Beruflich Dokumente

Kultur Dokumente

Steam Calculation: Assumption

Hochgeladen von

Omar Ahmed ElkhalilOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Steam Calculation: Assumption

Hochgeladen von

Omar Ahmed ElkhalilCopyright:

Verfügbare Formate

Steam calculation

Assumptioncrushing capacity

=580 TCH

Raw juice % cane

=102.23

C.J % cane

=102.23

filtrate juice % cane

=15

Total mixed juice %cane

=117.23

Clear juice brix

=13.35

Syrup brix

=56.86

A M/C % cane

=32.05

factor =0.5

BM/C % cane

=11.28

factor =0.4

C1 m/c % cane

=5.28

factor =0.5

C M/c % cane

=5.83%

factor =0.45

total M/c % cane

=54.44

juice heating

RJ1 heating through VLJH from

=34-440C

RJ2 heating through 3rd effect (from Dy.J.H.) from

=44-600c

RJ3 heating through VC vapours(500M2 HS JH No.1) from

=60-700C

SJ1 heating through flash vapours from 3rd chamber of cigar

=70-780C

SJ2 heating through VC vapours from

=78-900C

SJ3 heating through SK vapours from

=90-1020C

CJ1 heating through VC vapours from

=97-990C

CJ2 heating through SK vapours from

=99-1040C

=104-1120C

CJ3 heating through Direct contact heater

Clear juice quantity

=580 x1.0223 =592.934 ton /hr

Total quantity of clear juice

=592.934 + vapour add CJ3

=592.934 + 8.03

=600 ton/hr

Mixed juice quantity

=580x1.1723 =680 ton /hr

Total Evaporation

= 600 (56.86 13.35) / 56.86

= 459.86 Ton / Hr

Vapour required for RJ1 heating in VLJH

= 10.83

Vapour required for RJ2 heating by 3rd effect vapour

= 18.08

3.12%

= 11.38

1.96%

= 9.04

1.56%

= 13.65

2.35%

= 13.81

2.38%

= 1.98

.34%

= 5.02

.87%

= 8.03

1.38%

= 92.95

16.0%

Vapour required for RJ3 heating by VC vapour

Vapour required for SJ1 heating by flash vapour

Vapour required for SJ2 heating by VC vapour

Vapour required for SJ3 heating by SK vapour

Vapour required for CJ1 heating by VC vapour

Vapour required for CJ2 heating by SK vapour

Vapour required for CJ3 heating by SK vapour

(by DC heater)

Vapour required for A massecuite boiling from VC

Vapour required for B massecuite boiling from VC

= 26.17

4.51%

= 15.31

2.64%

= 15.22

2.62%

Vapour required for C1 massecuite boiling from SK

Vapour required for C massecuite boiling from SK

Total evaporation at vapour Cell

=RJ3+SJ2+CJ1+Am/c+Bm/c

=146.13 Ton / Hr

Total evaporation at S. K

= VC+SJ3+CJ2+CJ3+C&C1m/c

=203.51Ton / Hr

Total evaporation at DEVC

= 203.51 + 146.13

= 349.65 Ton / Hr.

Hence total evaporation at quintuple

= 459.86 349.65

= 110.21 Ton / Hr

Evaporation in 1st body of quintuple (SK)

= 29.28

Evaporation in 2nd body of quintuple

= 29.28

Evaporation in 3rd body of quintuple

= 29.28

Evaporation in 4th body of quintuple

= 11.19

Evaporation in 5th body of quintuple

= 11.19

Actual Total evaporation at S. K

= 232.79

Exhaust consumption at (DEVC+Quintuple)

= 232.79

Exhaust % cane

= 40.14 %

Condensation losses

Steam losses through venting in B/H & turbine

Live steam consumption

Soda boiling & pan washing

=1%

= 0.75%

= 0.6 %

= 0.75 %

STEAM % CANE

= 43.24 %

For juice & syrup

= 15 - 16 %

For massecuite

= 25 - 26 %

1.93%

This figures also achieved in during season 2008-09 as given

bellow

Date

Crushing

Steam % cane

28/12/08

1,42,000

42.02 %

30/12/08

1,40,000

42.30 %

31/12/08

1,40,000

41.81 %

01/01/09

1,40,000

42.48 %

06/01/09

1,40,000

42.89 %

09/01/09

1,37,000

42.03 %

Das könnte Ihnen auch gefallen

- Perhitungan Evaporator PG - Rendeng Kudus Desain Bleeding Ke Masakan Dan Juice HeaterDokument38 SeitenPerhitungan Evaporator PG - Rendeng Kudus Desain Bleeding Ke Masakan Dan Juice HeaterPengolahan Rendeng2018Noch keine Bewertungen

- Material - Balance - in - Milling - Tandem-2014 (Autosaved 14502016Dokument235 SeitenMaterial - Balance - in - Milling - Tandem-2014 (Autosaved 14502016dhairyashil jadhavNoch keine Bewertungen

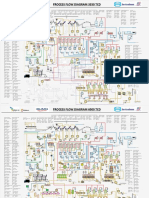

- PFD Asembagus Plan ADokument2 SeitenPFD Asembagus Plan AsafitriNoch keine Bewertungen

- Menghitung Air Yang Teruapkan Di Pan Masak CDokument4 SeitenMenghitung Air Yang Teruapkan Di Pan Masak CsobariniNoch keine Bewertungen

- Krista LizerDokument462 SeitenKrista Lizerdwi anggraeniNoch keine Bewertungen

- Steam Balance MPDokument19 SeitenSteam Balance MPSaifuddinHidayatNoch keine Bewertungen

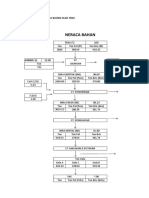

- Neraca BahanDokument14 SeitenNeraca BahanAkmal ZuhriNoch keine Bewertungen

- Cholesterol SynthesisDokument21 SeitenCholesterol SynthesisAbdimalik AliNoch keine Bewertungen

- Steam Balance TCDDokument12 SeitenSteam Balance TCDSaifuddinHidayatNoch keine Bewertungen

- PompaDokument93 SeitenPompaMaRhaenia TheresaNoch keine Bewertungen

- Pendataan Pedagang Desa GadunganDokument21 SeitenPendataan Pedagang Desa GadungansantiNoch keine Bewertungen

- Boiling House EfficiencyDokument14 SeitenBoiling House EfficiencyManoj KageNoch keine Bewertungen

- Stainless Steel Price-Jindal ERW Pipes-21-12-2020Dokument1 SeiteStainless Steel Price-Jindal ERW Pipes-21-12-2020SRINIVASAN TNoch keine Bewertungen

- Carbonation VS Phos Floation PDFDokument48 SeitenCarbonation VS Phos Floation PDFRAJKUMARNoch keine Bewertungen

- Sugar ProcessDokument1 SeiteSugar Processnizam habibieNoch keine Bewertungen

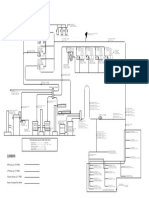

- Steam Balance Layout (TPH) ModelDokument1 SeiteSteam Balance Layout (TPH) ModelRemington SalayaNoch keine Bewertungen

- Grading For Vacuum Pan (Plantation White and Refined) Sugar: Draft Indian StandardDokument16 SeitenGrading For Vacuum Pan (Plantation White and Refined) Sugar: Draft Indian StandardAkhilesh Dhar DiwediNoch keine Bewertungen

- LOTTE E&C - IntroduceDokument14 SeitenLOTTE E&C - Introducemyusuf123Noch keine Bewertungen

- Milk or Lime or Lime Saccharate PDFDokument2 SeitenMilk or Lime or Lime Saccharate PDFAnand Atre100% (1)

- Optimization of Sugar Cane Bagasse Pretreatment Process Using RSMDokument10 SeitenOptimization of Sugar Cane Bagasse Pretreatment Process Using RSMInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Boiler DraftDokument22 SeitenBoiler DraftJAY PARIKHNoch keine Bewertungen

- Tutorial Answers - Separation B Tutorial - Combined Tutorial Solutions PDFDokument38 SeitenTutorial Answers - Separation B Tutorial - Combined Tutorial Solutions PDFBuyuNoch keine Bewertungen

- Technical Note - Number FF-25-02-08: Notes On Cleaning of Continuous Vacuum PansDokument11 SeitenTechnical Note - Number FF-25-02-08: Notes On Cleaning of Continuous Vacuum PansJavier Manuel IbanezNoch keine Bewertungen

- AlKhaleejEnergyEfficientRefinery1999 PDFDokument23 SeitenAlKhaleejEnergyEfficientRefinery1999 PDFnghiNoch keine Bewertungen

- Ejercicios de Ingeniería EconómicaDokument2 SeitenEjercicios de Ingeniería EconómicaDiego MoralesNoch keine Bewertungen

- 02 Affination Mingling Centrifugation MeltingDokument2 Seiten02 Affination Mingling Centrifugation MeltingjantskieNoch keine Bewertungen

- Trials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar FactoryDokument4 SeitenTrials of A New Stirrer-Less Juice Sulphiter at Experimental Sugar FactoryInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Distillery Wastwater Treatment-CDM Project-2012Dokument60 SeitenDistillery Wastwater Treatment-CDM Project-2012tsrinivasan5083Noch keine Bewertungen

- The Calculation of Mill Material Balance: PT Indocode SuryaDokument10 SeitenThe Calculation of Mill Material Balance: PT Indocode SuryaToat SumohandoyoNoch keine Bewertungen

- Effect of Non-PolDokument6 SeitenEffect of Non-PolKevynNoch keine Bewertungen

- Bulletin - 118 - E Audit in Sugar & DistilleryDokument4 SeitenBulletin - 118 - E Audit in Sugar & DistilleryBala MuruganNoch keine Bewertungen

- SRI Jigger Tubes System: Design, Installation and Commissioning ManualDokument16 SeitenSRI Jigger Tubes System: Design, Installation and Commissioning ManualSebastiánSaltarenNoch keine Bewertungen

- N-Butanol Plant Design BriefDokument5 SeitenN-Butanol Plant Design BriefTom Hart100% (1)

- Vacuum System ParametersDokument7 SeitenVacuum System ParametersOmar Ahmed ElkhalilNoch keine Bewertungen

- Milling Laboratory ManualDokument121 SeitenMilling Laboratory Manualkyamanywa richardNoch keine Bewertungen

- Carbonation ProcessDokument4 SeitenCarbonation ProcessFindi DiansariNoch keine Bewertungen

- Quality Changes During Storage of Raw Sugar.109132625Dokument9 SeitenQuality Changes During Storage of Raw Sugar.109132625Carlos TomeyNoch keine Bewertungen

- tmp7F33 TMPDokument11 Seitentmp7F33 TMPFrontiersNoch keine Bewertungen

- Brix Curve 2022-23.Dokument6 SeitenBrix Curve 2022-23.Mohit SrivastavaNoch keine Bewertungen

- Reference Control PhilosophyDokument22 SeitenReference Control PhilosophyReno MurdaNoch keine Bewertungen

- 2005 - Ravno - Dealing With Dextran in TheDokument20 Seiten2005 - Ravno - Dealing With Dextran in ThesutantyoNoch keine Bewertungen

- 31295019466605Dokument329 Seiten31295019466605ctomeyNoch keine Bewertungen

- Asme Section II A Sa-423 Sa-423mDokument6 SeitenAsme Section II A Sa-423 Sa-423mAnonymous GhPzn1xNoch keine Bewertungen

- SRI Jigger Steam ManualDokument23 SeitenSRI Jigger Steam ManualzalabiNoch keine Bewertungen

- Vacuum PanDokument7 SeitenVacuum Pananon_33049728Noch keine Bewertungen

- BEng DesignThesisfinal PDFDokument245 SeitenBEng DesignThesisfinal PDFprideNoch keine Bewertungen

- Al Khaleej Water Efficient Refinery 2000Dokument12 SeitenAl Khaleej Water Efficient Refinery 2000roy@daesNoch keine Bewertungen

- Data Impor Xylitol 2006-2016Dokument3 SeitenData Impor Xylitol 2006-2016Anonymous s7xTz1Noch keine Bewertungen

- Che Computer Simulation ProblemDokument12 SeitenChe Computer Simulation ProblemTots HolaresNoch keine Bewertungen

- Technicalreport Alcoholtechnology PDFDokument0 SeitenTechnicalreport Alcoholtechnology PDFAmol DeshmukhNoch keine Bewertungen

- Instrumentation & Control of Continuous Vacuum Pans: by M.A. GetazDokument28 SeitenInstrumentation & Control of Continuous Vacuum Pans: by M.A. GetazJavier Manuel IbanezNoch keine Bewertungen

- Production of Amorphous SIlica From Geothermal Sludge of Dieng IndonesiaDokument9 SeitenProduction of Amorphous SIlica From Geothermal Sludge of Dieng IndonesiaharizatuzzNoch keine Bewertungen

- 1994 Gibbon Cad Thrashplate DesignDokument3 Seiten1994 Gibbon Cad Thrashplate DesignsurachsNoch keine Bewertungen

- 21Dokument29 Seiten21Remington SalayaNoch keine Bewertungen

- Promo HNZ Sigma Aldrich Labware GuideDokument12 SeitenPromo HNZ Sigma Aldrich Labware GuideMargaretaSianneNoch keine Bewertungen

- Hexamine 1Dokument66 SeitenHexamine 1Pradhita Ramdani HNoch keine Bewertungen

- Alternative Process of Glucose To Be SorbitolDokument3 SeitenAlternative Process of Glucose To Be SorbitolNabilatun SholikhaNoch keine Bewertungen

- Exploration KerinciDokument6 SeitenExploration KerinciNovia Pirma Yeni PirdausNoch keine Bewertungen

- Emma MangarooDokument17 SeitenEmma MangarooCharlotte BNoch keine Bewertungen

- Unit Operation in Food Processing Chapter 6 ProblemsDokument12 SeitenUnit Operation in Food Processing Chapter 6 ProblemsTeh Sze Yin100% (3)

- Chapter 2: Species and Breeds: Traits Desi Naked Neck Aseel Kadak-Anath Black BengalDokument4 SeitenChapter 2: Species and Breeds: Traits Desi Naked Neck Aseel Kadak-Anath Black BengalBashir JunejoNoch keine Bewertungen

- Gross Profit Revenue (Sales) Operation Income (EBIT) Revenue (Sales) Net Income Revenue (Sales)Dokument7 SeitenGross Profit Revenue (Sales) Operation Income (EBIT) Revenue (Sales) Net Income Revenue (Sales)Omar Ahmed ElkhalilNoch keine Bewertungen

- Small-Scale Poultry Production - Chapter 01Dokument5 SeitenSmall-Scale Poultry Production - Chapter 01Omar Ahmed ElkhalilNoch keine Bewertungen

- Small-Scale Poultry Production - 00 CoverDokument2 SeitenSmall-Scale Poultry Production - 00 CoverOmar Ahmed ElkhalilNoch keine Bewertungen

- Asset ValuationDokument3 SeitenAsset ValuationOmar Ahmed ElkhalilNoch keine Bewertungen

- Asset Based ValuationDokument4 SeitenAsset Based ValuationOmar Ahmed ElkhalilNoch keine Bewertungen

- Solar EnergyDokument2 SeitenSolar EnergyOmar Ahmed ElkhalilNoch keine Bewertungen

- HVAC Design SourcebookDokument398 SeitenHVAC Design SourcebookMahmoud Gwaily96% (55)

- HVAC Procedures Forms ManualDokument279 SeitenHVAC Procedures Forms Manualgeneroso67100% (12)

- Alfa Laval Pump Handbook PDFDokument257 SeitenAlfa Laval Pump Handbook PDFkashifwarsiNoch keine Bewertungen

- Power Plant Commissioning PDFDokument274 SeitenPower Plant Commissioning PDFLaholDelveca89% (27)

- Power Plant Commissioning PDFDokument274 SeitenPower Plant Commissioning PDFLaholDelveca89% (27)

- Anaerobic Treatment of Vinasse From Sugarcane EthanolDokument9 SeitenAnaerobic Treatment of Vinasse From Sugarcane EthanolOmar Ahmed ElkhalilNoch keine Bewertungen

- Environments 06 00005Dokument13 SeitenEnvironments 06 00005MALAKIPWETKONoch keine Bewertungen

- MoP Foundation Sample PaperDokument19 SeitenMoP Foundation Sample PaperOmar Ahmed ElkhalilNoch keine Bewertungen

- M13 - Materials Handling - Rev02Dokument10 SeitenM13 - Materials Handling - Rev02Omar Ahmed ElkhalilNoch keine Bewertungen

- Sustainability 04 00092Dokument14 SeitenSustainability 04 00092Hansel Sterling SeverinoNoch keine Bewertungen

- Environments 06 00005Dokument13 SeitenEnvironments 06 00005MALAKIPWETKONoch keine Bewertungen

- Sugarcane EthanolDokument16 SeitenSugarcane EthanolAlexa MariusNoch keine Bewertungen

- JaggeryDokument8 SeitenJaggeryoswadiNoch keine Bewertungen

- Diffusion - HandoutDokument19 SeitenDiffusion - HandoutOmar Ahmed ElkhalilNoch keine Bewertungen

- Bucknells Cogeneration Power PlantDokument28 SeitenBucknells Cogeneration Power PlantOmar Ahmed ElkhalilNoch keine Bewertungen

- SWG Material Thickness ChartDokument1 SeiteSWG Material Thickness Chartm2110Noch keine Bewertungen

- Existing Capacity Calculation Sutiable For 13200 TCD (550TCH)Dokument13 SeitenExisting Capacity Calculation Sutiable For 13200 TCD (550TCH)Omar Ahmed Elkhalil67% (6)

- Project Standards and Specifications Steam Trap Systems Rev01Dokument6 SeitenProject Standards and Specifications Steam Trap Systems Rev01Omar Ahmed ElkhalilNoch keine Bewertungen

- Diffusion - HandoutDokument19 SeitenDiffusion - HandoutOmar Ahmed ElkhalilNoch keine Bewertungen

- SugarDokument12 SeitenSugarWattana ChanakitkarnchaiNoch keine Bewertungen

- General Mechanical Specification May 2013-HP 20 05 13 - New StyleDokument36 SeitenGeneral Mechanical Specification May 2013-HP 20 05 13 - New StyleOmar Ahmed ElkhalilNoch keine Bewertungen

- ISTU - Task Flow Chart - Sugar Projects REV00Dokument1 SeiteISTU - Task Flow Chart - Sugar Projects REV00Omar Ahmed ElkhalilNoch keine Bewertungen