Beruflich Dokumente

Kultur Dokumente

January 2005 Programming

Hochgeladen von

jegan1720 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

6 Ansichten1 SeiteOriginaltitel

Cnc Manual

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

6 Ansichten1 SeiteJanuary 2005 Programming

Hochgeladen von

jegan172Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

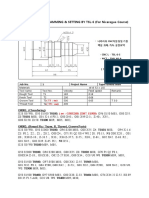

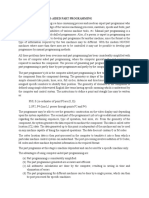

% :Program must begin and end with a %

O00018 ; :Letter O and a five digit program number

(CNC LATHE PROGRAM EXAMPLE) ; :Comment statement between parenthesis

N1 (Rough O.D.) ; :First operation

G28 ; :Return to machine zero for a tool change, cancel tool offset

T101 (O.D. TOOL x .031 TNR) ; :Select tool 1 with offset 1

G50 S2600 ; :Set spindle speed max. clamp 2600 RPM

G97 S414 M03 ; :Cancel CSS, 415 spindle speed, on forward

G54 G00 X3.6 Z0.1 MO8 ; :Work offset, rapid X, Z axes, coolant on

G96 S390 ; :CSS on at 390 SFM, coolant on

G00 Z0.005 ; :Rapid to .005 from the end of part

G01 X-0.063 F0.005 ; :Rough face end of part

G00 X3.6 Z0.1 ; :Rapid to start point above part

G71 P10 Q20 U0.01 W0.005 D0.1 F0.01 ;:Rough turning G71 canned cycle using the path

defined

:between N10 thru N20, leaving .010 stock on the X-axis

:diameters, .005 stock on the linear faces, with 0.1 depth

:of cut each pass, feeding .010 per revolution.

N10 G42 G00 X0.82 ; :N10 is the starting block called by the P block in the G71

G01 Z0. F0.004 ; :line that difines in it the geometery to rough out.

19

JANUARY 2005 PROGRAMMING

X0.9 ;

Das könnte Ihnen auch gefallen

- Module 2 Part 1Dokument147 SeitenModule 2 Part 1FRANCIS THOMASNoch keine Bewertungen

- Haas G72 Type I Rough and G70 Finish Facing Program ExampleDokument3 SeitenHaas G72 Type I Rough and G70 Finish Facing Program ExampleCnc Page100% (1)

- My CNCDokument5 SeitenMy CNCzoranteicNoch keine Bewertungen

- CNC Milling ReportDokument10 SeitenCNC Milling ReportDheeraj audichyaNoch keine Bewertungen

- CNC English Code Controller SystemDokument17 SeitenCNC English Code Controller Systemmarciano1980Noch keine Bewertungen

- CNC Milling ReportDokument10 SeitenCNC Milling ReportMohammad AL-MasriNoch keine Bewertungen

- CAM ASSIGNMENT RutuDokument10 SeitenCAM ASSIGNMENT RutuksdrNoch keine Bewertungen

- CNC Turning ExamplesDokument69 SeitenCNC Turning ExamplesThenarasumohanvelu100% (2)

- Haas TM-1P Vertical CNC Machining CenterDokument3 SeitenHaas TM-1P Vertical CNC Machining CenterSabir AliNoch keine Bewertungen

- CNC Lathe S& T P, G & Setting.1Dokument4 SeitenCNC Lathe S& T P, G & Setting.1marciano1980Noch keine Bewertungen

- Manufacturing of Rock Lever Shaft and Cam Follower in CNC MachineDokument28 SeitenManufacturing of Rock Lever Shaft and Cam Follower in CNC Machinepallivenu289Noch keine Bewertungen

- 6 Semester: Student ProfileDokument19 Seiten6 Semester: Student Profilealokkumar707977Noch keine Bewertungen

- 00 EAGLE FANUC OiDokument60 Seiten00 EAGLE FANUC OiFranciscoDanielRamirezFloresNoch keine Bewertungen

- Training Programme On CNC LatheDokument33 SeitenTraining Programme On CNC Lathesharafudheen_sNoch keine Bewertungen

- Programming GcodeDokument6 SeitenProgramming GcoderamjoceNoch keine Bewertungen

- Lathe NotesDokument48 SeitenLathe NotesMOUSIN PASHANoch keine Bewertungen

- CNC ProgrammingDokument48 SeitenCNC Programminglakshmichandranath889Noch keine Bewertungen

- How To Use Charly 4U Milling Mchine Using The GcodeDokument18 SeitenHow To Use Charly 4U Milling Mchine Using The GcodeAnish KumarNoch keine Bewertungen

- VMC ProgrammingDokument22 SeitenVMC ProgrammingDynamic bhagwanNoch keine Bewertungen

- Lesson Eighteen TextDokument4 SeitenLesson Eighteen TextVignesh WaranNoch keine Bewertungen

- Tugas Rutin Iv CNC - JulyadyDokument11 SeitenTugas Rutin Iv CNC - JulyadyNovita P SilalahiNoch keine Bewertungen

- Special G Codes of CNC ProgrammingDokument14 SeitenSpecial G Codes of CNC ProgrammingSimon Risteski100% (1)

- Slide01 Introduction CNCDokument149 SeitenSlide01 Introduction CNCalexiskandarNoch keine Bewertungen

- CNC ProgDokument38 SeitenCNC ProgPoornima JoshiNoch keine Bewertungen

- Chapter Two 2. Manual NC Part ProgrammingDokument33 SeitenChapter Two 2. Manual NC Part ProgrammingMulugeta WoldeNoch keine Bewertungen

- NC Part ProgrammingDokument57 SeitenNC Part ProgramminglijinthomasNoch keine Bewertungen

- Special G Codes of CNC ProgrammingDokument14 SeitenSpecial G Codes of CNC ProgrammingAntónio OliveiraNoch keine Bewertungen

- CNC Programming 1Dokument26 SeitenCNC Programming 1mohamed alsalhyNoch keine Bewertungen

- MSC Lecture 6Dokument28 SeitenMSC Lecture 6Chán Chênh VênhNoch keine Bewertungen

- Milling ProgramDokument20 SeitenMilling ProgramSudeep Kumar SinghNoch keine Bewertungen

- Experiment 6 - CNC Programing-MillingDokument9 SeitenExperiment 6 - CNC Programing-MillingG. Dancer GhNoch keine Bewertungen

- Fanuc CNC Lathe ProgrammingDokument3 SeitenFanuc CNC Lathe Programmingnaborcuellar100% (1)

- 2 CNCPDokument104 Seiten2 CNCPAnvit TiwariNoch keine Bewertungen

- 3 G Codes Part 1 CNC PDFDokument23 Seiten3 G Codes Part 1 CNC PDFMichael CampbellNoch keine Bewertungen

- Basic CNC Programming V2Dokument76 SeitenBasic CNC Programming V2nuzul hamdaniNoch keine Bewertungen

- Lesson Seventeen TextDokument6 SeitenLesson Seventeen TextVignesh WaranNoch keine Bewertungen

- Group 24 (Solar Mobile ChargingDokument22 SeitenGroup 24 (Solar Mobile ChargingBanothu RameshNoch keine Bewertungen

- Tut1 ManualProgram FacemillDokument10 SeitenTut1 ManualProgram FacemillPRABHU JNoch keine Bewertungen

- Assignment Automation and ControlDokument4 SeitenAssignment Automation and ControlSomsay ThongkedNoch keine Bewertungen

- CNC Part ProgrammingDokument61 SeitenCNC Part ProgrammingrajaNoch keine Bewertungen

- FANUC G-Code Education TrainingDokument31 SeitenFANUC G-Code Education TrainingFrancisco MorenoNoch keine Bewertungen

- CNC Shop ManualDokument15 SeitenCNC Shop Manualmsuhani011Noch keine Bewertungen

- G12 Circular Pocket Milling CW G13 Circular Pocket Milling CCW Group 00Dokument3 SeitenG12 Circular Pocket Milling CW G13 Circular Pocket Milling CCW Group 00anwar anwaryNoch keine Bewertungen

- Programing Training Strung OKUMA-OSP100Dokument42 SeitenPrograming Training Strung OKUMA-OSP100IoanAlexandru Stoian80% (15)

- Program Structure: January 2005 ProgrammingDokument1 SeiteProgram Structure: January 2005 Programmingjegan172Noch keine Bewertungen

- CNC TRAINDokument124 SeitenCNC TRAINakshat naiduNoch keine Bewertungen

- CNC-Lab Mechanical ManualDokument21 SeitenCNC-Lab Mechanical ManualHaresh RaisinghaniNoch keine Bewertungen

- CNC ProgrammingDokument27 SeitenCNC ProgrammingAbhijit BiswasNoch keine Bewertungen

- Computer-Aided Part ProgrammingDokument10 SeitenComputer-Aided Part ProgrammingPradip PatelNoch keine Bewertungen

- NC ProgrammingDokument54 SeitenNC ProgrammingVed Vrat NuclearNoch keine Bewertungen

- C - 12 X 3.PGM - Plasma Programming ExampleDokument14 SeitenC - 12 X 3.PGM - Plasma Programming ExampleLeonardo Eladio Vergara GuillenNoch keine Bewertungen

- CNC Turning (Bridgeport)Dokument63 SeitenCNC Turning (Bridgeport)Siti Idah TawhidNoch keine Bewertungen

- CNC Programming WRKB Lathe Sample LockedDokument51 SeitenCNC Programming WRKB Lathe Sample Lockedkree_bigdaddy100% (1)

- CNC Lab ManualDokument25 SeitenCNC Lab Manualiamav31Noch keine Bewertungen

- CCA Report 2 PDFDokument8 SeitenCCA Report 2 PDF39SEAShashi KhatriNoch keine Bewertungen

- Programming MillDokument81 SeitenProgramming MillEddy ZalieNoch keine Bewertungen

- Projects With Microcontrollers And PICCVon EverandProjects With Microcontrollers And PICCBewertung: 5 von 5 Sternen5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- English German French Italian Spanish Japanese Korean Chinese Simplified Chinese TraditionalDokument1 SeiteEnglish German French Italian Spanish Japanese Korean Chinese Simplified Chinese Traditionaljegan172Noch keine Bewertungen

- Creo Is A Family or Suite Of: CocreateDokument1 SeiteCreo Is A Family or Suite Of: Cocreatejegan172Noch keine Bewertungen

- PTC's Mechanical Engineering: Product DesignDokument2 SeitenPTC's Mechanical Engineering: Product Designjegan172Noch keine Bewertungen

- Product Design: 3D Cad Parametric ModelingDokument1 SeiteProduct Design: 3D Cad Parametric Modelingjegan172Noch keine Bewertungen

- Solutions Windchill Product Lifecycle Management (PLM) MathcadDokument1 SeiteSolutions Windchill Product Lifecycle Management (PLM) Mathcadjegan172Noch keine Bewertungen

- English German French Italian Spanish Japanese Korean Chinese Simplified Chinese TraditionalDokument1 SeiteEnglish German French Italian Spanish Japanese Korean Chinese Simplified Chinese Traditionaljegan172Noch keine Bewertungen

- Welcome To CNC Training ProgrammeDokument4 SeitenWelcome To CNC Training Programmejegan172Noch keine Bewertungen

- Ubpro Lling M TH Lu TH B Me THR Uti T TH ND ND TH Uti The Lling #1 LlingDokument1 SeiteUbpro Lling M TH Lu TH B Me THR Uti T TH ND ND TH Uti The Lling #1 Llingjegan172Noch keine Bewertungen

- Branding Client Server Collaborative Software Platform: BM Notes (Formerly Lotus Notes SeeDokument1 SeiteBranding Client Server Collaborative Software Platform: BM Notes (Formerly Lotus Notes Seejegan172Noch keine Bewertungen

- This MacroDokument1 SeiteThis Macrojegan172Noch keine Bewertungen

- Auto CadDokument1 SeiteAuto Cadjegan172Noch keine Bewertungen

- Polar Osnap Osnap PolarDokument2 SeitenPolar Osnap Osnap Polarjegan172Noch keine Bewertungen

- Basic Components of NC Machine SystemDokument1 SeiteBasic Components of NC Machine Systemjegan172Noch keine Bewertungen

- Autocad ProDokument1 SeiteAutocad Projegan172Noch keine Bewertungen

- Autocad 1Dokument1 SeiteAutocad 1jegan172Noch keine Bewertungen

- Basic Components of NC Machine SystemDokument1 SeiteBasic Components of NC Machine Systemjegan172Noch keine Bewertungen

- Autocad TutDokument1 SeiteAutocad Tutjegan172Noch keine Bewertungen

- A Basic Example: Setup and DefinitionsDokument1 SeiteA Basic Example: Setup and Definitionsjegan172Noch keine Bewertungen

- Program Structure: January 2005 ProgrammingDokument1 SeiteProgram Structure: January 2005 Programmingjegan172Noch keine Bewertungen

- A Basic Example: Setup and DefinitionsDokument1 SeiteA Basic Example: Setup and Definitionsjegan172Noch keine Bewertungen

- G Code Example LatheDokument1 SeiteG Code Example Lathejegan172Noch keine Bewertungen

- A Basic Example: Setup and DefinitionsDokument1 SeiteA Basic Example: Setup and Definitionsjegan172Noch keine Bewertungen

- G-Code Program: A Basic ExampleDokument1 SeiteG-Code Program: A Basic Examplejegan172Noch keine Bewertungen