV / IRS. The Thitd party inspection is in the scope

of the vendor. The quote from the vendor shall be inclusive of all Third party inspection

charges.

3. The material should be delivered along with the following documents.

8). Original third party inspection certificates

b) Original test certificates (Mechanical property, chemical composition and heat treatment

teport, supplementary tests, mandatory tests as per code, etc.). Photocopy of these

certificates are acceptable, if the third party inspector has endorsed the copies.

108s sectional drawings, if applicable.

°)

“Rel. No, Rev. No.

(09/08/2012 | VALVES FOR CRUDE SUCTION HOOK 3000002288 0

up

Sheet of 2

d) As per attached document submission list

4, The delivery of material will be deemed as incomplete in the absence of these certificates and

may lead to rejection of material.

5. Please attach full set of specification sheets duly signed and stamped by bidder as acceptance.

‘This shall be part of the technical offer. The offer will not be accepted without the same.

6. Any deviation to MRPL terms and conditions should be specifically stated in attached

deviation format, In absence of a duly filled and stamped deviation sheet it would be

understood that there are no deviations and vendor has accepted all conditions in toto,

7. Torque data to be supplied by vendor after order placement.

LIST OF ATTACHMEN

S.No. Title

1 Mechanical DataSheet for MOV.

2. Process Datasheet

3. Actuator datasheet

4 ‘Scope of Supply and Work

5. 7 List of Documents for submission

GEE ‘Standard Specification for Flanges

a Specification Sheet for Gate valve

8 Standard Specification for Valves

% EE Standard Specification for MOV Actuator

10. Procedure for Final Documentation

U. Deviation Format

Tek No. Tew, No,

1y08n0i2 | VALVES FOR CRUDE SUCTION HOOK 3000002288 6

up

Shoot 2 of 2

DATASHEET FOR MOV

Project Number 11-0240

[Tag no wv.070102

[Quantity 4

P&ID No: MMRPLLO70-024-2252-10

Inlet fine no 20-0-70508704-R1A

[Outlet line no 20-P-705087M- AYA

Insulation Type Nt

insulation thickness Nit

Service CRUDE/LIQUIO

Design pressure 35 beremzte)

[Design temperature 6 lc

[aP shutoff 05.23 beremate)

Inlet Line NPS 20

Inlet tine Schedule 6

[Outlet line NPS 20

[Outlet fine Schedule 6

[Type of Body Gate

Body Size 20

Port Size

Flange NPS 20

Flange rating 150%

Flange facing WARE, 125 ARH

Flange MOC ASTM A105

[Body material ASTM A216 GR WED

[Bonnet type EXTENOED

Packing material ‘GRAPHITE

[Stem materi 13 GR STEELINO CASTING)

Seat trim material 13.¢R STEEL

[Other wetted parts 13. cR STEEL

studs: A193 GeB?

Nuts (A194 Ge2tt

[Gaskets SSP Wd SS316-GRAFIL

Failure position FAILSAFE

[Opening time/Closing time 60 SECONDSIMAN)

[Gear Type Worm reduction

Limit Switches required Yes-2 nos{Open/Close)

Handwheel Required

Fluid type Hydrocorbon Crude

Fluid state Liquid

Flow of liquid Minimum 400 sine

Flow of liquid Normal 850 mayne

Flow of liquid Maximum 2800 maine

[Operating temperature 40¢

Maximum temperature esc

Density in ke/m3 770320

Viscosity

2.8-30 CSt @50 degree C

Prepared By

Checked

DATASHEET FOR MOV

Jarerata0s)

lssa

(Vapor pressure 7

Predicted sound level at 1m distance** Noted

valve make Noted

[Actuator make Note’

[Motor Make Notes

Notes

1 Each MOV integral actuator shall include controls;status and necessary push

‘buttons/selector switches etc for control.

2 Minimum metric threaded cable entries shall be provided in actuator for following:

i. 2nos for Open /Close Status

lino for open/close command

li.1 no. for field bus signal

iv.1 no. for power

v.A no. for spare

Unused cable entries shall be plugged

” Should be less than 85 dBA

3 Vendor to fill at time of offer submission

Prepared By Check

[MOV for Crude Line

Project MRPL-1

Project Site [Mangalore

Unit/Equipment OMa&s

Scheme Phi& 2 Grade Transfer Suction Hook-Up

Fluid / State [Crude Liquid

Location Pump House-13

Reference Number [MIRPE-1-070-02-4-9252-1-0

inlet Line Number E 20-P-705047M-ALA

Tag Number Uv=0701ee

Valve Duty Full Open & Full Close

Control Required Local & Remote (Note-6)

Local / Remote / Off Selector Switch Required

intermediate Travel Limit Switch Not Required

Potential Free Contacts for Indication

lon remote panel (for valve open and Required

r

Potential Free Contacts for Indicating Required

valve operation in proaress

[Maximum time of Operation (Opening /

60 seconds

Closing)

Operating Temp °C 7)

(Operating Pressure _Ksog 2

Design Temp °C 65

Design Pressure seg 35

faP Shut OFF ksog_ 35 _ 08 “RS pe

Nore Noe Note-1,2,3,4 & 5 |

[Note-

1. Type of MOV shall be Gate type

[2. Actuator Design shall be based on AP

3. Provide Hand wheel for MOV.

shut off.

4. Pressure Drop across valve shall be negligible.

IS, Refer P&ID No. - MRPL-1-070-024-2252-1-0 for details. iz

6, For Remote operation only CLOSE action to be provided.

ae

Kodera jot

Date (04/02/2012 KB/ VU AK SR

Rev 0 Prepared By [Checked By Approved B

MOV Data Sheet

Date Sheet No.

1.0

ui

12

13

14

15

16

17

2.0

2a

22

23

3.0

3

32

33

34

35

36

37

374

372

4.0

ad

42

43

44

45

iit] MOV Actuator Approved vendor List

Paget /4

DATA SHEET FOR MOV ACTUATOR

Part - I: PURCHASER'S DATA

Site Conditions

Altitude

Design ambient temperature

Max./Min, ambient temperature.

Humidity

climate

Project Site

MOV Tag Nos.

System Conditions

‘Supply Voltage,

Supply frequency

System earthing

Operating Environment

‘Area Classification

Gas Group

Temperature Class

Construction

Ingress Protection

Painting

‘Whether 'K-Mass' type or equivalent

Fireproofing required.

For MOV Tag Nos.

With Fireproofing rating

«1000 m above MSL

40°C

37,8 °C / 16,7°C

Max 91%

Highly polluted ond corrosive as

found in refineries,

MPL Mangalore

UV-070102

ABV 10%, 3ph. AC

BOHz + 3%

Solidity earthed

Zone 2

qc

3

Flameproof Ex(d)

1P65,

Epoxy base

No.

uv 070102

30 minutes

Valve Duty, Mode of Control and Devices for Control

Valve duty

a. Fully open and fully closed

b. Partially open and partially closed

Control requirement

Local / Remote / OFf selector switch

‘on MOV Actuator

Compatibility for interfacing with DCS

Setting of adjustable parameters of

Actuotor (for 2 wire control system)

Modification: Crude Suction Hook Up in OMS

Hel-O240

Yes

Yes

Local & Remote

Required

Required

From Field / Master station**

47

48

484

482

48.3

484

485

49

4.10

4at

42

4.13

5.0

5

52

53

6.0

Modification: Crude Suction Hook Up in OMS ATO?

Continuous position indication

Local

Remote ~ Poténtiometer / transducer for

Remote continuous indication

Intermediate travel limit switch

Potential free contacts for indication on

Remote ponel and other interlocks

For Valve open position

Fore Valve closed position

Fore remote indication of position of Local

Remote selector switch

Fore availability of MOV actuator for remote

Operation (contact from monitoring relay)

For indicating valve operation in progress

Remote emergency stop push button for

Stopping actuator

DCS interface for Remote control / indication:

‘Maximum time of operation

Opening

Closing

Double compression cable glands and plugs

For unused entries (To be supplied along with

MOV actuator)

Make of MOV actuator

MOV Actuator Approved vendor List

Pagei2/4

Mechanical and LCD indication

required

Not required

Not required

Required

Required

Required

Required

Required

Required

Required

‘As per valve data sheet

As per valve data sheet

Flameproof & WP type / WP type

Test and Approval Certificates for Flameproof Actuators

For indigenous make MOV Actuators

For imported make MOV Actuators

Submission of Type Test certificates along

with the offer

Applicable MRPL Specification

CMRI test certificates, Approvals of

CCE/ Other opplicable statutory

Authority ond valid BIS license.

icates from authorized

Certification agency of country of

Origin of actuators and Approvals of

CCE / Other applicable statutory

Authority.

Yes. (Certificate Numbers. of valid

dates to be indicated)

70

I MOV Actuator Approved vendor List

Page:3/4

Specification for electrical motor actuated

Valves

Special Requirements : NIL

NOTES :

2.

3

NA denotes ‘Not Applicable’.

‘Area classification Zone, Gas group and temperature. class indicated at S, Nos.3.1 to 3.3

above refer to IS/IEC Standards.

‘The purchaser shall provide single point power supply to the actuator as per S, No.2.0 above,

‘Any other control supply voltage required shall be internally derived by the manufacturer

within the actuator,

In cose ‘Remote continuous. position indication’ is required as per S.No.4.6.2 above, the

potentiometer / transducer required for position indication along with loose remote

continuous position indicator shall be included in the quoted prices of respective MOV

Actuator and supplied with it.

Vendor shall furnish complete data for each MOV actuator along with the offer.

Remote input signals for opening /closing / stopping the MOV shall be provided through the

‘momentary closing of separate potential free contacts in owner's panel, Necessary controls

required for running the motor for the complete opening / closing sequence of the valve

using such input signals shall be provided by manufacturer in the actuator.

Vendor shall quote for Maintenance spares for two years trouble free operation &

maintenance of the MOV actuators indicating recommended quantity and unit prices.

Vendor shall also identify a list of such spares along with quontity required for

commissioning the MOVs.

Wherever it is mentioned ‘vendor’ the same shall be read as MOV Supplier’ for the

activities 7. Items covered as a part of this requisition.

Modification: Crude Suction Hook Up in oms — M-11-0240

Uasercive

iitasilal MOV Actuator Approved vendor List

Page:4/4

DATA SHEET FOR MOV ACTUATOR

Part - IT : DATA BY VENDOR

(To be filled in separately for each actuator and furnished along with the offer)

MOV Tag No. :

1.0 Actuator :

11 Make

1.2 Type & Catalogue No.

1.3 Applicable Wiring Diagram No. :

14 Valve duty :

1.5 Maximum permissible number of

Open / close cycles per hour

1.6 Internal control supply used in actuator

1.7 Recommended backup HRC fuse rating

2.0 Motor

21 Make

22 a. kWrating

‘Power Consumption requirement in KVA

2.3 Rated speed in RPM

24 — Enclosure

2.5 Locked rotor (starting) current

2.6 — Rated torque (seating) current

2.7 Average load current

3.0 Basis for sizing and selection of actuator

40 Test and approved certificates

5.0 Component Makes

54 Contactors

5.2 Push buttons

53 Selector Switches

6.0 MOV Actuators suitable for 2 wire control System

6.1 Maximum No. of field units thet can be :

connected to one master station

62 Maximum permissible distance from field unit =

to the master station

63 Maximum number of Control inputs and

Control / status outputs from each field unit

‘that can be handled through the 2-wire

‘Modification: Crude Suction Hook Up in OMS

MOV Actuator Approved vendor List

Control system

The MOV actuator supplied shall be as per the following approved makes only,

ACTUATOR |:

‘AUMA INDIA LTO.

2 UIMITORQUE INDIA LIMITED

3. ROTORK CONTROLS (INDIA) LTO

Modification: Crude Suction Hook Up in OMS

SCOPE OF SUPPLY AND WORK:

SI | Description

No

Remarks/ Deviations if ony

Overall Scope

‘Selection, sizing, engineering

‘Manafacturing

‘Supply of materials a spec

‘Supply of services as specified

Factory Acceptance Test and Inspection of ex-foctory items

‘Supply of construction ond commissioning spares

List for 2 years operational ard maintenance spares

‘Supply of consumables

Pointing

1 | Pecking ond fornording

TL | Specil tools nd races

12,_| Transportation

13,_| Field Service if required during start wp ond commissioning

14,_| Docunentation-(Hord copy and soft copy)

15, | Statutory Approvals os pplicable

NOV Scope of Work and Supply

1] Supply of MOV along with accessories in prewired preteated condition

2, | Minimum metric threaded cable entries shall be provided in actuator for following!

2 nos for open close status

no for open close command

Lo. for fieldbus signal

“Le for power

sto spore

Plag for Spare cable eniry into electric actuator

Tog Nene plete( $5304)

Flange goskets and stud bolts

| Earthing Lug

Eyebolt

‘ERP Canopy for Actuator

Modification: Crude Suction Hook Up in OMS ~ M~

Vendor's Stamp and Sign

DOCUMENTS FOR SUBMISSION:

[SINo] Description

At the time of

| After Order

submission of quote _| placement

Filed Up Dinasion Table of Naor Operated Vale t

2 [ Actuator Sizing ond selection details Z

3 | Stroke tine details v

4 [Uist of bought out tens with sub-suppliers rane ond’detola | F

3} Genero orrangement drawing ¥

portlis

rome plate details

“installation details

“dimensional details

-acight details

6 Electrical load data v

7 _____| Wiring ond termination drawings v

8 [Motor Specifications z

9 [ator datasheet Z

10 | @A/ACdocument ard QA Pen Z

it | Tapection and test procedure z

12 | Trepection and test report(refer Indicative EV? of afTocked Tift Bacarenty

specification for ist of tests tobe performed)

3 Procedure qualification records ~~] irl Document

14 etificate of compliance EEE ¥ (Final Document)

8 Packing and storing procedure - ‘TFinal Document)

Test/Clbration/ Inspection reports ZFval Docurvent)

Statutory certificates if applicable Tiral Bocier

16 ‘Material test certificates ‘¥(Final Document)

19 Certificates for enclosure protection ingress protection,EME/RFL ‘V(Final Document)

protection

Thatlltion ateial —Wetificaton | TOOT by | Materiel Tet

material ke and correlation with | Vendor | certifiate

a |e | - | moter gears. reference tes certificate

indicctors int svitchesete, ruber

+ Operational Check

Electrical Motor Operated © Visual 100% by + Vendor

Valve Actuator Assembly + biesionl Vendor catalogue

+ Vee

dimensions 08

| per

jefel-| reference

APr/ANst

| standard

+ Drawings

approved by

ie

+H = Final Inspection T. Visual 100% by ‘© Vendor test

TT, Dimensional Vendor records

TH, Functionl nd calration | ond + 159936

| ‘test for torque and limit | Random’ #

switches by Third

IV. Neload curent Pasty

V.. direction of rotation | Inspection

Vi. Phase reverseh cgay |

VIL Responce tne test

ne]. VEEL Variation of suply

voltoge ond frequency

DX Test on cutput shaft

Xife Test

XLHondhee! and outa |

jee | ecuteh functioning | \

| XITRemote contact

functionality test

XIILHigh voltage test

X1VEnsulationresistonce test

STANDARD SPECIFICATION FOR ELECTRICAL MOTOR ACTUATED Sheet [12] of | 12

VALVES

Seger ex are aear wate a fre AEE.

Revo

wetter geo

29-6-2012

TWorgieProcton Syatan

Test

AVL Correctness of ame plte

“Submission oF cerifiates | Cerificate From Teslig apeney 1 > Wane tear

lite prototype report

ATEXCTMFREASEEFAFU/UL?TO | per medel | + Relownt

ete for sitolity in specified 1s/ee

hezaedou rea standorés

T.ertiticate of fire proofing st + 159934

explicable

TIL Test for motors as per relevant

TS/IEC standard

efel . IV.Type test certificates for

rotors,

V.A ald BIS lene for indigenous

sxpply

ViStatutery approval certificate

from PESO for use in specified

hazardous area

Vixbegree of protection

certificate os eppliable

VEELif cycle test report

Review of palong and pacing | + Vso 100%

fist + Carrelotion of each item

con packing fist with box

tog runber

W «| Tssue of Trapection Release | Peo —

Lo Neve Bae ete

Notes:

i Calibration certificates of al instruments used in performance testing to be submitted Accuracy

of the test or measuring instrument to be atleaset 2 times better than the instrument/part being

tested,

* IRN to be scanned and sent in soft ‘Copy to MRPL prior to dispatch of material.

Abbreviations;

PESO: Petroleum Explosive Safety Organization

R:Review

H:Hold

PEG pol

eer cere Sheet Vay G

ew Nos

| a i Flanges

ra

(00-£5-860-605 WyJo}aon

Prepared | Checked | Approved

by by by

a gare | 3 earn | a gare

— ARR _| ser | arte |

| Description

faaxor

FLANGES Sheet Pore |

Rev,

WEE RIOOS Wakon

1.0 GENERAL,

1 All times, their dimensions, tolerances, chemical composition, physical properties,

heat treatment and (esting ete. shall conform to the codes and standards specified

in the requisition, Deviations, if any, shall be clearly highlighted on a separate

sheet by the vendor in the quotation itself,

1.2.1 Test Reports shall be supplied for all mandatory tests as per the relevant material

specifications, “Test report sshall also be furnished for any supplementary tests as

specified in the requisition & Cl, 1,11, Cl. L12 & Ch. 14,

122 Material Test Certificates (physical property, chemical composition and heat

treatment repor() shall also be furnished for the flanges supplied,

(3 Ends of weld neck flanges shall be bevelled to suit the schedule / thickness of

matching pipe, as specified in the requisition,

14 Bevel end details for welding neck flanges shall be as per ANSI B16,25, The

contour of bevel end shall be as follows:

Wall thickness Weld Contour

Carbon Steed Upto 22 MM. Figure 2 Type A

(except low tem,

carbon steel) > 22MM, Figure 3 type A.

Alloy Stee! Upto 10MM, Figure 4

Stainless and > 10MM &upt25MM Figure 5 ‘Type A

Low temp. carbon > 25 MM, Figure 6 Type A

Steel,

eee

1.5 Bore of socket weld flanges and reducing blind flanges shall suit the outside

diameter and schedule / thickness of matching pipe.

1.6 Bow of stip on flanges shal suit the outside diameter of matching pipe.

1.7 Hlange face finish shall be normally specified in the requisition as serrated finish,

125 AARH eto, The interpretation for range of face finish shall be as follows:

Serrated Finish + Serrations with 250 to 500 ARH,

125 AARH Serrations with 125 to 200 AARH

63 AARH, + 32063 ARH,

(Cae A ca gb >

PLANGES [Sheet 3 of6

Rev,

sis 00-25-800-005 Libs (9}9) 200

Lio

12

13

Lat

1.14.2

1143

TT

Galvanized flanges shall be coated with Zine by Hot dip process conforming to

184736 / ASTM A 153 or by Electtogalvanising, Threaded protion shall be

suitably protected during galvanizing,

Ends of sorevved flanges unless otherwise specified shall have taper threads as per

ANSTB 2.1 (upto 1.5 in NB) and IS : 554 (for 2 in to 6 In. NB),

For ring joint flanges, blinds and spacers the hardaess shall be as follows:

Flange Materiat Min, Hardness of Groove (BIN)

‘Carbon Steel 140

1% Cr. to 5%Cr, 150

‘Type 304, 316, 347 160

Type 304L, 316L 140

For ring joint Manges, blinds and spacers, the hardness shall be recorded on the

lest report,

Flanges, blinds, drip rings under “NACE” category shall meet the requirements of

‘specified in the * Standard Specification for sour service Piping *

All austenitic stainless steel flanges shall be supplied in solution annealed

condition,

For all austenitic stainless stcel flanges, blinds, drip rings and Fig flanges

tergranuilar corrosion test shell have to be conducted as per following:

~ ASTM A 262 practice ‘B’ with acceptance criteria of “60 mils/year (max.)"

oR

+ ASTM A 262 practice “B? with acceptance criteria of “no racks as observed

from 20 X magnification” and “Microscopic structure to be observed from 250 X

Magnification”,

When specifically asked for high temperature application of some grades of

uustenitic stainless steel (like $S 309, 310, 316, 316H etc.) ASTM A 262 practice

‘C’ with acceptance eriteria of “15 Mits/year” shall have to be conducted.

For the IGC Test as described in 1.14.1 and 1.14.2, two sets of somples shall be

drawn from each solution treatment lot, one set corresponding to highest enrbon

content and other set conesponding (o the highest rating / thickness,

ican rags DOE —

FLANGES fe [ Sheet 406

Rev

"00-88-800-005 WSR

22

3.0

al

32

33

34

35

36

37

Flanges coming wnder the purview of IBR_ (Indian Boiler Regulations) shall be

accompanied with IBR Certificate in Form fil C duly approved and countersigned

by IBR Authority / Local Authority empowered by Central Boiler Boatd of India,

For carbon steel flanges described as “IBR", Chemical composition shall conform

to the follon

Carbon (Max) 0.25%

Olhers (S,P, Mn) As presetibed in IBR Regulation,

‘The chemical composition as indicated in this Ctause is not applicable for flanges

other than IBR.

‘Marketing and Despatch

All items shall be legibly and conspicusoly stamped in accordance with the

requitemnents of applicable ANSI, API and MSS standards, MRPL Code,

Purchase Order No, & Special Conditions like “IBR®, CRYO", “NACE” ete, shall

also be stamped,

All ems coming under the purview of “IBR", “CRYO” & “NACE” shall be

painted in Red strips, Light purple strips & canary yellow strips (25MM. width)

respectively for easy identification.

Paiut or ink for marking shall not contain any harmful metal or metal salts such as

zine, lead or copper which cause corrosive attack on heating,

tems shall be dry, clean and fice from moisture, dirt and loose foreign

‘materials of any kind,

All itoms shall be protected fom rust, corrosion and mechanical damage during

transportation, shipment and storage

Rust preventive on machines surfaces to be welded shall be easily removable with

petroleum solvent, and the same shall not be harmful to welding,

Bach encl of flange shall be protected with the following materials:

Flange face + Wood, Metal or Plastic cover

Beveled end + Wood, metal or plastic cover,

ERA STA NORD ein Beings DOE ;

FLANGES: Sheet 5 of 6

Rev3,

00-5S-800-008 (9psfzow

‘Threaded end 1 Plastic plug

Socket welding end: Plastic cover or plug

3.8 Exch size of flanges, blinds etc, shall be supplied in separate packagings

marked withthe Purehase Order No em, code no,, material specification,

size and rating.

40 All certification / records required as per the standatd shall be supplied slong

with the material itself Non- compliance of this may lead to material rejection

after receipt,

RISURWINAVSTANDRDS peciietion tr tanger DOC

Sheet GG

"00-ES-800-005

[A [approval Ht [Hold W [Witness

[1 information —— Px submie 1

4, "Witness inspection and/or document review by MiNPL/TDL

Witnoss inspection by Vendor/5ub vendor a =

3._|Centcaes and Oat tobe submitted by ver Yor Approval/Revaw by TPUAAR

Detaled Inspection and Test Plan & Quality Assurance plan after ious of ese

oder.

Inspection and eat Protedues including HDT recedes :

‘Packing Procedure/Shipping Drawing/Detals a

aw Material inspection and identiteaton =

Heat Treatment records and charts ca

Stamping of Samples for testing(samples/per heat/per heattreatment/per size/per

srating,ete) oe

‘Mechanical esting forthe Tolwing tes

1Tensile test

2.lmpact test{if applicable)

3.1GC and any other test{if: applicable)

‘4Mlardaess check on samples

S.Any other applcablefmentioned tests HH

X_ | Product chemical Analysis

x [sor ia

X_ | Final inspection Vial bin

Tr He z

H H Marking or stamping check/Review of manufacturer's certificates and

aa Stamping/Review of statutory certificates if applicable

it | / WJ pa for stainless Steet and Ay Sol anges, eceereLs}

/W [x | Packing and shipping as per stardacd :

x SS ceeeeereeer

afi

(a3 fir [in PT stamping andissue of inspection Release Cancale

g

=

sional ,etc}-100% by vendor and random (note 3) by

Notes:

3 This is ust an idieative pion and! the detalled test plan and QAP tobe submitted to MRPL for approval

2,Avhevcover Statutes ke 1BR/Petzoleum Rules/SMPV rules etc are applicable the same news re

sey lowed without deviation and supply shall be made along with relevant certileates The exe

shall be reflected in the QAP submiited to MAPL for approval,

3.Random sholl be defined as follows:

Random Inspection By TPi(for each size and type]

oriole

a VALVES Sheet Tof ii

Revd

aT TAOS,

Tos [ 5.3.1 and 5.3.2 revised MVK

3] 3/2107 | Requirement of Gear operation MVK

modified.

Para 7.2 modified

Baitorial Changes

2 [25/105 {9.1 modified to include | CS MVK

[reference fo MR-0103

Tf aaTtof57 | stan ncorporated

‘0 24703/97 [Issued as standavd MVK Vor

Roy [Date [Description Made by ‘Approved

HH ‘VALVES ‘Sheet 2 of 1

Revd

OES TiO

Qat

212

2S

216

2D

22

GENERAL

Vendor shall supply valves in accordance with tho valve specification shees slong

with auxiticies, If any, such as gear operator, bypasses, rains eto, wherover

specified in the specification sheets, subject notes and other enclosures to the

requisition,

Vendor shall quote in stiiet accordance with the valve data / specification shots,

subject technical notes aud all other enclosures to the requisition. ‘Deviations to the

spec / dala sheets, subject technical notes and other encloses of the requisition, If

‘any, shall be asked as explained in Clause 2.0,

All codes and standards for manufacture, testing, inspection ete., shall be of atest

editions,

DOCUMENTATION:

‘Vendor shall submit with the offer the follow

Manufacturer's complete descriptive and illustrative catalogue / erature,

Delaited dimensioned, cross section drawing with parts / material lists, weight te,

for the ball, plug, buttery valves, diaphragm valves nud valves to manufyctuter's

standard,

Drawings for valves with acessories tike gear operator, extension bounet, extended

stems withstands bypass etc giving major salient dimers

One copy of the vaive specification sheets signed as “accepted” by the manufacturer

With all deviations marked cleay,

IF the valve is regretted or has no deviation, the manufacturer shall waite clearly on

valve specification sheeis as “regret” or “no deviation?

For subject notes, if there is any deviation, the same shall be listed clause wise, even

lnuses which are nceeptable shal be categorically confirmed as “accepted”

Failure to submit documents as specified in clauses 2.1 to 2.1.6 above, the offer Is

likely (0 be rejected,

‘Vendor shall submit for approval drawings mentioned in item No.2.1.2.& 2.1.3 ater

Placement of orders and before start of manufacture. No other drawing shall be

“submited for approval,

23

24

32

33

a4

as

VALVES

‘Test Reports shall be supplid fra mandatory tests a8 ber the applicable code, ‘Test

alae s ign M80 be furnished for any supplemeniny tests as spetineg clause 3.13,

Material Test Certicstes (physical yropenty, chemical composition and heat

{reanentseport shall also be fished forte valves supped,

DESIGN AND CONSTRUCTION:

Nalves shall bo designed, manufactured, tested, inspected and marked as per the

‘rapufacturing standards design codes and standards (latest editions) indicated in the

respective valve specification sheots,

enclosures, specification sheets and referred 2

Notice ofthe purchaser for claeifiat

page alstion including subject notes shall govern. Ne dente’ ‘0 specification

‘ads shall be permited through vendor deaving approval Approval of draw

shall be valid only for design features,

Cane extenslon wherever speciid In the valve sheet to BS? 6364 shall be for “Ne

Gold Box Application” untess otherwise specified ia tne Fequisition, Bven if»

ale for In valve sheet, valves indicated as "Cayo" shy ‘snpplied with bonnet

extension,

For heavy valves provision shall be availble for ting by Way of lugs, eye bolts and

‘such standard devices,

uslanged valves shall have flanges integral (uless otherwise stated) with the valve

soeh-Melded-on anges are not accepable: Mange fick an be serrated finish

Rapele $00 AARH or 125 AARIT (125 AARH Mon) eee AARH (32 to 63

ARK),

Forall butt weld end valves with bevel ends per ANSIBU6.25,

‘The contour of bevel shall be as follow

MATERIAL WALL THICKNESS Weld

contour __

Caan See UR Type A

(except low temp, >22.MM Figwwe3 Type A

‘carbon steo)),

Alloy steel, Upto 10 Mit Figured

Stainless steet > 10MM to 25 MM, Figure $ Type A

& Low temp, carbon > 25MM. Figure 6 Type A

Steel,

VALVES Sheet fofii

Revd

[ wAsTeaT TBO)

37

38

3.81

3.8.2

383

3.84

39

3.10

312

313,

‘All check valves 3” and above shall have a drain boss at location *G (refer Fig.No.t

Of ANSI B 16.34). A tapped drain hole with plug shall be provided as per ANSI B

16.34,

{fan overlay weld-depostis used for the body seat ring, seating surfice, the seat ring

‘base material shall be atleast equal to the corrosion resistance of the matelal of the

shell

By-pass:

By-pass requirement for gate valves shall be as follows, unless otherwise indicated in

datasheet

ANSI 150 Class on sizes 26” and above.

ANSI 300 Class on sizes 16” and above,

ANSI 600 Class on sizes 6" and above,

ANSI 900 Class om sizes 4* and above.

ANSI 1500 Class on sizes 4” and above,

ANSI 2500 Class on sizes 3” and ubove.

'By-pass valve shall be of globe valve. ‘The valve speclfication sheet »

bbypass valve fs given in annexwe I, the sizes shall be as under:

On main valve <4" or “4” =

On main valve> 4” But< 10" 3/4"

On main valve= 10" or> 10" =I"

Vendor shall supply the by-pass valve duly tested and fited to the main valve.

Valves with by-pass, shall have the direction of How marked ou te main valve, By

pass attachment to the main valve body shall not be sorewed, Al fillet welds for by-

ass Installation shall bo 100% exumined by DP/MP Test

“The bypass piping arrangement shall be such that clearance between main valve body

‘aud bypass assembly shall be the minimum possible for layout reasons.

Valve body / bonnet stall be forged / cast as specified. Forging are acceptable in

place of casting bt not vice-versa.

Material of construction of yoke shall be mininum equivalent to body Bonnet

naterial

‘Stem shall be foxged or machined from a forged rolled bat, No casting is permitted.

However, integral stem of cast stainless steel ball valve is acceptable.

‘Stellting / hard facing by deposition, shall be eulnlmumn 1,6 mn thiek each,

Cryo Service Vaive

at VALVES Sheet Sofi

Revd

= HES HOO-OOT TOO

3.13.2

3.13.3

34

3.16

307

37

3072.

3.173

3.174

ATS

ryo! valves shall be subjected to

ene tests per BS 6364 and tea shall be witnessed and cetifet by thi party

peetion agency. ‘The vendor has to submit Test Certificate for prottype valves

slong wit tie offer, Prototype test eatied oma particular size ofthe samc rating ahd

design,

‘Ciyo! service shall

pact

welding procedure for austenitic staintess steel valves i

‘qualified for impact test as per ANSI B3L,3, Minimum aceeptabl

energy shall be 20) or lateral expansion of 0,381 al emp, of 196 Deg, C,

Wherever Impact Test of $$ Studs / Nuts i called for Inthe data shes, the Impact

valve shall be 275 at the intended service temperature speelMed in the datasheet

Valves under “NACE” should follow the requirements given in “Requirements for

speeltie corrosive environment”,

Austenltle stainless steel valves shall undergo Infergrantilar Corrosion Test (IGC) to

ASTM A 262 practice ‘Band acceptance eriteria shall be that corrosion rate shat!

tnot exceed 48 mils per year, Two sets of the samples shall be dravvn from each heat

lot, one set comesponiting to highest carbon content and other set

ding to highest rating,

Spiral wound bonnet gasket are to be provided with inner / outer ring except when

encapsulated gaskets type body-bomaet joints are employed,

Ball plug / butterfly valves:

As per prequalification, Fie Sufe Test as per API - 607 / APL GPA / BS 6755 Part It

shall be eatied on soft seated bal, plug, buttery valves and also on lubricated ph

Valves. ‘The test shall be witnessed ad certified by thied party inspection agency.

‘The vendor has to submit Test Certifete for the paticufar design of the valve

offered.

Bach valve shall be supplied with a lever / wrench except for gear operated / motor

‘operated valves,

Flre safe ball valves shall be supplied with aisatlc devices,

BW / SW end ball valves shal have « LOOM fong seamless pipe nipple (compatible

{0 body materi!) welded to cach end ofthe valve, Nipples are to be welded prior to

assembling Teflon seals / seals, Schedule of nipple shall be indiened inthe valve

specification sheet,

Pace to face dimensions of al ball valves shall be same as those of gate valves of the

sconresponding ANSI Class (except 12" onward ln ofass 150 where dimensions shall

be as per API 6D fong pattern).

oe ‘VALVES ‘Sheet Gofir

Revd

Hil ase aT STD

3.17.6. The ball ofthe ball valve shall nt protrude out ouside the end flanges of valve,

3:17.7 Ball valves shall bs floating ball type /ranion mounted type as per following:

1508 Pk below Floating ball Beer

10" & above ‘Trunion Mounted

3008 4" & below Floating ball

6" & above ‘Trunion mounted

oo 1.5” & below Ploating bal

Baboye __2”& above ‘Twunlon mounted, —

4. OPERATION:

‘41 Generally the valves are hand wheel or fever operated, Gear operation shall be

provided as unde, unless specified othenvise inthe individual valve data sheets

Valve Type Class ‘Size vequiting Gear-Oper

Gate Valve 150 Class 12 and tg.

& dlapinagm, 300 Class 12" and Inger

600 Class. 12” and larger,

900 Class 6” and larger.

1500 Class ‘and larger,

2500 Class 3" and Inger.

‘Globe valve 900 Class. 6" ond larger:

1500 Chss Yd lager

2500 Class and larger

Ball Plug 150.Clss 6 and large.

Valve (her 300 Class 6 ned lng.

the pressure 600 Cinss 4" and ingen

Bainnce plug 900 Class, 3” and lager

_valye) 1500 Class Standage

‘12. For pressure balanced plug valves the gear operator shall be as per manufacturers

For sizes lower thon these ranges, had wheel / lever / wrench shall

49 Gear operator shal be es wader wlth position indleators for open / close positions,

Limit stops shall be provided for'quarter turned valves,

For Gate /Glove Valve/ Diaphragm + Total enclosed Bovel Gear in

44

4S

16

47

5.1

52

53

53.

53.2

recy

2tnP TARO

a CS

VALVES ‘Sheet Tofir

Revd

Grease case with grease nipples

For Ball / Plug / Butterfly Valve ‘Totally euclosed helical worm gear

In grease case, with grease nipples

Where gear operator isnot called foras per elause 4.1 but vendor recommends a gear

operator, he shall highlight such ease(s) and quote separate prices for the valve and

‘gear operator,

Gear operitor shall be so designed to operate effectively withthe differential pressure

‘cross the closed valve equal (othe eold non-shook pressure rating,

‘and Butterfly valves even with wrench or lever operators shall have

‘position indicators with lint stops.

Hand whee! diameter shal not exceed 750 mm and fever length shall wot exceed S00

tmnt and effort to operate shall not exceed 35 kg al hand wheel periptery., However

failhig to meet the above requirements vendor shall offer gear operated valve oad

quote as percluse 4.3,

INSPECTION AND TESTING

Itory tests and checks called in the

Bvery valve shall be subjected to all the n

respective codes / data sheet

Every valve, ifs components and auxilintes be subjected to all the mandatory (esis

‘and checks called inthe respective coues, data sheets eto. by the mannfacta

‘The extent of third party / owner inspection shall be as follows:

Forged Valves:

‘Visual and dimensional inspection

Review of material test certificates

Any mandatory or supplementary test-review of records.

Witness liydrostatle test on 10% valves (or minimum 5 nombers for each size

‘and spec) selected on random basis, Review records for balance

Sip check is required for 196 of total ordered quantity of valves (min 1 no)

{or any Stainless Steel, Alloy Steel or valves meant for special service (like

Sulphuric acid service) oras mentioned tn the hiividual data sheet,

* 10% of ordered quantity of gate valves (mninimum 5 nos ofeach size and spec

fo be checked for satisfactory operation, Gate opening should be 100%.

Cast steel Valves:

+ Visual and dimensional inspection

VALVES Sheet Fort]

Reva

aS 66 G0T 911172008.

5.

4

$8

56

57

58

Revlew of Matec test eentitieates

+ Review of Radiographs / Radlographle reports or any otter NDT tests

‘wherever applicable as pr data shee,

4+ Any mandatory or supplementary test~ review of records,

+ Hyetrostalle test — Witness 100% for body, 10% other tests (mn

for each sae and pee). Review records for balance

4+ Strip cheok is vequited for 1% of total ordered quaitiy of valves (nin | no.)

for any Stainless Steel, Alloy Steel or valves meant for special service (like

Sulphutie acd service) oF as mentioned in the individual datasheet. Samples

for strip check shall be selected at random and shall generally be In the highest

size in the ol.

+ 10% of ordered quantity of gte valves (minimum 5 n0s of euch size and spee

)1o be cecked forsalistictory operation, Gate opening should be 100%.

imum S nos

1h case of motor operated or setuator operated valves, finctional/ operational checks

as per the requlrements ofthe spectffentions shall be made on each valve.

Valves unvder eritcal, very highly critical, lethal and toxic services. shall be

radiotephed as specified tn respective dota sheets. When specifically not

lin individual data sheets, valve castings shall undergo radiographic exa

specified heremnder:

Materint Rating Size Range Radiography

All 150# 24” und below Nid

150# 26" and above 100%

300% 16" and below Nil

3008 18" and above 100%

‘6008 and

above. Allsizes 100%

Radiography procedure, areas of casting {0 be radiographed shall be as per ANSI

16.34 and acceptance criteria shall be as per ANSI B 16.34 Annexue-B. However

for areas of casting to be radiographed for typos of valve not covered in ANSI B

16.34, vendor shall enclose details of areas (0 be radiographed in line with ANSI B

1634.

Random radiography wherever specified in individual data sheets the sampling s all

‘be per size of the quantity ordered for each foundry.

Radiography wherever specified in the data sheets or as per clause 6.1 shall be dane

by X-tay / Yo1ay (o get the required sensitivity,

a VALVES ‘Sheet Dorie

a

tee oS ATHOT TLE

iN

y Revd

61

62

63

64

a

uM

18

16

aL

82

IBR CERTIFICATION

For valve described “IBR®, valves shall be in accordance with the ttest IBR (Indian

Boiler Regulation) including the requlrements specified inthe specification,

SW _/ BW end carbon steel valves under IBR, the chemical composition shall

‘conform tothe following:

‘Carbon (Max.) 0.25%

Others (S.P.Mn) 5 Asper BR re

ulations

‘The above composition isnot valid for Non-IBR valves,

For vaives described “IBR® test certificate Inform I1-C shall be furnished, signed by

{BR inspection authority or an approved representative.

All “IBR” valves shal be pointed Red

MARKING

Valve makings, symbols, abbreviations eto, shall be in accordance with MSS-SP-25

or the stondard referred in specification sheet as applicable, Vendor's navn, Valve

rating, material designation, nominal size, direction of flow (if any) ete, shall be

integral on the body.

Lach valve shall have a corrosion resistant tag giving size, valve specification sheet

mber securely attached on the valve body,

ny harmful metal or metal salts such as

Paint oF ink for marking shall not cor

altack on heating

Zino, lead or copper which causes com

Carbon steel valves shall be palnted with two coats of Red Oxide Zine Chromate

primer,

All alloy steel high temperature valves shall be painted with heat resistant silicone

plot sultable for Intended temperature.

All3 -1/2% Ni Steel /LTCS valves shall be painted with paint suitable for tow temp.

DESPATCH

Valves shall be dry, clean and free fiom moisture, dit and loose foreign materlals of

any kind,

Valves shall be protected From rust, corrosion and any mechanical damage during

transportation, shipment and storege,

VALVES Sheet [ot

Reva

ein

fils SANT ‘wri T72005,

8.3 Rus preventive on machined surfers fo be welded shal be easly removable with a

peiralemn solvent or nt hanna to welding.

84 nd of valves sal be protected with th following mates:

Plage face Wood, metal oF paste cover

Bevelled end A Wood, metal or plastle cover

Wand scrowedend —:—_Plsliceap

85 End protestors to be used on flange feces shall be attached by a evs three bolls. oF

wiring through bolt holes and shall not be smaller than the outside diameter of he

flange, However plastic caps for SW and screwed end valves shall be press fit type.

8.6 Bnd protectors to be used on beveled end shall be seourely and tightly attached,

4:7 For speclal service valves additonal requirement of dispatch shall be presribed in

daa sheet

8.8 All certification / records required as per the stondard shall be supplied along with the

9.1

92

9.2.1

imateriat itself, Non-compliance ofthis may lead to material rejection after recelpt,

‘SPECIAL REQUIREMENTS.

‘This sectlon covers the miaimom requirements for material, fabrication and testing of

‘material in spectfic environment as listed below.

Wet Hydvogen Sulphide (H 28 resistant material)

Material shall confora to NACE MR-0103-2003. The maximum hardness of heat

affected zone after PWHT shall be less than 225 BHN.

Hantness of forged aud east components requiting resistance to Hydrogen Induced

Ciacing in Wet H2S environment shall have hardness limited o 225 DEIN.

‘VALVES Sheet Toft

Revd

wEFOAOT aio

BYPASS VALVE

SPECITICATION Type, TINGS SHEET

SHEET NUMBER fen

S1301X, SMOIX, | APISE GRB ‘105, Sw, 6oo0H | $2001X

51404X. SEAMLESS $160, H a

51503X, 51403, | A333 ORB ‘A350 GRLP2, SW] 52003X

S1303K. SEAMLESS sso |3000/

51302X, S1402X | A 106 GRB, S8OIBR | A105, SW 30008 TDR | 52002x

SISTIX, STATI, [APTSL ORB ‘Ai0s, SW 5000 | S2011K

SI3L1M. SEAMLESS, SCHXXS

‘S1336X, ST436X TABISORPSSIO [A 182 GR FS SW|S2036X

‘co0od

S1502X ‘A106 GRB, SSO TBR A105, SW, 3000MBR_ | s2072X_—

‘s1527X ‘A335 GR PI A 1e2 “GRE SW/S2027x

SEAMLESS $80, 15R_|3000# IB

51531 ‘A335 ORPLL ‘Al82_GR FIT, SW] 52031X

SEAMLESS $80 1BR__ } 30008 IBR

51339X, SUA39X, [A395 GR PD ‘A 182 Gk FY SW] 52039K

51530 SEAMLESS $160___| 60008

‘S1313X, S1413K | APISL GRD ‘A 105, SW 900087 | $2001X

SBAMLESS, SCH XXS

S1701X ‘APISL GRB. ‘ADA WEBTATOS BW | 52101

SEAMLESS S160_| S160

31702K APISL GRB, IBR ‘Az34 WEB / A105 BW | S2102K

SEAMLESS SCH160__| S1601BR

SITBIX ‘A33SORPITIBR | A234 WPII/AI&2 GR | 52131

SEAMLESS S160___| FI BW S160 1BR |

ungeufis pue dureis s opus,

48YO 247 UIA Buoy

Jarmecivose pepe | a

San a 31 84 wos Avo 94 eS Touebe ueRssdsu]

ens Pue uBisctweisIN, Buessewuo} sy dn oy ©1 1opuan'suojeinap ou

L

224WON ueWiNsog sousreyoy

StEIeg UoHeMag

ONIS

SSQMINN (ues Blog a1e SjueUWOD Yorym Yohusuno0g sopuen

QUINN soUsiajey J9B10 HOM sopuey

= ona] [ewaunasg

ae ovo _ a 3eWOY UoReinag

! Zoxrt-a | sow esodorg | OH2O-1-W (ON 2381044 |

Das könnte Ihnen auch gefallen

- KF Flanges (Swagelok)Dokument8 SeitenKF Flanges (Swagelok)vinay1999Noch keine Bewertungen

- Flanges Fittings PDFDokument24 SeitenFlanges Fittings PDFSalman KhanNoch keine Bewertungen

- Iso KF Flanges & FittingsDokument17 SeitenIso KF Flanges & Fittingsvinay1999Noch keine Bewertungen

- How Grooved Works: A Concise Guide to Mechanical Pipe JoiningDokument42 SeitenHow Grooved Works: A Concise Guide to Mechanical Pipe Joiningvinay1999Noch keine Bewertungen

- Flangge THK Calculation-20.10.10Dokument1 SeiteFlangge THK Calculation-20.10.10vinay1999Noch keine Bewertungen

- Surface Modification Methods: Dr. M. KamarajDokument68 SeitenSurface Modification Methods: Dr. M. KamarajEdukondalu PentapatiNoch keine Bewertungen

- Stamp Charging Coke OvenDokument10 SeitenStamp Charging Coke Ovenvinay1999Noch keine Bewertungen

- Flange Calculation Sheet: ImperialDokument11 SeitenFlange Calculation Sheet: Imperialvinay1999Noch keine Bewertungen

- Day 1Dokument47 SeitenDay 1vinay1999Noch keine Bewertungen

- Flangge THK CalculationDokument1 SeiteFlangge THK Calculationvinay1999Noch keine Bewertungen

- GRINNELL AP Mech Cat 2011Dokument180 SeitenGRINNELL AP Mech Cat 2011vinay1999Noch keine Bewertungen

- Tank design document analysisDokument71 SeitenTank design document analysisvinay1999Noch keine Bewertungen

- BSP - Innovations in Co & CCD - BSP - Op Comm Meeting - Feb 2011 at Jsw.Dokument21 SeitenBSP - Innovations in Co & CCD - BSP - Op Comm Meeting - Feb 2011 at Jsw.vinay1999Noch keine Bewertungen

- A New Dimension in Cokemaking Technology: Competence and Know-How by TraditionDokument28 SeitenA New Dimension in Cokemaking Technology: Competence and Know-How by Traditionvinay1999Noch keine Bewertungen

- Guide Car Platform Repair in No. 8 Battery in Running ConditionDokument19 SeitenGuide Car Platform Repair in No. 8 Battery in Running Conditionvinay1999Noch keine Bewertungen

- Kirloskar Presentation - KCPL Products For Pumps, Pipes, StructuresDokument61 SeitenKirloskar Presentation - KCPL Products For Pumps, Pipes, Structuresvinay1999Noch keine Bewertungen

- BSP - Innovations in Co & CCD - BSP - Op Comm Meeting - Feb 2011 at Jsw.Dokument21 SeitenBSP - Innovations in Co & CCD - BSP - Op Comm Meeting - Feb 2011 at Jsw.vinay1999Noch keine Bewertungen

- Design ManualDokument27 SeitenDesign Manualvinay1999Noch keine Bewertungen

- Volume of Tori Spherical HeadDokument4 SeitenVolume of Tori Spherical Headvinay1999Noch keine Bewertungen

- Input Conditions - by Test or Specification Fuel - Coal / LigniteDokument2 SeitenInput Conditions - by Test or Specification Fuel - Coal / Lignitevinay1999Noch keine Bewertungen

- ? CalendersDokument189 Seiten? Calendersvinay1999Noch keine Bewertungen

- Ascendant CalculationDokument14 SeitenAscendant CalculationDvs Ramesh100% (1)

- Floating Roof Design CalculationsDokument5 SeitenFloating Roof Design Calculationsvinay1999Noch keine Bewertungen

- Dev Energy - GASIFIERDokument33 SeitenDev Energy - GASIFIERvinay1999Noch keine Bewertungen

- ? CalendersDokument189 Seiten? Calendersvinay1999Noch keine Bewertungen

- Wheelchair Exercises PDFDokument154 SeitenWheelchair Exercises PDFAlina PasăreNoch keine Bewertungen

- T4S Regulation For CGDDokument42 SeitenT4S Regulation For CGDsumant.c.singh1694Noch keine Bewertungen

- Guidelines 07032016Dokument17 SeitenGuidelines 07032016Manjunath MadiwalarNoch keine Bewertungen

- Physiotherapy Bill FormatDokument8 SeitenPhysiotherapy Bill Formatvinay1999Noch keine Bewertungen

- Schedule 4: "Storage, Handling and Dispensing at LNG/LCNG Dispensing Stations"Dokument21 SeitenSchedule 4: "Storage, Handling and Dispensing at LNG/LCNG Dispensing Stations"vinay1999Noch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)