Beruflich Dokumente

Kultur Dokumente

Piping Fabrication, Installation, Flushing and Testing L-CR-004 Annex B Rev. 1, January 1996

Hochgeladen von

NaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Piping Fabrication, Installation, Flushing and Testing L-CR-004 Annex B Rev. 1, January 1996

Hochgeladen von

NaCopyright:

Verfügbare Formate

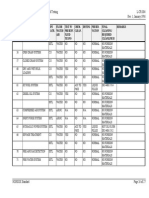

Piping Fabrication, Installation, Flushing and Testing

Annex B

SYSTEM SYSTEM DESCRIPTION

21

23

CRUDE HANDLING

L-CR-004

Rev. 1, January 1996

PIPE

FLUSH

TEST W/ CHEM. DRYING PRESERMATR. WATER/ PRESERV. CLEAN.

VATION

AIR

FLUID

YES/NO

FINAL

CLEANING/

REQUIRED

CLEANLINESS

C.S

WATER

YES

NO

NO

NORMAL

SSTL

WATER

NO

NO

NO

NORMAL

NO FOREIGN

MATERIALS

NO FOREIGN

MATERIALS

C.S

WATER

YES

NO

NO

NORMAL

NO

SSTL

WATER

NO

NO

23-20

GAS RECOMPRESSION,

COOLING AND SCRUBBING

GAS COOLING AND

SCRUBBING

GAS COOLING AND

SCRUBBING

GAS RECOMPRESSION

C.S

WATER

NO

23-20

If no chem.cleaning req.

C.S

WATER

YES

ACC. TO YES

P&ID

NO

YES

23-20

GAS RECOMPRESSION

SSTL

WATER

NO

23-20

If no chem.cleaning req.

SSTL

WATER

C.S

23-10

23-10

24

24-10

24-10

24-20/30

24-20/30

26

NO FOREIGN

MATERIALS

NORMAL

NO FOREIGN

MATERIALS

SEE NOTE 4 ISO 4406,17/14

YES

NO

ACC.TO

P&ID

NO

NO FOREIGN

MATERIALS

SEE NOTE 4 ISO 4406,17/14

YES

NORMAL

NO FOREIGN

MATERIALS

WATER

YES

NO

NO

NORMAL

SSTL

WATER

NO

NO

NO

NORMAL

C.S

WATER

NO

NO

NO

NORMAL

SSTL

WATER

NO

NO

NO

NORMAL

NO FOREIGN

MATERIALS

NO FOREIGN

MATERIALS

NO FOREIGN

MATERIALS

NO FOREIGN

MATERIALS

REMARKS

(100% visual insp. on suction side of

compressor).

NORMAL

(100% visual insp. on suction side of

compressor).

GAS TREATMENT

GAS COOLING AND

SCRUBBING

GAS COOLING AND

SCRUBBING

GAS DEHYDRATION/

REGENERATION

GAS DEHYDRATION/

REGENERATION

GAS REINJECTION TO

RESERVOIR

NORSOK Standard

Page 22 of 27

Piping Fabrication, Installation, Flushing and Testing

Annex B

L-CR-004

Rev. 1, January 1996

SYSTEM SYSTEM DESCRIPTION

PIPE

FLUSH

TEST W/ CHEM. DRYING PRESERMATR. WATER/ PRESERV. CLEAN.

VATION

AIR

FLUID

YES/NO

FINAL

CLEANING/

REQUIRED

CLEANLINESS

26-10/30

C.S

WATER

YES

NO

NO

NORMAL

NO FOREIGN

MATERIALS

SSTL

WATER

NO

NO

NO

NORMAL

NO FOREIGN

MATERIALS

C.S

WATER

NO

YES

SEE NOTE 4 ISO4406,17/14

C.S

WATER

YES

ACC.TO

P&ID

NO

NO

NORMAL

SSTL

WATER

NO

SSTL

WATER

C.S

26-10/30

26-20

26-20

26-20

26-20

27

27-10

27-10

27-20/30

27-20/30

REINJECTION GAS COOLING

AND SCRUBBING /

REINJECTION MANIFOLD

REINJECTION GAS COOLING

AND SCRUBBING /

REINJECTION MANIFOLD

REINJECTION GAS

COMPRESSION

If no chem.cleaning req.

REINJECTION GAS

COMPRESSION

If no chem. cleaning req.

GAS PIPELINE COMPRESSION,

MEETERING AND TRANSFER

GAS COOLING AND

SCRUBBING

GAS COOLING AND

SCRUBBING

GAS PIPELINE COMPRESSION /

GAS METERING

If no chem. cleaning req.

YES

NO

ACC.TO

P&ID

NO

NO FOREIGN

MATERIALS

SEE NOTE 4 ISO4406,17/14

YES

NORMAL

WATER

YES

NO

NO

NORMAL

SSTL

WATER

NO

NO

NO

C.S

WATER

NO

C.S

WATER

YES

ACC. TO YES

P&ID

NO

YES

GAS PIPELINE COMPRESSION / SSTL

GAS METERING

WATER

NO

ACC.TO

P&ID

YES

SEE NOTE 4 ISO 4406,17/14

27-20/30

If no chem. cleaning req.

SSTL

WATER

NO

NO

YES

NORMAL

NO FOREIGN

MATERIALS

GAS SWEETENING

SSTL

WATER

NO

NO

NO

NORMAL

NO FOREIGN

MATERIALS

NORSOK Standard

(100% visual insp. on suction side of

compressor)

(100% visual insp. on suction side of

compressor)

FOREIGN MAT.

27-20/30

28

(100% visual insp. on suction side of

compressor)

NO FOREIGN

MATERIALS

NO FOREIGN

MATERIALS

NORMAL

NO FOREIGN

MATERIALS

SEE NOTE 4 ISO 4406,17/14

NORMAL

REMARKS

(100% visual insp. on suction side of

compressor)

Page 23 of 27

Das könnte Ihnen auch gefallen

- Master List of Records 1Dokument2 SeitenMaster List of Records 1Anonymous i3lI9MNoch keine Bewertungen

- Pre-Commissioning Check List of GeneratorDokument26 SeitenPre-Commissioning Check List of Generatorvikivarma14780% (15)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsVon EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNoch keine Bewertungen

- Cat Sebp5922!00!01-All Mini Orugas PBDokument377 SeitenCat Sebp5922!00!01-All Mini Orugas PBWilliam RicoNoch keine Bewertungen

- Basic Gearbox and ClutchDokument89 SeitenBasic Gearbox and ClutchHenry Christian100% (2)

- SAIC-A-2010 Rev 0Dokument3 SeitenSAIC-A-2010 Rev 0philipyapNoch keine Bewertungen

- SAIC-A-2013 Rev 0Dokument2 SeitenSAIC-A-2013 Rev 0philipyapNoch keine Bewertungen

- Manual Atlas Copco Xa90Dokument29 SeitenManual Atlas Copco Xa90bvhdareldalmassoNoch keine Bewertungen

- NITON - HYDRO TEST PROCEDURE - Rev.0Dokument6 SeitenNITON - HYDRO TEST PROCEDURE - Rev.0PRASHANT100% (2)

- Sick Well Analysis & Remedial MeasuresDokument34 SeitenSick Well Analysis & Remedial MeasuresSumanth Reddy0% (1)

- Gas Sweetening and Processing Field ManualVon EverandGas Sweetening and Processing Field ManualBewertung: 4 von 5 Sternen4/5 (7)

- Instrumentation Standards ListDokument45 SeitenInstrumentation Standards ListRajeevNoch keine Bewertungen

- Control Valve PresentationDokument61 SeitenControl Valve PresentationDhanny Miharja100% (1)

- Insp Checklist - LO FlushingDokument3 SeitenInsp Checklist - LO Flushingaanouar7750% (2)

- Api 598Dokument13 SeitenApi 598SurachaiAumongkolNoch keine Bewertungen

- Breaker-HB Series 6904104 EnUS Om 10-15Dokument212 SeitenBreaker-HB Series 6904104 EnUS Om 10-15Henry Huayhua100% (1)

- AICIP ExamDokument8 SeitenAICIP Examcybercreed2002_11486100% (1)

- Mechanical Inspection Form For Handing Over Completed Room or AreaDokument12 SeitenMechanical Inspection Form For Handing Over Completed Room or Areacyno21Noch keine Bewertungen

- Project Standards and Specifications Hydrostatic Pressure Testing Rev01Dokument7 SeitenProject Standards and Specifications Hydrostatic Pressure Testing Rev01GabrielPantilicaNoch keine Bewertungen

- Pressure & Leak TestingDokument18 SeitenPressure & Leak TestingBilly KurniawanNoch keine Bewertungen

- Test Package AttachmentDokument3 SeitenTest Package AttachmentFrancis Mayowa Ezekiel100% (1)

- FP Diesel BrochureDokument2 SeitenFP Diesel BrochureRajesh SoundararajanNoch keine Bewertungen

- SAIC-K-2026 Rev 0Dokument2 SeitenSAIC-K-2026 Rev 0philipyapNoch keine Bewertungen

- Eaton Internormen Filtration For Oil Service EquipmentDokument4 SeitenEaton Internormen Filtration For Oil Service EquipmentEaton FiltrationNoch keine Bewertungen

- Scheme Tracing 25.06.09 FINALDokument91 SeitenScheme Tracing 25.06.09 FINALManan Mehta100% (2)

- Ag Test Package FormatDokument25 SeitenAg Test Package FormatoparoystNoch keine Bewertungen

- 7560-Hydro Test - Sequence 1Dokument9 Seiten7560-Hydro Test - Sequence 1Bala MuruganNoch keine Bewertungen

- Presentation2 Power Point/ Improve Cooking StoveDokument67 SeitenPresentation2 Power Point/ Improve Cooking StoveRamon Chua Jr.Noch keine Bewertungen

- QRF 930e-4Dokument2 SeitenQRF 930e-4Ralf Maurer100% (1)

- Procedure For Condenser Flood Test and Vacuum Tightness TestDokument13 SeitenProcedure For Condenser Flood Test and Vacuum Tightness TestJackSparrow86Noch keine Bewertungen

- MCL 1st Mock Board Exam PDFDokument11 SeitenMCL 1st Mock Board Exam PDFAdrian Joshua BernagaNoch keine Bewertungen

- Typical Specification of Volvo Truck PDFDokument3 SeitenTypical Specification of Volvo Truck PDFKartik BehereNoch keine Bewertungen

- Piping Fabrication, Installation, Flushing and Testing L-CR-004 Annex B Rev. 1, January 1996Dokument2 SeitenPiping Fabrication, Installation, Flushing and Testing L-CR-004 Annex B Rev. 1, January 1996NaNoch keine Bewertungen

- Piping Fabrication, Installation, Flushing and Testing L-CR-004 Annex B Rev. 1, January 1996Dokument2 SeitenPiping Fabrication, Installation, Flushing and Testing L-CR-004 Annex B Rev. 1, January 1996NaNoch keine Bewertungen

- IAD - A318 - A319 - A320 - A321 - AMM - 01-Aug-2021 - 29-00-00-790-001-A - Check of The External Leaks of The Hydraulic ComponentsDokument12 SeitenIAD - A318 - A319 - A320 - A321 - AMM - 01-Aug-2021 - 29-00-00-790-001-A - Check of The External Leaks of The Hydraulic ComponentsMONOJ ANoch keine Bewertungen

- Hydrostatic Test Procedure: Saudi Elastomer ProjectDokument5 SeitenHydrostatic Test Procedure: Saudi Elastomer ProjectKrishnamoorthi VenkatesanNoch keine Bewertungen

- Snag List-Hyatt House Hvac and Chiller System Valve Pakage CD Fa Duct Rooms or Areas Fcu and Duct ConnectionDokument10 SeitenSnag List-Hyatt House Hvac and Chiller System Valve Pakage CD Fa Duct Rooms or Areas Fcu and Duct ConnectionriyasudheenmhNoch keine Bewertungen

- Client: Asco Steel Plant: Description: Line List Page 1 of 1 Date: 18/8/2001 Rev. No: 0Dokument1 SeiteClient: Asco Steel Plant: Description: Line List Page 1 of 1 Date: 18/8/2001 Rev. No: 0vhpatel67100% (1)

- Satr B 4001Dokument3 SeitenSatr B 4001mahdi_gNoch keine Bewertungen

- Newcruz Shipbuilding & Eng Pte LTD: Hydrostatic Test ReportDokument1 SeiteNewcruz Shipbuilding & Eng Pte LTD: Hydrostatic Test Reportsank79Noch keine Bewertungen

- Saudi Aramco Inspection Checklist: Mech-Review Procedure - Lay-Up of Piping Systems or Vessels SAIC-A-2007 1-Dec-06Dokument23 SeitenSaudi Aramco Inspection Checklist: Mech-Review Procedure - Lay-Up of Piping Systems or Vessels SAIC-A-2007 1-Dec-06ரமேஷ் பாலக்காடுNoch keine Bewertungen

- List of Standard Test Procedure RevDokument1 SeiteList of Standard Test Procedure Revsharafudheen_sNoch keine Bewertungen

- Saudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 15-Dec-09 PlumbDokument2 SeitenSaudi Aramco Test Report: Building Drainage and Vent Piping Hydrotest SATR-S-4003 15-Dec-09 Plumbmahdi_gNoch keine Bewertungen

- 05 Hyd - Test ProcedureDokument3 Seiten05 Hyd - Test ProcedureirfanNoch keine Bewertungen

- 10028028Dokument2 Seiten10028028book_carlosNoch keine Bewertungen

- Steam Trace Trap List: No. Capacity (KG/HR) Size (DN) Type Qty Panel Code Manufacturer IdentificationDokument18 SeitenSteam Trace Trap List: No. Capacity (KG/HR) Size (DN) Type Qty Panel Code Manufacturer IdentificationEhsan PourangNoch keine Bewertungen

- SAIC-A-2017 Rev 2Dokument3 SeitenSAIC-A-2017 Rev 2ரமேஷ் பாலக்காடுNoch keine Bewertungen

- Handbook - ContentsDokument3 SeitenHandbook - ContentsJavad MonfaredNoch keine Bewertungen

- SAIC-A-2007 Rev 3Dokument12 SeitenSAIC-A-2007 Rev 3imrankhan22Noch keine Bewertungen

- Data Sheet: Company Country Area PlantDokument3 SeitenData Sheet: Company Country Area Plantbrome2014Noch keine Bewertungen

- Procedure Manual: Cast Valve ProductionDokument10 SeitenProcedure Manual: Cast Valve ProductionParveen Kohli0% (1)

- Application of The Safety Codes Act To Pressurized EquipmentDokument28 SeitenApplication of The Safety Codes Act To Pressurized EquipmentanishgirmeNoch keine Bewertungen

- Mechanical Commissioning 2Dokument66 SeitenMechanical Commissioning 2mohamed abd el attyNoch keine Bewertungen

- SAIC-G-2017 Rev 0 - Mechanical & Chemical Cleaning of Lube Andor Seal Oil SystemDokument3 SeitenSAIC-G-2017 Rev 0 - Mechanical & Chemical Cleaning of Lube Andor Seal Oil Systemবিপ্লব পালNoch keine Bewertungen

- Pressure Equipment Inspection Requirements: Upstream-Unit 82 U-A8300 Condensate Pre-CoolerDokument1 SeitePressure Equipment Inspection Requirements: Upstream-Unit 82 U-A8300 Condensate Pre-CoolerSiva KumarNoch keine Bewertungen

- Leak Test ProcedureDokument5 SeitenLeak Test ProcedureAhmed AlaaNoch keine Bewertungen

- Laksh Fine Chem. PVT LTD: - (AN ISO Certified)Dokument1 SeiteLaksh Fine Chem. PVT LTD: - (AN ISO Certified)ncubepharmaNoch keine Bewertungen

- Pressure Equipment Inspection Requirements: Train3-Unit-02 03-V0222 No.2 Reclaimer Overhead KO DrumDokument1 SeitePressure Equipment Inspection Requirements: Train3-Unit-02 03-V0222 No.2 Reclaimer Overhead KO DrumSiva KumarNoch keine Bewertungen

- Piping Test Pressure Calculations and Related StandartsDokument13 SeitenPiping Test Pressure Calculations and Related StandartsAhmet OVENNoch keine Bewertungen

- Safety AlertAccumalatorDokument1 SeiteSafety AlertAccumalatorAngel PerdomoNoch keine Bewertungen

- City of Dallas PDFDokument526 SeitenCity of Dallas PDFrafaelberaldiNoch keine Bewertungen

- NUMBER: 603-10 S.M. REF.: Listed in Table ENGINE: EPA10 DD Platform DATE: June 2010Dokument6 SeitenNUMBER: 603-10 S.M. REF.: Listed in Table ENGINE: EPA10 DD Platform DATE: June 2010Cuong DinhNoch keine Bewertungen

- Start-Up Check List-Eng ModificatoDokument12 SeitenStart-Up Check List-Eng ModificatoBayu KristiantoNoch keine Bewertungen

- Air Reciver Vessel-1 (Compressor Unit-3)Dokument5 SeitenAir Reciver Vessel-1 (Compressor Unit-3)MD Shadikul Huq ShezanNoch keine Bewertungen

- Advantages New Electroplating Technologies: Christ1: and DisadvantagesDokument19 SeitenAdvantages New Electroplating Technologies: Christ1: and DisadvantagesHarnani SharuddinNoch keine Bewertungen

- Procedure For Hydrostatic Test & Load Test of Pump ColumnDokument13 SeitenProcedure For Hydrostatic Test & Load Test of Pump ColumnHà HuệNoch keine Bewertungen

- Paling Technical ManualDokument15 SeitenPaling Technical Manualamg007Noch keine Bewertungen

- Forces and Moments (Api-617Dokument3 SeitenForces and Moments (Api-617NaNoch keine Bewertungen

- Attachment B - Flange CheckDokument1 SeiteAttachment B - Flange CheckNaNoch keine Bewertungen

- Steam 1Dokument5 SeitenSteam 1NaNoch keine Bewertungen

- Steam 1Dokument5 SeitenSteam 1NaNoch keine Bewertungen

- Steam 1Dokument4 SeitenSteam 1NaNoch keine Bewertungen

- Steam 1Dokument5 SeitenSteam 1NaNoch keine Bewertungen

- LANL EngDokument3 SeitenLANL EngNaNoch keine Bewertungen

- Stress Analysis of Piping Systems: & PV Code, 1998. (Courtesy of ASME.)Dokument5 SeitenStress Analysis of Piping Systems: & PV Code, 1998. (Courtesy of ASME.)NaNoch keine Bewertungen

- LANL EngDokument3 SeitenLANL EngNaNoch keine Bewertungen

- Stress B4Dokument5 SeitenStress B4NaNoch keine Bewertungen

- 2) Stress Analysis 2Dokument30 Seiten2) Stress Analysis 2Dennis Padec BwochengoNoch keine Bewertungen

- Stress B4Dokument7 SeitenStress B4NaNoch keine Bewertungen

- B4 StressDokument5 SeitenB4 StressNaNoch keine Bewertungen

- B4 StressDokument5 SeitenB4 StressNaNoch keine Bewertungen

- Stress Analysis of Piping Systems: /T 1, Section III, Division 1, ASME B & PV Code, 1998. Courtesy of ASME.)Dokument4 SeitenStress Analysis of Piping Systems: /T 1, Section III, Division 1, ASME B & PV Code, 1998. Courtesy of ASME.)NaNoch keine Bewertungen

- B4 Stress AnalysisDokument5 SeitenB4 Stress AnalysisNaNoch keine Bewertungen

- B4 Stress AnalysisDokument5 SeitenB4 Stress AnalysisNaNoch keine Bewertungen

- Brass Rotary Vane Pumps PO 70-400 Series: Main ApplicationsDokument2 SeitenBrass Rotary Vane Pumps PO 70-400 Series: Main ApplicationsMareReaNoch keine Bewertungen

- Https Exploringgeography - Wikispaces.com File View Chapter+5+Mineral+and+power+resource+ (New) PDFDokument8 SeitenHttps Exploringgeography - Wikispaces.com File View Chapter+5+Mineral+and+power+resource+ (New) PDFChaitanya SharmaNoch keine Bewertungen

- Nov152019 PROBLEM SETDokument2 SeitenNov152019 PROBLEM SETJerkyArquioDonesaNoch keine Bewertungen

- Chemistry SeparationDokument12 SeitenChemistry SeparationKashifntcNoch keine Bewertungen

- Lab Manual Manufacturing Proccesses IIDokument80 SeitenLab Manual Manufacturing Proccesses IIEntertainment Club100% (1)

- "Automatic Tyre Pressure Inflation System": Bachelor of TechnologyDokument41 Seiten"Automatic Tyre Pressure Inflation System": Bachelor of Technologymd washiqeNoch keine Bewertungen

- QSK50-G4: EPA Tier 2 and TA Luft CompliantDokument3 SeitenQSK50-G4: EPA Tier 2 and TA Luft CompliantMehrdad saeediNoch keine Bewertungen

- HVLS 10611 PDFDokument120 SeitenHVLS 10611 PDFDeives de PaulaNoch keine Bewertungen

- 1 9 7 6 Volvo 262 264 265: Notice To Owner: Your Volvo Has Been Built To Comply With All North American Safety and AntiDokument103 Seiten1 9 7 6 Volvo 262 264 265: Notice To Owner: Your Volvo Has Been Built To Comply With All North American Safety and AntiJohn DaneNoch keine Bewertungen

- D4G XLDokument24 SeitenD4G XLgychcontratistasNoch keine Bewertungen

- Liebherr PR 712 Litronic Final DrivesDokument8 SeitenLiebherr PR 712 Litronic Final DrivesLiebherr75% (4)

- Air Compressor BrosurDokument6 SeitenAir Compressor BrosurFick Ry'sNoch keine Bewertungen

- 39.0046 - Issue7 - July2002 - FMQ 10&FMQ 8 36&FMQ 7 42 - Install&OperateInstructionsDokument30 Seiten39.0046 - Issue7 - July2002 - FMQ 10&FMQ 8 36&FMQ 7 42 - Install&OperateInstructionsSubuk T. RathodNoch keine Bewertungen

- 2010 Trinidad y TobagoDokument22 Seiten2010 Trinidad y TobagorubenpeNoch keine Bewertungen

- Hoja de Datos - Válvula Modelo WDCLDokument9 SeitenHoja de Datos - Válvula Modelo WDCLEnriqueAzuaraNoch keine Bewertungen

- Troubleshooting Fuel Dilution of Engine Oil PDFDokument2 SeitenTroubleshooting Fuel Dilution of Engine Oil PDFmanu luvungaNoch keine Bewertungen

- Oxysystems 2v3x 172 4.1 ManualDokument21 SeitenOxysystems 2v3x 172 4.1 ManualDavid GarciaNoch keine Bewertungen

- Ripi - Light Naphtha IsomerizationDokument4 SeitenRipi - Light Naphtha IsomerizationAsifNoch keine Bewertungen

- Fluroelastomers Dyneon 0Dokument16 SeitenFluroelastomers Dyneon 0Sid ShahNoch keine Bewertungen

- Fisher Y291aDokument20 SeitenFisher Y291aJavi MoralNoch keine Bewertungen