Beruflich Dokumente

Kultur Dokumente

283-2009 Fell Down Chain Block

Hochgeladen von

nadhabindhuCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

283-2009 Fell Down Chain Block

Hochgeladen von

nadhabindhuCopyright:

Verfügbare Formate

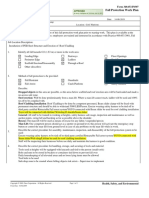

Safety Alert No.

036

Fell Down Chain Block (Near Miss)

Site Name: Chiyoda Construction Site in Japan

Date & Time of Incident: 9:40 Hrs. 5th November 2009

Location of Incident: Construction Site

Type of Job: Lifting of the pipe spool

Type of Incident: Near Miss

Description:

The worker was alone shifting a short pipe spool (6” x 500L, weight approx. 20kg) to the 2nd scaffold

platform from the 2nd floor when he was using the chain block hung from overhead horizontal scaffold pipe by

a webbing sling.

The suspended short pipe spool and the chain block fell down 9m together on the ground due to

uncompleted hooking of the top hook and the webbing sling (No closed fastener). The lifted pipe spool fell

down when it swung to the outside of the hand-rail of 2nd floor. No injured persons.

Webbing sling for lifting

3rd scaffold platform

Not in normal-function

the fastener

2nd scaffold platform

(Locking Device)

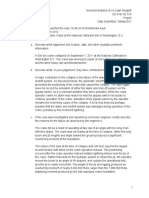

Causal Factor

The worker didn’t check and confirm the top hook, if it is in safe position.

The top hook had no close fastener (Locking Device).

The worker worked alone.

Corrective Actions

As of Near Miss Report:

①Check all chain block at site that the hook fastener must be closed and secured enough hooking with

sling wire rope or webbing sling before re-start of work.

②All lifting job using chain blocks must be checked the top hook of the chain block hooking figure to the

wire eyes or webbing sling, if the fastener completely close.

As comments of the Chiyoda HSE Management Office:

③Supervisors and Foremen receive the training to make everyone well known the Method Statements

and results of Risk Assessments on TBT, KYK and Stand down Meeting etc.

Especially about the lifting job used chain blocks

1) Check the hooks fastener effectiveness always.

2) Confirm the suitability of sling wire eye size and hook size of chain block.

3) Confirm the function of hook fastener and safety measures for their job area before start of lifting.

Das könnte Ihnen auch gefallen

- Dropped Object - Fatale AccidentDokument9 SeitenDropped Object - Fatale Accidentvikrant911Noch keine Bewertungen

- Foreman's Jobsite For The Location For InstallationDokument3 SeitenForeman's Jobsite For The Location For InstallationluqmanmazelanNoch keine Bewertungen

- CC43 ACE-0395-11 Investigation Report - 2Dokument3 SeitenCC43 ACE-0395-11 Investigation Report - 2hatakerobotNoch keine Bewertungen

- HSE Alert 180915 250 Petchem ADCraneTippedOverDokument1 SeiteHSE Alert 180915 250 Petchem ADCraneTippedOveralifNoch keine Bewertungen

- Rig Up Ops Manual - D00625669 - 1Dokument56 SeitenRig Up Ops Manual - D00625669 - 1Prakhar Sarkar100% (3)

- IMCASF - Dec 16Dokument4 SeitenIMCASF - Dec 16Shivkumar JadhavNoch keine Bewertungen

- MS - Gondola System Rev 2Dokument6 SeitenMS - Gondola System Rev 2Non Etabas Gadnatam100% (1)

- SOP Erection TC PDFDokument3 SeitenSOP Erection TC PDFRashidi RahmanNoch keine Bewertungen

- JCTC 57 EME Inspection Checklist 060223 To 110223Dokument2 SeitenJCTC 57 EME Inspection Checklist 060223 To 110223Suresh NaiduNoch keine Bewertungen

- Job Safety Analysis (Jsa) : DQE International Iraq BranchDokument4 SeitenJob Safety Analysis (Jsa) : DQE International Iraq Branchhassan100% (1)

- Passenger HoistDokument10 SeitenPassenger HoistParshant SainiNoch keine Bewertungen

- OSHA's New Rules For Crane-Suspended Personnel PlatformsDokument4 SeitenOSHA's New Rules For Crane-Suspended Personnel PlatformswitwatersrandNoch keine Bewertungen

- Shoring ModifedDokument15 SeitenShoring ModifedMohamed HasafyNoch keine Bewertungen

- Maintenance Y SERIESDokument10 SeitenMaintenance Y SERIESStowartNoch keine Bewertungen

- Jsa For The Installation of I EamDokument5 SeitenJsa For The Installation of I EamMohammed MinhajNoch keine Bewertungen

- Violation TrainingDokument12 SeitenViolation TrainingJey DigNoch keine Bewertungen

- SF 10 23Dokument6 SeitenSF 10 23Gusman TriadyNoch keine Bewertungen

- Porta Cabin Loading - Unloading by Two Hydra JSA HSE ProfessionalsDokument2 SeitenPorta Cabin Loading - Unloading by Two Hydra JSA HSE ProfessionalsSamadov 13Noch keine Bewertungen

- Cement Pipe Loading Unloading and Shifting Erection by Using Hydra JSA HSE ProfessionalsDokument1 SeiteCement Pipe Loading Unloading and Shifting Erection by Using Hydra JSA HSE ProfessionalsViron BaxhiaNoch keine Bewertungen

- Weekly Maintenance On Hydra RackerDokument4 SeitenWeekly Maintenance On Hydra Rackermohamed hamedNoch keine Bewertungen

- Work at Height Permit FormDokument3 SeitenWork at Height Permit FormEbenezer OpuniNoch keine Bewertungen

- 8-General Rules For Erection ProcedureDokument4 Seiten8-General Rules For Erection ProcedurePrijin UnnunnyNoch keine Bewertungen

- S-PCM Minutes of Meeting: Train 02Dokument4 SeitenS-PCM Minutes of Meeting: Train 02sudeesh kumarNoch keine Bewertungen

- Rigging and Pre Lift ChecklistDokument11 SeitenRigging and Pre Lift ChecklistPao Barillas100% (1)

- Technical Notice JAG SYSTEM 1Dokument29 SeitenTechnical Notice JAG SYSTEM 1Domingo Cabeza GuerraNoch keine Bewertungen

- TS2000 Pro Installation GuideDokument8 SeitenTS2000 Pro Installation GuideAhmed MijwilNoch keine Bewertungen

- Hoist ManualDokument14 SeitenHoist ManualgustavovicgarNoch keine Bewertungen

- Hoist and Jib Crane Safety InspectionDokument3 SeitenHoist and Jib Crane Safety InspectionSamsung Joseph0% (1)

- Assembly of Steel StructuresDokument2 SeitenAssembly of Steel StructuresDelta akathehuskyNoch keine Bewertungen

- Safety Notice - Work at HeightDokument5 SeitenSafety Notice - Work at Heightamanda welchNoch keine Bewertungen

- JSA - LOAD TEST PILE No. 1Dokument6 SeitenJSA - LOAD TEST PILE No. 1Sanjeet SinghNoch keine Bewertungen

- Builder Hoist Erection JSA HSE ProfessionalsDokument2 SeitenBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDONoch keine Bewertungen

- Type 678 - Running Instructions: 1. EquipmentDokument18 SeitenType 678 - Running Instructions: 1. EquipmentFabian MontoyaNoch keine Bewertungen

- Robert Laughton Memo Re Job Safety Analysis - 8-2-17Dokument29 SeitenRobert Laughton Memo Re Job Safety Analysis - 8-2-17syed khaja misbhuddinNoch keine Bewertungen

- 3 Monthly PM - OH CraneDokument3 Seiten3 Monthly PM - OH CraneMuhammad RosihanNoch keine Bewertungen

- S08-12 Luffing Jib Tower CranesDokument2 SeitenS08-12 Luffing Jib Tower CranesScooby DooNoch keine Bewertungen

- Part 2 Safe Operation and Use MethodDokument48 SeitenPart 2 Safe Operation and Use MethodrohanNoch keine Bewertungen

- Genie Scissor Lift GS 2632 - SWP Nov 12 2013Dokument5 SeitenGenie Scissor Lift GS 2632 - SWP Nov 12 2013Cvijic DejanNoch keine Bewertungen

- JSA - LOAD TEST PILE No. 1Dokument6 SeitenJSA - LOAD TEST PILE No. 1noahlungu96Noch keine Bewertungen

- Overhead Crane Manual 10tonDokument71 SeitenOverhead Crane Manual 10tonBuddhika MarasinghaNoch keine Bewertungen

- SF 17 22Dokument5 SeitenSF 17 22Shivkumar JadhavNoch keine Bewertungen

- Working at Height and Scaffolding Safety 1Dokument16 SeitenWorking at Height and Scaffolding Safety 1Young BoyNoch keine Bewertungen

- Side Door ElevatorDokument5 SeitenSide Door ElevatorDwi Agung AriyonoNoch keine Bewertungen

- Piping Forklift Operation: - ContentsDokument6 SeitenPiping Forklift Operation: - ContentsHMN YDVNoch keine Bewertungen

- Jsa 36 - Ppu ShedDokument2 SeitenJsa 36 - Ppu ShedgolusinghdataNoch keine Bewertungen

- Fall Protection Work Plan - Roof CladdingDokument2 SeitenFall Protection Work Plan - Roof CladdingGibbs PerNoch keine Bewertungen

- SOP 032 - QC Hoist Wire Rope Replacement - V 2.0Dokument6 SeitenSOP 032 - QC Hoist Wire Rope Replacement - V 2.0ncthanhck0% (1)

- Safety Inspection ChecklistDokument1 SeiteSafety Inspection ChecklistTubagus DikaNoch keine Bewertungen

- MOS Dismantling Aluminium Strips Ceiling and Aluminium Composits PanelDokument5 SeitenMOS Dismantling Aluminium Strips Ceiling and Aluminium Composits PanelAhmad Fauzi Bin OmarNoch keine Bewertungen

- Osha3884 PDFDokument2 SeitenOsha3884 PDFAamir Nazir AwanNoch keine Bewertungen

- Slickline WBEAC October 5 2011Dokument10 SeitenSlickline WBEAC October 5 2011AHMED AMIRANoch keine Bewertungen

- 15-Putting Into ServiceDokument5 Seiten15-Putting Into ServicePrijin UnnunnyNoch keine Bewertungen

- SF 15 23Dokument7 SeitenSF 15 23Shivkumar JadhavNoch keine Bewertungen

- Baldner, Mckenzie & Slingluff, Ke Liilah ProjectDokument2 SeitenBaldner, Mckenzie & Slingluff, Ke Liilah ProjectKé Liilah SlingluffNoch keine Bewertungen

- Pole Unit Install JhaDokument2 SeitenPole Unit Install JhafatimahNoch keine Bewertungen

- Safety Bulletin - Accdient During Ladder Cutting OperationDokument2 SeitenSafety Bulletin - Accdient During Ladder Cutting OperationalberioNoch keine Bewertungen

- JSA Painting Aut Tranformer Unit 3 OutageDokument7 SeitenJSA Painting Aut Tranformer Unit 3 OutageMarhendraNoch keine Bewertungen

- DM Dsi SPEC04Dokument39 SeitenDM Dsi SPEC04nadhabindhuNoch keine Bewertungen

- Asme Specifications SA36 ToSA423Dokument4 SeitenAsme Specifications SA36 ToSA423nadhabindhu0% (1)

- Steel: Statistical Analysis of Steel FormabilityDokument12 SeitenSteel: Statistical Analysis of Steel FormabilitynadhabindhuNoch keine Bewertungen

- Portable & Extension LaddersDokument1 SeitePortable & Extension LaddersnadhabindhuNoch keine Bewertungen

- Presentation 3Dokument1 SeitePresentation 3nadhabindhuNoch keine Bewertungen

- Pinch PointsDokument1 SeitePinch PointsnadhabindhuNoch keine Bewertungen

- 189 Bsu Best Practice Alert - Mobile Elevating Work PlatformsDokument2 Seiten189 Bsu Best Practice Alert - Mobile Elevating Work PlatformsnadhabindhuNoch keine Bewertungen

- Assisting Delivery Name: - Grade: - Year and Section: - DateDokument5 SeitenAssisting Delivery Name: - Grade: - Year and Section: - DateCrisia Jane LotaNoch keine Bewertungen

- JHU Press Fall 2013 CatalogDokument99 SeitenJHU Press Fall 2013 CatalogjhupressNoch keine Bewertungen

- Aldomet: (Methyldopa)Dokument6 SeitenAldomet: (Methyldopa)Riska AuliahNoch keine Bewertungen

- Understanding and Preparing For A CAtHeteRIZAtIon PRoCeDUReDokument7 SeitenUnderstanding and Preparing For A CAtHeteRIZAtIon PRoCeDUReBMTNoch keine Bewertungen

- BURNS SoftDokument3 SeitenBURNS SoftErlo John Asentista0% (1)

- Zombie Brains PDFDokument1 SeiteZombie Brains PDFLorna GrayNoch keine Bewertungen

- Body Image: Marika Tiggemann, Kristy HageDokument7 SeitenBody Image: Marika Tiggemann, Kristy HageRachel VictorianaNoch keine Bewertungen

- ProVari ManualDokument16 SeitenProVari ManualPatrickNoch keine Bewertungen

- Community Medicine DissertationDokument7 SeitenCommunity Medicine DissertationCollegePaperGhostWriterSterlingHeights100% (1)

- English Teacher's NotesDokument24 SeitenEnglish Teacher's NotesPrincess KimNoch keine Bewertungen

- Guidelines For Contemporary Air-Rotor StrippingDokument6 SeitenGuidelines For Contemporary Air-Rotor StrippingGerman Cabrera DiazNoch keine Bewertungen

- UFGS 09 97 13.17 Interior Coating of Steel Petroleum TanksDokument39 SeitenUFGS 09 97 13.17 Interior Coating of Steel Petroleum TanksThomas M RiddleNoch keine Bewertungen

- TNF-dental PulpDokument3 SeitenTNF-dental PulpNicolas PintoNoch keine Bewertungen

- Pollution Is An Unfavorable Change in The Environment That Makes It Less Fit For HumanDokument3 SeitenPollution Is An Unfavorable Change in The Environment That Makes It Less Fit For HumanLouwegie GrabilloNoch keine Bewertungen

- UrethralstricturesDokument37 SeitenUrethralstricturesNinaNoch keine Bewertungen

- Handout On The Concept of Health and Health EducationDokument5 SeitenHandout On The Concept of Health and Health Educationmomo connorNoch keine Bewertungen

- The Rating Scale Is As FollowsDokument3 SeitenThe Rating Scale Is As Followscarollim1008Noch keine Bewertungen

- COSWPDokument7 SeitenCOSWPjquanNoch keine Bewertungen

- Agility For FootballDokument42 SeitenAgility For Footballpflucho100% (2)

- A Comparison Between Indirect and Objective Wear-Time Assessment of Removable Orthodontic AppliancesDokument6 SeitenA Comparison Between Indirect and Objective Wear-Time Assessment of Removable Orthodontic ApplianceshelmysiswantoNoch keine Bewertungen

- Lecture #3 - Carbohydrates & LipidsDokument23 SeitenLecture #3 - Carbohydrates & Lipidsogangurel100% (3)

- 60 Substance Abuse Group Therapy ActivitiesDokument7 Seiten60 Substance Abuse Group Therapy ActivitiesHanes Labajos100% (1)

- Cancer Treatment - Capsaicin - Oil RecipeDokument4 SeitenCancer Treatment - Capsaicin - Oil RecipeJESUS IS RETURNING DURING OUR GENERATIONNoch keine Bewertungen

- Health and Welfare Committee ReportDokument4 SeitenHealth and Welfare Committee ReporttncircuitriderNoch keine Bewertungen

- Oet ReadingDokument118 SeitenOet ReadingSamia FarooqNoch keine Bewertungen

- PARCO Project HSE Closing ReportDokument22 SeitenPARCO Project HSE Closing ReportHabib UllahNoch keine Bewertungen

- Procedure Checklist On OxygenationDokument2 SeitenProcedure Checklist On OxygenationKhatlen BagaresNoch keine Bewertungen

- Business Ethics and Corporate Social Responsibility: Analyze Complex Issues in CSR and Corporate GovernanceDokument6 SeitenBusiness Ethics and Corporate Social Responsibility: Analyze Complex Issues in CSR and Corporate GovernanceDime PierrowNoch keine Bewertungen

- Intermittent Positive Pressure BreathingDokument12 SeitenIntermittent Positive Pressure BreathingHitesh RohitNoch keine Bewertungen

- Syba Economics Syll 20-21Dokument13 SeitenSyba Economics Syll 20-21Saniya ShaikhNoch keine Bewertungen