Beruflich Dokumente

Kultur Dokumente

Design capacity calculation of 3X156 KPH electrochlorination system

Hochgeladen von

shriyans5388Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design capacity calculation of 3X156 KPH electrochlorination system

Hochgeladen von

shriyans5388Copyright:

Verfügbare Formate

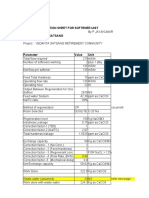

Design capacity Calculation of 3X156 KPH

Electrochlorination System

1. System Capacity

Total flow rate

For continuous Dosing

5760Kg / Day

Continuous dosing (@3 ppm) Cl require

Per Hour Requirement

Shock Dosing (@5ppm) Cl require

kg/Day

Per 20 min in an Hour Requirement

Total chlorine require per day

Total chlorine require per Hr

10% overdesigned is considered

System capacity selected

requirement)

Electro chlorination System

3. Hypo pump Capacity

Continuous Dosing Pump

Total chlorine to be dosed

kg/hr.

Chlorine content in NaOCl

Total NaOCl required

Take 10% extra

NaOCl Pump selected

No. of Pumps

Shock Dosing Pump

Total chlorine to be dosed

kg/hr.

Chlorine content in NaOCl

Total NaOCl

Take 10% extra

NaOCl pump selected

No. of Pumps

80,000 m/hr

80,000 X 3 X 24 =

=

=

1000

240 kg/hr.

2. Sea Water Pump Capacity

Sea water required for 1 kg/ hr.

Chlorine Production

Sea water required for 156 kg / hr.

Chlorine Production

Sea water pump capacity 10% extra

Sea water pump selected

specification)

No. of sea water pump

=

=

80,000 x 5 x 1 = 400

1000

=

134 kg per 20 min

=

5760+400=6160 kg /Day

=

6160 /24 = 256.66 kg/Hr

=

282.33 kg / hr

311 kg/hr. (as per client

=

3X156 kph (3x50%)

666.66 liters / hr.

=

156 x 666.66

103.99 m / hr.

=

114m/ hr.

120 m/ hr. (as per

=

3 (2W=1S)

5760 kg/day = 5760/24=240

1.5 GMS/ ltrs

=

240 /1.5 = 160 m/ hr.

=

176 m/ hr.

=

176 m

=

2 (1W+1S) (2x100%)

=

=

=

400 kg/day = 400/1 =400

1.5 gems / ltrs

400 / 1.5 = 266.67 m/hr

=

294 m/hr

=

147 m

=

3 (2W=1S) (3X50%)

4. NaOCl tank Capacity

Tank size selected for continuous Dosing

No. of tanks for contionous dosing

Tank size selected for shock dosing

No. of tanks

=

5. Blower Capacity

1 kg Cl

hr

=

=

=

Air (99%) required for dilution

hr

Blower capacity for 1kg/hr

Blower required for continuous dosing

Blower selected

No. of blowers

Blower required for shock Dosing

Blower selected

No. of blowers

=

20m

=

1 Nos.

=

30m

4 Nos.

=

=

=

=

6. DC Output ( Transformer Rectifier)

Voltage Calculation

No. of Electrolyzer per unit

No. of cell in each Electrolyzer

Total Nos. of Cells

=

Voltage required per cell

=

Voltage required for system

28.43gms of H release/

316 liters H/hr

0.316 m/hr

=

0.316 x 99 = 31.284 m /

=

31.284 m/hr

=

240 x 31.284

7507.2 m/hr

2252.16 m/hr

8000m/hr

=

2(1W+1S)

=

72x31.284

2500 m/hr

=

2 (1W+1S)

=

3 Nos.

=

10 Nos.

10 x 3 = 30

4 V or 4.5 V

=

total no. of cell x voltage

required per cell

=

30 x 4.5 = 135 V DC

Current Calculation

Total capacity of system

Current required for 1 kg/hr system

Total no. of cell

Current required for the system

kg/hr x current in

=

=

=

=

=

=

=

Required voltage & current for each stream

Ampere + total no. of cell

156 x 1000 +30

5200 A DC

=

135 V and 5200 A (DC) (only

indicative exact

detail

140 kg/hr

1000 A

30 Nos.

total cap of system in

Requirement shall be done during

engineer)

Das könnte Ihnen auch gefallen

- Aeration Tank and Clarifier DesignDokument6 SeitenAeration Tank and Clarifier DesignRajesh NareNoch keine Bewertungen

- Design and Operating Parameters of Electro Chlorination PlantDokument5 SeitenDesign and Operating Parameters of Electro Chlorination PlantKarthik SriramakavachamNoch keine Bewertungen

- Cooling Water Demand CalcDokument29 SeitenCooling Water Demand CalczamijakaNoch keine Bewertungen

- Guide to Water Treatment ChemicalsDokument136 SeitenGuide to Water Treatment ChemicalsBinyam KebedeNoch keine Bewertungen

- Chemical Pump Dosing CalcsDokument4 SeitenChemical Pump Dosing CalcsAnonymous BJ9omONoch keine Bewertungen

- Water Softner Design VedantaDokument5 SeitenWater Softner Design Vedantajaianit89Noch keine Bewertungen

- Rapid Mix Design Calculation 1Dokument4 SeitenRapid Mix Design Calculation 1Yang Ching HianNoch keine Bewertungen

- CIP Procedure of RO MembraneDokument2 SeitenCIP Procedure of RO MembraneTanzila SiddiquiNoch keine Bewertungen

- Healthcare Insulin ProblemDokument16 SeitenHealthcare Insulin ProblemTaufiq JaiNoch keine Bewertungen

- Water CalculationDokument6 SeitenWater CalculationRamkiNoch keine Bewertungen

- Process Design For 1.70 IFAS STPDokument18 SeitenProcess Design For 1.70 IFAS STPGenesis International0% (1)

- STP Design (With Aeration Tank)Dokument16 SeitenSTP Design (With Aeration Tank)Sagar Patel.Noch keine Bewertungen

- Electrochlor Ination System Operating and MaintenanceDokument50 SeitenElectrochlor Ination System Operating and Maintenancejarbas.otoni75% (4)

- Presentation - August 2016Dokument118 SeitenPresentation - August 2016shriyans5388Noch keine Bewertungen

- Electrochlorination Basic Process Training PDFDokument40 SeitenElectrochlorination Basic Process Training PDFraghuvarma100% (4)

- Water Treatment DegasifierDokument6 SeitenWater Treatment DegasifierEDUARDONoch keine Bewertungen

- Water Dosing Calculation BookDokument12 SeitenWater Dosing Calculation BookSugumar Panneer SelvamNoch keine Bewertungen

- Process Design of A Complete Sewage Treatment PlantDokument10 SeitenProcess Design of A Complete Sewage Treatment PlantSatish Charuvil100% (4)

- Design of Each Process of ETPDokument9 SeitenDesign of Each Process of ETPFaisal Sr. ExecutiveNoch keine Bewertungen

- WW ExcelDokument5 SeitenWW Excelpartha6789Noch keine Bewertungen

- SOP: Calculate OBR for DM-MB and CPU-MBDokument1 SeiteSOP: Calculate OBR for DM-MB and CPU-MBsoumitrabanNoch keine Bewertungen

- Design Calculation For Softener UnitDokument12 SeitenDesign Calculation For Softener Unitaraikun74775% (8)

- Basic Engineering Calculations-R1Dokument5 SeitenBasic Engineering Calculations-R1Prashant HuddarNoch keine Bewertungen

- Grit Removal DesignDokument5 SeitenGrit Removal Designnassif75Noch keine Bewertungen

- Design Calculation Sewage PitDokument12 SeitenDesign Calculation Sewage PitM N Hoda67% (3)

- 105.a.0 - RO-DM Plant Chain Sizing CalcDokument7 Seiten105.a.0 - RO-DM Plant Chain Sizing Calcmkchy12Noch keine Bewertungen

- Design of Ultra Filtration MembraneDokument3 SeitenDesign of Ultra Filtration MembraneMuhammad Zubair SharifNoch keine Bewertungen

- Coagulation and FlocctuationDokument35 SeitenCoagulation and FlocctuationAvinash Januzaj ChateeNoch keine Bewertungen

- Preliminar Calculo BlowerDokument3 SeitenPreliminar Calculo BlowerAlejo BaronNoch keine Bewertungen

- How To Calculate Resin Capacity For Softener - Softening PlantDokument10 SeitenHow To Calculate Resin Capacity For Softener - Softening PlantNithi Anand100% (4)

- Side Stream FiltrationDokument8 SeitenSide Stream FiltrationAhmed WagihNoch keine Bewertungen

- ES0153-75320100-DBR-0001DM PlantDokument73 SeitenES0153-75320100-DBR-0001DM Plantraaj bharath100% (1)

- Revised Material Balance of Waste Water Treatment PlantDokument28 SeitenRevised Material Balance of Waste Water Treatment Plantjobya_4100% (1)

- Chlorine Energy 2520 BalanceDokument4 SeitenChlorine Energy 2520 Balancetonzz10Noch keine Bewertungen

- Advanced Wastewater TreatmentDokument16 SeitenAdvanced Wastewater TreatmentvikkykambleNoch keine Bewertungen

- Pre TreatmentDokument65 SeitenPre TreatmentSagar SewlaniNoch keine Bewertungen

- DM Plant CulationDokument2 SeitenDM Plant CulationMukesh KumarNoch keine Bewertungen

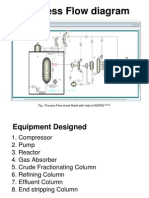

- Process Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENDokument42 SeitenProcess Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENSwarnim RajNoch keine Bewertungen

- Wastewater Treatment TechnologyDokument125 SeitenWastewater Treatment TechnologySheryl MH-PradaNoch keine Bewertungen

- DM Plant DesignDokument13 SeitenDM Plant DesignRavi Kumar100% (4)

- Basic Cooling Water Management IIDokument32 SeitenBasic Cooling Water Management IIDiaa GobranNoch keine Bewertungen

- Electrochlorination Basic Process TrainingDokument40 SeitenElectrochlorination Basic Process Trainingraghuvarma50% (2)

- Dose The Right Amount of ChemicalsDokument3 SeitenDose The Right Amount of ChemicalsrajachemNoch keine Bewertungen

- Design Basis: M/S Space Combine Kind Attn: Mr. Arun VishwakarmaDokument6 SeitenDesign Basis: M/S Space Combine Kind Attn: Mr. Arun Vishwakarmabyajaytyagi2266Noch keine Bewertungen

- 20 KLD STP Upgreation PROPOSAL-GMCPLDokument7 Seiten20 KLD STP Upgreation PROPOSAL-GMCPLTech Monger100% (1)

- Blower Calculation STP WWTPDokument3 SeitenBlower Calculation STP WWTPrizky hardiNoch keine Bewertungen

- Water Treatment PlantDokument28 SeitenWater Treatment PlantVuthpalachaitanya Krishna0% (1)

- Chlorination Mass Balance Calculation: Legend Overall Reactions (Mol/Hr)Dokument2 SeitenChlorination Mass Balance Calculation: Legend Overall Reactions (Mol/Hr)Husni RadiyanNoch keine Bewertungen

- Sistem SelcopermDokument39 SeitenSistem SelcopermGROIIM100% (1)

- Today'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"Dokument57 SeitenToday'S Topic "Cooling Water Treatement" "Condenser Leak Detection" "Chlorination Plant" AND "Effluent Treatment"saravan1891Noch keine Bewertungen

- Continuous Production Electrochlorinator Sea - Water - Based PDFDokument4 SeitenContinuous Production Electrochlorinator Sea - Water - Based PDFdubaisrinivasuluNoch keine Bewertungen

- MM Aqua Technologies LTD.: TubedekDokument47 SeitenMM Aqua Technologies LTD.: TubedekSourabh Manuja100% (1)

- Effluent Treatment Plant Tech Report for LAIL Sugar MillDokument28 SeitenEffluent Treatment Plant Tech Report for LAIL Sugar MillGarad MadhukarNoch keine Bewertungen

- SPE 131137 Steady-State Heat Transfer Models For Fully and Partially Buried PipelinesDokument27 SeitenSPE 131137 Steady-State Heat Transfer Models For Fully and Partially Buried Pipelinesmostafa shahrabi100% (1)

- Tank sizing design calculations and ratio checksDokument2 SeitenTank sizing design calculations and ratio checksaike_5Noch keine Bewertungen

- AVGFDokument56 SeitenAVGFDhruv Shah0% (1)

- RO Water System SpecificationDokument16 SeitenRO Water System SpecificationZachi UkiNoch keine Bewertungen

- 40 KLD MBR QuoteDokument15 Seiten40 KLD MBR QuoteV Narasimha RajuNoch keine Bewertungen

- ABE Quiz Bee Week 4: Easy QuestionsDokument7 SeitenABE Quiz Bee Week 4: Easy QuestionsKevin V LampaanNoch keine Bewertungen

- Atles Extaction System & Ancillary Equipment Operational CostsDokument1 SeiteAtles Extaction System & Ancillary Equipment Operational CostsDavidNoch keine Bewertungen

- Dso1 Studyguide VideosDokument68 SeitenDso1 Studyguide VideosRam CaceresNoch keine Bewertungen

- 1Dokument1 Seite1shriyans5388Noch keine Bewertungen

- Action PlanDokument6 SeitenAction Planshriyans5388Noch keine Bewertungen

- Statoil Lets Contracts For Work On 20 NCS Installations: by OGJ EditorsDokument1 SeiteStatoil Lets Contracts For Work On 20 NCS Installations: by OGJ Editorsshriyans5388Noch keine Bewertungen

- 1 - Icefield Gyro ToolsDokument4 Seiten1 - Icefield Gyro Toolsshriyans5388Noch keine Bewertungen

- Industrial Water Jet Hose Specifications and PricesDokument1 SeiteIndustrial Water Jet Hose Specifications and Pricesshriyans5388Noch keine Bewertungen

- Chemical Properties Item Description Unit QTY 1 Liquid Antifoam Drums 20Dokument2 SeitenChemical Properties Item Description Unit QTY 1 Liquid Antifoam Drums 20shriyans5388Noch keine Bewertungen

- Asset Flow Chart 11Dokument1 SeiteAsset Flow Chart 11shriyans5388Noch keine Bewertungen

- Look Inside The Extremely Rare, The Weirdest Encyclopedia EverDokument6 SeitenLook Inside The Extremely Rare, The Weirdest Encyclopedia Evershriyans5388Noch keine Bewertungen

- CD-MSC 07-03a Rev01 Sample GMDSS Radio Log BookDokument2 SeitenCD-MSC 07-03a Rev01 Sample GMDSS Radio Log Bookshriyans5388Noch keine Bewertungen

- Encyclopaedia of IslamDokument5 SeitenEncyclopaedia of Islamshriyans5388Noch keine Bewertungen

- Look Inside The Extremely Rare, The Weirdest Encyclopedia EverDokument6 SeitenLook Inside The Extremely Rare, The Weirdest Encyclopedia Evershriyans5388Noch keine Bewertungen

- Look Inside The Extremely Rare, The Weirdest Encyclopedia EverDokument6 SeitenLook Inside The Extremely Rare, The Weirdest Encyclopedia Evershriyans5388Noch keine Bewertungen