Beruflich Dokumente

Kultur Dokumente

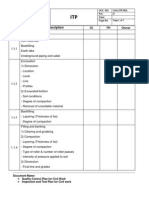

045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDF

Hochgeladen von

Köksal PatanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

045-ITP For MASONRY & PLASTERING WORKS (Buildings) PDF

Hochgeladen von

Köksal PatanCopyright:

Verfügbare Formate

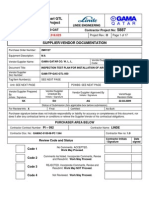

Pearl GTL

Project

Shell Project No: HP-3000-QAT

Project Document Number: T.4.234.571

Purchase Order Number:

2MH127

Tag/Item Number(s):

N/A

Unit(s):

ASU

PCWBS:

LINDE ENGINEERING

Contractor Project No:

Project Rev.: O

Page 2 of 8

5887

QATAR SHELL GTL PROJECT (PEARL)

C2 AIR SEPARATION UNITS CONSTRUCTION

11.01.09

Company Comments Incorporated

SB

EO

AG

CCI

05.01.09

Company Comments Incorporated

SB

EO

AG

CCI

04.01.09

Company Comments Incorporated

SB

EO

AG

CCI

31.12.08

Issued for Company Comments

SB

EO

AG

ICC

18.12.08

Issued for Review

SB

EO

AG

IFR

25.11.08

Issued for Internal Review

SB

EO

AG

IIR

Date

Description

GAMA

Rev.

No.

Project

Rev

No.

Prepared Checked Approved

By

By

By

ORIGINATOR

Status

Document Title:

LINDEGINEERING AG

ITP FOR MASONRY & PLASTERING WORKS

(BUILDINGS)

Document No.

Contractor

Gama Qatar Co. W. L. L.

LOC470

GAM

ITP

QAC

GTL

045

Org.

Code

Doc.

Type

Disc.

Code

Geogr.

Area

Seq.

No

Rev.

No

Project Document Number: T.4.234.571

Vendor Code

Rev No: O

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-045

C2 ASU Construction Works

ITP FOR MASONRY & PLASTERING WORKS

( BUILDINGS )

S. GAMA QATAR

X. CONTRACTOR QC

C. COMPANY

Date: 11.01.2009 Rev. F

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

1.0

1.1

Activity

Test Frequency

METHOD STATEMENTS/PROCEDURES

Method Statements /

Prior to start of

Procedures

activity

Preparation

2.0

MATERIALS CERTIFICATES

2.1

Verification of

construction materials.

2.2

3.0

Storage and handling

of construction

materials.

INSPECTIONS

3.1

Inspection for surface

preparation ( Chipping

& cleaning the RCC

surface)

3.2

Inspection for DPC

( Only for external

masonry walls)

T.4.234.571 Rev. O

100%

100%

100%

100%

Reference Document

Acceptance Criteria

Responsible Party

Verifying Documents

Subcontractor Method

Statements / Procedure

T.4.234.088 &

Project

Requirements

QA/QC

T.4.234.088 &

T.4.132.873

R R

QC Civil

Inspector

Manufactures

Technical Data

Sheets & Certificates

R R

Site Engineer

Visual confirmation

S S

Site Engineer &

QC Civil

Inspector

GAM-QCR-QACGTL- 168

S S

Site Engineer &

QC Civil

Inspector

GAM-QCR-QACGTL- 160

S S

T.4.234.088 , DEP

34.17.00.32-Gen & DEP

34.17.10.30-Gen

T.4.234.088 , DEP

34.17.00.32-Gen & DEP

34.17.10.30-Gen

T.4.234.088 ,

T.4.132.873 ,

DEP 34.17.00.32-Gen &

DEP 34.17.10.30-Gen

T.4.234.088 &

T.4.132.873

Manufacturers

Technical datas

Manufacturers

recommendation.

DEP 34.17.00.32Gen & DEP

34.17.10.30

DEP 34.17.00.32Gen & DEP

34.17.10.30-Gen

& Manufacturers

data sheet

Page 4

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-045

C2 ASU Construction Works

ITP FOR MASONRY & PLASTERING WORKS

( BUILDINGS )

S. GAMA QATAR

X. CONTRACTOR QC

C. COMPANY

Date: 11.01.2009 Rev. F

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

3.3

Activity

In process Inspection

for masonry work ( for

level, staggered joints ,

reinforcement , mixing

mortar etc )

a) Up to sill level

Test Frequency

100%

Reference Document

Acceptance Criteria

Responsible Party

Verifying Documents

T.4.234.088 &

T.4.132.873 & RFC

drawings

T.4.234.555 ,

DEP 34.17.00.32Gen & DEP

34.17.10.30-Gen

Site Engineer &

QC Civil

Inspector

GAM-QCR-QACGTL-160

T.4.234.088 &

T.4.132.873 & RFC

drawings

T.4.234.555 ,

DEP 34.17.00.32Gen & DEP

34.17.10.30-Gen

Site Engineer &

QC Civil

Inspector

T.4.234.088 &

T.4.132.873 & RFC

drawings

T.4.234.555 ,

DEP 34.17.00.32Gen & DEP

34.17.10.30-Gen

T.4.234.088 &

T.4.132.873

T.4.234.555 ,

DEP 34.17.00.32Gen & DEP

34.17.10.30-Gen

W S

GAM-QCR-QACGTL-160

Electrical

Engineer & QC

Civil Inspector

GAM-QCR-QACGTL-160

QC Civil

Inspector

GAM-QCR-QACGTL-160

H S

b) Up to lintel level

c) Up to roof level

3.4

Inspection for fixing

lintels and openings

for doors & windows

100%

3.5

Inspection for

embedded items

100%

3.6

Curing period finished

& released for next

activity (Masonry to

plastering)

T.4.234.571 Rev. O

100%

Page 5

QSGTL PEARL PROJECT

Document No.: GAM-ITP-QAC-GTL-045

C2 ASU Construction Works

ITP FOR MASONRY & PLASTERING WORKS

( BUILDINGS )

S. GAMA QATAR

X. CONTRACTOR QC

C. COMPANY

Date: 11.01.2009 Rev. F

A. THIRD PARTY (TPI)

I: INSPECTION / TEST

R: DOCUMENT ISSUED/REPORT REVIEW

S: SURVEILANCE

H: HOLD POINT (Notification Required and Presence Mandatory). W: WITNESS (Notification Required but Presence not Mandatory)

Item

3.7

3.8

3.9

3.10

Activity

Test Frequency

In process Inspection

for plastering or

rendering work

( for level, undulations ,

etc )

100%

Final checking

inspection.

Curing period finished

& released for next

activity ( Plastering to

Painting)

Disposal of wastes

T.4.234.571 Rev. O

Acceptance Criteria

Responsible Party

T.4.234.088 &

T.4.132.873

Visual confirmation

Site Engineer & QC

Civil Inspector

GAM-QCR-QACGTL-160

100%

Mechanical Completion

Documentation

Visual confirmation

Site Engineer & QC

Civil Inspector

Check Records &

Punch List

100%

----

Visual confirmation

Site Engineer & QC

Civil Inspector

-----

T.13.377.450Construction waste

Management Procedure

Check & ensure

in Hazard area

,flammable area

any paint material

100%

Reference Document

Site Engineer

Verifying Documents

W S

S S

Visual

Page 6

C2 ASU PEARL GTL PROJECT

RAS LAFFAN INDUSTRIAL CITY

Masonry & Plastering work

Check List

Subcontract Ref.:

Report No.:

Item Description:

Date:

Item Location/ Area:

ITP No.:

Subsystem:

Test Code No.:

GAM-ITP-QAC-GTL -

Ref. DWG / Docs:

Tag No and Tag Description :

Used Measurements & test equipment ref(if any) :

Check the following:

Item

No.

Masonry Work :

Description

QC Inspector

Initial

Date

1.

Surface chipping & Cleaning.

2.

Laying of Damp Proof Course (Exterior Wall Only)

3.

Levels, Staggered joints, reinforcement ect....

4.

Construction Stage (Sill or Lintel or Roof level).

5.

Lintels & wall openings.

6.

Installation of embedded items.

7.

Curing period finished.

8.

Released for plastering work.

Plastering Work:

1.

Marking levels (Button marks fixing)

2.

RCC faces hogging completed

3.

Plastering or rendering work (in process)

4.

Checking for finishing surface (Undulations, etc...)

5.

Repair works ( If any)

6.

Curing period finished

7.

Released for next activity ( Plastering to Painting)

REMARKS:

ORGANIZATIONS

Accepted By

THIRD PARTY REP.

GAMA REP.

LINDE REP.

QSGTL OR its PMC REP.

GAM-QCR-QAC-GTL-160

NAME

SIGNATURE

DATE

QSGTL-PEARL GTL PROJECT

C2-ASU-Construction Project

Inspection Form for Surface

Preparation(Buildings)

GAM-QCR-QAC-GTL-166

Date :

GAM-ITP-QAC-GTL-

Location Bldg/Area:

Drawing No:

Tag No and Tag description :

Item

Details of Activity

Remarks

Sign off will Confirm Released to Next activity

GAMA QATAR

Name

Signature

Date

GAM-QCR-QAC-GTL- 166

LINDE

QSGTL or its PMC

Das könnte Ihnen auch gefallen

- 016-CIVIL - MS Anchor Bolt Installation PDFDokument14 Seiten016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- 016-CIVIL - MS Anchor Bolt Installation PDFDokument14 Seiten016-CIVIL - MS Anchor Bolt Installation PDFKöksal Patan71% (7)

- RLC-AH-QP-91-3001 Inspection Test Plan For Plumbing Works-1Dokument6 SeitenRLC-AH-QP-91-3001 Inspection Test Plan For Plumbing Works-1nighttrasherNoch keine Bewertungen

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDokument16 Seiten012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFDokument16 Seiten012-MS For Wall Cladding, Roof Cladding & Life Line Installation PDFKöksal Patan91% (11)

- 9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1Dokument34 Seiten9686-6130-ITP - 000-1002 - Inspection and Test Plan For General Civil Works Rev A1anil pk100% (8)

- ITP For Civil WorksDokument15 SeitenITP For Civil WorksNoor A Qasim100% (8)

- Inspection and Test Plan: Cement Stucco (Exterior Plastering)Dokument3 SeitenInspection and Test Plan: Cement Stucco (Exterior Plastering)Alvene TagocNoch keine Bewertungen

- 043-ITP FOR Water Proofing (Buildings) PDFDokument13 Seiten043-ITP FOR Water Proofing (Buildings) PDFKöksal Patan100% (3)

- 041 - ITP For Painting (Building) PDFDokument12 Seiten041 - ITP For Painting (Building) PDFKöksal Patan78% (9)

- 015-Method Statement For Painting Works (Building) PDFDokument21 Seiten015-Method Statement For Painting Works (Building) PDFKöksal Patan86% (21)

- 035-Itp For Pumps PDFDokument30 Seiten035-Itp For Pumps PDFKöksal Patan100% (3)

- 015-MS For Night Works PDFDokument16 Seiten015-MS For Night Works PDFKöksal Patan80% (5)

- ITP-FW For Civil & Building WorksDokument17 SeitenITP-FW For Civil & Building WorksRajnath Rajbhar Pancham86% (7)

- 014-MS For Bolt Tightening (Piping& Equipments) PDFDokument23 Seiten014-MS For Bolt Tightening (Piping& Equipments) PDFKöksal PatanNoch keine Bewertungen

- Method Statement For Concrete Works: The Custodian of Two Holy Mosques King Abdullah Ibn Abdul-Aziz Project KAP5-Group 4Dokument41 SeitenMethod Statement For Concrete Works: The Custodian of Two Holy Mosques King Abdullah Ibn Abdul-Aziz Project KAP5-Group 4Domie Neil Bucag SalasNoch keine Bewertungen

- 024-Itp For Grouting Works PDFDokument8 Seiten024-Itp For Grouting Works PDFKöksal Patan100% (1)

- 010-MS For Welding and Hot Works For General Activities at TSF Area PDFDokument17 Seiten010-MS For Welding and Hot Works For General Activities at TSF Area PDFKöksal PatanNoch keine Bewertungen

- Concrete Method StatementDokument14 SeitenConcrete Method StatementWufei Chang95% (21)

- 4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1Dokument7 Seiten4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1ABHISHEKNoch keine Bewertungen

- QA-QC PlanDokument18 SeitenQA-QC PlanSen IMO67% (3)

- 025-ITP For Sewer & Drainage PDFDokument6 Seiten025-ITP For Sewer & Drainage PDFKöksal PatanNoch keine Bewertungen

- 014-MS For General Scaffolding PDFDokument33 Seiten014-MS For General Scaffolding PDFKöksal Patan100% (2)

- ITP For RC RC Slab, Beams WorkDokument3 SeitenITP For RC RC Slab, Beams WorkMohammed Ghareib NasrNoch keine Bewertungen

- 013-MS For Mass Concrete Works PDFDokument26 Seiten013-MS For Mass Concrete Works PDFKöksal Patan100% (1)

- FINAL-ITP Earthwork-Rev. 1 13-09-2014Dokument10 SeitenFINAL-ITP Earthwork-Rev. 1 13-09-2014Mohammed Mujahid100% (1)

- ITP CIVIL WORK-Rev-1Dokument6 SeitenITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- 030-Itp For Ug GRP Piping PDFDokument22 Seiten030-Itp For Ug GRP Piping PDFKöksal Patan89% (9)

- ITP-CONCRETE Blinding WorkDokument2 SeitenITP-CONCRETE Blinding WorkYash Sharma100% (1)

- Labour (Mazdoor) Required For Different Works Sr. No. Item Beldars Mazdoors Bhisti MasonDokument4 SeitenLabour (Mazdoor) Required For Different Works Sr. No. Item Beldars Mazdoors Bhisti MasonNikhil80% (5)

- ItpDokument7 SeitenItpJose Sherin100% (1)

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDokument25 Seiten007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNoch keine Bewertungen

- 021-Itp For Site Preparation and Earth Works PDFDokument6 Seiten021-Itp For Site Preparation and Earth Works PDFKöksal Patan100% (2)

- Excel Construction Project Management Templates Bid Tabulation TemplateDokument3 SeitenExcel Construction Project Management Templates Bid Tabulation TemplateJay HernandezNoch keine Bewertungen

- 009-Civil-Ms Concrete Works PDFDokument27 Seiten009-Civil-Ms Concrete Works PDFKöksal PatanNoch keine Bewertungen

- 011-Method Statement For Repair of Concrete Works PDFDokument25 Seiten011-Method Statement For Repair of Concrete Works PDFKöksal Patan91% (33)

- Inspection & Test Plan Project Name: Coring and Concrete Cutting of R/C WallsDokument1 SeiteInspection & Test Plan Project Name: Coring and Concrete Cutting of R/C WallsA S80% (5)

- 050-Itp For Installation of Air Intake Filter PDFDokument17 Seiten050-Itp For Installation of Air Intake Filter PDFKöksal PatanNoch keine Bewertungen

- 050-Itp For Installation of Air Intake Filter PDFDokument17 Seiten050-Itp For Installation of Air Intake Filter PDFKöksal PatanNoch keine Bewertungen

- 028-Itp For Building Works PDFDokument10 Seiten028-Itp For Building Works PDFKöksal Patan100% (3)

- Itp - Rebar & ConcreteDokument4 SeitenItp - Rebar & ConcreteMohammad Arif RasheedNoch keine Bewertungen

- ITP For CivilDokument85 SeitenITP For CivilBilibili weekly TOP 10 videos100% (6)

- 048-Itp For Installation of Hvac Unit PDFDokument8 Seiten048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 048-Itp For Installation of Hvac Unit PDFDokument8 Seiten048-Itp For Installation of Hvac Unit PDFKöksal Patan100% (4)

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDokument28 Seiten047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNoch keine Bewertungen

- 047-Itp For Oxygen Lines Fabrication and Installation PDFDokument28 Seiten047-Itp For Oxygen Lines Fabrication and Installation PDFKöksal PatanNoch keine Bewertungen

- ITP Excavation & Backfilling For MCUPDokument9 SeitenITP Excavation & Backfilling For MCUPShewale PravinNoch keine Bewertungen

- Civil ItpDokument60 SeitenCivil ItpBiswas100% (1)

- 017-CIVIL-MS For Installation of Fence & Gate PDFDokument18 Seiten017-CIVIL-MS For Installation of Fence & Gate PDFKöksal Patan100% (6)

- 008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFDokument23 Seiten008-MS For Prefabrication of CS, TT & CN Pipe Spools PDFKöksal PatanNoch keine Bewertungen

- 029-Itp Paving and Roads PDFDokument7 Seiten029-Itp Paving and Roads PDFKöksal Patan100% (3)

- 027-ITP For Pre - Cast Concrete PDFDokument11 Seiten027-ITP For Pre - Cast Concrete PDFKöksal Patan75% (4)

- 026-Itp For Structural Steel PDFDokument18 Seiten026-Itp For Structural Steel PDFKöksal Patan100% (11)

- 032-Itp For Painting and Coating PDFDokument19 Seiten032-Itp For Painting and Coating PDFKöksal Patan80% (20)

- Training Coordination Procedure Rev.A - PMC CommentsDokument32 SeitenTraining Coordination Procedure Rev.A - PMC CommentsYusufNoch keine Bewertungen

- 040-ITP For Repair of Steam Distribution Manifold PDFDokument11 Seiten040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanNoch keine Bewertungen

- 040-ITP For Repair of Steam Distribution Manifold PDFDokument11 Seiten040-ITP For Repair of Steam Distribution Manifold PDFKöksal PatanNoch keine Bewertungen

- Yra - 3rd Class - Building - Archi - ArchitectureDokument169 SeitenYra - 3rd Class - Building - Archi - ArchitectureAshru SigdelNoch keine Bewertungen

- 044-ITP For Installation of Gypsum Board (Buildings) PDFDokument10 Seiten044-ITP For Installation of Gypsum Board (Buildings) PDFKöksal Patan100% (3)

- ITP For Concrete Paving WorkDokument15 SeitenITP For Concrete Paving WorkShewale Pravin100% (1)

- Method Statement For ConcretingDokument23 SeitenMethod Statement For ConcretingVinod MasaniNoch keine Bewertungen

- ITP - Concrete Works PDFDokument2 SeitenITP - Concrete Works PDFntah8483% (35)

- ITP-01 - BackfillingDokument1 SeiteITP-01 - BackfillingMaddala Srinivasa Rao50% (2)

- 049-Itp For Lighting and Small Power (Building) PDFDokument15 Seiten049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- 009-Method Statement - Main Erection Sequence For Acc PDFDokument68 Seiten009-Method Statement - Main Erection Sequence For Acc PDFKöksal Patan100% (6)

- Inspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0Dokument3 SeitenInspection and Test Plan For HVAC Cladding Works: 0-WD860-CA250-00312 0ResearcherNoch keine Bewertungen

- 023-Itp Concrete Works PDFDokument32 Seiten023-Itp Concrete Works PDFKöksal Patan100% (5)

- Saudi Oger Ltd. (Project Name) : PlasteringDokument1 SeiteSaudi Oger Ltd. (Project Name) : PlasteringAnthony AngelesNoch keine Bewertungen

- ITP - Blockwork R0 - HKHDokument2 SeitenITP - Blockwork R0 - HKHabdou89% (9)

- 027 ITP For Pre Cast Concrete PDFDokument27 Seiten027 ITP For Pre Cast Concrete PDFlinga2014Noch keine Bewertungen

- Inspection & Test Plan For DrywallDokument2 SeitenInspection & Test Plan For Drywallexia1992100% (1)

- INSPECTION AND TESTING PLAN (ITP) : Concrete RepairsDokument1 SeiteINSPECTION AND TESTING PLAN (ITP) : Concrete RepairsYash Sharma100% (2)

- 010-MS For Grouting PDFDokument33 Seiten010-MS For Grouting PDFKöksal PatanNoch keine Bewertungen

- 010-MS For Grouting PDFDokument33 Seiten010-MS For Grouting PDFKöksal PatanNoch keine Bewertungen

- ITP 001 Fencing, CurbingDokument19 SeitenITP 001 Fencing, CurbingMikiRoniWijaya50% (2)

- Ibb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectDokument19 SeitenIbb Mcup & Modification of K-12 Building: Safco/Ibb Mobile Coating Unit PojectShewale PravinNoch keine Bewertungen

- 022-Itp For Fence & Gate PDFDokument5 Seiten022-Itp For Fence & Gate PDFKöksal Patan83% (6)

- Inspection and Test PlanDokument6 SeitenInspection and Test PlanMadison ChanNoch keine Bewertungen

- Kitchen Proposal From Palmer Residential 11182016Dokument8 SeitenKitchen Proposal From Palmer Residential 11182016CarlosNoch keine Bewertungen

- Inspection Test PlanDokument3 SeitenInspection Test Planfabin100% (3)

- 038-Itp For Coldboxes PDFDokument25 Seiten038-Itp For Coldboxes PDFKöksal PatanNoch keine Bewertungen

- 008-CIVIL-MS Backfilling Works PDFDokument16 Seiten008-CIVIL-MS Backfilling Works PDFKöksal Patan100% (1)

- Mechanical Rotating-Supervisor Training PDFDokument19 SeitenMechanical Rotating-Supervisor Training PDFWahyu IrwansyahNoch keine Bewertungen

- 046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFDokument18 Seiten046-ITP For INSTALLATION OF MAC-BAC-ST MACHINERY UNIT PDFKöksal PatanNoch keine Bewertungen

- 034-ITP For Air Cooled Steam Condenser PDFDokument41 Seiten034-ITP For Air Cooled Steam Condenser PDFKöksal PatanNoch keine Bewertungen

- 039-Itp For Embedded Plate PDFDokument7 Seiten039-Itp For Embedded Plate PDFKöksal PatanNoch keine Bewertungen

- Fidic Conditions of Contract Silver Book PDFDokument2 SeitenFidic Conditions of Contract Silver Book PDFKiera0% (1)

- 5.ITP For Excavation and Back FillingDokument19 Seiten5.ITP For Excavation and Back FillingDaniel Sinaga100% (5)

- MOS For CMU Block WorkDokument10 SeitenMOS For CMU Block WorkAlvene TagocNoch keine Bewertungen

- Itp For Construction of Precast FoundationDokument7 SeitenItp For Construction of Precast Foundationreachpunnya5538100% (2)

- 012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFDokument18 Seiten012-Civil - MS Ag and Ug Coating of Concrete Surfaces PDFKöksal PatanNoch keine Bewertungen

- 013-MS Utilization of Hilti DX 76 PDFDokument51 Seiten013-MS Utilization of Hilti DX 76 PDFKöksal PatanNoch keine Bewertungen

- Purpose: Method Statement - Raised Access Flooring / Cavity FlooringDokument7 SeitenPurpose: Method Statement - Raised Access Flooring / Cavity Flooringajit karandikar100% (1)

- Client Guide To Steel Chimney InspectionDokument27 SeitenClient Guide To Steel Chimney InspectionAnkit BiswasNoch keine Bewertungen

- PCA1080DXBKNJ1DSA00 04.17.18 CompressedDokument70 SeitenPCA1080DXBKNJ1DSA00 04.17.18 CompressedAtilaNoch keine Bewertungen

- C685C685M 14Dokument9 SeitenC685C685M 14Alvin BaraNoch keine Bewertungen

- What Are The 7 Wonders of The Ancient World - (PDFDrive)Dokument64 SeitenWhat Are The 7 Wonders of The Ancient World - (PDFDrive)umairaNoch keine Bewertungen

- Experiment No 1 Impact ValueDokument8 SeitenExperiment No 1 Impact Valuefaiz19aaNoch keine Bewertungen

- Sample Hotel Fire Safety Self1Dokument3 SeitenSample Hotel Fire Safety Self1KA MaromNoch keine Bewertungen

- 3 Upper Ground Floor PlanDokument1 Seite3 Upper Ground Floor PlanAtul JaiswalNoch keine Bewertungen

- Astm D1079Dokument8 SeitenAstm D1079Donnabel CaleNoch keine Bewertungen

- 9 2 Effect NEWDokument6 Seiten9 2 Effect NEWRadix CitizenNoch keine Bewertungen

- Draft Rate Analysis As Per New SDB 06-09-2021 Deepak KumawatDokument592 SeitenDraft Rate Analysis As Per New SDB 06-09-2021 Deepak KumawatPankaj SinghNoch keine Bewertungen

- Adv Fire Fighting (Exam) 2Dokument5 SeitenAdv Fire Fighting (Exam) 2Kristijan PolicNoch keine Bewertungen

- 04 Compressive Strength (Mix Design)Dokument1 Seite04 Compressive Strength (Mix Design)jitendraNoch keine Bewertungen

- Retaining Wall StandardsDokument3 SeitenRetaining Wall StandardssowjichNoch keine Bewertungen

- Atal Setu MCQsDokument11 SeitenAtal Setu MCQssmrutiodisha56Noch keine Bewertungen

- Job No. 26418: CollahuasiDokument1 SeiteJob No. 26418: Collahuasicutcnc.concepcionNoch keine Bewertungen

- Flexseal Puddle Flange Moulded FabricatedDokument2 SeitenFlexseal Puddle Flange Moulded FabricatedPritam DharNoch keine Bewertungen

- Doha Cables - Products CatalogueDokument174 SeitenDoha Cables - Products CatalogueJeremy Mcfadden50% (2)

- Captura de Pantalla 2023-07-20 A La(s) 14.25Dokument1 SeiteCaptura de Pantalla 2023-07-20 A La(s) 14.25Jonathan RodriguezNoch keine Bewertungen

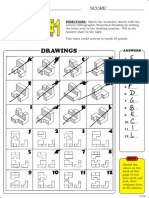

- Multi View Worksheet 1,2, and 3Dokument3 SeitenMulti View Worksheet 1,2, and 3Nik EhyenNoch keine Bewertungen

- Kee Safety Plate Clamp PDFDokument2 SeitenKee Safety Plate Clamp PDFCal MoranNoch keine Bewertungen

- Study of Light Weight Fibre Reinforced Concrete by Partial Replacement of Coarse Aggregate With Pumice StoneDokument10 SeitenStudy of Light Weight Fibre Reinforced Concrete by Partial Replacement of Coarse Aggregate With Pumice StoneMohammed Sohel AhmedNoch keine Bewertungen

- Memo 097.7 070419 Construction Materials Price Data CMPD 2nd Quarter CY 2019Dokument11 SeitenMemo 097.7 070419 Construction Materials Price Data CMPD 2nd Quarter CY 2019Daisy GF GamefowlsNoch keine Bewertungen

- NSC Piping Supt ChecklistDokument3 SeitenNSC Piping Supt ChecklistzahoorNoch keine Bewertungen