Beruflich Dokumente

Kultur Dokumente

Eurotrod

Hochgeladen von

Pedro SilvaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Eurotrod

Hochgeladen von

Pedro SilvaCopyright:

Verfügbare Formate

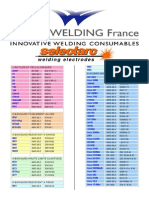

WELDING ELECTRODES

EUROTROD

APCER

CERTIFICADO

N.2000/CEP.1272

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

http://www.electroportugal.com

DATE: 03-09-2009

PAGE. 3/3

PAGE. 5 de 5

PAGE. 7/7

PAGE 9 de 9

NON-ALLOYED WELDING ELECTRODES

CELLULOSE

EUROTROD CN 10

EUROTROD CN 23

RUTILE

EUROTROD RC 14

EUROTROD RN 13

EUROTROD RN 15

BASIC

EUROTROD BD 22

EUROTROD BN 18

EUROTROD BN 18 G

EUROTROD BN 16

HIGH-EFFICIENCY

EUROTROD RH 30

EUROTROD BH 40

Date : 03-09-2009

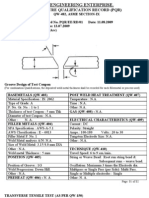

TECHNICAL DESCRIPTION

FT-DT.05.08

EUROTROD CN 10

PAGE 10/10

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.1: E 6010

EN ISO 2560-A-E 35 2 C 2 5

CLASSIFICATION:

DESCRIPTION:

Cellulose type electrode, indicated for welding of pipe lines in the vertical-downward position. Application in root

passes. Good radiography quality.

SUITABLE FOR:

St 37.0 to St 52.0

StE 210.7 TM to StE 360.7 TM

St 37.4 to St 52.4

API 5 LX: X 42 to X56

StE 210.7 to StE 360.7

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

P

0,10

0,25

0,35

< 0,02

S

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>410

Elongation

Charpy V (J)

5d (%)

>480

- 29 C

>20

- 20 C

>27

>47

PRODUCT INFORMATION:

Diameter

(mm)

2,5

WELDING PARAMETERS

Recommend

Length

ed Current

(mm)

(A)

350

70-90

PACKING DATA

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

AC/DC

300

5,0

3,2

350

90-140

AC/DC

190

5,0

4,0

350

130-180

AC/DC

120

5,0

5,0

450

160-230

AC/DC

85

7,2

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.05.08.doc

TECHNICAL DESCRIPTION

FT-DT.41.08

EUROTROD CN 23

PAGE 11/11

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

CLASSIFICATION:

AWS A5.5: E 7010-A1, E 7010-G

EN ISO 2560-A-E 42 2 Mo C 2 5

DESCRIPTION:

Cellulose type electrode, indicated for welding of pipe lines in the vertical-downward position. Application in root

passes. Good radiography quality.

SUITABLE FOR:

St 37.0 to St 52.0

StE 210.7 TM to StE 360.7 TM

St 37.4 to St 52.4

API 5 LX: X 42 to X56

StE 210.7 to StE 360.7

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Mo

0,10

0,25

0,35

< 0,02

< 0,02

0,40

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>410

Elongation

Charpy V (J)

5d (%)

>520

- 29 C

>22

- 20 C

>27

> 47

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,5

350

70 90

AC/DC

300

5,0

3,2

350

90 140

AC/DC

190

5,0

4,0

350

130 180

AC/DC

120

5,0

5,0

350

160 230

AC/DC

75

5,0

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.41.08.doc

TECHNICAL DESCRIPTION

FT-DT.30.08

EUROTRD RC 14

PAGE 12/12

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.1: E 6013

EN ISO 2560-A-E 42 A RC 1 1

CLASSIFICATION:

DESCRIPTION:

Medium coated rutile-cellulose type electrode for universal application and non-alloyed structural steel. Good for

all positional welding characteristics, including vertical-downward. Automatic striking and restriking.

SUITABLE FOR:

St 33 to St 52.3

St 35.8 to St 45.8

A, B

H I H II

StE 210.7 to StE 360.7

GS-38 to GS-52

St 37.4 to St 52.4

StE 210.7 TM to StE 360.7 TM

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

0,07

0,35

0,35

< 0,02

< 0,02

Mechanical Properties:

Yield Strength

(N/mm2)

Tensile

Strength

(N/mm2)

>450

Elongation

CHARPY V (J)

5d (%)

>500

20C

>22

>47

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole -)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,0

350

50 70

AC/DC

420

5,1

2,5

350

60 90

AC/DC

280

5,3

3,2

350

90 140

AC/DC

180

5,2

3,2

450

90 140

AC/DC

180

6,7

4,0

350

120 180

AC/DC

100

4,6

4,0

450

120 180

AC/DC

115

6,8

5,0

450

160 230

AC/DC

65

6,1

APPROVALS:

- Lloyd's Register of Shipping: Cert. N LIS0900023

- G.L. (Germanischer Lloyd): Cert. N WF0860081HH

- DNV Cert. N W-21790

DATE: 13-05-2009

WELDING POSITIONS:

1328

08

1328-CPD-0119

EN 13479 + ISO 2560 A E 42 A RC

Document: FT- DT.30.08.doc

TECHNICAL DESCRIPTION

FT-DT.31.05

EUROTROD RN 13

PAGE 13/13

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.1: E 6013

EN ISO 2560-A-E 42 Z RR 1 2

CLASSIFICATION:

DESCRIPTION:

Medium coated rutile type electrode for universal application and non-alloyed structural steel. Automatic striking

and restriking.

SUITABLE FOR:

St 33 to St 52.3

St 35.8 to 17 Mn 4

StE 255 to StE 355

H I, H II, 17 Mn 4

StE 210.7 to StE 360.7

GS-38 to GS-52

St 37.4 to St 52.4

StE 210.7 TM to StE 360.7 TM

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

0,07

0,40

0,45

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>420

Elongation

5d (%)

>470

>20

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole -)

2,0

350

50 - 60

AC/DC

450

5,4

2,5

350

60 90

AC/DC

300

5,6

3,2

350

90 140

AC/DC

180

5,4

4,0

350

120 180

AC/DC

115

5,5

5,0

450

160 230

AC/DC

70

6,8

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.31.05.doc

TECHNICAL DESCRIPTION

FT-DT.32.05

EUROTROD RN 15

PAGE 14/14

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.1: E 6013

EN ISO 2560-A-E 38 Z RR 1 2

CLASSIFICATION:

DESCRIPTION:

Medium coated rutile type electrode for universal application and non-alloyed structural steel, in special for thin

plates. Automatic striking and restriking.

SUITABLE FOR:

St 33 to St 52.3

St 35.8 to 17 Mn 4

StE 255 to StE 355

GS-38 to GS-52

H I, H II, 17 Mn 4

StE 210.7 to StE 360.7

WStE 255 to WStE 355

St 37.4 to St 52.4

StE 210.7 TM to StE 360.7 TM

A, B, D

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

0,07

0,35

0,35

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>420

Elongation

5d (%)

>470

>20

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole -)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,0

350

50 60

AC/DC

375

5,0

2,5

350

60 90

AC/DC

250

5,0

3,2

350

90 140

AC/DC

150

5,0

4,0

450

120 180

AC/DC

90

6,2

5,0

450

160 230

AC/DC

60

6,4

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.32.05.doc

TECHNICAL DESCRIPTION

FT-DT.42.08

EUROTROD BD 22

PAGE. 15/15

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.1: E 7016

EN ISO 2560-A-E 38 2 B 1 2 H10

CLASSIFICATION:

DESCRIPTION:

Double coating basic type electrode, owing a stable arc, is ideal for positional welding and root pass. Suitable for

carbon steels and some low alloy steels.

SUITABLE FOR:

St 33 to St 52.3

St 35.8 to 17 Mn 4

StE 255 to StE 355

H I, H II, 17 Mn 4

StE 210.7 to StE 360.7

WStE 255 to WStE 355

St 37.4 to St 52.4

StE 210.7 TM to StE 360.7 TM A, B, D, E

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

P

0,08

0,50

1,10

< 0,02

GS-38 to GS-52

S

< 0,02

Mechanical Properties:

Yield Strength

2

(N/mm )

Tensile

Strength

(N/mm2)

>450

Elongation

CHARPY V (J)

5d (%)

>550

+20C

>25

-30C

>100

>40

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

350

Recommended

Current

(A)

55 65

Current

Type

(Pole +)

AC/DC

Pieces

/Packet

(Un)

180

Weight

/Packet

(kg)

2,3

2,5

350

60 90

AC/DC

95

1,9

3,2

350

95 150

AC/DC

55

1,8

3,2

450

95 150

AC/DC

55

2,3

4,0

350

140 190

AC/DC

35

1,8

4,0

450

140 190

AC/DC

35

2,3

5,0

450

180 250

AC/DC

30

3,0

6,0

450

260 330

AC/DC

20

3,3

Diameter

(mm)

Length

(mm)

2,0

WELDING POSITIONS:

1328

09

1328-CPD-0135

EN 13479 + ISO 2560-A-E 38 2 B

DATE: 13-05-2009

Document: FT- DT.42.08.doc

TECHNICAL DESCRIPTION

FT-DT.03.09

EUROTROD BN 18

PAGE 16/16

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.1: E 7018.1 H4

EN ISO 2560-A-E 42 4 B 4 2 H 5

CLASSIFICATION:

DESCRIPTION:

Basic type electrode with 110% recovery. Suitable for highly crack- resistant, tough joints and some low alloy

steels. Welding without pore formation.

SUITABLE FOR:

St 33 to St 52.3

St 37.4 to St 52.4

StE 210.7 TM to StE 360.7 TM TStE 255 to TStE 355

St 50.2 to St 60.2

St 35.8 to 17 Mn 4

StE 255 to StE 355

A, B, D, E

H I, H II, 17 Mn 4

StE 210.7 to StE 360.7

WStE 255 to WStE 355

GS-38 to GS-52

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

0,07

0,45

1,35

< 0,02

< 0,02

Mechanical Properties:

Yield Strength

2

(N/mm )

Tensile

Strength

(N/mm2)

>450

Elongation

CHARPY V (J)

5d (%)

>500

-46C

>22

>47

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,0

350

40 60

DC

330

4,8

140

2,1

2,5

350

60 90

DC

210

4,7

80

1,8

3,2

350

90 140

DC

140

4,8

55

1,8

3,2

450

90 140

DC

140

6,0

55

2,4

4,0

350

140 190

DC

95

5,0

35

1,8

4,0

450

140 190

DC

95

6,4

35

2,4

5,0

450

180 240

DC

60

6,3

25

2,6

6,0

450

240 300

DC

40

6,5

20

3,3

APPROVALS:

- I.S.Q. (Welding Institute of Quality): Cert. N 09/1298

- Lloyd's Register of Shipping: Cert. N LIS 0900023

- Bureau Veritas / Rinave: Cert. N 09.L.2451

- G.L. (Germanischer Lloyd): Cert. N WF 0960165HH

- DNV: Cert. N W-21791

DATE: 13-05-2009

WELDING POSITIONS:

1328

08

1328-CPD-0118

EN 13479 + ISO 2560-A-E 42 4 B

Document: FT- DT.03.09.doc

TECHNICAL DESCRIPTION

FT-DT.55.01

EUROTROD BN 18 G

PAGE 17/17

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.5: E 7018 G

CLASSIFICATION:

DESCRIPTION:

Basic type electrode with 110% recovery. Suitable for highly crack- resistant, tough joints and some low alloy

steels. Welding without pore formation.

SUITABLE FOR:

St 33 to St 52.3

St 37.4 to St 52.4

StE 210.7 TM to StE 360.7 TM TStE 255 to TStE 355

St 50.2 to St 60.2

St 35.8 to 17 Mn 4

StE 255 to StE 355

A, B, D, E

H I, H II, 17 Mn 4

StE 210.7 to StE 360.7

WStE 255 to WStE 355

GS-38 to GS-52

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Ni

0,07

0,45

1,35

< 0,02

< 0,02

0,90

Mechanical Properties:

Yield Strength

2

(N/mm )

Tensile

Strength

(N/mm2)

>450

Elongation

CHARPY V (J)

5d (%)

>500

-60C

>22

>27

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,0

350

40 60

DC

330

4,8

140

2,1

2,5

350

60 90

DC

210

4,7

80

1,8

3,2

350

90 140

DC

140

4,8

55

1,8

3,2

450

90 140

DC

140

6,0

55

2,4

4,0

350

140 190

DC

95

5,0

35

1,8

4,0

450

140 190

DC

95

6,4

35

2,4

5,0

450

180 240

DC

60

6,3

25

2,6

6,0

450

240 300

DC

40

6,5

20

3,3

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.55.01.doc

TECHNICAL DESCRIPTION

FT-DT.02.04

EUROTROD BN 16

PAGE 18/18

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.1: E 7016.1

EN ISO 2560-A-E 42 4 B 2 2 H5

CLASSIFICATION:

DESCRIPTION:

Basic type electrode for universal application in high quality welding.

SUITABLE FOR:

St 33 to St 52.3

St 37.4 to St 52.4

StE 210.7 TM to StE 360.7 TM TStE 255 to TStE 355

St 50.2 to St 60.2

St 35.8 to 17 Mn 4

StE 255 to StE 355

A, B, D, E

H I, H II, 17 Mn 4

StE 210.7 to StE 360.7

WStE 255 to WStE 355

GS-38 to GS-52

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

0,07

0,45

1,35

< 0,02

< 0,02

Mechanical Properties:

Yield Strength

(N/mm2)

Tensile

Strength

(N/mm2)

>450

Elongation

CHARPY V (J)

5d (%)

>500

-46C

>22

>47

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,0

350

40 60

DC

330

4,8

140

2,1

2,5

350

60 90

DC

270

5,0

80

1,8

3,2

350

90 140

DC

140

4,8

55

1,8

3,2

450

90 140

DC

170

6,2

55

2,4

4,0

350

140 190

DC

110

6,3

35

1,8

4,0

450

140 190

DC

95

6,4

35

2,4

5,0

450

180 240

DC

70

6,3

25

2,6

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.02.04.doc

TECHNICAL DESCRIPTION

FT-DT.33.05

EUROTROD RH 30

PAGE 19/19

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.1: E 7024

EN ISO 2560-A-E 42 Z RR 7 3

CLASSIFICATION:

DESCRIPTION:

Heavy-coated rutile high-efficiency electrode with 160 % recovery. Suitable for fabrication and vessel

construction, filler and capping runs of multi-layer weldments.

SUITABLE FOR:

St 33 to St 52.3

A, B, D

H I, H II, 17 Mn 4

GS-38 to GS-52

StE 255 to StE 380

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

0,08

0,50

0,90

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>420

Elongation

5d (%)

>500

>20

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole -)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

3,2

450

120 180

AC/DC

90

6,0

4,0

450

180 220

AC/DC

55

6,0

5,0

450

250 300

AC/DC

35

5,8

6,0

450

300 350

AC/DC

25

6,0

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.33.05.doc

TECHNICAL DESCRIPTION

FT-DT.01.04

EUROTROD BH 40

PAGE 20/20

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.1: E 7028

EN ISO 2560-A-E 38 2 B 5 3

CLASSIFICATION:

DESCRIPTION:

High-efficiency basic type electrode with 150% recovery. Preferably used for welding fillets. Weld metal is crackfree and very tough. Smooth and clean welds blending into base metal without undercut. Suitable for welding

primer painted components.

SUITABLE FOR:

St 33 to St 52.3

WStE 255 to WStE 355

H I, H II, 17 Mn 4

A, B, D, E

StE 255 to StE 355

GS-38 to GS-52

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

0,07

0,45

1,15

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>410

>490

Elongation

CHARPY V (J)

5d (%)

-20C

>22

>47

PRODUCT INFORMATION:

Diameter

(mm)

WELDING PARAMETERS

Recommended

Current

Length

(A)

(mm)

PACKING DATA

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

3,2

450

150 - 180

AC/DC

95

6,1

4,0

450

180 230

AC/DC

60

6,2

5,0

450

230 - 300

AC/DC

40

6,4

6,0

450

300 - 360

AC/DC

25

6,1

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.01.04.doc

PAGE 21/21

LOW ALLOYED WELDING ELECTRODES

EUROTROD MC 27

EUROTROD MC 27 A

EUROTROD MC 33

EUROTROD MC 38

EUROTROD MC 40

EUROTROD MC 50

LOW ALLOYED WELDING ELECTRODES FOR

APPLICATION IN LOW TEMPERATURE

EUROTROD MC 30

EUROTROD MC 36

DATE: 03-09-2009

TECHNICAL DESCRIPTION

FT-DT.19.04

EUROTROD MC 27

PAGE 22/22

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

CLASSIFICATION:

AWS A5.5: E 8018-G

DESCRIPTION:

Basic type electrode for high-tensile fine-grained structural steels. Good weld ability in all positions. Low spatter

loss. Easy slag removal. Regular seams, high crack resistance. Diameters up to 3,2 mm especially suitable for root

passes in all welding position except vertical-downward.

SUITABLE FOR:

St 33 to St 52.3

H I, H II, 17 Mn 4

StE 210.7 to StE 415.7

St 50.2 to St 60.2

St 37.4 to St 52.4

StE 210.7 TM to StE 415.7 TM EStE 255 to EStE 355

Corten St 52.3-Cu

St 35.8 to 17 Mn 4 StE 255 to StE 460

WStE 255 to WStE 460 A, B, D, E

GS-38 to GS-52

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Ni

Cu

0,07

0,50

1,20

1,10

0,50

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>480

Elongation

4d (%)

>580

>22

PRODUCT INFORMATION:

Diameter

(mm)

WELDING PARAMETERS

Recommended

Length

Current

(mm)

(A)

Current

Type

(Pole +)

PACKING DATA

Pieces/

Weight/

Packet

Packet

(Un)

(kg)

2,5

350

65 95

DC

220

4,7

3,2

450

90 135

DC

140

6,0

4,0

450

140 180

DC

95

6,4

5,0

450

190 240

DC

60

6,4

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.19.04.doc

TECHNICAL DESCRIPTION

FT-DT.53.01

EUROTROD MC 27 A

PAGE 23/23

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

CLASSIFICATION:

AWS A5.5: E 8018 W2

DESCRIPTION:

Basic type electrode for high-tensile fine-grained structural steels. Good weld ability in all positions. Low spatter

loss. Easy slag removal. Regular seams, high crack resistance. Diameters up to 3,2 mm especially suitable for root

passes in all welding position except vertical-downward.

SUITABLE FOR:

St 33 to St 52.3

H I, H II, 17 Mn 4

StE 210.7 to StE 415.7

St 50.2 to St 60.2

St 37.4 to St 52.4

StE 210.7 TM to StE 415.7 TM EStE 255 to EStE 355

Corten St 52.3-Cu

St 35.8 to 17 Mn 4 StE 255 to StE 460

WStE 255 to WStE 460 A, B, D, E

GS-38 to GS-52

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Ni

Cu

0,07

0,50

1,20

0,60

0,50

Cr

< 0,02

< 0,02

0,55

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>460

Elongation

4d (%)

580-680

>19

PRODUCT INFORMATION:

Diameter

(mm)

WELDING PARAMETERS

Recommended

Length

Current

(mm)

(A)

Current

Type

(Pole +)

PACKING DATA

Pieces/

Weight/

Packet

Packet

(Un)

(kg)

2,5

350

65 95

DC

220

4,7

3,2

450

90 135

DC

140

6,0

4,0

450

140 180

DC

95

6,4

5,0

450

190 240

DC

60

6,4

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.53.01.doc

TECHNICAL DESCRIPTION

FT-DT.20.04

EUROTROD MC 33

PAGE 24/24

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

CLASSIFICATION:

AWS A5.5: E 9018-G

DESCRIPTION:

Basic type electrode for high-grained structural steels. Good weld ability in all positions. Low spatter loss. Easy

slag removal. Regular seams, high crack resistance. Diameters up to 3,2 mm especially suitable for root passes in

all welding positions except vertical-downward.

SUITABLE FOR:

StE 355 to StE 500

TStE 355 to TStE 550

11 Ni Mo V 5 3

WStE 355 to WStE 500

17 Mn Mo V 6 4

20 Mn Mo Ni 4 5

EStE 355 to EStE 500

15 Ni Cu Mo Nb 5

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Ni

Mo

0,07

0,55

1,50

1,00

0,45

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>550

Elongation

4d (%)

>650

>20

PRODUCT INFORMATION:

Diameter

(mm)

WELGING PARAMETERS

Recommended

Length

Current

(mm)

(A)

Current

Type

(Pole +)

PACKING DATA

Pieces/

Weight/

Packet

Packet

(Un)

(kg)

2,5

350

65 95

DC

220

4,7

3,2

450

100 140

DC

140

6,0

4,0

450

130 190

DC

95

6,4

5,0

450

180 240

DC

60

6,3

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.20.04.doc

TECHNICAL DESCRIPTION

FT-DT.22.04

EUROTROD MC 38

PAGE 25/25

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

CLASSIFICATION:

AWS A5.5: E 10018-G

DESCRIPTION:

Basic type electrode for high-grained structural steels. Good weld ability in all positions. Low spatter loss. Easy

slag removal. Regular seams, high crack resistance. Diameters up to 3,2 mm especially suitable for root passes in

all welding positions except vertical-downward.

SUITABLE FOR:

EStE 420 to EStE 620

TStE 420 to TStE 620

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

0,07

0,50

1,60

0,50

1,70

Mo

0,45

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>650

Elongation

4d (%)

>750

>16

PRODUCT INFORMATION:

Diameter

(mm)

WELDING PARAMETERS

Recommended

Length

Current

(mm)

(A)

Current

Type

(Pole +)

PACKING DATA

Pieces/

Weight/

Packet

Packet

(Un)

(kg)

2,5

350

65 95

DC

220

4,7

3,2

450

100 140

DC

140

6,0

4,0

450

130 190

DC

95

6,4

5,0

450

180 240

DC

60

6,3

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.22.04.doc

TECHNICAL DESCRIPTION

FT-DT.23.04

EUROTROD MC 40

PAGE 26/26

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

CLASSIFICATION:

AWS A5.5: E 11018-G

DESCRIPTION:

Basic type electrode for high-grained structural steels. Good weld ability in all positions. Low spatter loss. Easy

slag removal. Regular seams, high crack resistance. Diameters up to 3,2 mm especially suitable for root passes in

all welding positions except vertical-downward.

SUITABLE FOR:

EStE 460 to EStE 690

TStE 460 to TStE 690

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

0,07

0,60

1,50

0,50

1,80

Mo

0,45

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>700

Elongation

4d (%)

>800

>16

PRODUCT INFORMATION:

Diameter

(mm)

WELDING PARAMETERS

Recommended

Length

Current

(mm)

(A)

Current

Type

(Pole +)

PACKING DATA

Pieces/

Weight/

Packet

Packet

(Un)

(kg)

2,5

350

65 95

DC

220

4,7

3,2

450

100 140

DC

140

6,0

4,0

450

130 190

DC

95

6,4

5,0

450

180 240

DC

60

6,3

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.23.04.doc

TECHNICAL DESCRIPTION

FT-DT.24.05

EUROTROD MC 50

PAGE 27/27

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

CLASSIFICATION:

AWS A5.5: E 12018-G

DESCRIPTION:

Basic type electrode for high-grained structural steels. Good weld ability in all positions. Low spatter loss. Easy

slag removal. Regular seams, high crack resistance. Diameters up to 3,2 mm especially suitable for root passes in

all welding positions except vertical-downward.

SUITABLE FOR:

EStE 620 to EStE 890

TStE 620 to TStE 890

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

0,07

0,50

1,70

0,70

2,10

Mo

0,50

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>750

Elongation

4d (%)

>850

>15

PRODUCT INFORMATION:

Diameter

(mm)

WELDING PARAMETERS

Recommended

Length

Current

(mm)

(A)

Current

Type

(Pole +)

PACKING DATA

Pieces/

Weight/

Packet

Packet

(Un)

(kg)

2,5

350

65 95

DC

220

4,7

3,2

450

100 140

DC

70

3,0

4,0

450

130 190

DC

45

3,0

5,0

450

180 240

DC

60

6,3

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.24.05.doc

TECHNICAL DESCRIPTION

FT-DT.80.01

EUROTROD MC 30

PAGE 28/28

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

CLASSIFICATION:

AWS A5.5: E 8018 G

DESCRIPTION:

Basic type electrode for high-grained structural steels. Good weld ability in all positions. Low spatter loss. Easy

slag removal. Regular seams, high crack resistance. Diameters up to 3,2 mm especially suitable for root passes in

all welding positions except vertical-downward.

SUITABLE FOR:

STE 420, STE 460, STE

500

WSTE 420, WSTE 460

TSTE 420, TSTE 460

TSTE 500

WSTE 500

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Ni

0,06

0,50

1,60

0,9

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>510

Elongation

CHARPY V (J)

4d (%)

590-690

>23

-60C

+20C

60

200

PRODUCT INFORMATION:

Diameter

(mm)

WELGING PARAMETERS

Recommended

Length

Current

(mm)

(A)

Current

Type

(Pole +)

PACKING DATA

Pieces/

Weight/

Packet

Packet

(Un)

(kg)

2,5

350

65 95

DC

220

4,5

3,2

450

100 140

DC

140

6,0

4,0

450

130 190

DC

95

6,4

5,0

450

180 240

DC

60

6,4

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.80.01.doc

TECHNICAL DESCRIPTION

FT-DT.21.04

EUROTROD MC 36

PAGE 29/29

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

CLASSIFICATION:

AWS A5.5: E 8018 C1

DESCRIPTION:

Basic type electrode for high-grained structural steels. Good weld ability in all positions. Low spatter loss. Easy

slag removal. Regular seams, high crack resistance. Diameters up to 3,2 mm especially suitable for root passes in

all welding positions except vertical-downward.

SUITABLE FOR:

TTSt 35 N, TTSt 35 V, 10 Ni 14

TStE 255 TStE 420

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Ni

0,07

0,45

0,70

2,05

< 0,02

< 0,02

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>470

Elongation

CHARPY V (J)

4d (%)

>550

-60C

>25

>30

PRODUCT INFORMATION:

Diameter

(mm)

WELDING PARAMETERS

Recommended

Length

Current

(mm)

(A)

Current

Type

(Pole +)

PACKING DATA

Pieces/

Weight/

Packet

Packet

(Un)

(kg)

2,5

350

65 95

DC

220

4,5

3,2

450

100 140

DC

140

6,0

4,0

450

130 190

DC

95

6,4

5,0

450

180 240

DC

60

6,3

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.21.04.doc

PAGE 31/31

LOW ALLOYED CREEP RESISTANT ELECTRODES

EUROTROD MF 25

EUROTROD MF 29

EUROTROD MF 35

EUROTROD MF 41

EUROTROD MF 45

EUROTROD MF 47

EUROTROD MF 48

DATE: 03-09-2009

TECHNICAL DESCRIPTION

FT-DT.25.04

EUROTROD MF 25

PAGE 32/32

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.5: E 7018-A1

EN 1599 E Mo B

CLASSIFICATION:

DESCRIPTION:

Basic type electrode for creep resisting steels and cast steels with similar composition up to 500 C. Good weld

ability in all positions. Low spatter loss, good bead appearance. Ready striking and deslagging.

SUITABLE FOR:

St 35.8, St 45.8

WStE 255 to WStE 460

API: X 52 to X60

17 Mn 4, 19 Mn 5, 15 Mo 3, 16 Mo 5 StE 360.7 to StE 415.7

StE 255 to StE 460

StE 360.7 TM to StE 415.7 TM

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Mo

0,07

GS-C 25, GS-22 Mo 4

0,60

0,70

Mechanical Properties (after heat treatment):

Tensile

Yield Strength

Strength

(N/mm2)

(N/mm2)

>420

0,50

< 0,02

< 0,02

Elongation

4d (%)

>510

>25

PRODUCT INFORMATION:

Diameter

(mm)

WELDING PARAMETERS

Recommended

Length

Current

(mm)

(A)

Current/

Type

(Pole +)

PACKING DATA

Pieces/

Weight/

Packet

Packet

(Un)

(kg)

2,5

350

65 90

DC

200

4,5

3,2

350

90 130

DC

150

5,0

4,0

350

140 180

DC

95

4,8

5,0

450

190 230

DC

60

6,1

WELDING POSITIONS:

OBSERVATIONS:

Observe specifications on preheating and postweld heat treatment of base materials.

DATE: 13-05-2009

Document: FT- DT.25.04.doc

TECHNICAL DESCRIPTION

FT-DT.26.06

EUROTROD MF 29

PAGE 33/33

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.5: E 8018-B2

EN 1599 E CrMo 1 B

CLASSIFICATION:

DESCRIPTION:

Basic type electrode for creep resisting steels and cast steels with similar composition up to 530 C. Good weld

ability in all positions. Low spatter loss, good bead appearance. Ready striking and deslagging.

SUITABLE FOR:

13 Cr Mo 4 4, 16 Cr Mo 4 4, 22 Cr Mo 4 4

15 Cr 3, 16 Mn Cr 5, 20 Mn Cr 5

15 Cr Mo 5, 24 Cr Mo 5

GS-25 Cr Mo 5 5, GS-22 Cr Mo 5 4

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Mo

0,07

0,55

0,65

1,20

Mechanical Properties (after heat treatment):

Tensile

Yield Strength

Strength

(N/mm2)

(N/mm2)

>480

0,50

< 0,02

< 0,02

Elongation

5d (%)

>550

>20

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,5

350

65 90

DC

85

1,9

3,2

350

90 130

DC

55

1,9

4,0

350

140 180

DC

40

2,0

5,0

450

190 230

DC

30

3,2

WELDING POSITIONS:

OBSERVATIONS:

1328

08

1328-CPD-0116

EN 13479 + EN 1599 - E CrMo 1 B

DATE: 13-05-2009

Observe specifications on preheating and

post-weld heat treatment of base materials.

Document: FT- DT.26.06.doc

TECHNICAL DESCRIPTION

FT-DT.27.07

EUROTROD MF 35

PAGE 34/34

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.5: E 9018-B3

EN 1599 E CrMo 2 B

CLASSIFICATION:

DESCRIPTION:

Basic type electrode for creep resisting steels and cast steels with similar composition up to 600 C. Good weld

ability in all positions. Low spatter loss, good bead appearance. Ready striking and deslagging.

SUITABLE FOR:

10 Cr Mo 9 10, 12 Cr Mo 9 10, 24 Cr Mo 10

24 Cr Si Mo V 7

GS-12 Cr Mo 9 10, GS-19 Cr Mo 9 10

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Mo

0,07

0,50

0,60

2,20

Mechanical Properties (after heat treatment):

Tensile

Yield Strength

Strength

(N/mm2)

(N/mm2)

>540

1,10

< 0,02

< 0,02

Elongation

5d (%)

>650

>18

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,5

350

65 90

DC

85

1,9

3,2

350

90 130

DC

55

1,9

4,0

350

140 180

DC

40

2,0

5,0

450

190 230

DC

30

3,2

WELDING POSITIONS:

OBSERVATIONS:

1328

08

1328-CPD-0117

EN 13479 + EN 1599 - E CrMo 2 B

DATE: 13-05-2009

Observe specifications on preheating and

post-weld heat treatment of base

materials.

Document: FT- DT.27.07.doc

TECHNICAL DESCRIPTION

FT-DT.28.05

EUROTROD MF 41

PAGE 35/35

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.5: E 8015-B6

EN 1599 E CrMo 5 B

CLASSIFICATION:

DESCRIPTION:

Basic type electrode for creep resisting steels and cast steels with similar composition up to 600 C. Good weld

ability in all positions. Low spatter loss, good bead appearance. Ready striking and deslagging.

SUITABLE FOR:

12 Cr Mo 19 5

A 387 Gr. 5, A 387 Cl. 1, A 387 Cl. 2

A 182 Gr. F 5, A 199 Gr. T 5, A 213 Gr. T 5

GS-12 Cr Mo 19 5

A 335 Gr. P 5, A 336 Cl. F 5, A 369 Gr. FP 5

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Mo

0,07

0,55

0,75

4,80

0,50

Mechanical Properties (after heat treatment):

Yield Strength

Tensile Strength

(N/mm )

(N/mm )

>460

Elongation

CHARPY V (J)

5d (%)

>590

+20C

>19

>47

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,5

350

65 75

DC

230

4,8

3,2

350

75 110

DC

140

4,6

4,0

350

120 160

DC

95

4,8

WELDING POSITIONS:

OBSERVATIONS:

Observe specifications on preheating and postweld heat treatment of base materials.

DATE: 13-05-2009

Document: FT- DT.28.05.doc

TECHNICAL DESCRIPTION

FT-DT.29.05

EUROTROD MF 45

PAGE 36/36

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.5: E 8018-B8

EN 1599 E CrMo 9 B

CLASSIFICATION:

DESCRIPTION:

Basic type electrode for creep resisting steels and cast steels with similar composition up to 700 C. Good weld

ability in all positions. Low spatter loss, good bead appearance. Ready striking and deslagging.

SUITABLE FOR:

Creep Resisting Steels:

Cast Steels:

12 Cr Mo 91

12 Cr Mo 10

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Mo

0,09

0,30

0,80

9,0

Mechanical Properties (after heat treatment):

Yield Strength

Tensile Strength

2

(N/mm )

(N/mm )

>460

Ni

1,0

0,35

Elongation

CHARPY V (J)

5d (%)

>590

+20C

>19

>34

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,5

350

65 75

DC

230

4,8

3,2

350

75 110

DC

140

4,6

4,0

350

120 160

DC

95

4,8

WELDING POSITIONS:

OBSERVATIONS:

Observe specifications on preheating and postweld heat treatment of base materials.

DATE: 13-05-2009

Document: FT- DT.29.05.doc

TECHNICAL DESCRIPTION

FT-DT.77.01

EUROTROD MF 47

PAGE 37/37

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.5: E 9015-B9

CLASSIFICATION:

DESCRIPTION:

Basic type electrode for creep resisting steels. Good weld ability in all positions. Low spatter loss, good bead

appearance. Ready striking and deslagging.

SUITABLE FOR:

A335 Grd P9

A369 Grd FP9

A387 Grd 9

T 91 P91

Creep Resisting Steels:

9 Cr Mo 1

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Mo

0,11

0,13

0,85

8.1

Mechanical Properties (after heat treatment):

Tensile

Yield Strength

Strength

(N/mm2)

(N/mm2)

>530

1,12

Nb

0,09

0,053

0,22

<0,01

<0,01

Elongation

4d (%)

>620

>17

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

2,5

350

65 90

DC

90

1,9

3,2

350

90 130

DC

55

1,9

4,0

350

140 180

DC

35

1,9

WELDING POSITIONS:

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

OBSERVATIONS:

Observe specifications on preheating

and post-weld heat treatment of base

materials.

DATE: 13-05-2009

Document: FT- DT.77.01doc

TECHNICAL DESCRIPTION

FT-DT.76.04

EUROTROD MF 48

PAGE 38/38

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.5: E 9018-B9

EN 1599 E CrMo 91 B

CLASSIFICATION:

DESCRIPTION:

Basic type electrode for creep resisting steels. Good weld ability in all positions. Low spatter loss, good bead

appearance. Ready striking and deslagging.

SUITABLE FOR:

A335 Grd P9

A369 Grd FP9

A387 Grd 9

T 91 P91

Creep Resisting Steels:

9 Cr Mo 1

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Mo

0,11

0,13

0,85

8.1

Mechanical Properties (after heat treatment):

Tensile

Yield Strength

Strength

(N/mm2)

(N/mm2)

>530

1,12

Nb

0,09

0,053

0,22

<0,01

<0,01

Elongation

4d (%)

>620

>17

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,5

350

65 90

DC

90

1,9

3,2

350

90 130

DC

55

1,9

4,0

350

140 180

DC

35

1,9

WELDING POSITIONS:

OBSERVATIONS:

1328

08

1328-CPD-0115

EN 13479 + EN 1599 - E CrMo 91 B

DATE:13-05-2009

Observe specifications on preheating

and post-weld heat treatment of base

materials.

Document: FT- DT.76.04doc

PAGE 39/39

STAINLESS STEEL ELECTRODES

EUROTROD LC 71

EUROTROD LC 18

EUROTROD LC 24

EUROTROD LC 21

EUROTROD LC 26

EUROTROD LC 27

EUROTROD LC 28

EUROTROD LC 23

Cr-Ni(Mo) ALLOYS FOR DISSIMILAR JOINTS

EUROTROD LC 52

EUROTROD LC 54

EUROTROD LC 59

EUROTROD LC 62

DATE: 03-09-2009

TECHNICAL DESCRIPTION

FT-DT.37.05

EUROTROD LC 71

PAGE 40/40

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: E 308L-15

CLASSIFICATION:

DESCRIPTION:

Basic high-alloy extra-low carbon electrode (ELC) for non-stabilized and stabilized chromium-nickel steels 18

Cr/10 Ni type with Titanium or Niobium. Excellent welding (AC/DC), smooth running. Good striking and

restriking. Regular appearance, finely rippled, smooth junction. Easy slag removal.

SUITABLE FOR:

AISI 302, 304, 304 L, 308, 308 L

AISI 321, 347

W Nr 1.4541. 1.4550, 1.4552

W Nr 1.4306, 1.4311

W Nr 1.4301, 1.4303, 1.4308

W Nr 1.4310,1.4319

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

< 0,03

0,80

1,10

19,0

10,5

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>350

Elongation

CHARPY V (J)

5d (%)

>520

-196 C

>35

>30

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

1,6

300

25 30

DC

210

1,6

2,0

300

30 50

DC

145

1,8

2,5

300

50 75

DC

100

1,8

3,2

350

75 110

DC

55

2,0

4,0

350

110 150

DC

35

2,0

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.37.05.doc

TECHNICAL DESCRIPTION

FT-DT.57.00

EUROTROD LC 18

PAGE 41/41

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: E 318-17

CLASSIFICATION:

DESCRIPTION:

Rutile high-alloy stabilized at Niobium, for non-stabilized and stabilized chromium-nickel steels 18 Cr/10 Ni type

with Titanium or Niobium. Excellent welding (AC/DC), smooth running. Good striking and restriking. Regular

appearance, finely rippled, smooth junction. Easy slag removal. The arc is spray type giving a finely rippled

appearance having the tendency to be concave in positions.

SUITABLE FOR:

AISI 302, 304, 304 L, 308, 308 L

AISI 321, 347

W Nr 1.4541. 1.4550, 1.4552

W Nr 1.4306, 1.4311

W Nr 1.4301, 1.4303, 1.4308

W Nr 1.4310,1.4319

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

Nb

Mo

<0,03

0,75

0,90

19,0

12,0

0,42

2,20

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>400

Elongation

5d (%)

>550

>30

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

1,6

300

25 30

AC/DC

210

1,6

2,0

300

30 50

AC/DC

145

1,8

2,5

300

50 75

AC/DC

100

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

35

2,0

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.57.00.doc

TECHNICAL DESCRIPTION

FT-DT.14.08

EUROTROD LC 21

PAGE 42/42

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: E 308L-16

EN 1600: E 19 9 LR 12

CLASSIFICATION:

DESCRIPTION:

Rutile high-alloy extra-low carbon electrode (ELC) for non-stabilized and stabilized chromium-nickel steels 18

Cr/10 Ni type with Titanium or Niobium. Excellent welding (AC/DC), smooth running. Good striking and

restriking. Regular appearance, finely rippled, smooth junction. Easy slag removal.

SUITABLE FOR:

AISI 302, 304, 304 L, 308, 308 L

AISI 321, 347

W Nr 1.4541. 1.4550, 1.4552

W Nr 1.4306, 1.4311

W Nr 1.4301, 1.4303, 1.4308

W Nr 1.4310,1.4319

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

< 0,03

0,75

0,55

18,50

10,50

Mechanical Properties:

Yield Strength

(N/mm2)

Tensile

Strength

(N/mm2)

>350

Elongation

5d (%)

>520

>35

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

1,6

300

25 30

AC/DC

210

1,6

2,0

300

30 50

AC/DC

145

1,8

2,5

300

50 75

AC/DC

100

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

35

2,0

4,0

450

110 150

AC/DC

80

5,5

APPROVALS:

WELDING POSITIONS:

- I.S.Q. (Welding Institute of Quality): Cert. N 09/1299

- Bureau Veritas / Rinave: Cert. N 09.L.2452

1328

08

1328-CPD-0113

EN 13479 + EN 1600 - E 19 9 L R

DATE: 13-05-2009

Document: FT- DT.14.08.doc

TECHNICAL DESCRIPTION

FT-DT.40.05

EUROTROD LC 24

PAGE 43/43

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: E 308L-17

EN 1600: E 19 9 LR 12

CLASSIFICATION:

DESCRIPTION:

Rutile high-alloy extra-low carbon electrode (ELC) for non-stabilized and stabilized chromium-nickel steels 18

Cr/10 Ni type with Titanium or Niobium. Excellent welding (AC/DC), smooth running. Good striking and

restriking. Regular appearance, finely rippled, smooth junction. Easy slag removal. The arc is spray type giving a

finely rippled appearance having the tendency to be concave in positions.

SUITABLE FOR:

AISI 302, 304, 304 L, 308, 308 L

AISI 321, 347

W Nr 1.4541. 1.4550, 1.4552

W Nr 1.4306, 1.4311

W Nr 1.4301, 1.4303, 1.4308

W Nr 1.4310,1.4319

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

< 0,03

0,80

0,55

18,5

10,5

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>350

Elongation

5d (%)

>520

>35

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

1,6

300

25 30

AC/DC

210

1,6

2,0

300

30 50

AC/DC

145

1,8

2,5

300

50 75

AC/DC

100

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

35

2,0

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.40.05.doc

TECHNICAL DESCRIPTION

FT-DT.15.07

EUROTROD LC 26

PAGE 44/44

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: E 316L-16

EN 1600: E 19 12 3 LR 12

CLASSIFICATION:

DESCRIPTION:

Rutile high-alloy extra-low carbon electrode (ELC) for non-stabilized and stabilized chromium-nickel steels 18

Cr/12 Ni/2 Mo type with Titanium or Niobium. Excellent welding (AC/DC), smooth running. Good striking and

restriking. Regular appearance, finely rippled, smooth junction. Easy slag removal.

SUITABLE FOR:

W Nr 1.4404, 1.4406, 1.4429

AISI 316 Ti, 318

W Nr 1.4401. 1.4408, 1.4435

AISI 316, 316 L

W Nr 1.4571, 1.4580, 1.4581, 1.4583

W Nr 1.4436

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

Mo

< 0,03

0,75

0,55

18,0

12,0

2,55

Mechanical Properties:

Yield Strength

(N/mm2)

Tensile

Strength

(N/mm2)

>350

Elongation

5d (%)

>520

>30

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Intensidade

Corrente

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

1,6

300

25 30

AC/DC

210

1,6

2,0

300

30 50

AC/DC

145

1,8

2,5

300

50 75

AC/DC

100

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

35

2,0

4,0

450

110 150

AC/DC

80

5,5

APPROVALS:

WELDING POSITIONS:

- I.S.Q. (Welding Institute of Quality): Cert. N 09/1300

- Bureau Veritas / Rinave: Cert. N 09.L.2453

1328

08

1328-CPD-0114

EN 13479 + EN 1600 - E 19 12 3 L R

DATE: 13-05-2009

Document: FT- DT.15.07.doc

TECHNICAL DESCRIPTION

FT-DT.47.03

EUROTROD LC 27

PAGE 45/45

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: E 317L-16

CLASSIFICATION:

DESCRIPTION:

Rutile high-alloy extra-low carbon electrode (ELC) for non-stabilized and stabilized chromium-nickel steels 20

Cr/13 Ni/3 Mo type with Titanium or Niobium. Excellent welding (AC/DC), smooth running. Good striking and

restriking. Regular appearance, finely rippled, smooth junction. Easy slag removal.

SUITABLE FOR:

W Nr 1.4404, 1.4406, 1.4429

AISI 316 Ti, 318

W Nr 1.4401. 1.4408, 1.4435

AISI 316, 316 L

W Nr 1.4571, 1.4580, 1.4581, 1.4583

W Nr 1.4436

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

< 0,03

0,75

0,55

20,0

Mo

13,0

3,20

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>350

Elongation

5d (%)

>520

>30

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Intensidade

Corrente

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

1,6

300

25 30

AC/DC

210

1,6

2,0

300

30 50

AC/DC

145

1,8

2,5

300

50 75

AC/DC

100

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

35

2,0

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.47.03.doc

TECHNICAL DESCRIPTION

FT-DT.43.05

EUROTROD LC 28

PAGE 46/46

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: E 316L-17

EN 1600: E 19 12 3 LR 12

CLASSIFICATION:

DESCRIPTION:

Rutile high-alloy extra-low carbon electrode (ELC) for non-stabilized and stabilized chromium-nickel steels 18

Cr/12 Ni/2 Mo type with Titanium or Niobium. Excellent welding (AC/DC), smooth running. Good striking and

restriking. Regular appearance, finely rippled, smooth junction. Easy slag removal. The arc is spray type giving a

finely rippled appearance having the tendency to be concave in positions.

SUITABLE FOR:

W Nr 1.4404, 1.4406, 1.4429

AISI 316 Ti, 318

W Nr 1.4401. 1.4408, 1.4435

AISI 316, 316 L

W Nr 1.4571, 1.4580, 1.4581, 1.4583

W Nr 1.4436

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

Mo

< 0,03

0,80

0,55

18,0

12,0

2,20

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>350

Elongation

5d (%)

>520

>30

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Intensidade

Corrente

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

1,6

300

25 30

AC/DC

210

1,6

2,0

300

30 50

AC/DC

145

1,8

2,5

300

50 75

AC/DC

100

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

35

2,0

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.43.05.doc

TECHNICAL DESCRIPTION

FT-DT.56.01

EUROTROD LC 23

PAGE 47/47

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: E 347-17

EN 1600: E 19 9 Nb

CLASSIFICATION:

DESCRIPTION:

Rutile high-alloy extra-low carbon electrode (ELC), stabilized at Niobium, for non-stabilized and stabilized

chromium-nickel steels 18 Cr/10 Ni type with Titanium or Niobium. Excellent welding (AC/DC), smooth running.

Good striking and restriking. Regular appearance, finely rippled, smooth junction. Easy slag removal. The arc is

spray type giving a finely rippled appearance having the tendency to be concave in positions.

SUITABLE FOR:

AISI 302, 304, 304 L, 308, 308 L

AISI 321, 347

W Nr 1.4541. 1.4550, 1.4552

W Nr 1.4306, 1.4311

W Nr 1.4301, 1.4303, 1.4308

W Nr 1.4310,1.4319

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

Nb

<0,03

0,75

0,55

18,50

10,50

0,35

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>350

Elongation

5d (%)

>550

>30

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

1,6

300

25 30

AC/DC

210

1,6

2,0

300

30 50

AC/DC

145

1,8

2,5

300

50 75

AC/DC

100

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

35

2,0

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.56.01.doc

TECHNICAL DESCRIPTION

FT-DT.49.03

EUROTROD LC 52

PAGE 48/48

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: E 309 L 16

CLASSIFICATION:

DESCRIPTION:

Rutile high-alloy extra-low carbon electrode (ELC) for chromium-nickel steels type 23 Cr/13 Ni and dissimilar

joining of carbon steels to stainless steel. Also suitable as a buffer layer. Smooth running. Good striking and

restriking. Regular appearance, finely rippled, smooth junction. Easy slag removal.

SUITABLE FOR:

AISI 309, 309 L

All chromium-nickel steels with low or medium C content, as well as

titanium or Niobium stabilized stainless steels.

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

< 0,03

0,85

0,70

24,0

13,0

Mechanical Properties:

Tensile

Strength

(N/mm2)

Elongation

>600

>32

5d (%)

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(Kg)

2,0

300

30 50

AC/DC

155

1,8

2,5

300

50 75

AC/DC

100

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

35

2,0

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.49.03.doc

TECHNICAL DESCRIPTION

FT-DT.16.05

EUROTROD LC 54

PAGE 49/49

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: E 309 Mo L 16

EN 1600: E 23 12 2 LR 12

CLASSIFICATION:

DESCRIPTION:

Rutile high-alloy extra-low carbon electrode (ELC) for chromium-nickel steels type 23 Cr/13 Ni/3 Mo and

dissimilar joining of carbon steels to stainless steel. Also suitable as a buffer layer. Smooth running. Good striking

and restriking. Regular appearance, finely rippled, smooth junction. Easy slag removal.

SUITABLE FOR:

AISI 309, 309 L

All chromium-nickel steels with low or medium C content, as well as

titanium or Niobium stabilized stainless steels.

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

Mo

< 0,03

0,85

0,55

23,0

13,0

2,20

Mechanical Properties:

Yield Strength

(N/mm2)

Tensile

Strength

(N/mm2)

>350

Elongation

5d (%)

>550

>30

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(Kg)

2,0

300

30 50

AC/DC

155

1,8

2,5

300

50 75

AC/DC

100

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

35

2,0

APPROVALS:

WELDING POSITIONS:

- I.S.Q. (Welding Institute of Quality): Cert. N 09/1301

- Bureau Veritas / Rinave: Cert. N 09.L.2454

DATE: 13-05-2009

Document: FT- DT.16.05.doc

TECHNICAL DESCRIPTION

FT-DT.38.05

EUROTROD LC 59

PAGE 50/50

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: ~ E 310-16

EN 1600: E 25 20 R 12

CLASSIFICATION:

DESCRIPTION:

Rutile type electrode for 25 Cr 20 Ni type, up to 1100 C.

SUITABLE FOR:

-Refractory Steels:

AISI 309, 310, 310S,

DIN X15Cr NiSi 2520,

X12CrNi 2521, X15CrNiSi2012

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

0,10

0,85

1,20

25,0

20,0

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>350

Elongation

5d (%)

>550

>20

PRODUCT INFORMATION:

WELDING PARAMETERS

PACKING DATA

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

2,5

300

55 80

AC/DC

100

1,8

3,2

350

70 110

AC/DC

55

2,0

4,0

350

110 155

AC/DC

40

2,0

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.38.05.doc

TECHNICAL DESCRIPTION

FT-DT.54.01

EUROTROD LC 62

PAGE 51/51

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

CLASSIFICATION:

AWS A5.4: E 2209-17

DESCRIPTION:

Rutile high-alloy extra-low carbon electrode (ELC) for duplex steels. Excellent welding (AC/DC), smooth

running. Good striking and restriking. Regular appearance, finely rippled, smooth junction. Easy slag removal.

SUITABLE FOR:

X2 CrNiMoN 22 -5-3 1.4462

X3 CrNiMoN 27-5-2 1.4460

X2 CrNiN 23-4 1.4362

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

Mo

< 0,03

0,90

0,65

22,0

9,0

3,0

0,14

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>550

Elongation

4d (%)

>690

>20

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(kg)

1,6

300

25 30

AC/DC

210

1,6

2,0

300

30 50

AC/DC

145

1,8

2,5

300

50 75

AC/DC

100

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

35

2,0

4,0

450

110 150

AC/DC

80

5,5

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.54.01.doc

PAGE 53/53

SPECIAL APPLICATIONS ELECTRODES

EUROTROD LR 35

EUROTROD LR 37

EUROTROD LR 47

EUROTROD LR 82

DATE: 03-09-2009

TECHNICAL DESCRIPTION

FT-DT.17.05

EUROTROD LR 35

PAGE 54/54

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: ~E 312-16

EN 1600: E 29 9 R 12

CLASSIFICATION:

DESCRIPTION:

Rutile type electrode for high-alloy and unalloyed steels. Good for all-position weldability, execpt verticaldownward.

SUITABLE FOR:

AISI 312

Difficult weld steels, e.g. unalloyed and high-strength alloy steels, carbon

steels, high-alloy steels, tool steels, heat treating steels, spring steels, rail steels,

manganese hardening steels.

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

0,11

1,0

0,65

28,5

10,0

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>450

Elongation

5d (%)

>660

>19

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(Kg)

2,5

300

50 75

AC/DC

105

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

45

2,2

5,0

350

140 190

AC/DC

25

1,8

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.17.05.doc

TECHNICAL DESCRIPTION

FT-DT.48.03

EUROTROD LR 37

PAGE 55/55

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: ~E 312-17

EN 1600: E 29 9 R 12

CLASSIFICATION:

DESCRIPTION:

Rutile type electrode for high-alloy and unalloyed steels. Good for all-position weldability, execpt verticaldownward.

SUITABLE FOR:

AISI 312

Difficult weld steels, e.g. unalloyed and high-strength alloy steels, carbon

steels, high-alloy steels, tool steels, heat treating steels, spring steels, rail steels,

manganese hardening steels.

TYPICAL CHARACTERISTICS OF ALL-WELD METAL:

Chemical Analysis (%):

C

Si

Mn

Cr

Ni

0,11

1,0

0,65

28,5

10,0

Mechanical Properties:

Tensile

Strength

(N/mm2)

Yield Strength

(N/mm2)

>450

Elongation

5d (%)

>660

>19

PRODUCT INFORMATION:

WELDING PARAMETERS

VACUUM PACKING

Diameter

(mm)

Length

(mm)

Recommended

Current

(A)

Current

Type

(Pole +)

Pieces

/Packet

(Un)

Weight

/Packet

(Kg)

2,5

300

50 75

AC/DC

105

1,8

3,2

350

75 110

AC/DC

55

2,0

4,0

350

110 150

AC/DC

45

2,2

5,0

350

140 190

AC/DC

25

1,8

WELDING POSITIONS:

DATE: 13-05-2009

Document: FT- DT.48.03.doc

TECHNICAL DESCRIPTION

FT-DT.18.05

EUROTROD LR 47

PAGE 56/56

APCER

CERTIFICADO

N.2000/CEP.1272

CERTIFIED COMPANY:

SISTEMA PORTUGUS

DA QUALIDADE

NP EN ISO 9001

AWS A5.4: ~E 307-16

EN 1600: 18 8 Mn R 12

CLASSIFICATION:

DESCRIPTION: