Beruflich Dokumente

Kultur Dokumente

Penetration of Fuel Spray

Hochgeladen von

Sundar Mahalingam0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten10 SeitenFuel Spray Penetration

Originaltitel

4. Penetration of Fuel Spray

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenFuel Spray Penetration

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

15 Ansichten10 SeitenPenetration of Fuel Spray

Hochgeladen von

Sundar MahalingamFuel Spray Penetration

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 10

Penetration of fuel spray

Penetration of fuel spray

Fuel penetration during fuel injection limits

the size of the combustion chamber and

engine cylinder

Factors deciding fuel penetration

Fuel injection pressure

Diameter of the orifice

Length to diameter ratio of the orifice

Density of the air in the combustion chamber

Viscosity of the fuel

Two types of velocity in fuel injection

Spray tip velocity

Average individual particle velocity

Two types of penetration

Penetration of spray tip

Average penetration of individual particle

Orifice length to diameter ratio

4:1 to 6:1 ------ max penetration

1:1 to 3:1 ------minimum penetration

Dispersion of fuel spray

Increased fuel injection pressure

Reduced fuel oil viscosity

Higher air pressure in the combustion

chamber

Proper injection nozzle design

Large shape edged orifice

Reduced length to diameter ratio of orifice

Nozzle tip which gives a large cone shaped spray

or by a multihole nozzle

In airless injection system fuel

injection system is accomplished by

the following means

Nozzle tip which gives a cone shaped spray

A nozzle tip with several orifices (5 to 8)

2 or more separate nozzles, in large engines

Nozzle holes & fuel dispersion

Diameter of the nozzle hole 0.245 to 0.305

mm

Number of nozzle hole 3 to 8

Separation b/w orifice nozzle tip 0.2 mm

Dispersion of fuel spray is indicated by spray

cone angle

spray cone angle angle b/w the tangents

drawn to the periphery, at a distance equal to

60 d

d orifice diameter

Das könnte Ihnen auch gefallen

- 18ae502 - Aircraft Structures Ii: (18AE502 - Unit2 - FA2 - ASM)Dokument9 Seiten18ae502 - Aircraft Structures Ii: (18AE502 - Unit2 - FA2 - ASM)Sundar MahalingamNoch keine Bewertungen

- Module 3 NewDokument37 SeitenModule 3 NewSundar MahalingamNoch keine Bewertungen

- Paper 018Dokument24 SeitenPaper 018Sundar MahalingamNoch keine Bewertungen

- Aerospace 09 00028Dokument19 SeitenAerospace 09 00028Sundar MahalingamNoch keine Bewertungen

- 1st Qn.Dokument2 Seiten1st Qn.Sundar MahalingamNoch keine Bewertungen

- Complete Solar Direct Drive Refrigeration System For Vaccine StorageDokument8 SeitenComplete Solar Direct Drive Refrigeration System For Vaccine StorageSundar MahalingamNoch keine Bewertungen

- Lesson Plan TemplateDokument3 SeitenLesson Plan TemplateSundar MahalingamNoch keine Bewertungen

- Dear Sir/Madam,: "This Mail Finds You, Your Family Members and Colleagues Are Doing Well"Dokument2 SeitenDear Sir/Madam,: "This Mail Finds You, Your Family Members and Colleagues Are Doing Well"Sundar MahalingamNoch keine Bewertungen

- Lesson Plan TemplateDokument3 SeitenLesson Plan TemplateSundar MahalingamNoch keine Bewertungen

- FDP - EPE - Participants FDP IDDokument28 SeitenFDP - EPE - Participants FDP IDSundar Mahalingam100% (1)

- 7days FDP On Ethical Practices in Engineering: Department of Mechanical EngineeringDokument1 Seite7days FDP On Ethical Practices in Engineering: Department of Mechanical EngineeringSundar MahalingamNoch keine Bewertungen

- Thermal FDP Schedule-2Dokument1 SeiteThermal FDP Schedule-2Sundar MahalingamNoch keine Bewertungen

- 18is13 Occupational Health and Hygiene: Gas Poisoning (Such As CO, Ammonia, Coal and Dust) Their Effects and PreventionDokument25 Seiten18is13 Occupational Health and Hygiene: Gas Poisoning (Such As CO, Ammonia, Coal and Dust) Their Effects and PreventionSundar MahalingamNoch keine Bewertungen

- Day 1Dokument86 SeitenDay 1Sundar MahalingamNoch keine Bewertungen

- Module 4: Quasi-One Dimesional FlowsDokument1 SeiteModule 4: Quasi-One Dimesional FlowsSundar MahalingamNoch keine Bewertungen

- 5 PDFDokument1 Seite5 PDFSundar MahalingamNoch keine Bewertungen

- 1 PDFDokument1 Seite1 PDFSundar MahalingamNoch keine Bewertungen

- GDJP Model 14Dokument2 SeitenGDJP Model 14Sundar MahalingamNoch keine Bewertungen

- Mechanical - 17 12 17 QPDokument20 SeitenMechanical - 17 12 17 QPSundar MahalingamNoch keine Bewertungen

- GDJP Assignment 1Dokument1 SeiteGDJP Assignment 1Sundar MahalingamNoch keine Bewertungen

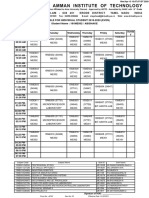

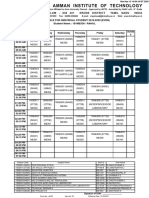

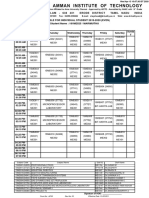

- Time Table For Individual Student 2019-2020 (Even) Student Name: 181ME502 / ABISHAKEDokument1 SeiteTime Table For Individual Student 2019-2020 (Even) Student Name: 181ME502 / ABISHAKESundar MahalingamNoch keine Bewertungen

- Lesson Plan GDJPDokument2 SeitenLesson Plan GDJPSundar Mahalingam100% (1)

- Time Table For Individual Student 2019-2020 (Even) Student Name: 181ME536 / RAHULDokument1 SeiteTime Table For Individual Student 2019-2020 (Even) Student Name: 181ME536 / RAHULSundar MahalingamNoch keine Bewertungen

- Ae341 - Aircraft Structures - IiDokument4 SeitenAe341 - Aircraft Structures - IiSundar MahalingamNoch keine Bewertungen

- Time Table For Individual Student 2019-2020 (Even) Student Name: 181ME514 / GOKULDokument2 SeitenTime Table For Individual Student 2019-2020 (Even) Student Name: 181ME514 / GOKULSundar MahalingamNoch keine Bewertungen

- Time Table For Individual Student 2019-2020 (Even) Student Name: 181ME531 / NUGAMATHI RAJDokument2 SeitenTime Table For Individual Student 2019-2020 (Even) Student Name: 181ME531 / NUGAMATHI RAJSundar MahalingamNoch keine Bewertungen

- Answer Keys of The Written Test For Recruitment To The Post of Scientist/Engineer 'SC' (Mechanical) (Be002) Held On 03.07.2016Dokument5 SeitenAnswer Keys of The Written Test For Recruitment To The Post of Scientist/Engineer 'SC' (Mechanical) (Be002) Held On 03.07.2016Sundar MahalingamNoch keine Bewertungen

- Unsymmetrical BendingDokument1 SeiteUnsymmetrical BendingSundar MahalingamNoch keine Bewertungen

- Time Table For Individual Student 2019-2020 (Even) Student Name: 181ME525 / MARIMUTHUDokument1 SeiteTime Table For Individual Student 2019-2020 (Even) Student Name: 181ME525 / MARIMUTHUSundar MahalingamNoch keine Bewertungen

- B.E. B.Tech. - V Semester (R2011) - REGULAR & ARREARDokument1 SeiteB.E. B.Tech. - V Semester (R2011) - REGULAR & ARREARSundar MahalingamNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)