Beruflich Dokumente

Kultur Dokumente

D Pi 175

Hochgeladen von

reza329329Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

D Pi 175

Hochgeladen von

reza329329Copyright:

Verfügbare Formate

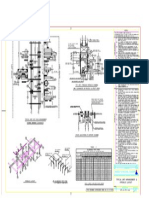

NOTES

1-ALL DIMENSIONS ARE IN mm. UNLESS OTHERWISE STATED.

2-THE SPECIFIED PROTECTIVE COATING OF BURIED PIPELINES IS TO BE

CONTINUOUS AT ROAD CROSSING.

EXTENT OF COATING

5000 MIN.

HIGHWAY

C

L OF HIGHWAY

4000

MIN.

SPECIFIED MIN.

BEND RADIUS

(SEE NOTE "5")

SPECIFIED MIN.

BEND RADIUS

(SEE NOTE "5")

600

MIN.

START OF BEND

START OF BEND

2000

PIPE SUPPORT

MIN. COVER

(SEE NOTE"5")

COLD FIELD BEND

SPECIFIED MIN.

BEND RADIUS

(SEE NOTE "5")

8-CARRIER PIPE TO BE CONTINUED WITHOUT VERTICAL OR SIDE BENDS

IN PROPERTY LIMIT OR MINIMUM DISTANCE OF 5000mm.

10-BLINDING CONCRETE TO BE CLASS 1:4:8.

11-ALL REINFORCEMENT TO BE MILD STEEL.

12-ALL REINFORCEMENT TO HAVE 40 COVER.

BURIED PIPELINES

SPECIFIED MIN.

BEND RADIUS

(SEE NOTE "5")

13-DISTRIBUTION BARS FOR ALL CASES TO BE 10 AT 250 c/c.

14-SAFETY BARRIER TO BE FABRICATED FROM 8"(DN200) PIPE

(OR OTHER AVAILABLE MATERIAL) AND SET IN CONCRETE. BARRIER

TO BE PAINTED BLACK AND WHITE AS SHOWN. BARRIER TO BE

LOCATED IN ACCORDANCE WITH INSTRUCTIONS OF THE ENGINEER.

500

350

PIPE OUTSIDE

DIAMETER

mk.b

(NOTE "15")

10 AT 250 c/c

2000

500

MIN.

4000

100

(TYP.)

100 BLINDING CONCRETE

C

SECTION A-A

CULVERT DETAILS

4000

4000

=

THIS DWG. SUPERSEDES DWG. No.S4L-6502

SECTION B-B

1000

COMPACTED SELECT

FILL MATERIAL

mk.c

WARNING SLAB

BURIED PIPELINES

100

1" C.S. PIPE

C+20

mk.a

MKd

500

MIN.

COLD FIELD BEND

10 E 150 c/c

150MIN.

MIN. COVER

(SEE NOTE "5")

SPECIFIED MIN.

BEND RADIUS

(SEE NOTE "5")

16

CONCRETE COVER

mk.d

MKc

ROAD SURFACE

1500

150

mk.a

MKb

EXTENT OF ROAD SURFACE

500

C+20

3000

500

MIN.

PIPE SUPPORT

ABOVE GROUND PIPELINES

350

5000MIN.

(NOTE "8")

START OF BEND

START OF BEND

START OF BEND

500

MIN.

500

MIN.

500

MIN.

2000

WARNING SLAB

150

MKa

GROUND LEVEL

SPECIFIED MIN.

BEND RADIUS

(SEE NOTE "5")

100

7-BACKFILL OVER PIPE SHALL BE PLACED IN 150 LAYERS AND

PNEUMATICALLY TAMPED TO REACH THE DENSITY OF UNDISTURBED

SURROUNDING AND SURFACE MATERIAL SHALL BE RESTORED TO

THE SATISFACATION OF THE ENGINEER.

C

L OF SECONDARY ROAD

MIN.

SPECIFIED MIN.

BEND RADIUS

(SEE NOTE "5")

6-ABOVE GROUND PIPELINES TO BE COATED WITH CLASS A OR B

(REF. IPS-C-TP-274) PROTECTIVE COATING FOR THE COMPLETE

LENGTH OF THE CROSSING. THE COATING SHALL EXTENT FOR

AT LEAST 4 METERS FROM WHERE THE PIPELINE IS COMPLETELY

CLEAR OF THE GROUND.

15-THE SHAPES OF REFERED MK ARE AS FOLLOWS:

GROUND LEVEL

150

4000

5000MIN.

(NOTE "8")

SAFETY BARRIER

SEE DETAIL "B"

ROAD SURFACE

5-THE MINIMUM BEND RADIUS AND THE MINIMUM COVER ARE SPECIFIED

ON THE PROJECT DRAWINGS.

PIPELINE SIZE

NPS

DN

UP TO 12"

UP TO 300

1100

700

200

16" TO 20"

400 TO 500

1310

910

200

24" TO 26" 600 TO 650

30"

1460 1060

200

750

1670 1170

250

36"

900

1820 1320

250

42"

1050

2070 1470

300

48"

1200

2220 1620

300

1300 2020 1720

300

52"

56"

1400

2120 1820

300

60"

1500

1730 1930

300

REINFORCEMENT

12 AT 250c/c MKa

12 AT 250c/c MKb

12 AT 250c/c MKc

416 STAG. MKd

GROUND LEVEL

500

SURFACE

4-ALL ROAD CROSSINGS SHOWN ON THIS DRAWING WILL BE

CONSTRUCTED BY CUT-AND-FILL METHOD. WHERE THIS METHOD

IS UNACCEPTABLE TO THE ROAD AUTHORITIES, THE CROSSING

MAY BE LAID IN THRUST BORED CASING AS DETAILED IN SHEET 2.

SURFACE AND

HARD SHOULDER

HIGHWAY

(SEE NOTE "6")

START OF BEND

5000

EXTENT OF ROAD

250MIN.

(NOTE "8")

EXTENT OF HIGHWAY

EXTENT OF COATING

C

L OF SECONDARY ROAD

16

5000

9-CONCRETE TO BE OF 1:2:4 MIX WITH MINIMUM CUBE OF 210

kg/cm3 CRUSHING STRENGTH AT 28 DAYS.

SPECIFIED MIN.

BEND RADIUS

(SEE NOTE "5")

ABOVE GROUND PIPELINES

100

5000 MIN.

GROUND LEVEL

GROUND LEVEL

3-DOUBLE COAT AND DOUBLE WRAP SHALL BE APPLIED

AT ALL ABOVE GROUND/BURIDE PIPELINES ROAD CROSSING.

2000

(NOTE "8")

SAFETY BARRIER

SEE DETAIL "B"

600

MIN.

SURFACE AND

HARD SHOULDER

START OF BEND

5000

EXTENT OF HIGHWAY

(SEE NOTE "6")

START OF BEND

C

L OF HIGHWAY

500

SLAB

PIPELINE

16 AT 250c/c MKa

12 AT 250c/c MKb

12 AT 220c/c MKc

420 STAG. MKd

18 AT 200c/c MKa

16 AT 200c/c MKb

16 AT 200c/c MKc

420 STAG. MKd

18 AT 200c/c MKa

16 AT 200c/c MKb

16 AT 200c/c MKc

420 STAG. MKd

(SEE NOTE "14")

C

B

A

REV.

DESCRIPTION

IRANIAN PETROLEUM STANDARDS

DATE

NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION

PIPELINE ROAD CROSSING

DETAIL "B"

MAJOR & SECONDARY ROAD CROSSING

TYPICAL SAFETY BARRIER

DATE

DRAWING No.

IPS-D-PI-175

SHEET

1

REV.

NOTES

HARD

DITCH

SHOULD

ER

T ROAD

C

L

ASPHAL

CASING

EXCAVATION

(SEE NOTE "5")

CONNECTED AT HIGH

END OF CASING

COMBINED POTENTIAL

SLOPE 1:20

450 SQ.x500 DEEP

CONCRETE BLOCK

GROUND LEVEL

BANDS & CLAMPS

MIN. COVER

900MIN.

600

1x10mm 2 PVC INSULATED

COPPER CABLE

INSULATORS

EQUALLY SPACED MAXIMUM SPACE TO BE 3000

CENTREING CRADLE

SEE DETAIL "B"

CENTREING CRADLE

NOTE "11"

"S" SEAL FIXED WITH STAINLESS STEEL

BANDS & CLAMPS

500

START OF BEND 180

500

START OF BEND 180

MARKER PLATE

300

1200MIN.

600

SLOPE 1:20

50

50

SLOPE 1:20

GROUND LEVEL

GROUND LEVEL

6mm. THK. M.S. SUPPORT

TO BE WELDED ALL ROUND

CASING & THE VENT PIPE

CASING PIPE

30

FULL PENETRATION

WELD

600

SECTION B-B

8"

10"

12"

14"

2

150

90 BEND

120

MAX. SPACE TO BE 3000

(SEE TABLE)

CARRER PIPE

SEE DETAIL "A"

SECTION A-A

4"

6"

SEE DETAIL "A"

350

CASING PIPE

NPS

WARNING SLAB

INSULATORS EQUAL SPACED

CARRIER PIPE

CARRIER

PIPE

C OF VENT

L

450 SQ.x500 DEEP

CONCRETE BLOCK

1000

1000

MARKER PLATE

450 SQ.x500 DEEP

CONCRETE BLOCK

500

SLOPE DOWN MIN. 1:100

600

"S" SEAL FIXED WITH STAINLESS STEEL

CONC. BASE

2000

WARNING SLAB

CASING

NOTE "11"

1500

2000

AT LOW END OF CASING

2000MIN.

500

MIN. COVER

(SEE NOTE 13)

VENT PIPE BOTTOM CONNECTED

14-CASING PIPE SHALL BE CARBON STEEL API 5LX-52.

TEST POINT & MARKER

DITCH

WARNING SLAB

13-THE MIN COVER ARE SPECIFIED ON THE PROJECT DRAWINGS.

500

VENT PIPE TOP

11- CARRIER PIPE TO BE CONTINUED WITHOUT VERTICAL OR SIDE BENDS

IN PROPERTY LIMIT OR FOR MINIMUM DISTANCE OF 5000.

12-BLOCK VALVES SHALL BE INSTALLED AT EACH SIDE OF ROAD CROSSING

WHERE SPECIFIED IN ROUTE AND PROFILE DRAWINGS.

1500

EDGE OF ROAD

C

L

OF ROAD

EDGE OF ROAD

6500MIN.

UNLESS SITE CONDITION

DOES ALLOW

10- PROPERTY LIMIT FOR DIFFERENT ROAD CROSSING IS ANNOUNCED

BY ENGINEER ACCORDING TO REGULATIONS OF MINISTRY OF ROAD

AND TRANSPORTATION.

GAUZE INSECT SCREEN

FITTED INSIDE PIPE

300MIN.

1000

SLOPE 1:20

50

GROUND LEVEL

9- BACKFILL OVER CASING SHALL BE PLACED IN 150 LAYERS AND

PNEUMATICALLY TAMPED TO REACH THE DENSITY OF UNDISTURBED

SURROUNDINGS AND SURFACE MATERIAL SHALL BE RESTORED TO

THE SATISFACTION OF THE ENGINEER.

50

1000

1500

TOE OF EMBANKMENT

500

R.O.W. LIMIT

7- CASING SHALL BE THOROUGHLY CHECKED TO ENSURE THAT

NO OUT-OF-ROUNDNESS OR DENTS ARE EXISTING, HOLES IN

CASING PIPE FOR VENTS SHOULD BE PREPARED AND VENTS

WELDED IN BEFORE INSERTION OF CARRIER PIPE.

8- EXPOSED PIPES SHALL BE PAINTED IN ACCORDANCE WITH N.I.O.C.

SPECIFICATION.

180 BEND

PROPERTY LIMIT

6500MIN.

MARKER PLATE

DETAIL "B"

LENGTH OF CASING IS SPECIFIED ON RELATED DRAWING

TOE OF EMBANKMENT

FITTED INSIDE PIPE

6- THE CASING SHALL BE SUPPORTED FOR ITS ENTIRE LENGTH AND

SHALL BE LAID SO AS TO SLOPE SLIGHTLY.

ON ALL ROAD CROSSING CASED OR UNCASED,

CONTRACTOR SHALL FURNISH AND INSTALL

SAND BAGS OR EARTH FILLED BAGS TO FULLY

SUPPORT INSTALLED FACILITIES.

SEE NOTE "6"

R.O.W. LIMIT

GAUZE INSECT SCREEN

NOTE:

5- EACH CASING END SHALL HAVE A MINIMUM DISTANCE OF 8 METER

FROM THE CENTER LINE OF ROAD.

PIPELINE

ROAD CROSSING PLAN

300MIN.

PIPE LINE

3- DOUBLE COAT AND DOUBLE WRAP ON CARRIER PIPE OVER LENGTH

OF CASING AND EXTENDING 3 METERS EITHER SIDE OF END OF

CASING, CASING PIPE TO BE SINGLE COAT DOUBLE WRAP VENT

PIPE TO BE SIMILARY TREATED TO A HEIGHT OF 300 mm.

ABOVE GROUND LEVEL. ABOVE THIS LEVEL THE VENT PIPE TO BE

PRIMED AND PAINTED DAYGLOW YELLOW.

4- CASING SHALL BE FREE OF BURRS AT WELDS,VENT PIPES SHALL

BE INSTALLED BEFORE INSERTION OF CARRIER PIPE.

EXCAVATED AREA

BOTTOM OF UNDERCUT

180 BEND

2- WITHIN A CASED CROSSING THE PIPELINE IS CATHODICALLY

PROTECTED.

CARE SHOULD BE TAKEN NOT TO DAMAGE COAT & WRAP WHEN

PULLING THROUGH CARRIER PIPE AND THAT INSIDE OF THE CASING

IS DRY BEFORE END SEALS ARE APPLIED.

(SEE NOTE 13)

SHOULD

ER

HARD

DITCH

BURROW AREA

CASING PIPE

C

L

1- ALL DIMENSIONS ARE IN MILLIMETRES UNLESS OTHERWISE STATED.

VENT

C CASING

L

END OF VENT PIPE TO BE

GROUNDFLUSHED WITH INSIDE

SURFACE OF CASING PIPE

DETAIL "A"

100

150

200

250

300

350

VENT

CASING PIPE

NPS

8"

10"

12"

16"

16"

18"

DN

200

250

300

400

400

450

THK. NPS DN SCH.

4.7

5.6

6.3

7.9

7.9

7.9

3"

3"

3"

3"

3"

3"

80

STD.

80

STD.

80

STD.

80

80

80

STD.

STD.

STD.

STD.

16"

400

20"

500

7.9

3"

20"

500

24"

600

7.9

4" 100 STD.

18"

DN

22"

24"

30"

36"

40"

450

550

600

750

900

1000

42" 1050

24"

26"

30"

600

650

750

7.9

7.9

9.5

900

11.1

48" 1200

15.8

36"

42" 1050

48"

1200

12.7

15.8

80

mm

3000

3000

3000

3000

3000

3000

3000

100 STD.

3000

4" 100 STD.

2000

4"

4"

100 STD.

4"

100 STD.

4"

100 STD.

4" 100 STD.

4"

100

STD.

THIS DWG. SUPERSEDES DWG. No.SM-6016

INSULATOR

SPACE

3000

C

B

A

REV.

PIPELINE ROAD CROSSING

TYPICAL ARRANGEMENT OF

CASED PIPE ROAD CROSSING

2000

2000

2000

DATE

NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION

2000

2000

DESCRIPTION

IRANIAN PETROLEUM STANDARDS

DATE

DRAWING No.

IPS-D-PI-175

SHEET

2

REV.

Das könnte Ihnen auch gefallen

- FS 3302 - FS-Temperature Transmitter (Electronic)Dokument10 SeitenFS 3302 - FS-Temperature Transmitter (Electronic)Binu ManiNoch keine Bewertungen

- PLC Interface Details PDFDokument1 SeitePLC Interface Details PDFSreekanthMylavarapuNoch keine Bewertungen

- Polyken Utility Tape 900 910 908 911 920Dokument2 SeitenPolyken Utility Tape 900 910 908 911 920Tracy EvansNoch keine Bewertungen

- Honeywell Prover PDFDokument12 SeitenHoneywell Prover PDFMelina SbhNoch keine Bewertungen

- Lco Tank Relief Valve (2016.04.11.) - For ApprovalDokument87 SeitenLco Tank Relief Valve (2016.04.11.) - For ApprovalEnoch TwumasiNoch keine Bewertungen

- 01-01-1865-D ELDS Technical Manual Iss13Dokument221 Seiten01-01-1865-D ELDS Technical Manual Iss13Alberyt099Noch keine Bewertungen

- Technical Doc 1 - Technical Scope of Work Drs Eac181Dokument25 SeitenTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09Noch keine Bewertungen

- 220 JLD JL10 21051 PDFDokument2 Seiten220 JLD JL10 21051 PDFFrancisco Antonio Guerrero MonsalvesNoch keine Bewertungen

- 10080-1-ENGG-DBD-CI-003 - 1 - Design Basis For Fundation Field BUSDokument69 Seiten10080-1-ENGG-DBD-CI-003 - 1 - Design Basis For Fundation Field BUSDinesh Boopalan100% (1)

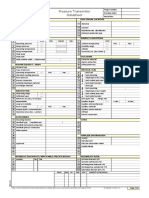

- Pressure Switch Mechanical Template SmallDokument1 SeitePressure Switch Mechanical Template Smallali AlinezhadNoch keine Bewertungen

- Power Point Fiber Optic Distributed Strain and Temperature SensorsDokument63 SeitenPower Point Fiber Optic Distributed Strain and Temperature SensorsjovinosubidoNoch keine Bewertungen

- Leak Detection in Pipeline-JijoDokument17 SeitenLeak Detection in Pipeline-Jijoamulbaby31Noch keine Bewertungen

- Tie-In Process PipeDokument1 SeiteTie-In Process PipeMaisam AbbasNoch keine Bewertungen

- Work Procedure Bitumen Mastic FlooringDokument6 SeitenWork Procedure Bitumen Mastic FlooringSWARUP MONDALNoch keine Bewertungen

- DPT Smart Pressure TransmitterDokument15 SeitenDPT Smart Pressure Transmitterprasanta_bbsrNoch keine Bewertungen

- Doha North Sewerage Treatment & Associated WorksDokument67 SeitenDoha North Sewerage Treatment & Associated WorksLito MendozaNoch keine Bewertungen

- Technical Volume PDFDokument14 SeitenTechnical Volume PDFindramaniNoch keine Bewertungen

- KROHNE - Leak Detection and LocalisationDokument8 SeitenKROHNE - Leak Detection and Localisationdaniel_afpNoch keine Bewertungen

- MDPE 03 Electro Fusuion Welding FormatDokument6 SeitenMDPE 03 Electro Fusuion Welding FormatAlok GiriNoch keine Bewertungen

- 123, SPECS-GAS-123, Mini QGM Floating Gas Trap, Rev 2Dokument2 Seiten123, SPECS-GAS-123, Mini QGM Floating Gas Trap, Rev 2fahrain2012Noch keine Bewertungen

- Maintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsDokument21 SeitenMaintenance and User Manual: Borehole TV Camera Inspection System Setting Up InstructionsFranklin L SilvaNoch keine Bewertungen

- Iranian Petroleum Standards: Typical Unit Arrangement & Piperack Layout IPS-D-PI-102Dokument1 SeiteIranian Petroleum Standards: Typical Unit Arrangement & Piperack Layout IPS-D-PI-102reza329329Noch keine Bewertungen

- Cathodic Protection BOMDokument4 SeitenCathodic Protection BOManonymous542Noch keine Bewertungen

- Chemical Injection Skids - FinalDokument2 SeitenChemical Injection Skids - Finallethanhcong228Noch keine Bewertungen

- Pipe Stress AnalysisDokument7 SeitenPipe Stress AnalysisTushar NaikNoch keine Bewertungen

- ITP InstrumentationDokument9 SeitenITP InstrumentationzhangyiliNoch keine Bewertungen

- Gas RegulationsDokument168 SeitenGas RegulationsJijo GeorgeNoch keine Bewertungen

- IPS-MBD21907-In-506 - Datasheet of Pressure Transmitter - ADokument7 SeitenIPS-MBD21907-In-506 - Datasheet of Pressure Transmitter - ANikhil KarkeraNoch keine Bewertungen

- BE-WI-248-01-F25 Datasheet Solenoid ValveDokument3 SeitenBE-WI-248-01-F25 Datasheet Solenoid Valvemika cabelloNoch keine Bewertungen

- FS 3210 - FS-Gas Flow ComputerDokument6 SeitenFS 3210 - FS-Gas Flow ComputerBinu ManiNoch keine Bewertungen

- ITP's and ITR's A Necessary - Monster - PDFDokument5 SeitenITP's and ITR's A Necessary - Monster - PDFshastri85Noch keine Bewertungen

- Mdpe Tpi Questions AnswerDokument29 SeitenMdpe Tpi Questions AnswerShashi ChouhanNoch keine Bewertungen

- MNT-INTG-2007OP - Maintenance Welding InspectionDokument43 SeitenMNT-INTG-2007OP - Maintenance Welding InspectionNatarajan MurugesanNoch keine Bewertungen

- PCV Data Sheet PDFDokument5 SeitenPCV Data Sheet PDFveenaNoch keine Bewertungen

- Mode of MeasurementDokument2 SeitenMode of MeasurementAnish BabuNoch keine Bewertungen

- Most Economical Tank Height Diameter RatioDokument3 SeitenMost Economical Tank Height Diameter RatioWei RongNoch keine Bewertungen

- 10.1 Construction ScheduleDokument104 Seiten10.1 Construction Schedulesanthoshtm 76Noch keine Bewertungen

- NG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedDokument16 SeitenNG-018-XX-PNL-430808 - Rev04 ITP Cable Tray UnsignedFolarin AyodejiNoch keine Bewertungen

- Swagelok TubingDokument1 SeiteSwagelok TubingMmstevens00Noch keine Bewertungen

- Lamination Recipe-700mmDokument1 SeiteLamination Recipe-700mmSai PrasathNoch keine Bewertungen

- Saudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalDokument10 SeitenSaudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalTariqMalikNoch keine Bewertungen

- Pressure Transmitter Template SmallDokument2 SeitenPressure Transmitter Template Smalldiksha surekaNoch keine Bewertungen

- Nawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFDokument29 SeitenNawppl-Bims-Nppl-320-Pl-Pro-00002 - 000 - Pre-Test of Test Headers Procedure PDFAhmed AbidNoch keine Bewertungen

- Inspection & Test Plan Key Valve Interlocks: To BS EN ISO 9001: 2008Dokument2 SeitenInspection & Test Plan Key Valve Interlocks: To BS EN ISO 9001: 2008Charles RobiansyahNoch keine Bewertungen

- 903-10004-SPC-M-001 Piping Material SpecificationDokument15 Seiten903-10004-SPC-M-001 Piping Material SpecificationChitradeep FalguniyaNoch keine Bewertungen

- PUB060-001-00 - 1110 RCL NetworksDokument8 SeitenPUB060-001-00 - 1110 RCL NetworksapisituNoch keine Bewertungen

- Electrical Tray InstallationDokument4 SeitenElectrical Tray InstallationClinton OlivierNoch keine Bewertungen

- Installation StandardDokument80 SeitenInstallation StandardSukdeb Maity100% (1)

- Earth Testing at New CCE Office STF Area.: Location ResultDokument1 SeiteEarth Testing at New CCE Office STF Area.: Location ResultImran Nawaz MehthalNoch keine Bewertungen

- Elster Instromet Q.sonicDokument2 SeitenElster Instromet Q.sonicsaid_rahmansyah4750Noch keine Bewertungen

- Control Valve DatasheetDokument13 SeitenControl Valve DatasheetRakesh Karan SinghNoch keine Bewertungen

- Pipeline DryingDokument2 SeitenPipeline DryingAriel Anasco100% (2)

- Product List: Pressure MeasurementDokument6 SeitenProduct List: Pressure MeasurementSr FarezNoch keine Bewertungen

- Optima Pass - Jeyakaran Thangaraj - 07-11-2021-1Dokument1 SeiteOptima Pass - Jeyakaran Thangaraj - 07-11-2021-1Anish AniNoch keine Bewertungen

- Mto ProcedureDokument3 SeitenMto ProcedureakilasrivatsavNoch keine Bewertungen

- ASME PTC19.3 TW-2010 Thermowell Design Standard: © Abb Month DD, YYYY - Slide 1Dokument23 SeitenASME PTC19.3 TW-2010 Thermowell Design Standard: © Abb Month DD, YYYY - Slide 1John PaulNoch keine Bewertungen

- Aa 036531 001Dokument1 SeiteAa 036531 001narutothunderjet2160% (1)

- Ac 036660 004Dokument1 SeiteAc 036660 004narutothunderjet216Noch keine Bewertungen

- تفاصيل انشائية لجسرDokument8 Seitenتفاصيل انشائية لجسرalaa4altaieNoch keine Bewertungen

- Lta StandardDokument178 SeitenLta Standardkokuei100% (5)

- Material and Equipment Standard: IPS-M-GN-330Dokument19 SeitenMaterial and Equipment Standard: IPS-M-GN-330reza329329Noch keine Bewertungen

- Material and Equipment Standard: IPS-M-AR-205Dokument50 SeitenMaterial and Equipment Standard: IPS-M-AR-205reza329329Noch keine Bewertungen

- E Ar 100Dokument46 SeitenE Ar 100reza329329Noch keine Bewertungen

- Engineering Standard: IPS-E-AR-130Dokument42 SeitenEngineering Standard: IPS-E-AR-130reza329329Noch keine Bewertungen

- Engineering Standard: IPS-E-AR-160Dokument76 SeitenEngineering Standard: IPS-E-AR-160reza329329Noch keine Bewertungen

- Ips e Ar 120Dokument91 SeitenIps e Ar 120reza329329Noch keine Bewertungen

- مباحث حسابداریDokument35 Seitenمباحث حسابداریreza329329Noch keine Bewertungen

- M GN 375Dokument53 SeitenM GN 375reza329329Noch keine Bewertungen

- M GN 365Dokument46 SeitenM GN 365reza329329Noch keine Bewertungen

- G GN 180Dokument34 SeitenG GN 180reza329329Noch keine Bewertungen

- Engineering Standard: IPS-E-GN-120Dokument45 SeitenEngineering Standard: IPS-E-GN-120reza329329Noch keine Bewertungen

- Testing Methods For Pipes, Valves & FittingsDokument86 SeitenTesting Methods For Pipes, Valves & Fittingsreza329329Noch keine Bewertungen

- M GN 360Dokument72 SeitenM GN 360reza329329Noch keine Bewertungen

- General Index TO Standards and Standard Drawings: IPS-E-GN-000Dokument96 SeitenGeneral Index TO Standards and Standard Drawings: IPS-E-GN-000reza329329Noch keine Bewertungen

- Itok Final Offer 14 SeptemberDokument2 SeitenItok Final Offer 14 Septemberreza329329Noch keine Bewertungen

- Fittings, Flanges & CouplingsDokument1 SeiteFittings, Flanges & Couplingsreza329329Noch keine Bewertungen

- FPSO MBC On Reel Whitepaper Marinebreakawaycouplings August 2018Dokument16 SeitenFPSO MBC On Reel Whitepaper Marinebreakawaycouplings August 2018koushkiNoch keine Bewertungen

- m-tp-750 NEWDokument185 Seitenm-tp-750 NEWreza329329Noch keine Bewertungen

- m-tp-750 NEWDokument185 Seitenm-tp-750 NEWreza329329Noch keine Bewertungen

- A85780-9 Attachment 7 To Ir No. 5.1 - Enb-A-wps-52 Rev.1 - A5t7r1Dokument5 SeitenA85780-9 Attachment 7 To Ir No. 5.1 - Enb-A-wps-52 Rev.1 - A5t7r1reza329329Noch keine Bewertungen

- E GN 100 PDFDokument67 SeitenE GN 100 PDFreza329329Noch keine Bewertungen

- Insulating JointDokument17 SeitenInsulating Jointreza329329100% (1)

- Norsok Material Data Sheet (M-630r2)Dokument77 SeitenNorsok Material Data Sheet (M-630r2)karuna346Noch keine Bewertungen

- Technical Information Sheet: 7-2508 Pipe CoatingDokument3 SeitenTechnical Information Sheet: 7-2508 Pipe Coatingreza329329Noch keine Bewertungen

- Biochemistry - Serum: Checked By: Dr. Majid SafaDokument2 SeitenBiochemistry - Serum: Checked By: Dr. Majid Safareza329329Noch keine Bewertungen

- Guidelines For Prediction of CO2 Corrosion in Oil and Gas Production SystemsDokument19 SeitenGuidelines For Prediction of CO2 Corrosion in Oil and Gas Production Systems4sentieriNoch keine Bewertungen

- 379 Ed PL PRC 0001 B1Dokument15 Seiten379 Ed PL PRC 0001 B1reza329329Noch keine Bewertungen

- M PL 033Dokument19 SeitenM PL 033Ali ClubistNoch keine Bewertungen

- Freecorp InstallationDokument4 SeitenFreecorp Installationreza329329Noch keine Bewertungen

- Weight Per Meter of WeldDokument1 SeiteWeight Per Meter of Weldreza329329Noch keine Bewertungen

- Profil - Ball - Return AMF 82-90XL PDFDokument48 SeitenProfil - Ball - Return AMF 82-90XL PDFblurmuruganNoch keine Bewertungen

- Best Practices in Sustainable Building Designcomentario PDFDokument129 SeitenBest Practices in Sustainable Building Designcomentario PDFBelen Acosta100% (3)

- WinCUPL GuideDokument2 SeitenWinCUPL Guidepra_sad50% (2)

- Design Example - WorkshopDokument4 SeitenDesign Example - WorkshoplaichmailNoch keine Bewertungen

- 24Kv Secogear: Metal-Clad Switchgear Instruction ManualDokument53 Seiten24Kv Secogear: Metal-Clad Switchgear Instruction Manualleidy vidalNoch keine Bewertungen

- Consumption StatementDokument7 SeitenConsumption StatementRonnie SinghNoch keine Bewertungen

- Euwa40 200MZDokument4 SeitenEuwa40 200MZClement WrightNoch keine Bewertungen

- Frontend Exercise - Rocket MediaDokument4 SeitenFrontend Exercise - Rocket MediajayantNoch keine Bewertungen

- The Pink CityDokument7 SeitenThe Pink CityKaur SimranNoch keine Bewertungen

- Handbuch GEObox Bag 00140404 MAILDokument44 SeitenHandbuch GEObox Bag 00140404 MAILvojammNoch keine Bewertungen

- CBAO DiagDokument4 SeitenCBAO Diagiker213Noch keine Bewertungen

- Contoh Descriptive Text About Paris Beserta ArtinyaDokument11 SeitenContoh Descriptive Text About Paris Beserta ArtinyaMarhani AmaliaNoch keine Bewertungen

- LDAP TutorialDokument28 SeitenLDAP Tutorialzorrito26Noch keine Bewertungen

- THERMO 4 Aswandi AlamDokument13 SeitenTHERMO 4 Aswandi AlamAhmad S AminudinNoch keine Bewertungen

- Fast, Accurate Simulation For SDN PrototypingDokument6 SeitenFast, Accurate Simulation For SDN PrototypingIbEn Id XRxNoch keine Bewertungen

- Googolsoft - Company ProfileDokument20 SeitenGoogolsoft - Company ProfileJaya ManiNoch keine Bewertungen

- MS09-050: Microsoft Windows SMB2 - Smb2ValidateProviderCallback Vulnerabilidad (975497) (EDUCATEDSDokument3 SeitenMS09-050: Microsoft Windows SMB2 - Smb2ValidateProviderCallback Vulnerabilidad (975497) (EDUCATEDS16183743-1 MARCELO ANDRESNoch keine Bewertungen

- Chapter-8 (Cavity Wall)Dokument17 SeitenChapter-8 (Cavity Wall)Susma DotelNoch keine Bewertungen

- E1 Lab 11 5 5Dokument19 SeitenE1 Lab 11 5 5Chris LeeNoch keine Bewertungen

- Concrete Pavement Design: Technical SummaryDokument2 SeitenConcrete Pavement Design: Technical SummaryHaris Restu UtamaNoch keine Bewertungen

- RAMI 4.0: An Architectural Model For Industrie 4.0Dokument31 SeitenRAMI 4.0: An Architectural Model For Industrie 4.0Finigan JoyceNoch keine Bewertungen

- Configuring OTLDokument136 SeitenConfiguring OTLHirenDesai100% (1)

- RNC Migration To A New SGSNDokument2 SeitenRNC Migration To A New SGSNEunice Bid MNoch keine Bewertungen

- From Mining Region To Industrial Heritage Sites - 50 Years of Documentation, Protection and Management in The Ruhr Area, GermanyDokument21 SeitenFrom Mining Region To Industrial Heritage Sites - 50 Years of Documentation, Protection and Management in The Ruhr Area, GermanyDimitrios MavromatidisNoch keine Bewertungen

- Anselm KieferDokument22 SeitenAnselm Kieferchnnnna100% (1)

- WSDL2 WsDokument5 SeitenWSDL2 WsgarcameNoch keine Bewertungen

- MAN10 33708 Proyector Mini AP E201-01Dokument20 SeitenMAN10 33708 Proyector Mini AP E201-01Imed RebaiNoch keine Bewertungen

- Materials of Floating Architecture DissertationDokument59 SeitenMaterials of Floating Architecture DissertationJCB100% (7)

- Seminar On Mivan Technology The Aluminium FormworkDokument36 SeitenSeminar On Mivan Technology The Aluminium FormworkCivilTY09Aditya GavaliNoch keine Bewertungen

- Electrical Design For HRB-Classroom Seminars Part-2-3Dokument166 SeitenElectrical Design For HRB-Classroom Seminars Part-2-3Ryan RamosNoch keine Bewertungen