Beruflich Dokumente

Kultur Dokumente

Stud Out 150

Hochgeladen von

Nguyen Thanh NguyenOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stud Out 150

Hochgeladen von

Nguyen Thanh NguyenCopyright:

Verfügbare Formate

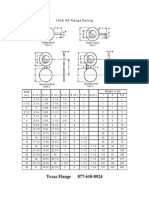

CLASS 150 STUDDING OUTLET

FLAT BOTTOM

Size

Outside

Dia.

Thick.

SHELL/HEAD MOUNT

RF

O.D.

Stud

Holes

1/2

3.50

1.25

1.38

3/4

3.88

1.25

1.69

4.25

1.25

1 1/4

4.62

5.00

Hole

Size

Hole

Depth

Stud

Circle

TANGENTIAL MOUNT

Tap

Size

T.P.I.

Tap

Depth

27/64

0.88

2.38

1/2

13

0.56

2.38

27/64

0.88

2.75

1/2

13

0.56

2.50

2.00

27/64

0.88

3.12

1/2

13

0.56

2.50

1.25

2.50

27/64

0.88

3.50

1/2

13

0.56

2.50

1.25

2.88

0.88

3.88

1/2

13

0.56

2.63

6.00

1.50

3.62

27/64

17/32

1.12

4.75

11

0.75

3.12

2 1/2

7.00

1.50

4.12

17/32

1.12

5.50

5/8

5/8

11

0.75

3.25

7.50

1.50

5.00

17/32

1.12

6.00

5/8

11

0.75

3.38

7.00

5/8

11

0.75

3.38

11

0.75

3.38

3 1/2

8.50

1.50

5.50

17/32

1.12

Stud

Length

9.00

1.50

6.19

17/32

1.12

7.50

5/8

10.00

1.75

7.31

8.50

3/4

10

0.88

3.75

11.00

1.75

8.50

21/32

21/32

1.31

1.31

9.50

3/4

10

0.88

3.88

13.50

1.75

10.62

21/32

1.31

11.75

3/4

10

0.88

4.00

10

16.00

1.81

12.75

12

49/64

1.44

14.25

7/8

1.00

4.38

12

19.00

1.81

15.00

12

49/64

1.44

17.00

7/8

1.00

4.50

14

21.00

2.00

16.25

12

7/8

1.56

18.75

1.12

5.00

16

23.50

2.00

18.50

16

7/8

1.56

21.25

1.12

5.00

18

25.00

2.25

21.00

16

1.81

22.75

1 1/8

1.25

5.50

20

27.50

2.25

23.00

20

1.81

25.00

1 1/8

1.25

5.62

24

32.00

2.50

27.25

20

11/8

2.12

29.50

1 1/4

1.44

6.25

Material:

Studding Outlets are most commonly provided in SA-105. They can also be made from a full

range of stainless and alloy materials.

Thickness:

The standard thickness shown in charts for all studding outlets is the minimum required per

ASME Section VIII Division I Paragraph UG-43(d) for thread engagement and an ID. mount. It is important to

note that each individual application should be analyzed for proper thickness. See general notes for more details.

Facing:

The studding outlet minimum thickness T includes proper raised face per ANSI B16.5. Outlets

can be supplied with any special facing as needed upon request.

Drilling and Tapping: Studding outlets are furnished to ANSI B16.5 specifications unless otherwise specified.

Thread depth is in accordance with ASME Section VIII Division I Para. UG-43(g) for a design temperature not to

exceed 650F, a base metal stress of 17,500 psi, and a stud stress of 25,000 psi. All other materials exceeding

these stresses should be checked for UG-43 compliance.

Bore:

Bore sizes shown above are standard, other sizes can be furnished upon request.

Curving:

All connections can be furnished contoured to fit any shell, head or cone at an additional cost.

TEXAS FLANGE 877-610-8924

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Welding Neck Orifice Class 2500Dokument1 SeiteWelding Neck Orifice Class 2500Nguyen Thanh NguyenNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Flanges Pn40 Din En1092 1Dokument2 SeitenFlanges Pn40 Din En1092 1Nguyen Thanh NguyenNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Jpep 0 1360 T 4141 PDFDokument44 SeitenJpep 0 1360 T 4141 PDFNguyen Thanh NguyenNoch keine Bewertungen

- Welding Neck Orifice Class 400: In. Mm. In. MMDokument1 SeiteWelding Neck Orifice Class 400: In. Mm. In. MMNguyen Thanh NguyenNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Welding Neck Orifice Class 600Dokument1 SeiteWelding Neck Orifice Class 600Nguyen Thanh NguyenNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Welding Neck Orifice Class 1500Dokument1 SeiteWelding Neck Orifice Class 1500Nguyen Thanh NguyenNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Welding Neck Orifice Class 900: In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. MMDokument1 SeiteWelding Neck Orifice Class 900: In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. MMNguyen Thanh NguyenNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- 300 Spec BlindDokument1 Seite300 Spec BlindNguyen Thanh NguyenNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Welding Neck Orifice Class 300Dokument1 SeiteWelding Neck Orifice Class 300Nguyen Thanh NguyenNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- 900 Spect BlindDokument1 Seite900 Spect BlindNguyen Thanh NguyenNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- 150 Spect BlindDokument1 Seite150 Spect BlindNguyen Thanh NguyenNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

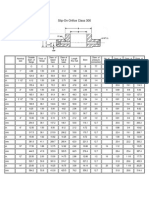

- Slip-On Orifice Class 300: In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. MMDokument2 SeitenSlip-On Orifice Class 300: In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. Mm. In. MMNguyen Thanh NguyenNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Threaded Orifice Class 300Dokument1 SeiteThreaded Orifice Class 300Nguyen Thanh NguyenNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Class 2500 Studding Outlet: TEXAS FLANGE 877-610-8924Dokument1 SeiteClass 2500 Studding Outlet: TEXAS FLANGE 877-610-8924Nguyen Thanh NguyenNoch keine Bewertungen

- Texas Flange 877-610-8924: Weld Neck Flange BoresDokument1 SeiteTexas Flange 877-610-8924: Weld Neck Flange BoresNguyen Thanh NguyenNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Class 300 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountDokument1 SeiteClass 300 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountNguyen Thanh NguyenNoch keine Bewertungen

- Class 600 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountDokument1 SeiteClass 600 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountNguyen Thanh NguyenNoch keine Bewertungen

- Class 900 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountDokument1 SeiteClass 900 Studding Outlet: Flat Bottom Shell/Head Mount Tangential MountNguyen Thanh NguyenNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Cadpipe 3D Design: TutorialDokument32 SeitenCadpipe 3D Design: TutorialNguyen Thanh NguyenNoch keine Bewertungen

- U-Bolts Supports PDFDokument4 SeitenU-Bolts Supports PDFNguyen Thanh NguyenNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Screwed Fiting BSP - 1 PDFDokument12 SeitenScrewed Fiting BSP - 1 PDFNguyen Thanh NguyenNoch keine Bewertungen

- Class 150 - Standard Connection SpecificationsDokument7 SeitenClass 150 - Standard Connection SpecificationsNguyen Thanh NguyenNoch keine Bewertungen

- QC - 16 Guided Bend Test.Dokument3 SeitenQC - 16 Guided Bend Test.mahendra100% (1)

- RDS - GMS Qoutation ProposalDokument2 SeitenRDS - GMS Qoutation ProposalLemuel Kim Cera TabinasNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Azolla TenderDokument4 SeitenAzolla TenderprashantkothariNoch keine Bewertungen

- Kohler Price 2022Dokument132 SeitenKohler Price 2022rajNoch keine Bewertungen

- H4103BDokument1 SeiteH4103BMichael IpNoch keine Bewertungen

- Ultimate Strength of High-Strength Composite Columns After Sustained Service LoadingDokument9 SeitenUltimate Strength of High-Strength Composite Columns After Sustained Service LoadingArielNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Star S07FS32DR Water Softener Owners GuideDokument38 SeitenStar S07FS32DR Water Softener Owners GuideBillNoch keine Bewertungen

- 308H and 16-8-2 Technical ProfileDokument23 Seiten308H and 16-8-2 Technical ProfilePS Pinturas pinturasNoch keine Bewertungen

- Martensitic Stainless Steel EN 1.4021-QT 700Dokument2 SeitenMartensitic Stainless Steel EN 1.4021-QT 700LebasNoch keine Bewertungen

- Plumbing Specifications: Catch Basin PlanDokument1 SeitePlumbing Specifications: Catch Basin PlanMark Allan RojoNoch keine Bewertungen

- 0511 Grob PDFDokument7 Seiten0511 Grob PDFJ VeluNoch keine Bewertungen

- Ikea Kitchens Jan-July 2007Dokument39 SeitenIkea Kitchens Jan-July 2007Luis VillegasNoch keine Bewertungen

- A545-6-44-0016 - Rev-3 NDT NEW SPECDokument20 SeitenA545-6-44-0016 - Rev-3 NDT NEW SPECSaheb YadavNoch keine Bewertungen

- Handbook of Materials For ASMDokument3 SeitenHandbook of Materials For ASMLilian RoseNoch keine Bewertungen

- Heat Treatment - Manufacturing Engineering Questions & Answers - SanfoundryDokument13 SeitenHeat Treatment - Manufacturing Engineering Questions & Answers - SanfoundryBrown Mesh0% (1)

- 5 - Water-Tight Reinforced Concrete StructuresDokument19 Seiten5 - Water-Tight Reinforced Concrete StructuresalbertoxinaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Chain Link FenceDokument8 SeitenChain Link FenceKABIR CHOPRA100% (1)

- 1591 EC2213 SignedDokument5 Seiten1591 EC2213 SignedDeepak HoleNoch keine Bewertungen

- LevelQuik RSDokument3 SeitenLevelQuik RSFlaTravelNoch keine Bewertungen

- Corrugated Box: Prepared by Sneha A. Chavan Department of Pharmaceutics M Pharm !ST Year II SemesterDokument29 SeitenCorrugated Box: Prepared by Sneha A. Chavan Department of Pharmaceutics M Pharm !ST Year II SemesterPreetha PalaniswamyNoch keine Bewertungen

- ASTM 380-99 - Cleaning, Descaling, and Passivation of Stainless SteelDokument12 SeitenASTM 380-99 - Cleaning, Descaling, and Passivation of Stainless SteelআসিফহাসানখানNoch keine Bewertungen

- Curing Time and Bead Sizes: Note On Bead Size Note On Curing InformationDokument1 SeiteCuring Time and Bead Sizes: Note On Bead Size Note On Curing InformationpicottNoch keine Bewertungen

- Water Supply Fixture UnitsDokument2 SeitenWater Supply Fixture UnitsLeila Joy Duco100% (1)

- Effect of Cooling Rate and Finish Rolling Temperature On Structure and Strength of API 5LX70 Linepipe Steel PlateDokument11 SeitenEffect of Cooling Rate and Finish Rolling Temperature On Structure and Strength of API 5LX70 Linepipe Steel Platek4dr0nNoch keine Bewertungen

- TANDEMLOC D-RingDokument4 SeitenTANDEMLOC D-RingPuvas NandakwangNoch keine Bewertungen

- Section 1: Conventional Blast Pots and SparesDokument10 SeitenSection 1: Conventional Blast Pots and SparesIgor NhamanoNoch keine Bewertungen

- Data Sheets Kga Plus Knife Gate Valves Clarkson en en 5196860Dokument8 SeitenData Sheets Kga Plus Knife Gate Valves Clarkson en en 5196860Cristian Mena HidalgoNoch keine Bewertungen

- D3 5-93PVDokument8 SeitenD3 5-93PVBirdyTheoNoch keine Bewertungen

- This Type of Water Closet Is Prohibited by Some Health CodesDokument1 SeiteThis Type of Water Closet Is Prohibited by Some Health CodesAna Renee SteeleNoch keine Bewertungen

- Plastic Glazing SpecsDokument9 SeitenPlastic Glazing SpecsJacob PriyadharshanNoch keine Bewertungen