Beruflich Dokumente

Kultur Dokumente

Hollow Core

Hochgeladen von

Magdy Bakry0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

282 Ansichten23 Seitenalrashed abetong hollow core slabs

Originaltitel

Hollow Core(3)

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenalrashed abetong hollow core slabs

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

282 Ansichten23 SeitenHollow Core

Hochgeladen von

Magdy Bakryalrashed abetong hollow core slabs

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 23

‘AlRashid Abetong. A Seudi-Swedish Company was

«established in 1977 and has grown rapidly to become

one ofthe largest and most successful precast concrete

companies in the Kingdom. The company has a ull

range ofthe Precast Concrete Products like: Hellowcore

‘Slabs, Double Tee (OT) Slabs, ARA Form Slabs and all

‘ypes of precast concrete structures in addition (othe

tulaue Swede Beam System.

‘ANRashid Abetong Co. has lour large lactories located

In the Second Industrial City in Riyadh. We serve our

‘customers through our main office in Riyadh and our two

branch offices situated in Jeddah and Alka

ur production output from the factories in Riyadh

exceeds 20,000 Cubic Meter of precast concrete

elements every month. AlRashid Abetong is composed

of dedicated teams of professionals fully avalifed and

Anowledgeable in their fields of expertise where they

have gained 2 reputation for providing state-of-the-art

products and services. The company is curently employing

‘more than 2.500 employees of varous professions.

When dealing with AlRashld Abetong you can be

sure that we will satisfy every need wherever and

whenever required

le bapa! Bisa Muley 35 caus

Wdlaed ciasasig 2 pps Zaye AS SAA

Lathes patty pl el eat tee

sits pean Spall gs) Ala poual Bll

SUI LAs gine GL LN

cot Urolbdly (DT) etup sLbolyae iat!

Aiud Ay

6

aMielaleenstohe

apd gasp copa gL aL ata

Gi ilasde sy! gigy deat as sd

Salish Ras pga. vals Qala cat

Lee ty alll gL

srblgiae gd

Se BL BLL bela aS SI

ApSLayhil geal galing dq getevess

Jat JAS 8 AI, gia AZaaall

erate

Bypbll pede Days che Gett ge Nad

PPh ee ly Say plac pb Layealy

isola Jel ee OLS y ol atlas

lag Oe? pe jong Lele aS ti 6 BT

ecient UIC ge

Byes Belay APE BS gal Lae

eta Sede bp AS AISI LGD ole LSS

Omp oSs Jedy gh papSilalo!

ALRASHID-ABETONG Aan Sowell ail

HS slabs are made with GSO concrete and 1/2" or

3/8" strands, ASTM AIG as standard.

The top surface ofthe HCS slab is normally prepared

for a levelling screed (structural or non-structural) as

beeing for Noor finishing,

The underside surface of the HCS slab can be

Used as a finished ceiling as installed by applying,

painting system.

Holes and openings can be arranged in accordance

with instructions later inthis folder. A Hollow Core

slab (HICS) is a precast presiressed concrete member

with continous voids provided to reduce weight and

therefore cost. HCS is primarily used for Noor or reof

deck systems,

Day cast or extrusion system is used as manufacturing

method for HCS slab, The cores are formed hy

augers with the concrete being compacted around

the cores. Hollow Core slabs are cast in a continous

length of about 100m. after hardening, the slabs are

ut into accurate length according to design

reauitements. This is made by a special cutting

machine using a diamond sawing blade,

CS slabs are most widely known for providing

‘economical and efficient floor and roof systems,

Structurally, HCS slabs provide the effeciency of

prestiessed members concerning load capacity, span

J deflection control. In adaltion, by connecting

the slabs with joint reinforcement, the floor ean be

arranged 25 a diaphragm, distributing lateral forces

for stability purpose.

Excellent fire resistance Is another attribute of the

LCS slabs. This is achieved by using sufficient slab

thickness and concrete cover for strands

Used as floor-celling assemblies, HCS slabs have the

‘excellent sound transmission characteristics associated

with concrete

‘The fast and convenient installation of HCS slabs

‘minimizes the execution period at the site and enables

‘early start of finishing and ether works to follow

RANGE OF SPAN

The table below shows the normal range of span for each size of HC slabs. The shorter span can cary heavy

loads white the longer is applicable for lighter loads (ike oof loads ete.)

us 200 | [OOOOOO! 2)

HGS 250

HGS 300

Hes 320, FI lO0a0d

vs. 360 { 0000 Z

4 6 8 10 12 4 16 1B

RANGE OF SPAN (m)

Later in this folder there is more comprehensive design information sbout load capacities, camber, weight, ete

IM there is a need for even more detailed or Sophisticsted analysis, AlRashid-Abetong design department will

aways be at your sevice.

DESIGN

Aloor consisting of hollow cere slabs can be designed to provide a rigid and homogenous part of the sructure

(diaphragm). This (diaphragm) can be used ay part of the stabilizing system and is achived by arranging the joint

reinforcement to tie the slabs together. Nowmally theres no need for structural scred for stability purpose. This

design ts done by the party who Is responsfle for the general stabiliy of the building

Each single element Is designed to carry loads accoiding to specifications. This ts normally done by AlRashid-

Abetong design department. there Is a need for structural screed to act together with the stab for vertical load

bearing this will be advised by AlRashid-Abetong designer

‘Topping for levelling purpose is needed to level the slab considering camber and other irregularities.

ARIA

Some examples of connection details fo HCS slabs are shown below. These details can be modified [simpler or

‘mote sophisticated) depending on the conditions for each project.

T

sant Sdn

vel pe!

Sala Plan Dota AA

HG

2 —

ae sli

Sandwich & A

selpel

Sandi

al sation

Vertical Section Yertcal Section

End of HGS testing on external wall Side Connection of HCS to wall

said

val pos

Seed + Pot

a

sali

wal po

Vertical Section a

End of HCS resting on internal wall (double support)

Stel gle

va

Yertical Section

End of HCS resting on local support at column

Vorticel Section

HGS slab resting on beom

SOG

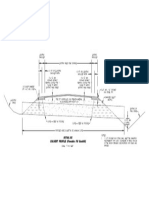

a

HCS 200

1ss_22

2

TYPICAL SECTION OF HCS 200 SLAB (a moasores in wn)

2 TECHNICAL INFORMATION

hy

DIMENSIONS OF HCS 200 SLAB,

WIDTH 196 mm

“HEIGHT 200 mm

LENGTH ACCORDING TO LOAD CURVES

(SEE NEXT PAGE)

200

dolor cnet ont

SELF WEIGETT 2.45 kN

SELF WEIGET (IOINTED) 2.60 N/m?

FIRE RATING - 60 MIN WITHIN LOAD/SPAN

SHOWN ON NEXT PAGE

LOAD BEARING CAPACITIES AND EXPECTED.

en ‘CAMBER ARE SHOWN ON NEXT PAGE

HCS200 SLAB

230 Prefed sce by HOS ends in 30 mn.

Gou TT

| <__tesared sever with is 70 om _

139 Frere sho ws 150m

‘SUPPORT ARRANGEMENT FOR HCS 200

HCS 200

Load curves are given for service load (unfoctored) and ultimate load (Factored) and for the mest favourable

(echnical, commercially, etc) reinforcement alternative. Self weight is already include in capacities. For yey

high loads at short span there might be a need for entra shear contol

Camber is shown for erection stage (prestrssing an selF.weight are considered)

“The two curves ae showing estimated rang of camber for highest and lowest reinforcement akematve

LOAD BEARING CAPACITY TABLE OF HCS 200

3 z 3

2 3 3

Allowable Superimposed Load (KPa)

3

000 1

40 45°50) «SS 60 SDS BOSS

Length of member (m)

= === Uimate toad Service Load

Camber Ronge of HCS 200

nn

Tin

ip ====

4 ion

2 oo

.

7

20.00

40 45 ~«50«5S 60 OS 70S OOS

Length of member (m)

31

0

1s

1196

TYPICAL SECTION OF HCS 250 SLAB (ll neasrsia ne)

a TECHNICAL INFORMATION

DIMENSIONS OF HCS 250 SLAB

AVIDTH 196 mm

HEIGHT 250 mam

LENGTH ACCORDING TO LOAD CURVES

(SEE NEXT PAGE)

250

SELF WEIGHT 2.84 kN?

SELF WEIGHT (JOINTED) 3.04 kin

Nod ena cnt

FIRE RATING - 60 MIN VEITHIN LOAD/SPAN,

SHOWN ON NEXT PAGE

LOAD BEARING CAPACITIES AND EXPECTED

CAMBER ARE SHOWN ON NEXT PAGE

‘SIDE EDGE OF

HCS 250 SLAB 230 refed sae by HCS ond isin 30.

fon

: fe, us 0

o Designed supp wih 580.0

10 Pele shall wid 150

‘SUPPORT ARRANGEMENT FOR HC5 250

HCS 250

load curves are given for service load (unfactored) and ultimate load (Iactored) and for the most favourable

(echnicaly, commercially, etc) reinforcement alternative. Self weight is alrealy Included in capacities.

Camber is shown for erection stage (prestressing and selfaveight are considered).

‘The two curves are showing estimated range of camber for highest and lowest reinforcement alternative.

LOAD BEARING CAPACITY TABLE OF HCS 250

20.00 I

15.00

10.00 PH >

soo ~

Allowable Superimposed Load (KPa)

[|

00

to 76 to 90 100 Me wo

Length of member (m)

== == Ulimate oad — sewcetoas

Comber Range of HCS 250

000

T sooo

F 000

j 0.00

5 000

4000

Ds

so 60 70 80 90 100 @ 120 130 140 1s0

Length of momber (m)

TYPICAL SECTION OF HCS 300 SLAB (all meosres ie mm)

SIDE EDGE OF

HGS 300 SLAB

10

TECHNICAL INFORMATION

DIMENSIONS OF HES 300 SLAB,

WIDTH 1196 mm,

HEIGHT 300 mm

-LENGTH ACCORDING TOLOAD CURVES.

(SEE NEXT PAGE)

‘SELF WEIGHT 3.3 kan?

‘SELF WEIGHT (JOINTED) 3:5 kn?

FIRE RATING - 60 MIN WITHIN LOADASPAN,

SHOWN ON NEXT PAGE

LOAD BEARING CAPACITIES AND EXPECTED.

‘CAMBER ARE SHOWN ON NEXT PAGE

30, Prefoned sac by HCS ord ia 30.

10 esd supp wid 98 om

|< Donel apr it 9m

10 ofr shell wits 150.0

SUPPORT ARRANGEMENT FOR HCS 300

HCS 300

Load curves are given for service load (unfactored) and ultimate load (factored) and for the most favourable

(Gechnically. commercially, etc) reinforcement alternative. Self weight is already included in capacities

Camber is shown for erection stage (prestressing and self-weight are considered)

‘The two curves are showing estimated range of camber for highest and lowest reinforcement alkemative.

LOAD BEARING CAPACITY TABLE OF HCS 300

2500

5

5

Allowable Superimpored Load (KPa)

8

5.00

0.00

70 80 0 100 Wo 10 10

Length of member (m)

=== = Ultimate toad Service toad

Cambor Range of HS 300

000

4000

2000

2000.

40000

Camber at Erection Sage tm)

8

oo 70 80 90 100 NO 120 130 We 150 160

Length of member (9)

ARIA

"

ae,

Ss,

300

50

8

4 Sl 95 sss sa SYS, | Stands

ma. 23 23 288 m Hales

1196

TYPICAL SECTION OF HCS 320 SLAB (aii meowres e mm)

2

sto

__Maddor crete oat

SIDE EDGE OF

HCS 320 SLAB

TECHNICAL INFORMATION

DIMENSIONS OF HS 320 SLAB

-WIDTH 1196 mm,

HEIGHT 320 tom

LENGTH ACCORDING TO LOAD CURVES

(SEE NEXT PAGE)

SELF WEIGHT 3.56 kV?

‘SELF WEIGHT (JOINTED) 3.80 kN/m?

FIRE RATING - 60 MIN WITHIN LOAD/SPAN,

SHOWN ON NEXT PAGE

LOAD BEARING CAPACITIES AND EXPECTED

CAMBER ARE SHOWN ON NEXT PAGE.

ne epg wih 99

Prolred shell wits 150mm

0 Prefered space by HCS ends in 30 mm.

Mm

SUPPORT ARRANGEMENT FOR HCS 320

2

load curves are given for service load (unfoctored] and ultimate load (factored) and for the most favourable

(Ceehnicaly, commercially, etc) reinforcement alternative. Self weight is already included in capacities.

‘Camber is shown for erection stage (prestressing and self weight are considered)

‘The two curves are showing estimated range of camber for highest an lowest reinforcement akemative,

LOAD BEARING CAPACITY TABLE OF HCS 320

Allowable Superimposed Load (KPa)

80 90 100 no 120 130 140

Length of member (m)

~ Ultimate Load Service Load

‘Camber Range of HCS 320

30 90 100 110 120 180 140 150 160 WO 180

Length of member (m)

13

LSS)

1" F [

a atc? 00 000. 000 ova

f 3 25,25 25 25 25 35 51, Sands

Lm 2 201 203 m Nes

96

TYPICAL SECTION OF HCS 380 SLAB (ol masse inmm)

21, TECHNICAL INFORMATION

DIMENSIONS OF HCS 380 SLAB

AVI TH 196 rm

HEIGHT 380 mm

dsr cent ot

Gout

SIDE EDGE OF

HCS 380 SLAB

1“

-LENGTH ACCORDING TO LOAD CURVES

(SEE NEXT PAGE)

‘SELF WEIGHT 4.20 KNW?

‘SELF WEIGHT (JOINTED) 4.55 kN/n?

FIRE RATING - 60 MIN WITHIN LOAD/SPAN,

SHOWN ON NEXT PAGE

LOAD BEARING CAPACITIES AND EXPECTED

‘CAMBER ARE SHOWN ON NEXT FAGE

230 Prefeed space by HS ends in 30:0,

Designed sppat widths 190mm

Pref hall wits 150mm

SUPPORT ARRANGEMENT FOR HCS 380

Load curves are given for service load (unfactored) and ultimate load (factored) and for the most favourable

(echnicaly, commercially, etc) reinforcement alternative. Self weight is already included n capacities

Camber is shown for erection stage (prestressing and se weight ate considered)

‘he two curves are showing estimated range of camber for highest and lowest reinforcement alkemeatve,

LOAD BEARING CAPACITY TABLE OF HCS 380

2500

2000

1500

000

Allowable Superimpoted Load (KPa)

500

0.00

90 100 0 120 120 40 150

Length of member (m)

Ultimate Load — senvice toad

Camber Range of HCS 380,

60.00.

Foo

From

§ 000

5 2000

40.00

OMe Too Ho 0 130 140 80 160 170 180 Wo

Length of member (m)

16

OPENINGSVAND}HOLES

‘Openings and holes can be made in slabs but has to be coordinated with locations and sizes of cores and strands.

‘Smaller vertical holes could preferrably he cut on site after castng/erection. Locations of holes should match with

‘cores and maximum sizes ae 2 follows:

HOLLOW CORE DEPTH (MAXIMUM HOLE SIZE

Hes 200 610

a CS 250 060

HS 300 185

HS 320, 0185,

HS 380 185

Bigger openings and cut-outs than above can also be done but has tobe arranged during fabrication and ned to

be coordinated with ARA during design stage

‘The standard width of the slabs is 1200 mm (including joints). This has to be taken into consideration

luring design of the building in order to minimize the numer of ct slabs

Wis possible to cut one full stab and rest it on adjacent slabs using a steel hanger (see detail below).

‘This will provide an opening 120mm wide and with flexible length.

‘The partitioning of a floor inio slabs is made by AlRashid-Abetong design department considering required

‘openings and standards for cuting of narrow slabs. tis therefore essential that the openings for air conditioning,

electromechanical provisions, etc are coordinated with AlRashid-Abetong in avery early stage of design.

T — i IT

1200 ——

(ee: iO Sooo O CC

16

Hollow core slabs are designed for quick and easy installation, However, make sure that the building site and

roads provide free access for the mobile crane and the delivery truck to the place of erection. Also ensure that

‘rection can be completed without interupption.

LIFTING

Lifting can be done by iting clamps or by hooks cast into the slabs inthe factory.

When lifting with clamps, lifting beam or speader beam must be used to ensure only vertical lifting in clamps

(see figure below)

Lifting clamps shall be placed close to the ends of the stab according to fig below.

Only one slab to be lifted simultaneously!

Msi stone when ogi 0.50

Posie conilerer to ene of damp whe tings 1m

INSTALLATION

Hollow core stabs are installed either on beams or on walls. The supporting beam or wall should be straight,

smooth and even in order to install the slab directly concrete without rubber strip or other support material

The support width should be minimum as per reauirement given foreach different sizeof slab

(see specifications inthis folder) It needs also toe considered that the fabrication tolerance for length of sb

is 4/-0.5inch (4/-13mm),

1 the support length ts less than given In this folder AlRashid-Abetong design department should be contacted

for advice,

ARI

7

‘The standard hollow core slab element is fabricated for 2 module width of 1200 mm. The actual width

‘of the element is 196 mm leaving a clearance of 4mm in all joints (see fig below). For correct instalation, the

1200 mm module must be masked on the supporting beam or wall before installation, This is made to ensure

acontoled and uniform joint width between all elements,

ova yo

O,

4 in borane

Joints between two cuts slabs should be minimum 30 mm in order to ast the joint propery.

AA joint between one ful slab and one cut siab should be minimum 20 mm (see figure below),

Jatzed at n

ith 9.5000

GROUTING OF JOINTS

‘Aiter installing the hollow core slabs al joints must be filled with concrete grout and reinforcement as per

structural design reauirements. It is recommended to do the grouting immediately ater installing one floor

(before installing next oor),

For grouting of joints, use a concrete of minimum G20 (cube strength 20MPa),

‘Aggregate should have maximum stone size of 10mm.

When grouting cut slabs there isa need for form work as shown above,

TOPPING (SCREED)

‘Topping (sereed} could be for levelling purpose only or for structural purpose as well. The topping is added alter

casting the joins in a separate operation.

ARI

18

EMEC eC ILIAC

Bolted connections in Hollow core slabs could preferrably be made with anchor type SPIT PRIMA or cual,

‘The recommended maximum load on each fixing is F=1.5 kN (ISO kg) given from pull out tests

(This was tested on a 200 mm slab with MS SPIT PRIMA boll and i is applicable forall thicknesses of slab.)

‘The bolt should be placed in the core to avoid clashing with strands (see sketch below).

AL BABTAIN SHOPPING CENTER, RIVADH DELMON SHOWROOM, AL KHOBAR

‘AL MARAI FACTORY, AL KHAR}

AL FAROUK MOSQUE, JEDDAH SARI COMMERCIAL CENTER, JEDDAH

DEWAN AL JAZEERA, AL KHOBAR CRYSTAL RESORT, JEDDAH

EXIT 15 .

BAA GI Bayles! 4) IK Oa

EAST RING ROAD ‘ALKHARJ HIGHWAY

a S>_ SIF

2 IND IND, CY “cas

3 Main EASTERN Gare | | staTiOn

z |

a ruRiruRe

9 FACTORY q

gu —

- WATER TANK

i

| =e

FE

a

‘Aumuoawes racronr o| >

‘mie MARKET er AL-SHARG FACTORY

eSTAURAN 6 FOR PLASTIC

savorcename | |spaH srepco| | 8

3

z

:

2

i

s

rn ee |)|#

Seating z

‘SEWAGE CHANNEL

AAR _ ele diiGnbe

'ALKHARY OLD ROAD

Swarr SOS TG

EXIT ARAMCO : meas

———

SECOND INDUSTRIAL CITY 3 ‘TO: RIYADH

nut oa nN psSITO gst ali UIT Ah MTT a Est tho eb

1.0.x O58. Roch We To! 49822 Fa: 498200 fel Tet 020 Fax: GEIS AlKNoar Te 896924 fax 844

al: Riidh:sareh@alasbdatetng con, Aleta aabho@alnshteangcon_ fea

apjedalashattongcom Website: wor atasisbetong com

La

re

~

=

)

=

mo)

a

hkl

a)

=

TT

3

ss

<7)

3

ce

—

<=

aV1S JAODMOTIOH

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Culvert Profile (Flowable Fill Backfill) PDFDokument1 SeiteCulvert Profile (Flowable Fill Backfill) PDFMagdy BakryNoch keine Bewertungen

- Sample Earthwork Take Off 1Dokument7 SeitenSample Earthwork Take Off 1Magdy BakryNoch keine Bewertungen

- SM CG BackfillDokument3 SeitenSM CG BackfillMagdy BakryNoch keine Bewertungen

- El-Samny M. Kassem and Abd El-Samee W. Nashaat Rehabilitation of Existing Foundation Building To ResistDokument12 SeitenEl-Samny M. Kassem and Abd El-Samee W. Nashaat Rehabilitation of Existing Foundation Building To ResistMagdy BakryNoch keine Bewertungen

- Print TV - 21 - 2014!2!435 - 445 Assessment and Repair of The Bearing Structure of The Gradiska - NorestrictionDokument11 SeitenPrint TV - 21 - 2014!2!435 - 445 Assessment and Repair of The Bearing Structure of The Gradiska - NorestrictionMagdy Bakry100% (1)

- Steel-Tables 2 PDFDokument110 SeitenSteel-Tables 2 PDFMahmoud AllamNoch keine Bewertungen

- Design Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesDokument9 SeitenDesign Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesMagdy Bakry100% (1)

- Swede BeamDokument12 SeitenSwede BeamMagdy BakryNoch keine Bewertungen

- Steel-Tables 2 PDFDokument110 SeitenSteel-Tables 2 PDFMahmoud AllamNoch keine Bewertungen

- Form SlabDokument11 SeitenForm SlabSeifeldin Ali MarzoukNoch keine Bewertungen

- HC All PCI Recommended DetailsDokument32 SeitenHC All PCI Recommended DetailsMagdy BakryNoch keine Bewertungen

- Nalytical Modelling of Groundwater Wells and Well Systems How To Get It RightDokument40 SeitenNalytical Modelling of Groundwater Wells and Well Systems How To Get It RightMagdy BakryNoch keine Bewertungen

- How To Design A Safe and Economical PC & RC Isolated FootingsDokument4 SeitenHow To Design A Safe and Economical PC & RC Isolated FootingsMagdy BakryNoch keine Bewertungen

- Torsion Analysis of Nonuniform Shearwall Cores by The Stiffness Matrix MethodDokument23 SeitenTorsion Analysis of Nonuniform Shearwall Cores by The Stiffness Matrix MethodMagdy BakryNoch keine Bewertungen

- Torsion Analysis of Nonuniform Shearwall Cores by The Transfer Matrix Method PDFDokument23 SeitenTorsion Analysis of Nonuniform Shearwall Cores by The Transfer Matrix Method PDFMagdy BakryNoch keine Bewertungen

- Required RC Jacket Thickness and Reinforcement Ratio For Repairing RC Tied Rectangular and Circular Concrete ColumnsDokument17 SeitenRequired RC Jacket Thickness and Reinforcement Ratio For Repairing RC Tied Rectangular and Circular Concrete ColumnsMagdy Bakry100% (1)