Beruflich Dokumente

Kultur Dokumente

VA1 LSC 00100 QA M8 TPD 0006 (Steel Structure Fabrication Procedure) Rev.1

Hochgeladen von

MungNguyenDinhOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

VA1 LSC 00100 QA M8 TPD 0006 (Steel Structure Fabrication Procedure) Rev.1

Hochgeladen von

MungNguyenDinhCopyright:

Verfügbare Formate

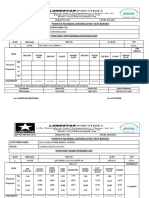

DOCUMENT SUBMISSION STATUS: FC

30/03/11

ISSUED FOR CONSTRUCTION

T.V.CUONG

D.V.HIEU

P.N.QUANG

11/03/11

ISSUED FOR CONSTRUCTION

T.V.CUONG

D.V.HIEU

N.H.QUAN

26/01/11

ISSUED FOR APPROVAL

T.V.CUONG

N.V.BIEN

P.N.QUANG

D

C

B

10/01/11

18/11/10

29/10/10

ISSUED FOR APPROVAL

ISSUED FOR APPROVAL

ISSUED FOR APPROVAL

REV

DATE

PREP.

CHKD

APPN

DESCRIPTION

OWNER

OWNERS CONSULTANT

POYRY ENERGY LTD

VIETNAM OIL AND GAS GROUP (PVN)

EPC CONTRACTOR

EPC CONTRACTORS CONSULTANT

VIETNAM MACHINERY

INSTALLATION CORPORATION (LILAMA)

PROJECT TITLE

VUNG ANG 1 THERMAL POWER PLANT 2 x 600MW

PACKAGE: M8

CONTRACT No.

222010/ LILAMA-LISEMCO

DRAWING TITLE:

steel structure FABRICATION PROCEDURE

SUB-CONTRACTOR

HAIPHONG EQUIPMENT MANUFACTURE AND

SHIPBUILDING CO.LTD, (LISEMCO)

DOCUMENT No.VA1-LSC-00100-QA-M8-TPD-0006

FUNCTION

NAME

SIGN

PREPARED

TO VIET CUONG

30/03/11

CHECKED

DAM VAN HIEU

30/03/11

APPROVED

PHAM NGOC QUANG

30/03/11

SCALE

DATE

REV. 1

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 1/19

Steel structure Fabrication

Procedure

project

Vung Ang1 Thermal Power Plant

Item

COAL HANDLING SYSTEM M8

location

Ky Loi commune - Ky Anh District-Ha Tinh province

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 2/19

Index

No

Title

Page

Chapter 1: General Introduction.

Chapter 2: Fabrication procedure.

Chapter 3: Fabrication method.

Chapter 1: General Introduction

I. General Introduction

1. Executing Organization Chart (As shown in page 4).

Hai phong Equipment Manufacture and Shipbuilding CO., LTD

a. Responsibilities and rights

Hai Phong Equipment Manufacture and Shipbuilding CO., LTD is a member

company belonging to Vietnam Machinery Installation Corporation (LILAMA).

With its big site plan (8ha), modern equipment, and the teams of experienced

engineer and equipped with knowledge and new executing technologies, a large

number of workers as well as skillful workers, Hai phong Equipment

Manufacture and Shipbuilding CO., LTD is responsible for providing materials

and installation of equipment for Vung Ang 1 thermal power plant 2x600 MWCoal handling plant M-lot 2

All steel structure will be fabricated in factory of Lisemco in Hai Phong to

ensure quality, error and convenience for installation process of steel structure.

The whole process of structural steel fabrication, company will carry out by

itself equipment and staff member.

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 3/19

b. The director of project

Full name: Nguyen Hong Quan

Position:

Project Director

Tel

: 031-3522496

Fax

: 031-3850120.

: vungangpj@lisemco.com.vn

2. Inspection unit- quality control

Inspection unit quality control belonging to quality control Department which

is an independent organization with in manufacturing units operating under the

leaderships of the parent company, is responsible for quality control, checking to

ensure the steps of manufacturing technology and installation implemented

seriously for quality assurance of construction.

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Mar. 30th, 2011

Rev: 1

Vung Ang 1 Thermal Power Plant

Code: VA1-LSC-00100-QA-M8-TPD-0006

Ky Loi commune, Ky Anh district, Ha Tinh province

Page: 4/19

ITEM: COAL HANDLING SYSTEM M8

ORGANIZATION CHART FOR LOT-M8

VUNG ANG 1.THERMALPOWER PLANT PROJECT

LILAMA PMB

LISEMCO ltd,.

GENERAL DIRECTOR

Mr. TRAN VIET KHANH

Email: lisemco@hn.vnn.vn

PROJECT MANAGER

Mr.NGUYEN HONG QUAN

E-mail: quanhn.nd37@gmail.com

psb.lisemco@vnn.vn

PROJECT COORDINATOR

Mr. TO VIET CUONG

Mobi: 01696815187

E-mail: vietcuong.lisemco@gmail.com

DEPUTY PROJECT MANAGER

& SITE MANAGER

MANUFACTURING MANAGER

Mr. NGUYEN VAN BIEN

Mobi: 0989126635

E-mail: Bienlisemco@yahoo.com.vn

Mr. PHAM NGOC QUANG

E-mail: ngocquang32id@gmail.com

RECEIVING EQUIPMENT

AND HAND MANAGER

OFFICE MANAGER

Mr. NGUYEN DINH QUYNH

Ms.TRUONG THI HUONG

Ms.HO THI KHANH HOA

SAFETY&SECURITY MANAGER

QC/QA PRJ. MANAGER

Mr.PHAN VAN HUNG

Ms: NGUYEN THI LAM

Mr. VU VAN QUANG

Mr MAI HUY CUONG

Mr.VU DUC THANH

TECHNICAL MANAGEMENT

MATERIALS MANAGEMENT

Mr. DO XUAN DUNG

Mobi: 0982592029

Mr. BUI DUC THIET

Mobi: 0904828298

SAFETY&SE MANAGEMENT

QC/QA PRJ. MANAGEMENT

Mr. PHAM VAN TUYEN

Mobi: 0934692591

E-mail: tuyen.lisemco@gmail.com

Mr. NGUYEN QUANG VINH

WORK SHOP SUPERVISOR

ENGINEERS

ELECTRICIAN+

INSULATING+

COMMISSONING

TEAM 01

PEPLE 19

STEEL STRUCTURE

+MECHANIC

TEAM-02

PEPLE 30

PAINTER

TEAM - 01

PEPLE 8

WELDER

TEAM - 01

PEPLE 15

WORK-SHOP No1

WORK-SHOP No2

Mr NGUYEN VAN DOANH

Mr. NGUYEN VAN HUNG

MECHANIC AND WELDER

TEAM - 25

MECHANIC AND WELDER

TEAM - 25

STEEL STRUCTURE

TEAM 02

PEOPLE 35

STEEL STRUCTURE

TEAM 02

PEOPLE 35

PAINTING

PACKING & SHIPPMENT

Mr.DOANVAN HA

PAINTING

TEAM-01

PEOPLE 12

PACKING & SHIPPMENT

TEAM -01

PEOPLE 06

Date of isuue: Otc 12th, 2010

Inspection unit- quality control has rights of suspending activities which not

comply with procedures , and has risk of bad influence on quality manufactured

products as well as installation leading bad effects on construction quality.

Inspection shall followed he details in lines with the approved ITP which are

completed by LILAMA.

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 5/19

3. Reference:

- Specification of the project.

- FLS General Workshop instructions.

- Document No. VA1-LI-00100-M-G1-ITP-0002 INSPECTION AND TEST

PLAN FOR STEEL STRUCTURE SHOP FABRICATION

- Document No. VA1-LI-00100-QA-G1-ITP-0001 INSPECTION AND TEST

PLAN FOR PAINTING

- Standard: DIN.

4. Shop, fabrication teams

Fabrication teams are responsible for executing construction in accordance with

design, quality assurance and work progress and directly carry out at shop in

lisemco.

In case of unexpected problems in construction process exceeds the capacity of

fabrication units. They can request related parts supporting technology,

eqiupment, manpower. All the requirements of fabrication groups must be

presented in writen form system of Lisemco (in case the customers do not have

special

requiremetns). These requirements are given Economy-Technology

Department, Lisemco. Economy-Technology Department must have answer in

writen form within 24 hours.

II. Objects, scopes and references.

1. Objects

The process of structural steel fabrication is to give a manufacturing scientific

plan, strict inspection system, ensuring quality to meet the quality control system

ISO 9001 : 2000 which company Lisemco is applying, also satifies the

customers requirements about product quality and construction progress.

2. Application scope

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 6/19

This process is applied to fabrication equipment and manufacturing of steel

structure.

3. References

Shop drawings, related technical documents and standards.

The technical standards are given by Owner.

4. Fabrication chart and inspection

o

Content of

Work

Implementation unit Inspection criteria Evaluation

criteria

-Check

input -Executing technology

materials.

-Material officer.

-Quality control

- Supervisor party A

- Original

- Number

- Dimension

- Visual inspection

Inspection tools Report form

Certificate

o- Certificates

Manufacturer.

- Comparing orders

- Accroding to Tape-measure,

order

caliper

- No wrapping, - By visual.

rust, blistery.

- Marking and - Workers

- Dimension, beveled - Design drawing. - Tape-measure.

cutting

- Executing technology angel.

-Inspections

- Quality control

- External insepction.

-Straightening - Workers

Dimension, - Design drawing Welding

joint

-Detailed

-Executing technology. straightness,

welding and error.

checking

tapeassembly

- Quality control.

joint prepared.

measure,

control

- External inspection.

-Inspection

wire,

- Assembly.

- Workers

- Straightness, square, -Design drawing - Meter, tape for

Assembly - Executing technogy

dimension...

and error

inspection of square

inspection

- Quality control

angle.

- Supervisor party A

- Welding beam, - Welder with valid - According to welding

pillar, accessory. certificates.

procedure system.

External -Executing technology. Welding

joint - According to - By visual, welding

inspection.

- Quality control.

surrounding.

welding procedure. joint tape inspection.

Checking

by

-Nondestructive - Supervisor party A.

-External inspection.

Tecnical testing.

- Subcontractor.

- Cheking welding joint requirement

of ultrasonic.

construction.

inside.

- Welders.

According

to - Accroding to - Grinder, welding

Repairingdefects - Subcontractor.

inspection results.

quality

machine.

.

-External inspection.

requirement

of - By visual, checking

-Checking and

- Cheking welding joint construction.

by ultrasonic.

fixing.

inside.

- Sanding blast, - Manufacturing unit.

paint.

- Executing technology

- Quality control.

Painting - Supervisor party A.

inspection.

- Surfaces preparation - According to - Checking by visual.

and paint.

technical

- Checking by gauge

- Painting inspection. requirement (see for

measuring

painting

thickness of paint.

procedure).

III. Construction organization design.

1 -Bases on the construction design.

- Basing on technical standards of designer.

- Basing on tecnical design document of construction.

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 7/19

- Basing on real condition of construction plan and construction work

quantity.

- Basing on rate canculating document for construction and construction

organization.

- Basing on material capacity, machinery, and manpower.

2 - Construction organization design.

Construction organization is very important task ensuring fast construction

process and achieved the best effect. The contractor will be responsible for this

task. They carry out the supported work like working platform, storage, yards of

materials gathered as well as products, water allocation system for construction.

The construction work quantity is mainly organized as follows:

In the shop of company

+ Fabrication of steel structure.

+ Cleaning, painting steel structure.

In the construction process, contractor is in full compliance with technical

procedures, rules and regulations of acceptance in accordance with designers

standard and owners requirement.

Basing on construction plan, the contractor carries out to clean ground, prepare

assembling platform, machinery for construction work.

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 8/19

Chapter 2: Fabrication procedure

Material receiving

Returni

Inspectio

False

Delivery for units

Cutting

Repairing

Inspectio

False

Tack welding

Repairing

Inspectio

False

Finish welding

Repairing

Inspectio

False

Assembly

Repairing

Inspectio

False

acceptance report

blast cleaning

Repairing

Inspectio

False

acceptance report

finish painting

Repairing

Inspectio

False

acceptance report

Packing

Complete payment

document

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 9/19

Chapter 3: Fabricating methods

I. Check input materials of Work.

According to designers requirements, Contractor supply types of material

having clear origin, attaching material certificate.

Material inspection made as below requirement:

- Check material certificate of origin.

- Standard geometrical size: check by tape-measure, caliper

- Surface: convex, concave, void, crack, warping

- Technical characteristics of material:

- Physical-mechanical properties of steel: sampling, testing and certificating.

- Welding material properties according approved WPS & PQR.

- Components, properties of other materials.

- Control, inspection process of input materials for works following to designers

standard and the below diagram:

Materials

Delivering to company

HaiPhong equipment

Manufacture and

Shipbuilding CO., LTD

material department

inspection, correlation,storage

certificate of quality, quantity,

weight

Gim st cng ty (QC)

check size, type of materials...

A partys supervisor

inspect steel tag,

...

type of materials

Type of steel for fabrication works consist of:

1. Steel plate according to project standard, or appropriate

2. Steel shape according to project standard, or appropriate

3. Materials service for fabrication: welding material, painting material, the

other auxiliary materials

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 10/19

Entire above materials strictly controlled and monitored according to materials

summary tables including detailed data. After be imported to Company, the

materials delivered to executing units for fabrication

II. Construction ground preparing.

In order to service for fabrication as well as asembly all parts in Company,

Company perform arrangement the construction ground at units. Assemblying

platform for fabrication and inspection carefully prepared achieving standard

surface.

III. Products fabricating

Common fabricating steps:

Step 1: The parts shall be marked and cut according to marking and cutting dwgs

and design dwgs.

Marking and cutting according to the diagram shall be performed by assembly

group, parts marked and cut on the platform under the control, monitoring of

shop, group engineering staff, and QC of Company. The parts must be checked

the size, cleaness, beveled angle, hole welding, ... according to the Project

standard by Companys QC during marking and cutting process, when QC find

out that the parts achieving requirement, they shall be moved to the next stage.

Step 2: Assembly parts

After cutting, the parts shall be moved to assembling areas where assembling

work made by assembling group. Companys QC inspects the size, joint

clearance, tack welding, reinforced measure against deformationwhen these

achieve the Projects standard, the parts moved to the welding stage.

Before welding, structure should be inspected according to FIT-UP

INSPECTION FOR WELDING No: VA1-QCF-M-15 in document No: VA1-LI00100-M-GI-ITP-0002 (INSPECTION AND TEST PLAN FOR STEEL

STRUCTURE SHOP FABRICATION).

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Mar. 30th, 2011

Rev: 1

Vung Ang 1 Thermal Power Plant

Code: VA1-LSC-00100-QA-M8-TPD-0006

Ky Loi commune, Ky Anh district, Ha Tinh province

Page: 11/19

ITEM: COAL HANDLING SYSTEM M8

Step 3: Welding

Welded connection executed according to welding procedure (WPS) which

Lisemco submitted to the Owner and supervisors, consultants. This procedure

performed by welders having valid certificates. Overall welding process strictly

inspected by welding QC about welding materials, the welders, quality of

welding jointsso as to restrict welding defects and avoid failures at the

beginning of the stage. All welding joints checked 100% external form

according to technical requirement of the project. The defected welding joints

shall be carried out to prepare following to repairing welding joint procedure

during inspection. .

Size of the parts inspected after finish welding ensuring to be in allowable

tolerance of the Project.

The weld should be inspection according to WELDING VISUAL RECORDS

No:

VA1-QCF-M-14

in

document

No:

VA1-LI-00100-M-GI-ITP-0002

(INSPECTION AND TEST PLAN FOR STEEL STRUCTURE SHOP

FABRICATION).

After welding, the struture should be inspection according to STEEL

STRUCTURE FABRICATION FINAL INSPECTION REPORT No: VA1QCF-M-013

in

the

document

No:

VA1-LI-00100-M-G1-ITP-0002

(INSPECTION AND TEST PLAN FOR STEEL STRUCTURE SHOP

FABRICATION) before painting.

All of taking-over form made according to Projects requirements and after the

parties ( the Owner, TVGS, LISEMCO contractor) have finished signing the

acceptance certificate, then move to painting stage

*) Welding procedure specification, process welding, and NDT for welding

work of reclaimers, stackers, unloaders, and towers shall be completely followed

FLS General Workshop Instructions which was issued.

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 12/19

Step 4: Painting.

After checking according to STEEL STRUCTURE INSPECTION RECORD

BEFORE PAINTING No: VA1-QCF-M-012 in the document No: VA1-LI00100-M-G1-ITP-0002 (INSPECTION AND TEST PLAN FOR STEEL

STRUCTURE SHOP FABRICATION), products will be cleaned by abrasive

grain for blasting, boring machine for hard-to-handle, ensuring technical

requirements of this project. The quality control is ensured to move painting

stage and final acceptance for packing.

All the acceptance forms are made according to project requirements and after

the parties signed acceptance report to move the working stage, its time for

packing.

Due to design of parts with its own features, the construction part of work like

scraper, piler, unloader, tower of project have some different features.

III.1.The fabrication of Reclaimer: the fabrication of each unit

The cutting stage must carry out on CNC machine. After cutting, the plates are

connected together according to working drawing and finish welding for

connecting plates; check Nondectructive testing (NDT). If these results are

achived, conduct the assembly beam. The platform is used for assembly beam,

for example:

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Steel structure Fabrication Procedure

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 13/19

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 14/19

During beam assembling in three-sided process, each unit is connected

completely according to design set, bracing to avoid welding deformation; and

then weld the whole beam inside. After checking by visual about welding of

beam inside, cap the plate to control the dimension of the beam and conduct to

welding finish. Checking by visual the overall dimensions of welding seam; the

flatness of beam sides according to the length design of beam. If these results

achieved, conduct Nondestructive testing and acceptance to move for cleaning

and painting.

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 15/19

Roller support is made with the same way.

Dump bailer supports in fabricating procedure and inspection are skidded on the

platform.

Dump bailer will be fabricated and accepted in accordance with gauge.

All units connecting together which are difficult to clean and paint, after

finishing, they are cleaned and painted with anticorrosive paint before

assembling.

The remains of scraper will be completely fabricated, accepted and finish

painting at the LISEMCO Contractors shop, and then conduct to assembly and

install.

III.2. The fabrication of Stacker: the fabrication of each unit

The cutting stage must carry out on CNC machine. After cutting, the plates are

connected together according to working drawing and finish welding for

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 16/19

connecting plates; check Nondestructive testing (NDT). If these results are

achieved, conduct the assembly beam. The platform is used for assembly beam.

During beam assembling in three-sided process, each unit is connected

completely according to design set, bracing to avoid welding deformation; and

then weld the whole beam inside. After checking by visual about welding of

beam inside, cap the plate to control the dimension of the beam and conduct to

welding finish. Checking by visual the overall dimensions of welding seam; the

flatness of beam sides according to the length design of beam. If these results

achieved, conduct Nondestructive testing and acceptance to move for cleaning

and painting.

Roller support is made with the same way.

Band conveyor support in fabricating process and inspection is performed on

gauge support.

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 17/19

All units connecting together which are difficult to clean and paint, after

finishing, they are cleaned and painted with anticorrosive paint before

assembling.

The remains of Stacker will be completely fabricated, accepted and finish

painting at the LISEMCO Contractors shop, and then conduct to assembly and

install.

III.3. Unloader machine fabrication : execution with each unit.

Cutting stage performed by CNC machine. After pleteting , the plates connected

according to fabrication drawing and finishing welded, if NDT checking is

achieved, beam assembling will be implemented. Platform used for this work

During beam assembling in three-sided process, each unit is connected

completely according to design set, bracing to avoid welding deformation; and

then weld the whole beam inside. After checking by visual about welding of

beam inside, cap the plate to control the dimension of the beam and conduct to

welding finish. Checking by visual the overall dimensions of welding seam; the

flatness of beam sides according to the length design of beam. If these results

achieved, conduct Nondestructive testing and acceptance to move for cleaning

and painting.

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Vung Ang 1 Thermal Power Plant

Ky Loi commune, Ky Anh district, Ha Tinh province

ITEM: COAL HANDLING SYSTEM M8

Mar. 30th, 2011

Rev: 1

Code: VA1-LSC-00100-QA-M8-TPD-0006

Page: 18/19

The remains of unloader will be made with the same way and cleaned and

painted at the LISEMCO Contractors shop, and then conduct to pack and

install.

III.4. Fabrication for direction turning tower: Because tower structure

coupling bolt, so fabrication process is process which fabricate loose parts , after

that testing assembly each unit.

+ The pillar, beam are cut by steel shape (I,V...) with right dimension, marked by

arrows directing position of gusset plate, attaching gusset plate after drilling

hole.

+ Bracing is performed with cutting dimension, attached gusset plate, welding,

dimension inspection after welding and flatness, then move to clean and paint.

Steel structure Fabrication Procedure

Hai phong equipment manufacture and

shipbuilding company limited

Mar. 30th, 2011

Rev: 1

Vung Ang 1 Thermal Power Plant

Code: VA1-LSC-00100-QA-M8-TPD-0006

Ky Loi commune, Ky Anh district, Ha Tinh province

Page: 19/19

ITEM: COAL HANDLING SYSTEM M8

+ Platform and ladder are fabricated with the same way.

+ After loose materials are checked, cleaned and painted.

+ Packing and installing in construction site.

IV. Inspection of dimensional tolerance

+ Measurement testing, tolerance in dimension acceptance inspection according

to project standards (Document no:VA1-FLS-00100-M-M2-DST-6040)

TOLERANCES

>0.5

30

120

315

1000

2000

4000

8000

12000 16000 20000

12000 16000 20000

30

120

315

1000

2000

4000

8000

0.1

0.1

0.2

0.3

0.5

0.8

1.2

0.2

0.5

0.2

0.5

10

12

14

=3

0.8

1.2

3 < S = 50

1.5

1.5

2.5

3.5

50 < S = 100

2.5

2.5

3.5

4.5

L=10

10<L=50

50<L=120

120<L=315

1.8/100 mm

0.9/100 mm

0.6/100 mm

0.3/100 mm

2.6/100 mm

1.5/100 mm

0.7/100 mm

0.4/100 mm

5.2/100 mm

3.5/100 mm

1.8/100 mm

1.3/100 mm

Steel structure Fabrication Procedure

315<L=1000

L>1000

0.9/100 mm

0.6/100 mm

16

Das könnte Ihnen auch gefallen

- Fabrication Method For HSM 2 ProjectDokument14 SeitenFabrication Method For HSM 2 ProjectMikiRoniWijayaNoch keine Bewertungen

- 3 Steel Structure Installation CLDokument2 Seiten3 Steel Structure Installation CLwhah11Noch keine Bewertungen

- LPP-013-MEC-VP-042-V - WELDING MAP DEMIN WATER TANK 10GCL10BB001 Eng ReviewDokument13 SeitenLPP-013-MEC-VP-042-V - WELDING MAP DEMIN WATER TANK 10GCL10BB001 Eng ReviewabdiNoch keine Bewertungen

- Api-Mip-5lDokument76 SeitenApi-Mip-5lVan LinhNoch keine Bewertungen

- Hydrostatic Test Procedure For Ug Non-Metallic Piping SystemDokument16 SeitenHydrostatic Test Procedure For Ug Non-Metallic Piping SystemabrayalamNoch keine Bewertungen

- Inspection and Test Plan Piping Works Main Deck, Service Platform, Module, EtcDokument3 SeitenInspection and Test Plan Piping Works Main Deck, Service Platform, Module, Etcaditya kokoNoch keine Bewertungen

- P6012MAB.000.10.03.771 - O3 - With JV Comments PDFDokument27 SeitenP6012MAB.000.10.03.771 - O3 - With JV Comments PDFMukesh MuraleedharanNoch keine Bewertungen

- MD1-0-T-030-05-00071 ITP For Steel Structure ErectionDokument10 SeitenMD1-0-T-030-05-00071 ITP For Steel Structure ErectionTran KhuynhNoch keine Bewertungen

- General Method Statement R1.Dokument21 SeitenGeneral Method Statement R1.Ganjar Dreadlocks NugrahaNoch keine Bewertungen

- MD1-0-T-030-05-00072 - ITP For AG Piping of Alloy SteelDokument8 SeitenMD1-0-T-030-05-00072 - ITP For AG Piping of Alloy SteelTran KhuynhNoch keine Bewertungen

- Welding Specification ChartDokument189 SeitenWelding Specification ChartVivek SatapathyNoch keine Bewertungen

- 6.9. Handling Storage & Preservation ProcedureDokument10 Seiten6.9. Handling Storage & Preservation Procedurerendra syamNoch keine Bewertungen

- Wps Mig PDF FreeDokument3 SeitenWps Mig PDF Freehanz bermejoNoch keine Bewertungen

- Inspection Test and Plan For Storage Tank For Material Carbon SteelDokument5 SeitenInspection Test and Plan For Storage Tank For Material Carbon SteelPLTU SULUT QC PASTINoch keine Bewertungen

- Pmi ReportDokument5 SeitenPmi ReportMANIMARAN QCNoch keine Bewertungen

- Lifting Sequence Boiler Steel StructureDokument18 SeitenLifting Sequence Boiler Steel StructureXwerty BoxNoch keine Bewertungen

- MD1 0 T 052 05 00114 CDokument20 SeitenMD1 0 T 052 05 00114 Chunkenx01100% (1)

- Updated Rigging and Lifting Plan GTG 2 OverhaulingDokument2 SeitenUpdated Rigging and Lifting Plan GTG 2 OverhaulingHamzaNoumanNoch keine Bewertungen

- Foundation Calculation For Gasline Pig Receiver (2020 - 01 - 20)Dokument107 SeitenFoundation Calculation For Gasline Pig Receiver (2020 - 01 - 20)Didi Hadi RiantoNoch keine Bewertungen

- GK04-SM-6P-00-202 Rev.B Steel Structure Erection ProcedureDokument15 SeitenGK04-SM-6P-00-202 Rev.B Steel Structure Erection ProcedureElias EliasNoch keine Bewertungen

- ITP Installation of Boiler - R1Dokument14 SeitenITP Installation of Boiler - R1crys100% (4)

- Cover MDR, MDR Index Dan Pembatas (Rev)Dokument19 SeitenCover MDR, MDR Index Dan Pembatas (Rev)Richard Adolf100% (1)

- (WMS) Piping Installation Around Eqipment Procedure (AFC) REV.F#Dokument20 Seiten(WMS) Piping Installation Around Eqipment Procedure (AFC) REV.F#Norman MoralesNoch keine Bewertungen

- Fabrication ProcedureDokument12 SeitenFabrication ProcedureDwikappa Asri UtamaNoch keine Bewertungen

- Standard PracticeDokument14 SeitenStandard PracticeRomi Abdul RahmanNoch keine Bewertungen

- W2021C-DNGF-CV-900-SPE-0001 - RevBSpecification For Structural SteelDokument22 SeitenW2021C-DNGF-CV-900-SPE-0001 - RevBSpecification For Structural SteelDidi Hadi RiantoNoch keine Bewertungen

- PROJ 1051 FAB 001 - 2 Fabrication ProcedureDokument13 SeitenPROJ 1051 FAB 001 - 2 Fabrication ProcedureIksan Adityo MulyoNoch keine Bewertungen

- 0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDokument11 Seiten0468-Asom20-92p1-0006-001 - Flange Repair and Machining (Revised) PDFDenny AgusNoch keine Bewertungen

- Monthly Progress ReportDokument15 SeitenMonthly Progress Reportyoonchankim0911Noch keine Bewertungen

- 17-020-Ms-002 Welding For Fuel Gas r2Dokument53 Seiten17-020-Ms-002 Welding For Fuel Gas r2Alaa M. GhazalahNoch keine Bewertungen

- FORM DimensionalDokument15 SeitenFORM DimensionalAlbet MulyonoNoch keine Bewertungen

- Activity Report Running WPS & PQRDokument3 SeitenActivity Report Running WPS & PQRAndre Brama AlvariNoch keine Bewertungen

- Nde Map & Nde Procedure (Sudah Di Revisi)Dokument4 SeitenNde Map & Nde Procedure (Sudah Di Revisi)Hardika SambilangNoch keine Bewertungen

- QMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Dokument10 SeitenQMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Vasilica BarbarasaNoch keine Bewertungen

- F-CD-19 Pipe and Weld Book 26-Abr-19Dokument84 SeitenF-CD-19 Pipe and Weld Book 26-Abr-19Jorge Isaac Lara RamosNoch keine Bewertungen

- Procedure For Instalattion of VesselDokument6 SeitenProcedure For Instalattion of Vesselyayan hNoch keine Bewertungen

- Itp Transfer Tower - Xls (Bvi Comment)Dokument52 SeitenItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNoch keine Bewertungen

- RFI Chipping & PaddingDokument80 SeitenRFI Chipping & Paddingcrys suryo prayogoNoch keine Bewertungen

- Condensate Tank WELDING LOGDokument6 SeitenCondensate Tank WELDING LOGhasan shahriarNoch keine Bewertungen

- Stack WeldingDokument76 SeitenStack WeldingKatie Ramirez100% (1)

- Jms Demolishing RGTP p20220019 Esb Con Jms 9243 0002 ADokument14 SeitenJms Demolishing RGTP p20220019 Esb Con Jms 9243 0002 Aamir hakimNoch keine Bewertungen

- Calculation 240 (Rev02)Dokument15 SeitenCalculation 240 (Rev02)KM YapNoch keine Bewertungen

- 001 Detail Welding Map For Site Project Economizer (PLTU Malinau 2x3 MW)Dokument22 Seiten001 Detail Welding Map For Site Project Economizer (PLTU Malinau 2x3 MW)Muhammad Fitransyah Syamsuar Putra100% (2)

- Standard Inspection & Test Plan (ITP) FOR Tank PadDokument5 SeitenStandard Inspection & Test Plan (ITP) FOR Tank PaddendyNoch keine Bewertungen

- Afes Calc. of Found. Diesel Oil TankDokument52 SeitenAfes Calc. of Found. Diesel Oil TankIman RahmatullahNoch keine Bewertungen

- Welding ProceduresDokument29 SeitenWelding ProceduresLaith Salman100% (1)

- RAPID-FE1-TPX-CMM-SPN-0001-0903, Rev 1Dokument6 SeitenRAPID-FE1-TPX-CMM-SPN-0001-0903, Rev 1Đình NamNoch keine Bewertungen

- Procedure-Part-A - Structural Works - PDFDokument58 SeitenProcedure-Part-A - Structural Works - PDFquiron2014Noch keine Bewertungen

- 105-Structural Steel ErectionDokument7 Seiten105-Structural Steel Erectionzaki fadlNoch keine Bewertungen

- Gangway Tower Preservation Procedure On SiteDokument4 SeitenGangway Tower Preservation Procedure On SiteSalim Mohd RazNoch keine Bewertungen

- MSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryDokument1 SeiteMSOG-QAQC-F-19 Welder Qualification Test (WQT) SummaryMohd SaffririzalNoch keine Bewertungen

- Sub-Contractor Comments Response Sheet: Ain Tsila DevelopmentDokument23 SeitenSub-Contractor Comments Response Sheet: Ain Tsila DevelopmentZaidiNoch keine Bewertungen

- Erection Boiler Method StatementDokument62 SeitenErection Boiler Method StatementsatheeshkumarNoch keine Bewertungen

- F5063a-K-003-00 NDT Procedure PDFDokument11 SeitenF5063a-K-003-00 NDT Procedure PDFJatmika Budi SantosaNoch keine Bewertungen

- Ms For Repair and Welding Jointscoating and PaintingDokument9 SeitenMs For Repair and Welding Jointscoating and Paintingmansih457100% (1)

- Installation Procedure For TowerDokument4 SeitenInstallation Procedure For TowerRachel FloresNoch keine Bewertungen

- Fabrication of Steel Structure and Steel Equipment (Itp)Dokument4 SeitenFabrication of Steel Structure and Steel Equipment (Itp)Javed MANoch keine Bewertungen

- KP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSDokument21 SeitenKP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSUtku Can KılıçNoch keine Bewertungen

- Itp For Fabrication Steel Structure of Warehouse and WorkshopDokument6 SeitenItp For Fabrication Steel Structure of Warehouse and WorkshopPhong Do100% (1)

- Mechanical Engineer - Bui Van DiepDokument5 SeitenMechanical Engineer - Bui Van DiepHieuNoch keine Bewertungen

- Paper:: 01 Human Resource Management 17Dokument14 SeitenPaper:: 01 Human Resource Management 17dadapeer h mNoch keine Bewertungen

- Bugreport 2022 01 04 15 15 29 Dumpstate - Log 29625Dokument3 SeitenBugreport 2022 01 04 15 15 29 Dumpstate - Log 29625Yorman Ruiz AcstaNoch keine Bewertungen

- Piping Insulation Types of Pipe Insulation With PDFDokument7 SeitenPiping Insulation Types of Pipe Insulation With PDFSo SacarNoch keine Bewertungen

- Asset Management Council 1205 TheAsset0602 PDFDokument48 SeitenAsset Management Council 1205 TheAsset0602 PDFSushmit SharmaNoch keine Bewertungen

- OptiX OSN 8800 6800 3800 Supporting Tasks (V100R008)Dokument290 SeitenOptiX OSN 8800 6800 3800 Supporting Tasks (V100R008)Thunder-Link.comNoch keine Bewertungen

- Keywords: Choice of Jurisdiction, Choice of Law, International Business Disputes in IndonesiaDokument32 SeitenKeywords: Choice of Jurisdiction, Choice of Law, International Business Disputes in IndonesiaLee Xiang'sNoch keine Bewertungen

- Gold Prospecting in OhioDokument2 SeitenGold Prospecting in OhioJannette FerreriaNoch keine Bewertungen

- Narrative Report de ChavezDokument48 SeitenNarrative Report de ChavezGerald De ChavezNoch keine Bewertungen

- Debate-Script 1Dokument3 SeitenDebate-Script 1api-537254339Noch keine Bewertungen

- Lab 5 - InformationDokument11 SeitenLab 5 - InformationTomas PirirNoch keine Bewertungen

- Cambium PTP 250 Series 02-14 System Release NoteDokument6 SeitenCambium PTP 250 Series 02-14 System Release NotemensoNoch keine Bewertungen

- National Food Safety Standard - General Safety Requirements On Food Contact Materials and ArticlesDokument4 SeitenNational Food Safety Standard - General Safety Requirements On Food Contact Materials and ArticlesShariq HaiderNoch keine Bewertungen

- Nur Shazleen Afina 2021794579 Forum DiscussionDokument4 SeitenNur Shazleen Afina 2021794579 Forum DiscussionNur Shazleen AfinaNoch keine Bewertungen

- Designing Data Analysis ProcedureDokument15 SeitenDesigning Data Analysis ProcedureShadowStorm X3GNoch keine Bewertungen

- Port Scanning Tools AdhiDokument10 SeitenPort Scanning Tools AdhiCinthuja KaliyamoorthyNoch keine Bewertungen

- Viva Website1Dokument8 SeitenViva Website1api-61083281Noch keine Bewertungen

- CS Training With See YesDokument8 SeitenCS Training With See Yesvjkaha100% (4)

- FIN350 Quiz 2 Monday First Name - Last Name - Version BDokument6 SeitenFIN350 Quiz 2 Monday First Name - Last Name - Version BHella Mae RambunayNoch keine Bewertungen

- 1 s2.0 S2213343717303950 MainDokument9 Seiten1 s2.0 S2213343717303950 MainSeyram DavidNoch keine Bewertungen

- United States v. Juvenal Martinez Alvarado, 321 F.2d 336, 2d Cir. (1963)Dokument5 SeitenUnited States v. Juvenal Martinez Alvarado, 321 F.2d 336, 2d Cir. (1963)Scribd Government DocsNoch keine Bewertungen

- Syllabus Income TaxationDokument10 SeitenSyllabus Income TaxationValery Joy CerenadoNoch keine Bewertungen

- Pumper March 2011 IssueDokument108 SeitenPumper March 2011 IssuePumper MagazineNoch keine Bewertungen

- Possible Test1Dokument32 SeitenPossible Test1Azim Jivani100% (3)

- Rishabh Malhotra - Offer LetterDokument4 SeitenRishabh Malhotra - Offer LetterrishabhNoch keine Bewertungen

- 2-CFOT Handout 23Dokument113 Seiten2-CFOT Handout 23SumitNoch keine Bewertungen

- Jcss Probabilistic Modelcode Part 3: Resistance ModelsDokument4 SeitenJcss Probabilistic Modelcode Part 3: Resistance Modelsdimitrios25Noch keine Bewertungen

- Test HariharanDokument6 SeitenTest HariharanHàrìhàrån Ďe CàssîaNoch keine Bewertungen

- Ward Clerk - GenericgfgfDokument3 SeitenWard Clerk - GenericgfgfNeil OsborneNoch keine Bewertungen

- NDEC Medication Standing Orders General InformationDokument2 SeitenNDEC Medication Standing Orders General InformationSillieteNoch keine Bewertungen

- Day Care CentersDokument16 SeitenDay Care CentersAndreea RaduNoch keine Bewertungen