Beruflich Dokumente

Kultur Dokumente

355 Jr+Ar: Weldi NG Procedure Data Sheet

Hochgeladen von

Kawser HossainOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

355 Jr+Ar: Weldi NG Procedure Data Sheet

Hochgeladen von

Kawser HossainCopyright:

Verfügbare Formate

WELDI NG

PROCEDURE

DATA SHEET

Al Yarmouk Metal Construction LLC, Dubai , UAE

Company Name:

WPDS NO.:

DATE:

YMK-WPS002

Ref.

Standa

rds:

Ref.

Address:

Welding Processes:

Shielding Gas

P

No

u Yes

l

s

e

d

Machine :

Auto

GMAW

90%Ar/ 10% CO2

Type:

Positions:

Process Mode:

Manual

Joint Type:

Butt

Semi-Auto

Tee

Yes

Backgouging:

Yes

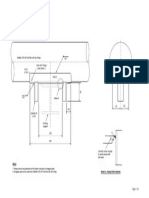

Joint Configuration & Pass/Layer Sequence

Corner

Partial

Penetration:

Backing:

AWS D1.1/

GMAW -1

W PS:

N

/A

Method:

ETT=

Rev.:

P

No

u

l

s

e

d

:

Thickness:

No

Electrode

Extension:

Nozzle Diameter(s):

16 mm

Flux Classification: N/A

Tungsten Electrode: Type:

Cleaning

Wire

Procedures

N/A

brush, clean between passes

Dia.:

Indirect

Lap Splice

Splice

Rebar to Structural Member Only

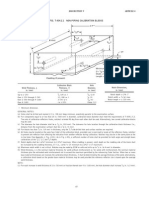

Identification of Base Material (for EN 10025 indicate carbon equivalent, max. phosphor us & sulphur content)

ASTM A572

Splice Type:

Direct Splice

Part

I

II

Specification & Grade

Thickness or Dia.

ASTM 572, 355 Jr+Ar

ASTM 618 , 355 Jr+Ar

Special Requirements

6-10 mm

6-10 mm

N/A

N/A

Filler Material

Trade Name

Classification

Group

N/A

Weld

ness ( Size/

)

ETT

Pass

Layer

Welding Dia.

Process ( mm

Number

Wire Feed Current

Speed

A

GMAW

1

2

GMAW

1

GMAW

2-3

GMAW

Heat Input

( l/min

260

28

DC+

400-500

20

1.2

10

260

28

DC+

300-400

20

1.2

1.2

10

10

260

260

28

28

DC+

DC+

400-500

400-500

20

20

Interpasstemp.max

.:

Interpasstemp.mi

n.:

10

CWB Acceptance

10 C

Burn-Off Gas Flow

Rate

Rate

1.2

Heat

Preheat min:

Volt Current Welding

V

Polarity Speed

( mm/mi n )

10

Filler Treatment

N/A

Company Aut horization

250 C

10 C

To be signed by the

engineer

or supervisor before

submission to the

Consultant

Date:

Das könnte Ihnen auch gefallen

- Wps SawDokument2 SeitenWps Sawdevendrasingh2021100% (6)

- KD Panels - Tds (En)Dokument4 SeitenKD Panels - Tds (En)Dilon FernandoNoch keine Bewertungen

- PQR-WPS-WPQR XXX Rev 0Dokument6 SeitenPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- 0160e - Welding Procedures Data SheetDokument1 Seite0160e - Welding Procedures Data SheetAmanpreet SinghNoch keine Bewertungen

- Welding Procedure DatasheetDokument1 SeiteWelding Procedure Datasheetsajeev27Noch keine Bewertungen

- BORAL Silkwood Installation Guide & WarrantyDokument12 SeitenBORAL Silkwood Installation Guide & Warrantyjonzak1234Noch keine Bewertungen

- Calculation of Block Wall Load On First & Second FloorDokument1 SeiteCalculation of Block Wall Load On First & Second FloorIrfan AliNoch keine Bewertungen

- Design Capacity Check For New Proposed MaterialDokument2 SeitenDesign Capacity Check For New Proposed MaterialKawser HossainNoch keine Bewertungen

- Restrained Beams HandoutDokument2 SeitenRestrained Beams Handoutikanyu79Noch keine Bewertungen

- Bo QDokument9 SeitenBo QAdnan Ali ChaudhryNoch keine Bewertungen

- QW 482 WPS (Gtaw+smaw) 04.01.2015Dokument8 SeitenQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNoch keine Bewertungen

- 2014 Davis and AvciDokument11 Seiten2014 Davis and Avcigene_sparcNoch keine Bewertungen

- Steel Structure Design CalculationDokument12 SeitenSteel Structure Design CalculationSenthooran MahendranNoch keine Bewertungen

- ASTM E84 ACP Test Report PDFDokument10 SeitenASTM E84 ACP Test Report PDFaziz hNoch keine Bewertungen

- Weld GaugesDokument15 SeitenWeld GaugessojeckNoch keine Bewertungen

- CEN TOOL Standard Padeyes V4 Rollup Padeye SheaveDokument5 SeitenCEN TOOL Standard Padeyes V4 Rollup Padeye SheaveMarvan100% (1)

- Gas Metal Arc WeldingDokument52 SeitenGas Metal Arc WeldingBalakumarNoch keine Bewertungen

- Welding DesignDokument19 SeitenWelding DesignSarahFiegener100% (1)

- Shear Force CalculationDokument2 SeitenShear Force Calculationdrwhite48Noch keine Bewertungen

- Trial Assembly of Columns & Ceiling GirdersDokument1 SeiteTrial Assembly of Columns & Ceiling GirdersAnonymous gr5Pr9AVNoch keine Bewertungen

- Wind Loads For Permiable Facades With High PorosityDokument12 SeitenWind Loads For Permiable Facades With High PorosityNikola IvanovicNoch keine Bewertungen

- WPS ExampleDokument2 SeitenWPS ExampleMarcio Jr.Noch keine Bewertungen

- BC MT 1688-0000Dokument84 SeitenBC MT 1688-0000Tuấn ĐậuNoch keine Bewertungen

- Complete List of Colleges Merit Scholarships WebsiteDokument26 SeitenComplete List of Colleges Merit Scholarships WebsiteBerhance G0% (1)

- Pipefitter/WelderDokument2 SeitenPipefitter/Welderapi-122242190Noch keine Bewertungen

- Quantity Unit Tools Description RemarksDokument2 SeitenQuantity Unit Tools Description RemarksnashNoch keine Bewertungen

- Welding Gauges PDFDokument4 SeitenWelding Gauges PDFsopan kharcheNoch keine Bewertungen

- ISO 5817 Chennai 2011 Pres PDFDokument17 SeitenISO 5817 Chennai 2011 Pres PDFcesargamboaNoch keine Bewertungen

- Welding R1Dokument49 SeitenWelding R1proxywarNoch keine Bewertungen

- Arabic Welding Defects RT PDFDokument42 SeitenArabic Welding Defects RT PDFlucianaNoch keine Bewertungen

- Astm f682 1982Dokument7 SeitenAstm f682 1982dharlanuctcomNoch keine Bewertungen

- Meiser GratingDokument122 SeitenMeiser GratingTtx Endless LoveNoch keine Bewertungen

- Hot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 MannessmanDokument3 SeitenHot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 Mannessmandnageshm4n244Noch keine Bewertungen

- A Review On Various Welding TechniquesDokument7 SeitenA Review On Various Welding TechniquesIJMER100% (1)

- Facade Undertaking Letter FormالاستشاريDokument3 SeitenFacade Undertaking Letter FormالاستشاريKawser HossainNoch keine Bewertungen

- Welding Bevel Design 3.1 Bevels For Other Than GTAW Root PassDokument2 SeitenWelding Bevel Design 3.1 Bevels For Other Than GTAW Root PassaezeadNoch keine Bewertungen

- WeldingDokument752 SeitenWeldingAndres_Pastor1987100% (3)

- PQR Saw ProcessDokument1 SeitePQR Saw ProcessARUL ARON JOSENoch keine Bewertungen

- Visual Examination of Welds - Welds 3-14Dokument64 SeitenVisual Examination of Welds - Welds 3-14carlos100% (1)

- Handrail Coring Check (Calculation)Dokument56 SeitenHandrail Coring Check (Calculation)Rey GonzalesNoch keine Bewertungen

- Reincorcing Pad DetailsDokument1 SeiteReincorcing Pad DetailsmkstngrNoch keine Bewertungen

- Thermal Stress ExamplesDokument10 SeitenThermal Stress ExamplesVishal V BhagwatNoch keine Bewertungen

- BLOQUEDokument1 SeiteBLOQUEAlvaro Alexis Mendoza PradaNoch keine Bewertungen

- Stair Hand Rail Connection Design Calculation-WPCDokument12 SeitenStair Hand Rail Connection Design Calculation-WPCUmesh ChamaraNoch keine Bewertungen

- 9 Welding Processes Cwip 3.1Dokument12 Seiten9 Welding Processes Cwip 3.1Jawed AkhterNoch keine Bewertungen

- ALUMIL - Accessories Guarantee Guidelines - EN-2019.V3Dokument11 SeitenALUMIL - Accessories Guarantee Guidelines - EN-2019.V3Aleksandar Sasa DjurkovicNoch keine Bewertungen

- RP 18 MPT 001 TCR AlupcoDokument3 SeitenRP 18 MPT 001 TCR AlupcoRonel John Rodriguez CustodioNoch keine Bewertungen

- Collar EyeBolt To BS4278 Table 1Dokument9 SeitenCollar EyeBolt To BS4278 Table 1Rajesh N Priya GopinathanNoch keine Bewertungen

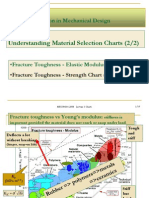

- Caceres-L3 Understanding Materials Selection ChartsDokument23 SeitenCaceres-L3 Understanding Materials Selection ChartsUngku Mohd RafiqNoch keine Bewertungen

- Result Test Panel (SUS409) HES-specDokument25 SeitenResult Test Panel (SUS409) HES-specLe Manh DungNoch keine Bewertungen

- I-963 Welder Certificate Smaw-Gtaw-1Dokument1 SeiteI-963 Welder Certificate Smaw-Gtaw-1nivedithdigitals onlineservices100% (1)

- Project Name: Revision:: Calcs By: DateDokument1 SeiteProject Name: Revision:: Calcs By: DateYam BalaoingNoch keine Bewertungen

- MY4130 Lecture 4Dokument4 SeitenMY4130 Lecture 4Erik WadeNoch keine Bewertungen

- Specification: Galvanized Iron Scaffold Tubes: Scaffold Tubes Used As Standard, Ledgers, Transoms, TieDokument2 SeitenSpecification: Galvanized Iron Scaffold Tubes: Scaffold Tubes Used As Standard, Ledgers, Transoms, TiesalmanNoch keine Bewertungen

- PWHTDokument3 SeitenPWHTharishcsharmaNoch keine Bewertungen

- Uponor Montazni Manual EN FIN PDFDokument72 SeitenUponor Montazni Manual EN FIN PDFAmar BayasgalanNoch keine Bewertungen

- WPS - D1.1Dokument1 SeiteWPS - D1.1Nam_HitechNoch keine Bewertungen

- PQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0Dokument12 SeitenPQ7-GM-16Mo3-B1 - AWSD1.1 Rev 0rodwellbNoch keine Bewertungen

- How to prepare Welding Procedures for Oil & Gas PipelinesVon EverandHow to prepare Welding Procedures for Oil & Gas PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- D1004 - Al Nahda Building - G+2P+10 Al Nahda 2nd: NOC'sDokument4 SeitenD1004 - Al Nahda Building - G+2P+10 Al Nahda 2nd: NOC'sKawser HossainNoch keine Bewertungen

- Design Status: Status Plan: ROOF FLOOR SLAB - Roof FLOOR - CPT - 11/10/2020Dokument1 SeiteDesign Status: Status Plan: ROOF FLOOR SLAB - Roof FLOOR - CPT - 11/10/2020Kawser HossainNoch keine Bewertungen

- Structural Assesment 2Dokument1 SeiteStructural Assesment 2Kawser HossainNoch keine Bewertungen

- Combined Footing AnalysisDokument2 SeitenCombined Footing AnalysisKawser HossainNoch keine Bewertungen

- Electrical SpecificationsDokument1 SeiteElectrical SpecificationsKawser HossainNoch keine Bewertungen

- Table of Steel Area and Weight For Distributed ReinforcementDokument4 SeitenTable of Steel Area and Weight For Distributed ReinforcementKawser HossainNoch keine Bewertungen

- Cover Sheet For Site ReportDokument3 SeitenCover Sheet For Site ReportKawser HossainNoch keine Bewertungen

- 052 IELTS-Listening-Fill-the-Blank-Strategy PDFDokument20 Seiten052 IELTS-Listening-Fill-the-Blank-Strategy PDFTarunNoch keine Bewertungen

- 1.sulphate Attack On Concrete - Process and Control of Sulphate AttackDokument6 Seiten1.sulphate Attack On Concrete - Process and Control of Sulphate AttackKawser HossainNoch keine Bewertungen

- Civil Defence 1Dokument1 SeiteCivil Defence 1Kawser HossainNoch keine Bewertungen

- Civil Defence 2Dokument1 SeiteCivil Defence 2Kawser HossainNoch keine Bewertungen

- Cover Sheet For Site ReportDokument1 SeiteCover Sheet For Site ReportKawser HossainNoch keine Bewertungen

- 052 IELTS Listening Fill The Blank StrategyDokument1 Seite052 IELTS Listening Fill The Blank StrategyKawser HossainNoch keine Bewertungen

- General 2.0 Stage 1: Data Collection, Preparation Work: D100X - Plot No. 1341556, Al Manzar BuildingDokument1 SeiteGeneral 2.0 Stage 1: Data Collection, Preparation Work: D100X - Plot No. 1341556, Al Manzar BuildingKawser HossainNoch keine Bewertungen

- UK Home Office Information.Dokument3 SeitenUK Home Office Information.Kawser HossainNoch keine Bewertungen

- Rfi 02Dokument1 SeiteRfi 02Kawser HossainNoch keine Bewertungen

- Bob - BT84 Camber Power PointDokument48 SeitenBob - BT84 Camber Power PointMarcoFranchinottiNoch keine Bewertungen

- ALQASSIMI - A-101r FULL FLOOR PLAN02 PDFDokument1 SeiteALQASSIMI - A-101r FULL FLOOR PLAN02 PDFKawser HossainNoch keine Bewertungen

- Seismic Design of Building With ETABSDokument151 SeitenSeismic Design of Building With ETABSKawser Hossain100% (1)

- Solar TowerDokument18 SeitenSolar Towerbupbethiensu_btk100% (2)

- DEtail EDokument7 SeitenDEtail EKawser HossainNoch keine Bewertungen

- Facade Undertaking Letter FormالاستشاريDokument3 SeitenFacade Undertaking Letter FormالاستشاريKawser HossainNoch keine Bewertungen

- Manual of Green Building MaterialsDokument153 SeitenManual of Green Building MaterialsKawser HossainNoch keine Bewertungen

- SAP2000 Ba Sic Anal y Sis Ref Er Ence ManualDokument100 SeitenSAP2000 Ba Sic Anal y Sis Ref Er Ence Manualasghar70% (1)

- Alqassimi - A-101r Full Floor Plan02Dokument1 SeiteAlqassimi - A-101r Full Floor Plan02Kawser HossainNoch keine Bewertungen

- Skills and ExperiencesDokument1 SeiteSkills and ExperiencesKawser HossainNoch keine Bewertungen

- Excavation Plan AutodromeDokument1 SeiteExcavation Plan AutodromeKawser HossainNoch keine Bewertungen

- Allowable Drift or Side Sway Calculation According To Diff CodeDokument30 SeitenAllowable Drift or Side Sway Calculation According To Diff CodeKawser HossainNoch keine Bewertungen

- Gutter DetailsDokument1 SeiteGutter DetailsKawser HossainNoch keine Bewertungen

- Gutter DetailsDokument1 SeiteGutter DetailsKawser HossainNoch keine Bewertungen