Beruflich Dokumente

Kultur Dokumente

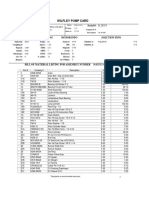

830 CB 120 M07 - Rev0

Hochgeladen von

EDUARDOOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

830 CB 120 M07 - Rev0

Hochgeladen von

EDUARDOCopyright:

Verfügbare Formate

3600 W.P. TO W.P.

1200

1200

/L 35 CARRY

IDLER

/L 35 CARRY

IDLER

15

100

34

/L 35 CARRY

IDLER

45 45

2 BOLT

793AR1301-61-A2

50

5/8"DIA

A307 1

3/4"

793AR1301-61-ER1

C18A

L80*6

22

L80*6

80

793AR1301-61-A1

L80*6

40

793AR1301-61-A1

80

L80*6

L63*40*4

793AR1301-61-A1

160

L63*40*4

793AR1301-61-A1

L80*6

L80*6

PL9.5X150

793AR1301-61-ER1

C18A

C18A

L70*5

R1

3A

C /L 10 VEE

RETURN IDLER

30

1-6

1-D

2 BOLT

500

BOLTS FOR CARRY IDLERS

(TOP FLANGE) AND RETURN

IDLERS (BOTTOM FLANGE)

SUPPLIED BY KRUPP.

5/8"DIA

A307 1

793AR1301-61-A2

E-E

SCALE: 1:7.5

SCALE: 1:7.5

793AR1301-61-A1

L80*6

793AR1301-61-A1

C8

2 BOLT

L80*6

C /L 10 VEE

RETURN IDLER

793AR1301-61-SP1

L7

SCALE: 1:7.5

H-H

L63*40*4

DET. 2

79 0*5

G-G

30

30

3/4"

PL9.5X226

36

L70*5

C18A

829

(02) 21 HOLES FOR

3/4" ANCHOR BOLT.

L63*40*4

793AR1301-61-A2

793AR1301-61-A1

793AR1301-61-A1

230

793AR1301-61-A2

C18A

15

150

835

1200

C

/L 35 CARRY

IDLER

50

167

300

793AR1301-61-A2

22X50 SLOTS

IN PLATE

30

5/8"DIA

A307 1

3/4"

793AR1301-61-A2

L63*40*4

L63*40*4

793AR1301-61-D1

36

50

2 BOLT

80

C18A

5/8"DIA

A307 1

2 BOLT

3/4"

5/8"DIA

A307 1

1/2"

PL6.3X50.8

35

DET. 1

793AR1301-61-ER1

3600

C18A

L70*5

RETURN IDLERS

PL9.5X150

60

5/8"DIA

A307 1

6

437

3/4"

3600

A-A

C18A

C18A

C18A

2 BOLT

PL6.3X50.8

793AR1301-61-A3

L40*5

45

60

L70*5

793AR1301-61-ER1

1800

DETAIL 2

D-D

F-F

SCALE: 1:7.5

SCALE: 1:7.5

SCALE: 1:7.5

SCALE: 1:15

3600 W.P. TO W.P.

3600 W.P. TO W.P.

1200

C

1200

/L 35 CARRY

IDLER

15

4 BOLT

/L 35 CARRY

IDLER

885

L40*5

L40*5

793AR1301-61-SP1

C8

793AR1301-61-A1

L70*5

793AR1301-61-ER1

793AR1301-61-A1

685

WIND GUARD,SCREW WIND GUARD

TO L63X40 AND C8 WITH SELF

TAPPING SCREWS.

437

793AR1301-61-D1

L40*5

437

C18A

150

760 TO C/ L CONVEYOR

142

793AR1301-61-A3

793AR1301-61-A3

437

249

L80*6

C18A

793AR1301-61-A3

L80*6

793AR1301-61-A1

50

80

(2) PIG TAILS THIS SIDE

MOUNTED AS SHOWN FOR

PULL CORD-(BY KRUPP)

793AR1301-61-A1

50

C18A

15

L63*40*4

A325 1 3/4"

F

C

/L 35 CARRY

IDLER

885

793AR1301-61-A2

3/4"DIA

900

L80*6

2 BOLT

5/8"DIA

5/8"DIA

A307 1

A307 1

25

300

50

3600 W.P. TO W.P.

3/4"

2 BOLT

2 BOLT

L80*6

1/2"

5/8"DIA

A307 1

3/4"

(02)HOLES FOR

BOLTS

L63*40*4

L70*5

A307 2

1/2"

60

5/8"DIA

793AR1301-61-PL1

PL12X75

L70*

19

2 BOLT

3/4"DIA

A325 1

3/4"

19

PL12X75

G

PL9.5X226

200

793AR1301-61-A1

55

L80*6

55

249

150

793AR1301-61-D2

L80*6

793AR1301-61-A1

L80*6

15

885

L80*6

C-C

95 95

TIP.

1800

50

45 45

793AR1301-61-A1

(2) PIG TAILS THIS SIDE

MOUNTED AS SHOWN FOR

PULL CORD-(BY KRUPP)

L70*5

685

SCALE: 1:7.5

DETAIL 1

TIP.

SCALE: 1:7.5

3570

GENERAL NOTES

90

1.-ALL MEASUREMENT PREVAIL OVER DRAWING.

2.-WELDING PROCEDURE ACCORDING TO AWS D1.1.

3.-MATERIAL SPECIFIED:

a.-PLATES: A572 GR.50 AND ASTM-A36.

b.-CHANNEL SHAPES : Q235B of GB/ T700 and standard shapes of GB/ T707.

c.-"S" or "M" SHAPES :Q235B of GB/ T700 and standard shapes of GB/ T706.

d.-"W" and "WT"SHAPES : Q235, H and T of GB/ T700 and standard shape profiles of GB/ T11263.

e.-EQUAL ANGLES :

Main Elements: Q235B Angles of GB/ T700 and standard shape profiles of GB/ T9787.

Connection Elements: ASTM-A36.

f.-UNEQUAL ANGLES:

Main Elements: Q235B Unequal Angles of GB/ T700 and standard shape profiles of GB/ T9788.

Connection Elements: ASTM-A36.

g.-STEEL FOR HSS, SQUARE OR RECTANGULAR SHAPES: Q345B of GB/

T1951 and standard shape

profiles of GB/ T6728.

h.-PIPING: Q235B of GB/ T700 and of standard shape profiles of GB/ T6728.

4.-PAINTING SYSTEM FOR STRUCTURE:

ALL MANUFACTURING STEEL SHALL BE PROTECTED WITH A COATING WORKSHOP.

ACCORDING TO TECHNICAL SPECIFICATIONS OF PAINT N997601-5000-G-ST-002 Rev.1".

5.- ALL IDLER HOLES ARE FOR 18 HOLES A307 H.H. BOLTS, COMPLETE WITH NUT,

TAPER WASHER, FLAT WASHER AND LOCK WASHER. NOT PROVIDED BY FABRICATOR.

6. -FABRICATOR SHALL ASSEMBLE ONE (1) ENTIRE DECK SECTION INCLUDING NEAR SIDE AND FAR

SIDE BOLTED MEMBERS FOR TRIAL FIT BEFORE MASS PRODUCTION OF A LARGE QUANTITY.

FABRICATOR SHALL CHECK ALL DIMENSIONS INCLUDING HOLE DIMENSIONS AS PER DESIGN

REQUIREMENTS. ONCE ALL IS APPROVED, DECK SHALL BE DISASSEMBLED FOR SHIPPING. IN THIS

MANNER ALL THE ISSUES THAT MAY ARISE SHALL BE WORKED AND RESOLVED PRIOR TO ANY

OTHER WORK.

PLAN VIEW - TYPICAL DECK SECTION

SCALE: 1:15

3600 W.P. TO W.P.

870

160

1040

HOOD COVERS BRACKET

160

1040

HOOD COVERS BRACKET

160

170

1520

HOOD COVERS BRACKET

1448 C/ L IDLER HOLES

HOLE FOR 1/2 " BOLT

FOR GROUND STRAP

437

B

150

CARRY BELT

TYP.

793AR1301-61-A1

L80*6

793AR1301-61-A1

793AR1301-61-A1

L80*6

50

249

150

L70*5

25

793AR1301-61-ER2

C18A

1448 C/ L IDLER HOLES

BEARING BARS DIRECTION

829

CHEKERED PLATE PROTRUSION

PL12X75

L70*5

3/4"

L70*

L70*

793AR1301-61-PL1

5

PL12X75

793AR1301-61-ER1

C18A

08/08/2014

08/07/2014

REV.

FECHA

PROYECTO:

685

LUGAR:

AREA:

Tekla structures

1565

1620

TITULO:

3420

B-B

SCALE: 1:15

ELEVATION - TYPICAL DECK SECTION

SCALE: 1:15

BRANDS ARE PRECEDED BY:

DATUM PLANE: 48 CONVEYOR 830-CB-120

IN METERS. (S.I.C.)

IN. (mm)

SEE GENERAL NOTES

MINIMUM SIZE TILLET: 6mm (U.N.O).

ELECTRODE:

WELD E70XX CONFORM TO THE AWS.

793AR1301-61-PL1

793AR1301-61-D2

230

65

200

A325 1

660

HOLE FOR 1/2 " BOLT

FOR GROUND STRAP

(04) HOLES

FOR 5/8 "BOLTS

L70*5

3/4"DIA

ELEVATIONS:

DIMENSIONS:

MATERIAL:

WELD:

3/4"

793AR1301-61-D2

2 BOLT

(2) PIG TAILS THIS SIDE

MOUNTED AS SHOWN FOR

PULL CORD-(BY KRUPP)

(2) PIG TAILS THIS SIDE

MOUNTED AS SHOWN FOR

PULL CORD-(BY KRUPP)

C18A

A325 1

PRINCIPAL NOTES

GENERALES NOTES IN DRAWING:

L40*5

1350

230

3/4"DIA

COVERS TO BE FIELD INSTALLED

SCREW COVER BANDS TO ANGLE

BRACKETS W/ SELF TAPPING SCREWS.

3/4"

350

C18A

829

1094

2 BOLT

A307 1

793AR1301-61-ER2

C18A

L80*6

L80*6

60

793AR1301-61-ER2

793AR1301-61-A1

793AR1301-61-A1

5/8"DIA

793AR1301-61-A3

80

90

80

90

50

L80*6

BOLTS FOR CARRY IDLERS

(TOP FLANGE) AND RETURN

IDLERS (BOTTOM FLANGE)

SUPPLIED BY KRUPP.

2 BOLT

400

BOLTS IN EVERY 5TH DECK

SPLICE SHOULD BE FINGER TIGHT

AND DISTRESS THREADS TO ALLOW

EXPANSION/ CONTRACTION.

793AR1301-61-PL1

1448

L7

0 *5

L70*5

L7

0 *5

L70*5

5

0*

L7

760

L70*5

W.P.

L70*5

1520

C/L CONVEYOR DECK SECTION

W.P.

149

100

2 BOLT

65

100

2TROUGHING & RETURN IDLER

1520 +0/ -2 B/ B STRINGERS

L63*40*4

1450

793AR1301-61-A1

ANCHORING ROPE

CLAMPED BETWEEN

LEG & CLAMP PLATE

W/5/8" A307 BOLTS,

NUTS & WASHERS,

TYP.BOTH SIDES.

793AR1301-61-D1

793AR1301-61-A2

L70*5

42

793AR1301-61-A2

L63*40*4

95

793AR1301-61-A2

L70*

65

L70*5

760

L80*6

829

793AR1301-61-A1

350

829

1/2"

ESTE PLANO ES PROPIEDAD INTELECTUAL DE

FABERTEK

DG/YE

DG/YE

REV.POR

S.M

ISSUED FOR CONSTRUCTION

S.M.

ISSUED FOR APPROVAL

APR.POR

DESCRIPCION

SHOUGAN HIERRO PERU

10-04-2014

GENERAL ARRANGEMENT_CONVEYOR 830-CB-120

830-CB-120-M07

TYPICAL DECK SECTION

PLANO DE REFERENCIA

CLIENTE:

MODELADO:

REVISO:

AC

S.M.

N PROYECTO:

130130110544

N DE PLANO

FECHA:

10-04-2014

OT:

21110

ORDEN DE COMPRA:

ESCALA

21110

SEC.

REVISION

SU REPRODUCCION, DIFUSION, COMERCIALIZACION O USO

DE CUALQUIER TIPO SIN AUTORIZACION ESCRITA DE SUS

PROPIETARIOS ESTA PENADA POR LA LEY.

906MR1301

830-CB-120-M07

1:7.5

1:15

(S.I.C.)

Das könnte Ihnen auch gefallen

- Idlers: TRF Limited TRF LimitedDokument10 SeitenIdlers: TRF Limited TRF LimitedAjit SarukNoch keine Bewertungen

- BHG - Transfer Chute Data SheetDokument2 SeitenBHG - Transfer Chute Data Sheetacas35Noch keine Bewertungen

- Bucket Elevator ChainDokument4 SeitenBucket Elevator Chainluisreng100% (1)

- Is 8531 1986Dokument6 SeitenIs 8531 1986Srini KumarNoch keine Bewertungen

- KWS Screw Conveyor and Bucket Elevator Engineering GuideDokument126 SeitenKWS Screw Conveyor and Bucket Elevator Engineering GuideargaNoch keine Bewertungen

- Pipe Dimensions and Friction FactorDokument22 SeitenPipe Dimensions and Friction FactorSARAVANANNoch keine Bewertungen

- Static Shaft Pulleys With Internal BearingsDokument14 SeitenStatic Shaft Pulleys With Internal Bearingsjonodo89100% (1)

- I Feeder Application Design CalculationsDokument2 SeitenI Feeder Application Design Calculationsarsaniose100% (1)

- Heavy Duty Conveyor Pulley Catalog PDFDokument84 SeitenHeavy Duty Conveyor Pulley Catalog PDFJoel MooreNoch keine Bewertungen

- 3 Date 2 1 0 R e V I S I o N Checked by Checked by Approve DbyDokument2 Seiten3 Date 2 1 0 R e V I S I o N Checked by Checked by Approve DbyidilfitriNoch keine Bewertungen

- Is 14416 1996Dokument20 SeitenIs 14416 1996kaustavNoch keine Bewertungen

- Material and Equipment Standard For ConveyorsDokument71 SeitenMaterial and Equipment Standard For ConveyorsRezaNoch keine Bewertungen

- Designing Hopper Discharge SystemsDokument8 SeitenDesigning Hopper Discharge Systemsafzalian_ali5352Noch keine Bewertungen

- Idler Selection PDFDokument13 SeitenIdler Selection PDFkhuong_unoNoch keine Bewertungen

- Energy & Data Transmission Systems For StockyardsDokument12 SeitenEnergy & Data Transmission Systems For StockyardsNos GoteNoch keine Bewertungen

- IdlerDesignGuide PROKDokument25 SeitenIdlerDesignGuide PROKEge UgurluNoch keine Bewertungen

- IHS document detailsDokument86 SeitenIHS document detailstalal omhammad mohammad100% (1)

- Raw Material Conveyor Tunnel DrawingDokument1 SeiteRaw Material Conveyor Tunnel DrawingHritika PatelNoch keine Bewertungen

- CHAIN CONVEYOR FOR DUSTPROOF TRANSPORTDokument8 SeitenCHAIN CONVEYOR FOR DUSTPROOF TRANSPORTMiguel OrhlNoch keine Bewertungen

- The Evolution of the Pipe-ConveyorDokument9 SeitenThe Evolution of the Pipe-ConveyorJohnjun ChenNoch keine Bewertungen

- Power Plant and Calculations - 40 Important Question & Answers On Belt Conveyor For Power Plant Engineers & OperatorsDokument9 SeitenPower Plant and Calculations - 40 Important Question & Answers On Belt Conveyor For Power Plant Engineers & OperatorsRajeshNoch keine Bewertungen

- Drawing Damper1Dokument1 SeiteDrawing Damper1OKKYNoch keine Bewertungen

- Conveyor StringersDokument9 SeitenConveyor StringersAnup DoluiNoch keine Bewertungen

- Sole PlatesDokument12 SeitenSole Platesjonodo89Noch keine Bewertungen

- Aac Spec 373001 PDFDokument13 SeitenAac Spec 373001 PDFJakesNoch keine Bewertungen

- ChE-205 Particle Technology Screening EffectivenessDokument31 SeitenChE-205 Particle Technology Screening EffectivenessInsiram NaveedNoch keine Bewertungen

- Eriez-Vibratory Feeders PDFDokument16 SeitenEriez-Vibratory Feeders PDFruben quedo salazarNoch keine Bewertungen

- PV-0013-MEC-MC-0021-B Correa CC-101Dokument14 SeitenPV-0013-MEC-MC-0021-B Correa CC-101Mario Leonel Guerra Box100% (1)

- Heavy Duty Conveyor Pulley CatalogDokument100 SeitenHeavy Duty Conveyor Pulley Catalogkosmc123Noch keine Bewertungen

- 185-170-5-300-M44-0058 RevDDokument1 Seite185-170-5-300-M44-0058 RevDVashish RamrechaNoch keine Bewertungen

- RATIONAL DESIGN OF CONVEYOR CHUTES - J Rozentals PDFDokument9 SeitenRATIONAL DESIGN OF CONVEYOR CHUTES - J Rozentals PDFJakesNoch keine Bewertungen

- Beltwall: Corrugated Sidewall BeltingDokument8 SeitenBeltwall: Corrugated Sidewall Beltingcanito73Noch keine Bewertungen

- Takraf Apron Feeder: Optimal Solutions For Mining, Material Handling and ProcessingDokument6 SeitenTakraf Apron Feeder: Optimal Solutions For Mining, Material Handling and ProcessingJakesNoch keine Bewertungen

- Dunlop Conveyor Belt Design Manual. Page 2 PDFDokument17 SeitenDunlop Conveyor Belt Design Manual. Page 2 PDFMuthuvel VivekNoch keine Bewertungen

- Apron FeederDokument12 SeitenApron FeederMidDeL'OrmeNoch keine Bewertungen

- NW1213 GA Primary (With TK11-42-2V)Dokument1 SeiteNW1213 GA Primary (With TK11-42-2V)darko1969Noch keine Bewertungen

- Stockpile SegregationDokument2 SeitenStockpile SegregationEdwin BatallanosNoch keine Bewertungen

- Transfer Chute For Bulk Materi PDFDokument131 SeitenTransfer Chute For Bulk Materi PDFAkhilprasad SadigeNoch keine Bewertungen

- Material Handling Expertise: Screw Conveyors, Drag Conveyors & Bucket ElevatorsDokument18 SeitenMaterial Handling Expertise: Screw Conveyors, Drag Conveyors & Bucket ElevatorsSanjeevNoch keine Bewertungen

- Conveyor Chains & Accessories for Pulp & Paper, Mining, Cement IndustriesDokument8 SeitenConveyor Chains & Accessories for Pulp & Paper, Mining, Cement IndustriesJoelCristobalNoch keine Bewertungen

- Pressure-Resistant Gravimetric Coal Feeder CatalogueDokument10 SeitenPressure-Resistant Gravimetric Coal Feeder CataloguesuparnabhoseNoch keine Bewertungen

- FMC Bucket ElevatorsDokument17 SeitenFMC Bucket ElevatorsErizal HamdiNoch keine Bewertungen

- Bins & Feeders in Cement IndustryDokument29 SeitenBins & Feeders in Cement IndustryNaelNoch keine Bewertungen

- Horizontal Transportador TB24-01RH 83 TPHDokument9 SeitenHorizontal Transportador TB24-01RH 83 TPHfernando garzaNoch keine Bewertungen

- FEECO Handbook Section4Dokument62 SeitenFEECO Handbook Section4hashem62100% (2)

- Belt Tensioning Methods For Small Package ConveyorsDokument13 SeitenBelt Tensioning Methods For Small Package ConveyorsAdin SoftićNoch keine Bewertungen

- Bulk Unloading Sys.Dokument4 SeitenBulk Unloading Sys.setavietnamNoch keine Bewertungen

- Draft VTUSA Conveyor Bridge Report v4Dokument219 SeitenDraft VTUSA Conveyor Bridge Report v4ken stanleyNoch keine Bewertungen

- Coal Gallery Conveyor Isometric DrawingDokument16 SeitenCoal Gallery Conveyor Isometric DrawingBudhi KurniantoNoch keine Bewertungen

- AB-10-03 Internal Tripper CarDokument2 SeitenAB-10-03 Internal Tripper CarIim Hilmi Arif75% (4)

- Bucket Elevators for Powder and Granular MaterialsDokument20 SeitenBucket Elevators for Powder and Granular MaterialsCORDOVA DAVILA HECTOR ALONSONoch keine Bewertungen

- Tsubaki ChainDokument8 SeitenTsubaki Chainbmihaiela100% (1)

- Hopper Discharge Systems PDFDokument8 SeitenHopper Discharge Systems PDFcachorrexNoch keine Bewertungen

- Feeder-Breaker BrochureDokument4 SeitenFeeder-Breaker BrochurekrisezhilNoch keine Bewertungen

- Conveyor ChainsDokument184 SeitenConveyor ChainsAchinNoch keine Bewertungen

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFDokument8 SeitenCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- Standard Equipment: Welding Package Selection GuideDokument27 SeitenStandard Equipment: Welding Package Selection GuidePCNoch keine Bewertungen

- Beumer - Pipeconveyor TechnologyDokument51 SeitenBeumer - Pipeconveyor TechnologyAli AlatasNoch keine Bewertungen

- 10 SEER air conditioner specsDokument4 Seiten10 SEER air conditioner specsOscar Sanchez Velasquez0% (1)

- BTC Gate ValvesDokument26 SeitenBTC Gate ValvesCamilo Sanchez VanegasNoch keine Bewertungen

- Dry CobbingDokument1 SeiteDry CobbingEDUARDONoch keine Bewertungen

- 820 CB 120G WM26 - Rev0Dokument1 Seite820 CB 120G WM26 - Rev0EDUARDONoch keine Bewertungen

- Mine Operation Expansion Project and Benefit PlantDokument10 SeitenMine Operation Expansion Project and Benefit PlantEDUARDONoch keine Bewertungen

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014Dokument14 SeitenMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.09.2014EDUARDONoch keine Bewertungen

- Durban Classic Cover + Caposide in One Side (Shougang Project)Dokument4 SeitenDurban Classic Cover + Caposide in One Side (Shougang Project)EDUARDONoch keine Bewertungen

- Mine Operation Expansion Project and Benefit PlantDokument10 SeitenMine Operation Expansion Project and Benefit PlantEDUARDONoch keine Bewertungen

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Dokument12 SeitenMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONoch keine Bewertungen

- 820 CB 120G WM25 - Rev0Dokument1 Seite820 CB 120G WM25 - Rev0EDUARDONoch keine Bewertungen

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Dokument14 SeitenMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONoch keine Bewertungen

- 5921 D E DWG 0205 - RevADokument6 Seiten5921 D E DWG 0205 - RevAEDUARDONoch keine Bewertungen

- 830 CB 120 M06 - Rev0Dokument1 Seite830 CB 120 M06 - Rev0EDUARDONoch keine Bewertungen

- 5720 D E DWG 0201 - RevADokument4 Seiten5720 D E DWG 0201 - RevAEDUARDONoch keine Bewertungen

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Dokument12 SeitenMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONoch keine Bewertungen

- Mine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014Dokument14 SeitenMine Operation Expansion Project and Benefit Plant: A D For Quotation MNS MNS MNS MNS 02.06.2014EDUARDONoch keine Bewertungen

- Schedule Levels - Major Projects: Core Scheduling Papers: #6Dokument5 SeitenSchedule Levels - Major Projects: Core Scheduling Papers: #6EDUARDONoch keine Bewertungen

- 5921 D E DWG 0105 - RevADokument6 Seiten5921 D E DWG 0105 - RevAEDUARDONoch keine Bewertungen

- Data Sheet: DescriptionDokument6 SeitenData Sheet: DescriptionEDUARDONoch keine Bewertungen

- 5921 D E DWG 0205 - RevADokument6 Seiten5921 D E DWG 0205 - RevAEDUARDONoch keine Bewertungen

- StrainerDokument3 SeitenStrainerEDUARDONoch keine Bewertungen

- Steam BoilerDokument10 SeitenSteam BoilerEDUARDONoch keine Bewertungen

- Sewage Treatment Tank MixerDokument1 SeiteSewage Treatment Tank MixerEDUARDONoch keine Bewertungen

- Silencer Data Sheet ReviewDokument2 SeitenSilencer Data Sheet ReviewEDUARDONoch keine Bewertungen

- Sewage Treatment MenbraneDokument1 SeiteSewage Treatment MenbraneEDUARDONoch keine Bewertungen

- Sewagw Treatment FilterDokument1 SeiteSewagw Treatment FilterEDUARDONoch keine Bewertungen

- Sewage Treatment PlantDokument2 SeitenSewage Treatment PlantEDUARDONoch keine Bewertungen

- Separation CellDokument11 SeitenSeparation CellEDUARDONoch keine Bewertungen

- Sewage Treatment Ultraviolet DeinfectionDokument1 SeiteSewage Treatment Ultraviolet DeinfectionEDUARDONoch keine Bewertungen

- Sewage Treatment FloculantDokument1 SeiteSewage Treatment FloculantEDUARDONoch keine Bewertungen

- Sewage Treatment EfluentDokument5 SeitenSewage Treatment EfluentEDUARDONoch keine Bewertungen

- Grand Prideco Connection Type Lead Taper Thread Height Thread ProfileDokument1 SeiteGrand Prideco Connection Type Lead Taper Thread Height Thread ProfileEdwin MPNoch keine Bewertungen

- Massey Ferguson MF 3635 TRACTOR Service Parts Catalogue Manual (Part Number 1637256)Dokument14 SeitenMassey Ferguson MF 3635 TRACTOR Service Parts Catalogue Manual (Part Number 1637256)qlb898316Noch keine Bewertungen

- Bolt sizes and tightening torquesDokument40 SeitenBolt sizes and tightening torquesponcatoera83% (6)

- 7.5m MMCD DavitDokument1 Seite7.5m MMCD Davitduda_sekaNoch keine Bewertungen

- 7Dokument12 Seiten7juan carlos zavalaNoch keine Bewertungen

- Pakistan Petroleum Tender InvitationDokument32 SeitenPakistan Petroleum Tender Invitationsolid_impactNoch keine Bewertungen

- Tool Maintenance - CU-Profi - Station - C - EN - 02-2022Dokument12 SeitenTool Maintenance - CU-Profi - Station - C - EN - 02-2022RodrigoNoch keine Bewertungen

- Thread Standards & DefinitionsDokument2 SeitenThread Standards & Definitionsspmg222Noch keine Bewertungen

- 7000X Grain HeaderDokument71 Seiten7000X Grain HeaderArmorNoch keine Bewertungen

- Manual Thread Cutting - Cou..Dokument2 SeitenManual Thread Cutting - Cou..Sabir AliNoch keine Bewertungen

- Ce 401 Structural Design Lecture 1: Steel Connections-Bolted ConnectionsDokument22 SeitenCe 401 Structural Design Lecture 1: Steel Connections-Bolted ConnectionsIsrael PopeNoch keine Bewertungen

- Gaurav Bera 18101103064 Machine DrawingDokument3 SeitenGaurav Bera 18101103064 Machine Drawingderek brainNoch keine Bewertungen

- Power ScrewsDokument10 SeitenPower ScrewsamanggayamNoch keine Bewertungen

- Unified Thread StandardDokument8 SeitenUnified Thread Standarddanaka007Noch keine Bewertungen

- Ocean Cot-Bed Instructions - Mamas & Papas PDFDokument16 SeitenOcean Cot-Bed Instructions - Mamas & Papas PDFJulieNoch keine Bewertungen

- More More Value! Value!Dokument4 SeitenMore More Value! Value!dimulerNoch keine Bewertungen

- Stub - Acme - Thread - Data - Sheets Rev ADokument4 SeitenStub - Acme - Thread - Data - Sheets Rev Aakaalj qhseNoch keine Bewertungen

- ThreadTables PDFDokument1 SeiteThreadTables PDFRichard HockleyNoch keine Bewertungen

- EJOT - AcupointDokument1 SeiteEJOT - AcupointLucas VeronaNoch keine Bewertungen

- Din 6914Dokument2 SeitenDin 6914vpjagannaathNoch keine Bewertungen

- Screw DimensionDokument2 SeitenScrew DimensionAbhijeet SinghNoch keine Bewertungen

- 12m Gate Design 18.04.2023-ModelDokument1 Seite12m Gate Design 18.04.2023-ModelQS SSA UnionNoch keine Bewertungen

- BE-80 Gear Pump Parts ListDokument1 SeiteBE-80 Gear Pump Parts ListMauricio Ariel H. OrellanaNoch keine Bewertungen

- Hes A3003-03 Chamfer of Thread EndDokument5 SeitenHes A3003-03 Chamfer of Thread EndPreetam Kumar100% (1)

- Lista de Materiales 6KDokument3 SeitenLista de Materiales 6KRoyer SanchezNoch keine Bewertungen

- HSFG WeightsDokument2 SeitenHSFG WeightssirfrakeshNoch keine Bewertungen

- 01 MF FastenersDokument15 Seiten01 MF FastenerspattersondxbNoch keine Bewertungen

- Figure UG-34 Forged HeadDokument8 SeitenFigure UG-34 Forged Headmiteshpatel191Noch keine Bewertungen

- Manual Esmeril DW758Dokument4 SeitenManual Esmeril DW758marlon diazNoch keine Bewertungen

- LifeFitness LOW ROW MJRW Low RowDokument8 SeitenLifeFitness LOW ROW MJRW Low RowpowerliftermiloNoch keine Bewertungen