Beruflich Dokumente

Kultur Dokumente

Report

Hochgeladen von

api-301270531Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Report

Hochgeladen von

api-301270531Copyright:

Verfügbare Formate

12/12/2014

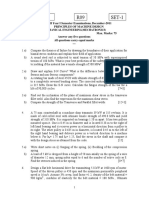

Corner Drill

Professor:RonGriswald

MET4820CapstoneFall2014

Authoredby:NickBoyer,Rick Girt,DaveHendricks,JeffKalina,

KeithPovec

MET4820CapstoneFall2014

The Problem

Each custom ATA (Airline Transit Authority Specification) case produced by LM

Engineering requires the use of multiple 4 hole tapered clamps (Figure 1.1 & 1.2).

Depending on the style case there are 4 to 16 clamps on a case with 4 holes per

clamp, this translates to 16 64 holes (#8 drill bit) that need to be hand drilled

throughthealuminumtongueandgroove.

Currently astandard drill is used however the operatorexperiences fatigue by the

endoftheshiftbypressingthedrillintothematerial.Additionallywhenacaseisset

on a table, the drill handle is placed at a 90 angle creating a nonergonomic

position.

Figure1.1FourHoleTaperedClampFigure1.2FourHoleTaperedClamp

Design Process

ThedesignprocessbeganinSeptemberfirstbyvisitingLMEngineering.

Observingtheircurrentprocessofmountingthecornerbracket.Testsweredone

tomeasurethecurrentspeed,forceandtimingtodrillthefourholesmanually,

asiscurrentlydone.

Inclassthegroupdiscussedthecriteriafortheproject.

MET4820CapstoneFall2014

Goals:

Designfixture/jigmachinetodrillclampsoncases(lid/tray)

Minimizeoperatorefforttoincreaseproductivityanddecreasefatigue,

Decreasecycletime

Increaseproductivity

Safety

Productrepeatability

Quality

Eliminatorerror

Repeatability

Keepcasesquare,willmakedividerinstalleasier(improvement)

Design parameters:

Lightweight25lbmax

Ergonomics

Rigidity

Sturdy(impactresistance)

Takelesstimethandoingitbyhand(20seconds)

Portability

Easeoftoolchange

Easeofmaintenance

Costeffective(LookatROI)

Existingpowersources(airand110v)

needtoaccommodatedifferentthicknesscasesandfortongueandgroove.

needtolocatethepartconsistently

Getquotedatafabshop.

Lookalistofwearablepartsandwhatwewouldkeepinstock.

Documentationforhowtouse

Constraints:

6wx6dx3.5h

Notmorethan100psiairpressure

110v15amp

Accommodatefordifferentsizedtongueandgroove

#8drillbit

Desirable Features:

Balancedsymmetricallysothatitiseasytolift(lookatcenterofgravity)

Rubber

Lightaspossibly

Rubberpadsforclamping

Eliminatesplintering

MET4820CapstoneFall2014

Operatingbytrigger(maybesomethingelsetoeliminatetriggerfinger)

How to improve from here

Someimprovementsthatmadefoundalongthewaywereasfollows:

Findingamotorthatcancarrytheloadfoundanairdiegrinder

MachiningpartsImprovedourmachiningskillstocorrectthebadparts

TimingissueswithgettingpartsWorkedonotheritemsuntilpartscamein

Some3DprintedpartsdidnotcorrectlyReconstructwithwood.Itwouldbe

betterifmoretimewasallowedfortheprintingsothatcorrectionscouldbe

madeifnecessary.

WeightalittleontheheavysideFindmaterialsthatcouldreducetheweight

howeverthisisdifficultasthemotoranddrillspindlewerethebulkofthe

weight.

Credits

ThankstoProfessorCostarellandYSUSTEMdepartmentforallowingustoworkonthis

RealWorldproject.

ThankstoProfessorGriswoldforTeachingthisclassandhelpingusalongtheway.

ThankstoLandMCasesforhavingtheneedfortheprojectandfundingtheproject.

ThankstoProfessorConnerfordoingthe3Dprintingforthisassignment

JohnDodsonforallowingtheteamtousethemachineshopforlatehours.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Astm E2818-11 PDFDokument4 SeitenAstm E2818-11 PDFJhonatan CalloapazaNoch keine Bewertungen

- Clevite Bearing Book EB-10-07 PDFDokument872 SeitenClevite Bearing Book EB-10-07 PDFlowelowel60% (5)

- Structural Analysis of Steering Knuckle For Weight ReductionDokument6 SeitenStructural Analysis of Steering Knuckle For Weight ReductionMithun V KulkarniNoch keine Bewertungen

- 6 Load Rating Analysis (Revised Title) : 6.0 (New) Overview of Load Rating Methods and ProceduresDokument13 Seiten6 Load Rating Analysis (Revised Title) : 6.0 (New) Overview of Load Rating Methods and ProceduresaamirNoch keine Bewertungen

- Aashto Tp101 Las May 2013 v2Dokument8 SeitenAashto Tp101 Las May 2013 v2saeedNoch keine Bewertungen

- ME 1302 - MACHINE DESIGN (5th Mech)Dokument7 SeitenME 1302 - MACHINE DESIGN (5th Mech)Madhu MithaNoch keine Bewertungen

- Mangalore Institute of Technology and Engineering: Material Science and MetallurgyDokument203 SeitenMangalore Institute of Technology and Engineering: Material Science and MetallurgyNISHAANTH S 1861462Noch keine Bewertungen

- API-571 Chart - UdayDokument11 SeitenAPI-571 Chart - UdayRaghavan Venkatraman100% (1)

- 2007 Russian Aluminum Alloys For Ultra Deep Water EngDokument8 Seiten2007 Russian Aluminum Alloys For Ultra Deep Water EngHossam Ali RaghebNoch keine Bewertungen

- 3.9.3 Asme Code Class 1 2 and 3 Components Component SupporDokument44 Seiten3.9.3 Asme Code Class 1 2 and 3 Components Component SupporHamza NoumanNoch keine Bewertungen

- Multidisciplinary Design Optimization of A Regional Aircraft Wing BoxDokument10 SeitenMultidisciplinary Design Optimization of A Regional Aircraft Wing Boxyema82811Noch keine Bewertungen

- Analisador Parker KittiwakeDokument12 SeitenAnalisador Parker KittiwakeAnonymous alQXB11EgQNoch keine Bewertungen

- NX Advanced Simulation Fs W18Dokument10 SeitenNX Advanced Simulation Fs W18jegjegtNoch keine Bewertungen

- 06 Steel Chimney CodeDokument47 Seiten06 Steel Chimney CodeTuan Dang100% (3)

- Hindustan Institute of Technology and Science: School of Aeronautcial SciencesDokument35 SeitenHindustan Institute of Technology and Science: School of Aeronautcial SciencesSanthiNoch keine Bewertungen

- Bridge Chapt. 1Dokument14 SeitenBridge Chapt. 1GoftaNoch keine Bewertungen

- Guia de Reusabilidad d10r Eje de Levas PDFDokument28 SeitenGuia de Reusabilidad d10r Eje de Levas PDFcarlos sernaNoch keine Bewertungen

- Engineering Failure Analysis: Khlefa A. Esaklul, Tawfik M. AhmedDokument8 SeitenEngineering Failure Analysis: Khlefa A. Esaklul, Tawfik M. AhmedMatheus Paes PeçanhaNoch keine Bewertungen

- Form of Corrosion Illustration Form of Corrosion IllustrationDokument2 SeitenForm of Corrosion Illustration Form of Corrosion IllustrationkhalesnabilNoch keine Bewertungen

- InternDokument26 SeitenInternrakeshNoch keine Bewertungen

- M. E. (Production Engineering) Cad/CamDokument39 SeitenM. E. (Production Engineering) Cad/CamOneCharuNoch keine Bewertungen

- Implant Materials - Unalloyed TitaniumDokument28 SeitenImplant Materials - Unalloyed TitaniumSebastian De Ossa RestrepoNoch keine Bewertungen

- Design of Anchorages To Concrete: Comm. B3.) Design BasisDokument390 SeitenDesign of Anchorages To Concrete: Comm. B3.) Design Basisedginton1comedorNoch keine Bewertungen

- Very High Cycle Fatigue - Testing MethodsDokument17 SeitenVery High Cycle Fatigue - Testing Methodsالحمد اللهNoch keine Bewertungen

- Fundamentals of Fatigue and Fracture Mechanics: RVC EDokument69 SeitenFundamentals of Fatigue and Fracture Mechanics: RVC ESaima naazNoch keine Bewertungen

- Peter C. McKeighan and Narayanaswami Ranganathan, Editors Fatigue Testing and Analysis Under Variable Amplitude Loading Conditions ASTM Special Technical Publication, 1439 PDFDokument588 SeitenPeter C. McKeighan and Narayanaswami Ranganathan, Editors Fatigue Testing and Analysis Under Variable Amplitude Loading Conditions ASTM Special Technical Publication, 1439 PDFAbdulCain100% (1)

- Pressure Vessel Design PhilosophyDokument54 SeitenPressure Vessel Design PhilosophyDilip Patel100% (1)

- PMD ModelDokument8 SeitenPMD ModelDamodara SatyaDeva MadhukarNoch keine Bewertungen

- 625-NR Consolidated NovemberDokument321 Seiten625-NR Consolidated NovemberArturoNoch keine Bewertungen