Beruflich Dokumente

Kultur Dokumente

4890 Guide Bar Installation For Weld Tees

Hochgeladen von

Lorena DávilaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4890 Guide Bar Installation For Weld Tees

Hochgeladen von

Lorena DávilaCopyright:

Verfügbare Formate

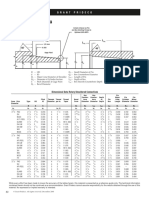

Standard

Engineering Standards

4890

Page

1 of 2

GUIDE BAR INSTALLATION

FOR WELD TEES

Issue Date

06/86

4

08/91

Rev. No.

Date

BRANCH

R

U

N

4

3/8

10

3/8

3/8

3/8

3/8

3/8

10

3/8

3/8

3/8

3/8

12

3/8

3/8

3/8

3/8

3/8

14

3/8

3/8

3/8

3/8

3/8

1/2

16

3/8

3/8

3/8

3/8

3/8

1/2

1/2

18

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

20

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

22

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

24

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

26

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

1/2

28

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

1/2

5/8

30

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

1/2

5/8

5/8

32

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

1/2

5/8

5/8

5/8

34

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

1/2

5/8

5/8

5/8

5/8

36

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

1/2

5/8

5/8

5/8

5/8

5/8

42

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

1/2

5/8

5/8

5/8

5/8

5/8

1

* Indicates revised paragraph, this Rev. No.

12

14

16

18

20

22

24

26

28

30

32

34

36

42

5/8

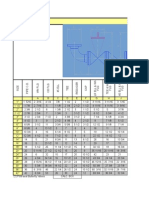

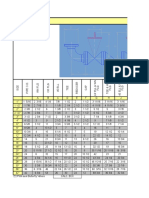

Engineering Standards

Standard

4890

Page

2 of 2

GUIDE BAR INSTALLATION

FOR WELD TEES

Issue Date

Rev. No.

Date

NUMBER OF GUIDE BARS INSTALLED

Preheat fitting in guide bar weld area to a minimum of 250 F prior to welding. Use SMAW process w/ low

hydrogen electrodes or GMAW process utilizing CO2 shielding gas and wire for welding guide bars to tee.

* Indicates revised paragraph, this Rev. No.

06/86

4

08/91

Das könnte Ihnen auch gefallen

- GP Tool Joint Dimensional ValueDokument3 SeitenGP Tool Joint Dimensional ValuecalamarejoNoch keine Bewertungen

- GP Tool Joint Dimensional Value PDFDokument2 SeitenGP Tool Joint Dimensional Value PDFamerNoch keine Bewertungen

- Polysymetrics: The Art of Making Geometric PatternsVon EverandPolysymetrics: The Art of Making Geometric PatternsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Footer ValveDokument200 SeitenFooter Valveali96161Noch keine Bewertungen

- Nwhois: Corrosive Oil & Highly Corrosive Solution ApplicationsDokument1 SeiteNwhois: Corrosive Oil & Highly Corrosive Solution Applicationskarim karimNoch keine Bewertungen

- Weld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingVon EverandWeld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingNoch keine Bewertungen

- Stainless Steel Socket Weld FittingsDokument4 SeitenStainless Steel Socket Weld FittingsJimmy Alfaro HernandezNoch keine Bewertungen

- British Commercial Computer Digest: Pergamon Computer Data SeriesVon EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNoch keine Bewertungen

- Piper SguideDokument278 SeitenPiper SguideJordy PerezNoch keine Bewertungen

- Electric Motor NEMA Frame Sizes Table PDFDokument6 SeitenElectric Motor NEMA Frame Sizes Table PDFpevareNoch keine Bewertungen

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingVon EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNoch keine Bewertungen

- Fig. Ptp-1: Short Variable SpringDokument1 SeiteFig. Ptp-1: Short Variable Springali murtadhoNoch keine Bewertungen

- Steel Pipe Vessel1Dokument279 SeitenSteel Pipe Vessel1mdishong27Noch keine Bewertungen

- VibrationControl CATALOGO SOPORTES PDFDokument12 SeitenVibrationControl CATALOGO SOPORTES PDFMilena Lemus FonsecaNoch keine Bewertungen

- AcadDokument15 SeitenAcadSanjay PathakNoch keine Bewertungen

- Flange Dimension ChartDokument10 SeitenFlange Dimension ChartSalvador TelloNoch keine Bewertungen

- Piping Design DataDokument148 SeitenPiping Design Datarerezhassan100% (1)

- Piping Valve Flange DimensionsDokument270 SeitenPiping Valve Flange DimensionschadNoch keine Bewertungen

- Steel BookDokument468 SeitenSteel BookFabian PorrasNoch keine Bewertungen

- Pocket Bolt Reference ChartDokument6 SeitenPocket Bolt Reference ChartVictor GarciaNoch keine Bewertungen

- American SteelBook 2Dokument472 SeitenAmerican SteelBook 2MiguelRagasNoch keine Bewertungen

- Steel Pipe Vessel DataDokument281 SeitenSteel Pipe Vessel DataGajanan GaikwadNoch keine Bewertungen

- Pipping DataDokument273 SeitenPipping DataidiazgNoch keine Bewertungen

- Temporary Cone & Basket Strainers: 2089 Ninth Avenue, New York 11779Dokument1 SeiteTemporary Cone & Basket Strainers: 2089 Ninth Avenue, New York 11779Anonymous FH8OunZrXNoch keine Bewertungen

- Steel PipeDokument193 SeitenSteel PipeBerenice ChávezNoch keine Bewertungen

- Nema Electrical Motors FrameDokument11 SeitenNema Electrical Motors FrameLuckie IbrahimNoch keine Bewertungen

- Steel Member SizesDokument265 SeitenSteel Member SizesMubashar HassanNoch keine Bewertungen

- Crystal ViewerDokument2 SeitenCrystal Viewerchrismoore8Noch keine Bewertungen

- World Flange StandardsDokument10 SeitenWorld Flange StandardsIsaac KendallNoch keine Bewertungen

- Flange TableDokument2 SeitenFlange TableTeodor Ioan Ghinet Ghinet DorinaNoch keine Bewertungen

- Ring Joint Flanges: ANSI B16.5, ANSI B16.20Dokument1 SeiteRing Joint Flanges: ANSI B16.5, ANSI B16.20vijayakumar2015Noch keine Bewertungen

- CARNET de Soudage - CopieDokument3 SeitenCARNET de Soudage - Copiemaatouguiabdelkader04Noch keine Bewertungen

- Rexroth Cylinder Accessories: Part No. CB CD CE CH CW F L A KK ERDokument1 SeiteRexroth Cylinder Accessories: Part No. CB CD CE CH CW F L A KK ERdinobrncicNoch keine Bewertungen

- Steel BookDokument477 SeitenSteel BookAKSHEYMEHTANoch keine Bewertungen

- Guide To Steel Pipes For Vessels - Wide Flange Beams ExcelDokument195 SeitenGuide To Steel Pipes For Vessels - Wide Flange Beams ExcelAlmario SagunNoch keine Bewertungen

- 15 LP 2013 Condulets PDFDokument3 Seiten15 LP 2013 Condulets PDFJUAN PETITNoch keine Bewertungen

- Channel Bar: A B t1 t2 20ft 30ft 40ft LB/FT KG/M Dimensions Inches Unit Weight Length Weight (KG)Dokument2 SeitenChannel Bar: A B t1 t2 20ft 30ft 40ft LB/FT KG/M Dimensions Inches Unit Weight Length Weight (KG)Efren Fernandez ElegadoNoch keine Bewertungen

- Mega BlocDokument14 SeitenMega BlocRobert RojasNoch keine Bewertungen

- Make Up TorqueDokument2 SeitenMake Up TorquemehrdadNoch keine Bewertungen

- Heavy Hex Nuts Dimensions, Weight Imperial Metric SizesDokument2 SeitenHeavy Hex Nuts Dimensions, Weight Imperial Metric SizesspvengiNoch keine Bewertungen

- Heavy Hex Nuts Dimensions Weight Imperial - MetricDokument2 SeitenHeavy Hex Nuts Dimensions Weight Imperial - MetricAkshay PoddarNoch keine Bewertungen

- MKT-001 Rev 02 Rotary Shoulder Handbook RSDokument116 SeitenMKT-001 Rev 02 Rotary Shoulder Handbook RSArsalan AhmadNoch keine Bewertungen

- GVSTDokument1 SeiteGVSTduncmcleodNoch keine Bewertungen

- Taper Lock BushingsDokument10 SeitenTaper Lock Bushingsila reehasNoch keine Bewertungen

- Torque (N-M) For Class 150 Asme B16.5 Raised Face Flanges (Sheet Gaskets - Ptfe Fluoropolymer Coated Fasteners)Dokument2 SeitenTorque (N-M) For Class 150 Asme B16.5 Raised Face Flanges (Sheet Gaskets - Ptfe Fluoropolymer Coated Fasteners)vesselyNoch keine Bewertungen

- 6 - Stud Bolt & Ring Joint MeasurementDokument2 Seiten6 - Stud Bolt & Ring Joint MeasurementErin JohnsonNoch keine Bewertungen

- Rail Chart: Nominal Weight Per Yard Type of Rail Dimensions in Inches Section Designation HT BW HW W HD FD BD EDokument5 SeitenRail Chart: Nominal Weight Per Yard Type of Rail Dimensions in Inches Section Designation HT BW HW W HD FD BD ECarlos A. RocaNoch keine Bewertungen

- Flange SeriesSKRDokument6 SeitenFlange SeriesSKRHendra JurbonNoch keine Bewertungen

- Spin Prod 928088812Dokument2 SeitenSpin Prod 928088812Josè Manuel Coronado SaucedoNoch keine Bewertungen

- Steel Pipe 2Dokument21 SeitenSteel Pipe 2JuanCarlosNoch keine Bewertungen

- TorqueDokument6 SeitenTorquelucianaNoch keine Bewertungen

- TorqueDokument6 SeitenTorquelucianaNoch keine Bewertungen

- SW ELBOW WT PDFDokument1 SeiteSW ELBOW WT PDFBárbara MontealegreNoch keine Bewertungen

- A Pi Ring Joint Flange DataDokument2 SeitenA Pi Ring Joint Flange DataSusin LimNoch keine Bewertungen

- Flange IdentifierDokument2 SeitenFlange IdentifierBabi Lakhdari100% (1)

- Estado Mecanico Tyc-04Dokument13 SeitenEstado Mecanico Tyc-04Byron marinNoch keine Bewertungen

- Learn Korean Ep. 5: "Also" and "Again"Dokument3 SeitenLearn Korean Ep. 5: "Also" and "Again"Billy GoNoch keine Bewertungen

- hsk2 HanziDokument31 Seitenhsk2 HanziPrajakta DigheNoch keine Bewertungen

- Learn Korean Ep. 78: "Worth Doing": Action Verb Stem + (을/ㄹ) 만하다Dokument3 SeitenLearn Korean Ep. 78: "Worth Doing": Action Verb Stem + (을/ㄹ) 만하다Lorena DávilaNoch keine Bewertungen

- Visit For More Chinese Learning ResourcesDokument60 SeitenVisit For More Chinese Learning ResourcesLorena DávilaNoch keine Bewertungen

- Hsk4 SmallestDokument79 SeitenHsk4 SmallestLorena DávilaNoch keine Bewertungen

- Learn Korean Ep. 5: "Also" and "Again"Dokument3 SeitenLearn Korean Ep. 5: "Also" and "Again"Billy GoNoch keine Bewertungen

- Visit For More Chinese Learning ResourcesDokument32 SeitenVisit For More Chinese Learning ResourcesLorena DávilaNoch keine Bewertungen

- Hsk3 SmallestDokument50 SeitenHsk3 SmallestLorena DávilaNoch keine Bewertungen

- Flares and Stacks: G2 © ICARUS Corporation, 1998Dokument10 SeitenFlares and Stacks: G2 © ICARUS Corporation, 1998Lorena DávilaNoch keine Bewertungen

- Local Maximum Flame Length of Flares in A CrosswindDokument5 SeitenLocal Maximum Flame Length of Flares in A CrosswindLorena DávilaNoch keine Bewertungen

- Learn Korean Ep. 5: "Also" and "Again"Dokument3 SeitenLearn Korean Ep. 5: "Also" and "Again"Billy GoNoch keine Bewertungen

- Level 2 Lesson 1: Future TenseDokument3 SeitenLevel 2 Lesson 1: Future Tensedomon46Noch keine Bewertungen

- A2-14 Noise Barrier Screening (06 Jul 09)Dokument1 SeiteA2-14 Noise Barrier Screening (06 Jul 09)Lorena DávilaNoch keine Bewertungen

- EHB en 0-IntroductionDokument2 SeitenEHB en 0-IntroductionGabriel RangelNoch keine Bewertungen

- Easy Control Valve SelectionDokument5 SeitenEasy Control Valve SelectionhrtoroNoch keine Bewertungen

- Water Section 10 PDFDokument48 SeitenWater Section 10 PDFLorena DávilaNoch keine Bewertungen

- NoiseCon 2004 PaperDokument9 SeitenNoiseCon 2004 PaperLorena DávilaNoch keine Bewertungen

- GAPS Guidelines: Distillation of Flammable or Combustible LiquidsDokument7 SeitenGAPS Guidelines: Distillation of Flammable or Combustible LiquidsLorena DávilaNoch keine Bewertungen

- 006 - 2008 Jockey Pumps - RH May 18Dokument5 Seiten006 - 2008 Jockey Pumps - RH May 18Amin UdinNoch keine Bewertungen

- Engineering Information - Flow Charts - "C" FactorsDokument1 SeiteEngineering Information - Flow Charts - "C" FactorsLorena DávilaNoch keine Bewertungen

- Ees Manual PDFDokument356 SeitenEes Manual PDFLorena DávilaNoch keine Bewertungen

- wl118 0308 Pressure20rating PDFDokument4 Seitenwl118 0308 Pressure20rating PDFLorena DávilaNoch keine Bewertungen

- Pressure Relief Valve Engineering HandbookDokument93 SeitenPressure Relief Valve Engineering Handbookakrouti92% (12)

- Wheatley Series 822 Check Valves FlyerDokument2 SeitenWheatley Series 822 Check Valves FlyerLorena DávilaNoch keine Bewertungen

- Days of Creation Wheel2 PDFDokument2 SeitenDays of Creation Wheel2 PDFLorena DávilaNoch keine Bewertungen

- Slug Catcher PDFDokument9 SeitenSlug Catcher PDFLorena DávilaNoch keine Bewertungen

- 11-7449 Brochure PIMS FINAL PDFDokument6 Seiten11-7449 Brochure PIMS FINAL PDFLorena DávilaNoch keine Bewertungen

- 103102024Dokument5 Seiten103102024Lorena DávilaNoch keine Bewertungen

- 08 2009 128 Nikollic 04Dokument12 Seiten08 2009 128 Nikollic 04Lorena DávilaNoch keine Bewertungen

- Comparative Study of Flare Dispersion Modeling MethodologiesDokument15 SeitenComparative Study of Flare Dispersion Modeling MethodologiesLorena DávilaNoch keine Bewertungen