Beruflich Dokumente

Kultur Dokumente

Flange PK

Hochgeladen von

BenOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Flange PK

Hochgeladen von

BenCopyright:

Verfügbare Formate

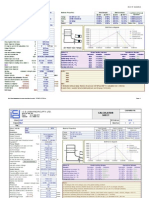

ICD (Asia Pacific) Pty. Ltd.

Bottom Feed Entry Nozzle Flange

ICD J/N 0510

ICD (Asia Pacific) Pty. Ltd.

Bottom Feed Entry Nozzle Flange

ICD J/N 0510

ICD (Asia Pacific) Pty. Ltd.

3.6965089

Operating

OK

OK

OK

OK

OK

Bottom Feed Entry Nozzle Flange

ICD J/N 0510

ICD (Asia Pacific) Pty. Ltd.

Bottom Feed Entry Nozzle Flange

ICD J/N 0510

ICD (Asia Pacific) Pty. Ltd.

C6=

C7=

C8=

C9=

C10=

C11=

C12=

C13=

C14=

C15=

C16=

C17=

Gasket

OK

OK

OK

OK

OK

Bottom Feed Entry Nozzle Flange

ICD J/N 0510

ICD (Asia Pacific) Pty. Ltd.

Bottom Feed Entry Nozzle Flange

ICD J/N 0510

I.C.D. (ASIA PACIFIC) PTY. LTD.

ACN 087 485 087

Phone

61 2 9636 3777

Facsimile

61 2 9688 4124

Calculation No.

CALCULATION

SHEET - Bolted flange

design to AS1210

Client:

ICD Job no:

Project:

Sheet no:

Title: BOTTOM FEED ENTRY NOZZLE FLANGE

INTEGRAL FLANGE DESIGN TAPERED HUB TYPE - AS1210 - 1997 ( As per fig. 3.21.3 (l)

Design Conditions

0.785PG

= 111,437

2bGmP

= 50,192

= 1,651

mm2

Material Properties

Am2 = bGy Sfa

= 8,098

mm2

Bolting : ASTM A193 B8M Class 1

W g = 0.5Sa(Am+Ab)

= 1,929,424

HD = 0.785BP

= 38,470

H=

Design Pressure P =

0.550

MPag

Design Temperature

210

Sfo @ 210 C =

97.89

MPa

Sfa @ 50 C =

129.60

MPa

Hp =

Am1 = H+HP Sfo

Moments Arms For Operating Conditions

Flange : ASTM A182 F321

Sfo @ 210 C =

88.80

MPa

Sfa @ 50 C =

129.00

MPa

(As Per Table 3.21.6.5)

hD = (C-B-g1) 2

= 145.25

mm

hG = (C-G) 2

hT = (C-B)4+ (hg 2)

= 72.98

mm

= 125.37

mm

Flange Moments For Operating Conditions

Flange Details

(As Per Rule 3.21.6.5 )

A=

743.00

mm

MD = HDhD

= 5,587,752

Nmm

C=

654.00

mm

MG = HGhG

= 3,662,977

Nmm

G=

508.04

mm

MT = (H-HD)hT

= 9,147,481

Nmm

= 18,398,210

Nmm

B=

298.50

M op

mm

Flange Moments For Gasket Seating

Gasket Details

Spiral Wound 321ss With Anti-Oxidation

Mg =

= 140,809,334

Nmm

Filled with 321ss Inner and Outer Rings

M=

M operating B

= 61,636

Nmm

M gasket B

= 471,723

Nmm

O.D.=

527.10

mm

I.D.=

469.90

mm

Face :

1a

N=

bo =

28.60

mm

14.30

mm

b=

9.52947

mm

m=

3.00

y=

69.00

Use

20

Bolts

41.275

Dia.

Area =

Ab =

1083.87

mm 2

21,677.4

mm 2

Am =

8,097.7

mm2

g1 =

65.00

mm

go =

12.70

mm

102.73

mm

Pitch =

M Gasket

(As Per Rule 3.21.6.5)

W ghG =

1 5/8"- 8

OK

OK

Check Bolt Spacing as Per Rule 3.21.4.1

Pb = (2Db)+((6t) (m+ 0.5))

Pb = 224.15

mm

Use

t=

82.60

mm

h=

55.00

mm

Integral Factors

d = (UV)hogo

d = 513,868.7

g1go = 5.1181

QF-20

Rev. B

Page 1 of 1

ho = (Bgo)

ho = 61.571

hho= 0.8933

L = (te+1)T+(t) d

L = 2.5216

e = Fho

e = 0.011052706

Gasket Seating Governs

Prepared by: D.Oliff

Authorised by: B.Watson

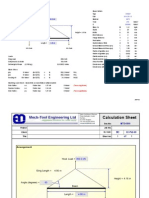

ICD (Asia Pacific) Pty. Ltd.

UNSTAYED FLAT ENDS AND COVERS

AS1210 - 1997 Rule 3.15

Note : To suit Integral Flange Design

0

Minimum calculated thickness for circular ends:

AS1210 - 1997 Rule 3.15.3

For Bolted Ends,Covers, and Blind Flanges with Edge Moments See Fig. 3.15.1(k) and (I)

t = D[(P K)+(1.78Whg ) (D )]

Where:

Temp. =

For Operating Conditions

D = 1082.46

mm

P = 0.350

MPag

K = 3.3

Refer Fig. 3.15.1 (k)

= 35.00

MPa

Material :

1.0

W = H + Hp

N

H = 111,436.7

N

Hp = 50,191.5

N

W = 161,628.2

N

hg = 72.98

mm

Ca = 1.0

ASTM A185 F5

550

mm

t calc = 64.07

mm

For Gasket Seating

D = 1082.46

P= 0

K = 3.3

= 121.00

1.0

W = 1,929,423.6

hg = 73.0

Ca = 1.0

t calc = 43.74

Therefore

550

t=

Temp. =

50

mm

mm

MPag

MPa

Material :

ASTM A185 F5

50

N

mm

mm

mm

t=

65.07

65.07

t=

mm

t actual =

115.8

44.74

mm

mm

OK

ICD J/N 0510

Blind Flange for Manway A12

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Patel, Anita - Super Indian Snack and Street Food Recipes PDFDokument117 SeitenPatel, Anita - Super Indian Snack and Street Food Recipes PDFBella ImèneNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- FlangeCalc AS1210 v1.5Dokument28 SeitenFlangeCalc AS1210 v1.5Ben100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 3rd Quarter Examination in Hope 4Dokument5 Seiten3rd Quarter Examination in Hope 4Hazel Joan Tan100% (3)

- Role of BisoprololDokument43 SeitenRole of BisoprololFidel Martua Marpaung67% (3)

- Spreader Beam CalcDokument2 SeitenSpreader Beam CalcBen100% (3)

- Spreader Beam CalcDokument2 SeitenSpreader Beam CalcBen100% (3)

- Padeye CheckDokument12 SeitenPadeye CheckBen100% (1)

- STPM Mathematics T Past Year Question P1 P2 P3Dokument19 SeitenSTPM Mathematics T Past Year Question P1 P2 P3Sou Voyage0% (3)

- Process Pipeline Repair ClampsDokument4 SeitenProcess Pipeline Repair ClampsHeru SuryoNoch keine Bewertungen

- Seismic Isolation For Buildings Catalog 2013 by Bridgestone Corp - Multi Rubber BearingDokument44 SeitenSeismic Isolation For Buildings Catalog 2013 by Bridgestone Corp - Multi Rubber BearingitetejacNoch keine Bewertungen

- Flange Diagrams1Dokument9 SeitenFlange Diagrams1BenNoch keine Bewertungen

- Learn Horse Riding: at HPRCDokument16 SeitenLearn Horse Riding: at HPRCAkashNoch keine Bewertungen

- Research Paper On TurbojetDokument6 SeitenResearch Paper On Turbojetqptwukrif100% (1)

- CompAir 4-Pages SmartAir MasterDokument4 SeitenCompAir 4-Pages SmartAir MasterKaisar Ahmed BhuyanNoch keine Bewertungen

- Vibration ControlDokument513 SeitenVibration ControlchandankrdumkaNoch keine Bewertungen

- Metal-Tek Electric Contact Cleaner Spray - TDS (2021)Dokument1 SeiteMetal-Tek Electric Contact Cleaner Spray - TDS (2021)metal-tek asteNoch keine Bewertungen

- Perbedaan Fermentasi Dan Respirasi Anaerob (Campbell Biology 12th Ed.)Dokument4 SeitenPerbedaan Fermentasi Dan Respirasi Anaerob (Campbell Biology 12th Ed.)Oppof7 OppoNoch keine Bewertungen

- DEH S4150BT Owners Manual PDFDokument96 SeitenDEH S4150BT Owners Manual PDFfatih konaçoğluNoch keine Bewertungen

- Do Now:: Please Come in and Complete The Worksheet at Your Desk!Dokument13 SeitenDo Now:: Please Come in and Complete The Worksheet at Your Desk!api-278483100Noch keine Bewertungen

- Catalyst PreparationDokument15 SeitenCatalyst PreparationVISHAL SHARMANoch keine Bewertungen

- Harmonization of HR Policies - RoughDokument119 SeitenHarmonization of HR Policies - RoughFrancis SoiNoch keine Bewertungen

- User Manual For Emvólio: WWW - Blackfrog.InDokument22 SeitenUser Manual For Emvólio: WWW - Blackfrog.InmariaNoch keine Bewertungen

- Ancient CivilizationsDokument9 SeitenAncient CivilizationsMarienne LaoNoch keine Bewertungen

- A Better World - Volume 5Dokument146 SeitenA Better World - Volume 5Zainuddin BusuNoch keine Bewertungen

- 017 - Chapter 3 - L13Dokument6 Seiten017 - Chapter 3 - L13nanduslns07Noch keine Bewertungen

- Mass, Weigth and Density IGCSEDokument6 SeitenMass, Weigth and Density IGCSEsapiniNoch keine Bewertungen

- Lymphoid OrganDokument23 SeitenLymphoid OrganSwetha RameshNoch keine Bewertungen

- Nuitration in Human 3Dokument2 SeitenNuitration in Human 3Usman AmeenNoch keine Bewertungen

- Nokia 6131 NFCDokument5 SeitenNokia 6131 NFCvetvetNoch keine Bewertungen

- Advent of SkyscrapersDokument27 SeitenAdvent of SkyscrapersJoshua AlboNoch keine Bewertungen

- Karunungang BayanDokument6 SeitenKarunungang BayanGeronimo DiazNoch keine Bewertungen

- 8 - Precast Concrete Structures-Students PDFDokument17 Seiten8 - Precast Concrete Structures-Students PDFsitehabNoch keine Bewertungen

- PVC Duct DesignDokument10 SeitenPVC Duct DesigncitramuaraNoch keine Bewertungen

- BJT Common Emitter Characteristics: Experiment 6Dokument5 SeitenBJT Common Emitter Characteristics: Experiment 6beesahNoch keine Bewertungen

- Fuel Tank Truck Afd-091005-058Dokument40 SeitenFuel Tank Truck Afd-091005-058cascade1100% (1)