Beruflich Dokumente

Kultur Dokumente

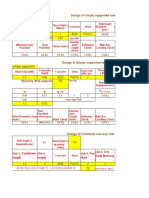

Design of RCC Slab

Hochgeladen von

rajseema_n21Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design of RCC Slab

Hochgeladen von

rajseema_n21Copyright:

Verfügbare Formate

SECTION (MM) PI (constant) 3.

14159265

LONG SPAN 6700

SHORT SPAN 4300

COVER 15

MATERIAL:

GRADE OF CONCRETE M15

GRADE OF STEEL - MAIN Fe 415

GRADE OF STEEL - SECONDARY Fe 415

LOADS (Kn/m2) :

LIVE LOAD 3.00

FF LOAD 0.60

PARTITION LOAD 0

MISCELLANEOUS LOAD 0

SAFETY FACTOR:

FORCES 1.50

CONDITION:

R

3

ASSUME OVERALL THICKNESS OF SLAB 125 mm

EFFECTIVE DEPTH AS PER DESIGN 79.72 mm

ADOPT EFFECTIVE DEPTH AS 105 mm

OVERALL DEPTH 125 mm

REINFORCEMENT:

DIA OF MAIN REINFORCEMENT IN MM 10

DIA OF DISTRIBUTION REINFORCEMENT IN MM 8

DIA OF TORSION REINFORCEMENT IN MM 8

Reinforcement in middle strip:

Steel along short span: 754 mm2

Dia of reinforcement 10 mm

Spacing of bars c/c 104.16 mm O.K.

PROVIDE SPACING OF BARS c/c 100 mm

Total area provided 785.4 mm2

Area of tension steel Aty along long

span: 226.08 mm2

since required area is greater than

minimum required area, hence o.k.,

provide area 226.08 mm2

Dia of reinforcement 8 mm

Spacing of bars c/c 222.35 mm O.K.

PROVIDE SPACING OF BARS c/c 150 mm

Total area provided 335.13 mm2

Reinforcement in edge strip:

Minimum reinforcement 150.00 mm2

Dia of reinforcement 8 mm

Along short span :

Spacing of bars c/c 335.13 mm Revise

PROVIDE SPACING OF BARS c/c 200 mm O.K.

Total area provided 251.35 mm2 O.K.

Along short span :

Spacing of bars c/c 335.13 mm O.K.

PROVIDE SPACING OF BARS c/c 300 mm O.K.

Total area provided 167.57 mm2 O.K.

Corner Reinforcement:

Length of corner reinforcement 876 mm

Area of each layer of reinforcement 566 mm2

Dia of reinforcement 8 mm

Spacing of bars c/c 83 mm

Check for shear at short edge:

Nominal shear stress,τv 0.21 N/mm2

In slabs τc' 0.321 N/mm2

The Slab panel is SAFE in shear.

Check for development length at short edge:

Dia of bar used 8 mm

Ø ≤ 8.13 mm

Dia of bar used is less than required one , hence o.k.

Check for deflection:

Allowable L/d =α β γ λ 44.8

Actual L/d 41.95

Deflection requirements are O.K.

DESIGN OF R.C.C. SLAB (IS456-1978)

DESIGN DATA :

SECTION (MM):

LONG SPAN, Ly 6700

SHORT SPAN, Lx 4300

COVER 15

MATERIAL:

GRADE OF CONCRETE M15

GRADE OF STEEL - MAIN Fe 415

GRADE OF STEEL - SECONDARY Fe 415

LOADS (Kn/m2) :

LIVE LOAD 3.00

FF LOAD 0.60

PARTITION LOAD 0

MISCELLANEOUS LOAD 0

SAFETY FACTOR:

FORCES 1.50

CONDITION:

RESTRAINED SLAB

ONE LONG EDGE DISCONTINUOUS

DESIGN:

σck = 15 N/mm2

σy(main) = 415 N/mm2

σy (secondary) = 415 N/mm2

N.A. factor = 0.48

Ly / Lx = 1.56

This is two-way slab.

Assume overall thicness of slab, D 125 mm

Effective depth, d 105 mm

Effective spans will be

lx = Lx + d 4.405 m

ly = Ly + d 6.805 m

ly / lx = 1.5

Moments along short span Mx and along

long span My are given by :

Mx = βx w lx²

My = βy w lx²

Corresponding ly /lx,

For positive moment at mid span

βx = 0.0512

βy = 0.028

For negative moment at continuous edge

βx = 0.0672

βy = 0.037

DESIGNED & DEVELOPED BY IDCS BASTI, INDIA

contd. On next page

DESIGN OF R.C.C. SLAB (IS456-1978)

Dead load of slab, wd = D x 25 3.13 kN/m2

Live load, wl 3.00 kN/m2

Finish load, wf 0.60 kN/m2

Partition Load, wp 0.00 kN/m2

Miscellaneous load, w' 0.00 kN/m2

Total load, w = wd+wl+wf+wp+w' 6.73 kN/m2

Factored load, wu = safety factor x w 10.09 kN/m2

Positive moment at mid span

Mx = βx w lx² 10.024 kNm/m

My = βy w lx² 5.482 kNm/m

For negative moment at continuous edge

Mx = βx w lx² 13.157 kNm/m

My = βy w lx² 7.244 kNm/m

The effective depth shall be designed for

maximum of moment,i.e. 13.157 kNm/m

The effective depth d of the slab is given by

0.138σckbd2

d = 79.72 mm

Adopt effective depth,d 105 mm

Adopt overall depth,D 125 mm

Along the long edge:

Length 0f the middle strip 5.10 m

Length 0f the edge strip 0.851 m

Along the short edge:

Length 0f the middle strip 3.304 m

Length 0f the edge strip 0.551 m

Minimum area of steel 0.12%

Hence, Minimum area of steel 150.00 mm2

Reinforcement in middle strip:

Steel along short span:

Atx = 0.36 σck b Xm / 0.87σy 754 mm2

Dia of reinforcement 10 mm

Area of bar 78.54 mm2

Spacing of bars c/c 104.16 mm O.K.

Providing spacing of bars c/c 100 mm

Total area provided, Atxp 785.4 mm2 O.K.

Area of tension steel Aty along long

span:

d' = d - dia of bar 95 mm

a = 0.87 x σy2 / σck x 1000 9.989

b = 0.87 x σy x d' 34299.750

c = Mx 7244000

Aty =( b±√b²-4ac) / 2a 226.08 mm2

DESIGNED & DEVELOPED BY IDCS BASTI, INDIA

contd. On next page

DESIGN OF R.C.C. SLAB (IS456-1978)

since required area is greater than

minimum required area, hence o.k.,

provide area 226.08 mm2

Dia of reinforcement 8 mm

Area of bar 50.27 mm2

Spacing of bars c/c 222.35 mm O.K.

Providing spacing of bars c/c 150 mm

Total area provided, Atyp 335.13 mm2 O.K.

Curtail alternate bars at 1/10 th of effective span in each

direction in accordance with clause C-2.1.1 of the Code.

Provide 50% of the maximum positive steel at top near the

supports to resist bending moment due to partial fixity. This

steel is provided in length 0.1l from the face of supports.

Reinforcement in edge strip:

Minimum reinforcement = 150.00 mm2

Dia of reinforcement 8

Area of bar 50.27 mm2

Along short span :

Spacing of bars c/c 335.13 mm Revise

Providing spacing of bars c/c 200 mm O.K.

Total area provided, Atyp 251.35 mm2 O.K.

Along long span :

Spacing of bars c/c 335.13 mm O.K.

Providing spacing of bars c/c 300 mm O.K.

Total area provided, Atyp 167.57 mm2 O.K.

Corner reinforcement:

Length of corner reinforcement=0.2 lx 876 mm

Area of each layer of reinforcement= 75%

0f area required for maximum midspan

moment 566 mm2

Dia of reinforcement 8 mm

Area of bar 50.27 mm2

no. of bars per rm 12

Spacing of bars c/c 83 mm

Check for shear at short edge:

Maximum SF, Vu = 0.5wLx 21.69 kN/m

Nominal shear stress,τv= Vu/bd 0.21 N/mm2

Percent tension steel = 100As / bd 0.11 %

Shear strength of concrete,τc =

DESIGNED & DEVELOPED BY IDCS BASTI, INDIA

contd. On next page

DESIGN OF R.C.C. SLAB (IS456-1978)

β = 0.8 σck / 6.89 Pt > 1.0 15.833

τc = 0.85/6β √0.80σck (√(1+5β) -1) 0.247 N/mm2

In slabs τc' = k τc 0.321 O.K.

The Slab panel is SAFE in shear.

Check for development length at short edge:

d' = 96 mm

Moment of resistance,

M1 = 0.87σy At(d'-(σy At / σck b)) 5527464.11 Nmm

Vu = 21.69 kN

Anchorage value of bars,Lo =60+ 8Ø 124 mm

Development length, Ld = 56Ø

Ld ≤ 1.3 M1/Vu + Lo

56Ø ≤ 1.3 M1/Vu + Lo 455.29 mm

Ø ≤ 8.13 mm

Dia of bar used is less than required one

, hence o.k.

Check for deflection:

Percent tension steel at midspan =

100As / bd 0.32 %

γ = 1.4

β = 1

λ = 1

α = 32

Allowable L/d =α β γ λ 44.8

Actual L/d = 41.95

Deflection requirements are O.K.

Das könnte Ihnen auch gefallen

- RCC Design SheetsDokument69 SeitenRCC Design SheetsFahim H bepari100% (1)

- Flat Slab ExcelDokument50 SeitenFlat Slab ExcelJEFFY JACOB100% (1)

- Design of Slab (One Way)Dokument9 SeitenDesign of Slab (One Way)anumned100% (1)

- Strap FootingDokument30 SeitenStrap Footinganon_140586866Noch keine Bewertungen

- RCC Slab Design and Reinforcement DetailsDokument79 SeitenRCC Slab Design and Reinforcement Detailssurendra_panga100% (2)

- Slab Design ExcelDokument6 SeitenSlab Design ExcelsahmeduNoch keine Bewertungen

- RCC - Design Excel SheetDokument10 SeitenRCC - Design Excel SheetYashas KatugamNoch keine Bewertungen

- Beam Design by SP 16Dokument1 SeiteBeam Design by SP 16Arnab Deb67% (3)

- Slab Design ExcelDokument30 SeitenSlab Design Excelwajid ahmadNoch keine Bewertungen

- RCC Doubly Reinforced Beam by Is 456: 2000 (LSM)Dokument26 SeitenRCC Doubly Reinforced Beam by Is 456: 2000 (LSM)mafiapumba67% (3)

- Continuous One Way Sunk Slab Design ProgrammeDokument24 SeitenContinuous One Way Sunk Slab Design ProgrammeNikhilNoch keine Bewertungen

- All Footing DesignDokument16 SeitenAll Footing Designer.praveenraj30Noch keine Bewertungen

- SLAB DESIGN CALCULATIONSDokument6 SeitenSLAB DESIGN CALCULATIONSsharathkn50% (2)

- Design of WingwallDokument29 SeitenDesign of WingwallMar MartillanoNoch keine Bewertungen

- Stair Case Design Single FlightDokument3 SeitenStair Case Design Single Flightrahul100% (1)

- 11.staircase Design Spreadsheet As Per IS 800Dokument4 Seiten11.staircase Design Spreadsheet As Per IS 800Mahadev D. Bhandare0% (1)

- Two Way Slab Design Excel SheetDokument11 SeitenTwo Way Slab Design Excel SheetZevanyaRolandTualakaNoch keine Bewertungen

- Strap Footing Design As Per Is 456Dokument4 SeitenStrap Footing Design As Per Is 456Sanjay Rokka75% (4)

- StaircaseDokument2 SeitenStaircaseMAGED MOHMMED AHMED QASEMNoch keine Bewertungen

- RCDC Plinth BeamsDokument25 SeitenRCDC Plinth BeamsEr Suresh Kumar50% (2)

- R.C.C. Column DesignDokument5 SeitenR.C.C. Column Designgufran khan60% (5)

- Design of Isolated FootingDokument1 SeiteDesign of Isolated FootingchanakyaNoch keine Bewertungen

- Design BookDokument53 SeitenDesign BookmollikaminNoch keine Bewertungen

- DESIGN OPTIMIZEDDokument5 SeitenDESIGN OPTIMIZEDJitendra Kumar100% (1)

- JEC+Prog+ +Combined+Rectangular+FootingDokument6 SeitenJEC+Prog+ +Combined+Rectangular+FootingLaura HernandezNoch keine Bewertungen

- Design of Columns As Per IS 456-2000Dokument68 SeitenDesign of Columns As Per IS 456-2000S Praveenkumar87% (93)

- Corbel Excel Sheet WorksDokument5 SeitenCorbel Excel Sheet WorksIbrahim A.LNoch keine Bewertungen

- 1.0 Beam DesignDokument8 Seiten1.0 Beam Designklynchelle100% (1)

- SL - No Description Refrence 1 Beam Design - B1 1.1 INPUTDokument2 SeitenSL - No Description Refrence 1 Beam Design - B1 1.1 INPUTkushaljp8989Noch keine Bewertungen

- Design of Steel STAADDokument61 SeitenDesign of Steel STAADPrashant Sunagar100% (1)

- Design of Two Way Slab by IS 456Dokument8 SeitenDesign of Two Way Slab by IS 456Mohmmedhusain Fruitwala50% (2)

- Design of Staircase - 04Dokument8 SeitenDesign of Staircase - 04Engr SwapanNoch keine Bewertungen

- 8.0 Slab Design (Aci)Dokument4 Seiten8.0 Slab Design (Aci)klynchelleNoch keine Bewertungen

- One Way Slab DesignDokument10 SeitenOne Way Slab DesignBijendra PradhanNoch keine Bewertungen

- Analysis and Design of Cantilever SlabDokument9 SeitenAnalysis and Design of Cantilever SlabOscarKonzultNoch keine Bewertungen

- Beam Design With RCCDokument24 SeitenBeam Design With RCCOsarieme Osakue100% (1)

- Staircase Design IS456-2000Dokument2 SeitenStaircase Design IS456-2000Nitesh SinghNoch keine Bewertungen

- Design RCC 2 Storey BuildingDokument37 SeitenDesign RCC 2 Storey BuildingNeetesh Sharma91% (44)

- Cantilever Slab DesignDokument18 SeitenCantilever Slab DesignSarah Huff67% (9)

- Design of Cantilever Chajja SlabDokument4 SeitenDesign of Cantilever Chajja SlabMaheshNoch keine Bewertungen

- Design of combined footing and strap beamDokument4 SeitenDesign of combined footing and strap beamSakar ShresthaNoch keine Bewertungen

- Combined Strap FootingDokument8 SeitenCombined Strap FootingNoman Khan100% (2)

- L Shaped Reatining WAll With HORZONTAL Bach FillDokument29 SeitenL Shaped Reatining WAll With HORZONTAL Bach Fillsarveshfdk48100% (2)

- Slab Design As Per IS 456Dokument7 SeitenSlab Design As Per IS 456RitaBiswas100% (1)

- Design of Simply Supported One Way SlabDokument15 SeitenDesign of Simply Supported One Way SlabNikhil100% (2)

- Slab Design SpreadsheetDokument16 SeitenSlab Design SpreadsheetmuraliNoch keine Bewertungen

- Strip Footing DesignDokument4 SeitenStrip Footing Designkm_ananth100% (1)

- Design of Combined FootingDokument12 SeitenDesign of Combined FootingAhmmed Muhsee100% (2)

- Slab Design Calculation: f (5* f A /8 A βDokument1 SeiteSlab Design Calculation: f (5* f A /8 A βchannajayamangala100% (1)

- Design of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2Dokument5 SeitenDesign of Continuos Beam As Per IS 456-2000 1) Design Data: Eff CK 2 2khaniskhan03Noch keine Bewertungen

- StariDokument28 SeitenStariBikal BastakotiNoch keine Bewertungen

- S4 - Roof DeckDokument2 SeitenS4 - Roof DeckJoemarie MartinezNoch keine Bewertungen

- SRB DesignDokument3 SeitenSRB DesignRam LangheNoch keine Bewertungen

- Escaltor Cantilever Beam: Load CalculationDokument6 SeitenEscaltor Cantilever Beam: Load CalculationJAYASHREEBHUVANANoch keine Bewertungen

- Slab design calculations for two-storey residential projectDokument6 SeitenSlab design calculations for two-storey residential projectZulkiflee TaugNoch keine Bewertungen

- Hetauda Raft DesignDokument92 SeitenHetauda Raft DesignSurendra MaharjanNoch keine Bewertungen

- Base Plate DesignDokument21 SeitenBase Plate Designtitir bagchi100% (1)

- DEEP BEAM DesignDokument2 SeitenDEEP BEAM DesignmangeshNoch keine Bewertungen

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDokument13 SeitenBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Expt 2 - Two Way SlabDokument4 SeitenExpt 2 - Two Way Slabganesh rajaNoch keine Bewertungen

- LG Power Supply Reference GuideDokument29 SeitenLG Power Supply Reference GuideOrlando Jose PascuaNoch keine Bewertungen

- HandRail Specsgf For CfvdrfsDokument3 SeitenHandRail Specsgf For CfvdrfsTarek TarekNoch keine Bewertungen

- MAGLEV User ManualDokument19 SeitenMAGLEV User ManualAnthony LittlehousesNoch keine Bewertungen

- Driver Control Master NXT Service Manual 092137-8Dokument53 SeitenDriver Control Master NXT Service Manual 092137-8Piero Capretti0% (1)

- Hazardous Area ClassificationDokument15 SeitenHazardous Area ClassificationpmnasimNoch keine Bewertungen

- MVE XC Series Dewars | Millennium XC 20 | XC 21/6 | XC 22/5 | XC 32/8 | XC 33/22 | XC 34/18 | XC 34/18 Plus | XC 43/28 | XC 47/11-10 | XC 47/11-6 | XC 47/11-6 2 Square | XC 47/11-6 3 | Sample Storage DewarsDokument14 SeitenMVE XC Series Dewars | Millennium XC 20 | XC 21/6 | XC 22/5 | XC 32/8 | XC 33/22 | XC 34/18 | XC 34/18 Plus | XC 43/28 | XC 47/11-10 | XC 47/11-6 | XC 47/11-6 2 Square | XC 47/11-6 3 | Sample Storage DewarsPrincestonNoch keine Bewertungen

- Main Bearing Journal: Shutdown SIS Previous ScreenDokument3 SeitenMain Bearing Journal: Shutdown SIS Previous Screenariy yuli styawanNoch keine Bewertungen

- Basic Driving Instructor CourseDokument9 SeitenBasic Driving Instructor CourseRafael AbdullaNoch keine Bewertungen

- Experiment Central 2010Dokument1.481 SeitenExperiment Central 2010D BASU100% (1)

- Cisco IOS XR Configuration Guide Master IndexDokument66 SeitenCisco IOS XR Configuration Guide Master IndexvictorpetriniNoch keine Bewertungen

- THS Structural Plans (Combine)Dokument12 SeitenTHS Structural Plans (Combine)genciNoch keine Bewertungen

- 6338d1285569848 Task Alfa 300ci SB Toner PDFDokument3 Seiten6338d1285569848 Task Alfa 300ci SB Toner PDFjosealcudiacastellas100% (1)

- UAE Visa Occupation ListDokument89 SeitenUAE Visa Occupation ListSiddharth JaloriNoch keine Bewertungen

- Tensile Test AnalysisDokument8 SeitenTensile Test AnalysisNazmul HasanNoch keine Bewertungen

- Laboratory Design Capacitive Displacement SensorDokument10 SeitenLaboratory Design Capacitive Displacement SensorElizabethNoch keine Bewertungen

- VAS5054ADokument3 SeitenVAS5054AKarim ElmahrokyNoch keine Bewertungen

- Aiwa NSX-VC58Dokument41 SeitenAiwa NSX-VC580000AbdielNoch keine Bewertungen

- Acer Aspire 4735z 4736z 4935z 4936z - COMPAL LA-5272P KALG1 - REV 0.1secDokument46 SeitenAcer Aspire 4735z 4736z 4935z 4936z - COMPAL LA-5272P KALG1 - REV 0.1secIhsan Yusoff IhsanNoch keine Bewertungen

- Statement of PurposeDokument2 SeitenStatement of PurposeAan DaisyNoch keine Bewertungen

- AF09-30-01-13 100-250V50/60HZ-DC Contactor: Product-DetailsDokument5 SeitenAF09-30-01-13 100-250V50/60HZ-DC Contactor: Product-DetailsTheo Pozo JNoch keine Bewertungen

- Journallistofscopus PDFDokument630 SeitenJournallistofscopus PDFSatyanarayana RentalaNoch keine Bewertungen

- VENTILADOR INDUSTRIAL enDokument4 SeitenVENTILADOR INDUSTRIAL enFelipe BarrientosNoch keine Bewertungen

- MLU Spec Sheet 250W 255WDokument2 SeitenMLU Spec Sheet 250W 255WAdrian TurcanuNoch keine Bewertungen

- GNB Absoltye IIPDokument18 SeitenGNB Absoltye IIPFederico Tellez QNoch keine Bewertungen

- Zit 64 BVDokument12 SeitenZit 64 BVVT86Noch keine Bewertungen

- Datasheet CONTI SILENTSYNC ENDokument1 SeiteDatasheet CONTI SILENTSYNC ENViniciusNoch keine Bewertungen

- Jacoby TarboxDokument7 SeitenJacoby TarboxBayu Permana RydhaNoch keine Bewertungen

- Gearbox Efficiency and LubricationDokument6 SeitenGearbox Efficiency and Lubricationrashm006ranjanNoch keine Bewertungen

- Fls Brochure Usa v2 PDFDokument4 SeitenFls Brochure Usa v2 PDFXa ViNoch keine Bewertungen

- TM 9-1340-222-34 - 2.75 - Inch - Low - Spin - Folding - Fin - Aircraft - Rockets - 1994 PDFDokument56 SeitenTM 9-1340-222-34 - 2.75 - Inch - Low - Spin - Folding - Fin - Aircraft - Rockets - 1994 PDFWurzel1946Noch keine Bewertungen