Beruflich Dokumente

Kultur Dokumente

TL End Term Case

Hochgeladen von

vibhor19900 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

8 Ansichten1 SeiteTrade Logistics

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenTrade Logistics

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

8 Ansichten1 SeiteTL End Term Case

Hochgeladen von

vibhor1990Trade Logistics

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

“If they can’t be nested, they'll cost an arm and a leg t0 ship,” said Ms. Her-

nande2, “and I doubt that we could price them competitively with all those ship.

ping charges. What you should do is taper your wastebaskets so that when

they're packed, one can be slipped inside another and so on. The tapering

wouldn't affect the sil: screen pattems, which are the feature we want. T need

price quotes, CIF, alongside ship, in Vancouver, B.C. Customs charges, if any,

will be my problem,

Machado agreed to make some cost calculations, and Ms. Hernandez said she

had several days of business in nearby Hong Kong and would return to his of-

fice on Thursday. She left, and Machado called Cameron Wong, an overseas

freight forwarder with whom Machado did business, Machado explained the

problem to Wong, and Machado also asked Henry Ng, his plant supervisor, ©

make some cost calculations regarding the manufacture of conical, rather than

cylindcical, wastebaskets.

‘AL9:00 A.M. Wednesday they met, Ng explained that the machinery could be

modified to cut and assemble wastebaskets with three different amounts of taper,

and he referred to them as Styles A, B, and C. Production costs woutd differ be-

cause of trim and fitting. For conventional, non-tapered wastebaskets, the costs

of production are $10,000 for 10,000 units. (All cost figures inthis case are given

in US. dollars.) For Style A, they would be $11,500 for the same number of

units; Style B, $14,000, and Style C, $15,000. All could be silk-sereened. The

conventional wastebaskets weigh 10 pounds each; Style A, nine pounds; Style B,

nine pounds; and Style C, eight pounds, The amount of taper determined how

many wrapped baskets could be placed inside each other. Shipping ‘volume, in

‘cubic feet per 100 wastebaskets; would be conventional, non-tapered,200 eubic™

fect; Style A, 150 cubic feet; Style B, 100 cubic feet; and Style C, 90 cubic feet.

Note that styles A, B, and C attpered and nested inside each other wh

shipped. —

"Machado then turned to Wong and asked, “What about transport costs?”

Wong replied, “There are several components. First, you have (0 get the

packed wastebaskets from here to port. The best rate [can fis is from Joseph

Wong, who will charge $50 per trip from your factory to the piet. His truck will

carry 800 cubic feet each tip; in this instance we don't have to worry about

‘weight, The ocean freight rate on wastebaskets such as yours is $111.00 per ton

(2,000 pounds) except that if they can get more revenue by considering every

40 cubic feet a ton, they charge you that way’

What do you mean?” asked Ng.

“Ie’s called ‘vessel option’ and is intended to encourage denser cargo,” an-

swered Wong. “All cargo given to the vessel is measured in both linear and

weight measures, and if counting 40 cubic feet—or a cubic meter, which is

about the same—as weighing 2,000 pounds, that’s what they will do. An old

Votkswagen bus, fr example, might weigh only 3,000 pounds, bu it if occupies,

say, 300 cubic feet, W's charged as though it weighed

“re there other charges?” inquired Machado.

“Only one,” answered Wong, “Insurance, Add your costs of production, de-

livery to port, ocean transportation, and that is C & F. For CIF you have to add

the costs of insurance from here to alongside ship in Vancouver. Right nox, in-

surance charges are about one percent of C & F. Sorry I didn’t make all these

exact calculations before coming, but | needed to hear what Ng had to say.”

‘Okay said Machado. “Now, l's figure out whether we can afford to taper

10,000 wastebaskets. Let's get some sharp pencils and go to work.”

\®

1®

\O

©.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

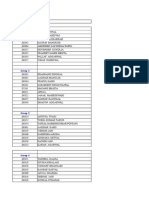

- Group 1: Group / Roll No. NameDokument8 SeitenGroup 1: Group / Roll No. Namevibhor1990Noch keine Bewertungen

- Ratings Terms You Need To Know FINAL 030509Dokument6 SeitenRatings Terms You Need To Know FINAL 030509vibhor1990Noch keine Bewertungen

- Blue Ocean Red OceanDokument8 SeitenBlue Ocean Red Oceanvibhor1990Noch keine Bewertungen

- Voda India DistributionDokument19 SeitenVoda India Distributionvibhor1990Noch keine Bewertungen

- IPL - A Group 9 - FinalDokument8 SeitenIPL - A Group 9 - Finalvibhor1990Noch keine Bewertungen