Beruflich Dokumente

Kultur Dokumente

Welding Calculation

Hochgeladen von

Denial BasanovicOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Welding Calculation

Hochgeladen von

Denial BasanovicCopyright:

Verfügbare Formate

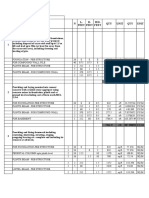

OVERLAY WELD KG & RUN TIME ESTIMATION

TOME REQUIRED FOR RADIOGRAPHY TEST

C/SEAM OR L/SEAM OR T-FRAME (LS/CS/TF)?

LG OF SHELL/NOZZLE=

LOWER THK INCLUDING RAINFORCEMENT

RADIOGRAPHY BY IRIDIUM/COBALT(I/C)?

SPOT RT OR PENOROMIC RT (S/P)?

LG OF SHELL/NOZZLE=

SPOT LENGTH=

NO. OF SPOT=

3000

300

10

LS

TIME REQUIRED FOR RT=

3000

50

I

S

THK=

50

TIME CALCUCATION

SPOT

SPOT FOR FILLET IN T-FRAMES

PEMOROMIC

297503042.xls

IRIDIUM

86.4

691.2

2592.0

COBALT

23.8

113.0

458.2

12/06/2015

864

14.4

0.60

MIN

HRS

DAYS

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

SINGLE 'V'

RUN TIME TIME REQUIRED FOR

L/SEAM OR C/SEAM (LS/CS)=

LS

HRS/KG

1). SMAW

2). SAW

45

52

R.F.=

R.G.=

PARAMETERS SETTING

PROCESS

KG/SHIFT

THK= 54

LG OF LONG SEAM= 58000

MATERIAL (SS/STEEL)= ss

DENSITY= 0.000008

4

2.00

(C/S)

30

0.27

(L/S)

18

0.44

3).FCAW (1.2 )

6

1.33

4). GTAW

1.6

5.00

5). TWIN HD. (C/S 24 48

0.330.66

SAW **

(L/S) 14.428.8

0.561.11

** WITH 2 OPERATORS

POSITION OF

MULTIPLICATION

WELDING

FACTOR

1). 1G

1

2). 2G

1.6

3). 3G

1.3

ALL DIMENSIONS ARE IN MM

PREHEATING

REQUIRED?

YES

NO

CROSS SEC. AREA TOTAL WELD KG

O/S WELDING=

C/B WELDING=

TOTAL WELDING=

1420.3

298.2

1718.5

LONG SEAM

659.0

138.4

797.4

CHIP BACK DEPTH(MM)

THK <= 30

THK > 30

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

OUTSIDE ROOT RUN

20%

0.444

1.0

OUT SIDE BALANCE

80%

1.0

CHIP BACK WELDING

100%

1.0

TOTAL =

297503042.xls

MULTIPLICATION

FACTOR

1.15

1

12/06/2015

RUN TIME

(min)

(Hrs)

3514.7

58.6

63264.4

1054.4

16603.5

276.7

83382.6

1389.7

6

12

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

0.66

1.11

297503042.xls

12/06/2015

LONG SEAM/ CIRC SEAM WELD KG & RUN TIME ESTIMATION

DOUBLE 'V'

RUN TIME TIME REQUIRED FOR

L/SEAM OR C/SEAM (LS/CS)=

PARAMETERS SETTING

PROCESS

KG/SHIFT HRS/KG

ls

45

1). SMAW

2). SAW

36.0

THK= 54

R.F.=

LG OF LONG SEAM= 1364

MATERIAL (SS/STEEL)= steel

15.0

R.G.=

60

DENSITY= 0.00000785

ALL DIMENSIONS ARE IN MM

PREHEATING

REQUIRED?

YES

NO

CROSS SEC. AREA TOTAL WELD KG

O/S WELDING=

C/B WELDING=

TOTAL WELDING=

710.3

514.4

1224.7

LONG SEAM

7.6

5.5

13.1

MULTIPLICATION

FACTOR

1.15

1

CHIP BACK DEPTH(MM)

THK <= 30

6

THK > 30

12

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

OUTSIDE ROOT RUN

12%

1.0

1.15

OUT SIDE BALANCE

88%

0.444

1.0

CHIP BACK WELDING

100%

0.444

1.0

TOTAL =

297503042.xls

4

2.00

(C/S)

30

0.27

(L/S)

18

0.44

3).FCAW (1.2 )

6

1.33

4). GTAW

1.6

5.00

5). TWIN HD. (C/S 24 48

0.330.66

SAW **

(L/S) 14.4

0.561.11

28.8

** WITH 2 OPERATORS

POSITION OF

MULTIPLICATION

WELDING

FACTOR

1). 1G

1

2). 2G

1.6

3). 3G

1.3

12/06/2015

RUN TIME

(min)

(Hrs)

120.7

2.0

178.5

3.0

146.9

2.4

446.1

7.4

LONG SEAM/ CIRC SEAM WELD KG & RUN TIME ESTIMATION

0.66

1.11

297503042.xls

12/06/2015

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

BACKING STRIP

10

PARAMETERS SETTING

PROCESS

KG/SHIFT

cs

RUN TIME TIME REQUIRED FOR

L/SEAM OR C/SEAM (LS/CS)=

1). SMAW

2). SAW

THK= 8

I/D OF SHELL 5486

MATERIAL (SS/STEEL)= STEEL

R.G.=

4

(C/S)

30

(L/S)

18

3).FCAW (1.2 )

6

5). TWIN HD. (C/S) 24 48

SAW **

(L/S) 14.428.8

** WITH 2 OPERATORS

10

DENSITY= 0.00000785

POSITION OF

WELDING

1). 1G

2). 2G

3). 3G

MULTIPLICATION

FACTOR

1

1.6

1.3

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION

FACTOR

1.15

1

ALL DIMENSIONS ARE IN MM

CROSS SEC. AREA

TOTAL WELD KG

O/S WELDING=

119.8

16.2

TOTAL WELDING=

119.8

16.2

CIRC SEAM

OUT SIDE BALANCE

100%

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

0.267

1.6

TOTAL =

297503042.xls

12/06/2015

RUN TIME

(min)

(Hrs)

0.0

0.0

0.0

0.0

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

ETTING

HRS/KG

48

28.8

2.00

0.27

0.44

1.33

0.330.66

0.561.11

MULTIPLICATION

FACTOR

1.3

MULTIPLICATION

FACTOR

1.15

1

297503042.xls

12/06/2015

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

J GROOVE

RUN TIME TIME REQUIRED FOR

L/SEAM OR C/SEAM (LS/CS)=

PARAMETERS SETTING

PROCESS

KG/SHIFT HRS/KG

CS

10

1). SMAW

2). SAW

59.0

THK= 80

R= 12

11.0

R.F.=

R.G.=

I/D OF SHELL 379

MATERIAL (SS/STEEL)= STEEL

DENSITY= 0.00000785

10

ALL DIMENSIONS ARE IN MM

PREHEATING

REQUIRED?

YES

NO

CROSS SEC. AREA TOTAL WELD KG

O/S WELDING=

C/B WELDING=

TOTAL WELDING=

2186.6

486.7

2673.3

CIRC SEAM

24.8

5.5

30.3

MULTIPLICATION

FACTOR

1.15

1

CHIP BACK DEPTH(MM)

THK <= 30

THK > 30

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

OUTSIDE ROOT RUN

20%

1.0

1.15

OUT SIDE BALANCE

80%

1.0

1.15

CHIP BACK WELDING

100%

1.0

1.15

TOTAL =

297503042.xls

4

2.00

30

0.27

18

0.44

3). FCAW

6

1.33

4). GTAW

1.6

5.00

5). TWIN HD. (C/S) 24 48

0.33

0.66

SAW **

(L/S) 14.428.8

0.56

1.11

** WITH 2 OPERATORS

POSITION OF

MULTIPLICATION

WELDING

FACTOR

1). 1G

1

2). 2G

1.6

3). 3G

1.3

(C/S)

(L/S)

12/06/2015

RUN TIME

(min)

(Hrs)

683.1

11.4

2732.5

45.5

760.3

12.7

4175.9

69.6

6

12

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

HRS/KG

0.66

297503042.xls

12/06/2015

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

COMPOUND 'V'

RUN TIME TIME REQUIRED FOR

L/SEAM OR C/SEAM (LS/CS)=

10

45

12

R.F.=

R.G.=

O/S WELDING=

C/B WELDING=

TOTAL WELDING=

738.6

298.2

1036.8

CIRC SEAM

HRS/KG

2.00

(C/S)

0.27

(L/S)

0.44

3).FCAW (1.2 )

1.33

4). GTAW

5.00

THK= 50

I/D OF SHELL= 2600

5). TWIN HD. (C/S) 24 48

0.330.66

SAW **

(L/S) 14.4 28.8

MATERIAL (SS/STEEL)= STEEL

0.56

1.11

** WITH 2 OPERATORS

DENSITY= 0.00000785

POSITION OF

MULTIPLICATION

WELDING

FACTOR

1). 1G

1

ALL DIMENSIONS ARE IN MM

2). 2G

1.6

3). 3G

1.3

PREHEATING

REQUIRED?

YES

NO

CROSS SEC. AREA TOTAL WELD KG

48.3

19.5

67.8

4

30

18

6

1.6

MULTIPLICATION

FACTOR

1.15

1

CHIP BACK DEPTH(MM)

THK <= 30

THK > 30

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

OUTSIDE ROOT RUN

20%

1.0

1.15

OUT SIDE BALANCE

80%

0.267

1.0

CHIP BACK WELDING

100%

0.267

1.0

TOTAL =

297503042.xls

PARAMETERS SETTING

PROCESS

KG/SHIFT

1). SMAW

2). SAW

36

CS

12/06/2015

RUN TIME

(min)

(Hrs)

1332.3

22.2

617.9

10.3

311.8

5.2

2262.0

37.7

6

12

LONG SEAM/CIRC SEAM WELD KG & RUN TIME ESTIMATION

HRS/KG

0.66

297503042.xls

12/06/2015

NOZZLE WELD KG & RUN TIME ESTIMATION

SINGLE 'V'

NOZZLE ON SHELL/DEND) (D/S) ?

CFW= 10

INC. ANG=45

MATERIAL (SS/STEEL)= STEEL

DENSITY= 7.85E-006

NOZZLE O/D=

60

OFF SET=

0

THK= 26

SHELL I/D=

4300

R.F.= 2

R.G=

4

NOZ O/D

60

ELLIPSE DIMENSION

MAJOR AXIS=

64.0

MINOR AXIS=

64

LG. OF WELDING= 201.066

WELD KG

WEIGHT

CROSS SEC.

ON SHELL ON D/END

CALCULATION

AREA

O/S WELDING=

338.00

0.53

0.53

C/B WELDING=

56.55

0.09

0.09

TOTAL WELDING=

0.62

0.62

PROCESS

POSITION

HEATING

ON SHELL

CODE

CODE

(Y/N)

OUTSIDE ROOT RUN 20%

1

2.5

1

1.0

Y

1.15

OUT SIDE BALANCE 80%

1

2.5

1

1.0

Y

1.15

CHIP BACK WELDING 100%

1

2.5

1

1.0

Y

1.15

TOTAL =

297503042.xls

PARAMETERS SETTING

PROCESS

KG/SHIFT

1). SMAW

3.2

2). SAW

14.4

3). FCAW (1.2 )

6.0

4). GTAW

1.3

12/06/2015

POSITION OF

WELDING

1). 1G

2). 2G

3). 3G

MULTIPLICATION

FACTOR

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION

FACTOR

1

1.6

1.3

1.15

CHIP BACK DEPTH(MM)

THK <= 30

THK > 30

RUN TIME

(min)

(Hrs)

18.4

0.3

73.6

1.2

15.4

0.3

107.4

1.8

NOZZLE WELD KG & RUN TIME ESTIMATION

TTING

HRS/KG

2.50

0.56

1.33

6.25

MULTIPLICATION

FACTOR

1

1.6

1.3

MULTIPLICATION

FACTOR

1.15

K DEPTH(MM)

6

12

297503042.xls

12/06/2015

NOZZLE WELD KG & RUN TIME ESTIMATION

BACKING STRIP

NOZZLE ON SHELL/DEND) (D/S) ?

MATERIAL (SS/STEEL)= STEEL

CFW= 9

INC. ANG= 15

DENSITY= 0.00000785

NOZZLE O/D=

300

SHELL I/D=

6800

R.G=

10

NOZ O/D

300

CROSS SEC.

AREA

875.44

WELD KG

ON SHELL ON D/END

7.63

7.63

TOTAL WELDING=

ON D/END

OUT SIDE BALANCE 100%

BACKING STRIPP DIMENSION

OUTER MAJOR AXIS 358.4

OUTER MINOR AXIS

340.0

WIDTH=

32.3

297503042.xls

PROCESS

CODE

1

2.5

3).FCAW (1.2 )

HRS/KG

2.50

0.56

1.33

6.0

OFF SET=

1100

THK= 50

ELLIPSE DIMENSIO o/d

I/d

MAJOR AXIS=

353.4

303.4

WEIGHT

MINOR AXIS=

353.4 303.377 CALCULATION

LG. OF WELDING= 1110.17

O/S WELDING=

PARAMETERS SETTING

PROCESS

KG/SHIFT

1). SMAW

3.2

2). SAW

14.4

7.63

POSITION

CODE

1

1.0

O/D= 358.4

I/D= 275.4

12/06/2015

POSITION OF

WELDING

1). 1G

2). 2G

3). 3G

MULTIPLICATION

FACTOR

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION

FACTOR

1

1.6

1.3

CHIP BACK DEPTH(MM)

THK <= 30

THK > 30

7.63

HEATING

(Y/N)

Y

1.15

TOTAL =

1.15

RUN TIME

(min)

(Hrs)

1316.0

21.9

1316.0

21.9

6

12

NOZZLE WELD KG & RUN TIME ESTIMATION

DOUBLE 'V'

NOZZLE ON SHELL/DEND) (D/S) ?

CFW= 9

INC. ANG= 45

MATERIAL (SS/STEEL)= STEEL

1). SMAW

2). SAW

3).FCAW (1.2 )

4). GTAW

DENSITY= 0.00000785

NOZZLE O/D=

OFF SET=

194

44

THK= 65

R.F.= 2

3020

SHELL I/D=

19

R.G=

NOZ O/D

194

INC. ANG= 35

ELLIPSE DIMENSION

MAJOR AXIS=

MINOR AXIS=

LG. OF WELDING=

197.1

197

619.1137

ON SHELL

OUTSIDE ROOT RUN

WEIGHT

CALCULATION

O/S WELDING=

C/B WELDING=

TOTAL WELDING=

WELD KG

CROSS SEC. AREA ON SHELL ON D/END

1146.50

5.57

5.57

336.45

1.64

1.63

7.21

7.20

PROCESS

POSITION

CODE

(Y/N)

20%

2.50

1.0

1.15

OUT SIDE BALANCE

80%

2.5

1.0

CHIP BACK WELDING

100%

2.5

1.0

TOTAL =

297503042.xls

12/06/2015

3.2

14.4

6.0

1.3

HRS/KG

2.50

0.56

1.33

6.25

POSITION OF

WELDING

1). 1G

2). 2G

3). 3G

MULTIPLICATION

FACTOR

1

1.6

1.3

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION

FACTOR

1.15

1

CHIP BACK DEPTH(MM)

THK <= 30

6

THK > 30

12

HEATING

CODE

PARAMETERS SETTING

PROCESS

KG/SHIFT

RUN TIME

(min)

(Hrs)

192.2

3.2

668.6

11.1

245.3

4.1

1106.2

18.4

NOZZLE WELD KG & RUN TIME ESTIMATION

'J' GROOVE

NOZZLE ON SHELL/DEND) (D/S) ?

PARAMETERS SETTING

PROCESS

HRS/KG

KG/SHIFT

MATERIAL (SS/STEEL)= STEEL

1). SMAW

2). SAW

DENSITY= 0.00000785 3).FCAW (1.2 )

4). GTAW

NOZZLE LIP O/D=

R.G=

369

3

R.F.= 10

3.2

14.4

6.0

1.3

2.50

0.56

1.33

6.25

OFF SET=

0

R= 12

4644

SHELL I/D=

THK= 80

INC. ANG.= 5

369

INC. ANG.= 5

372.4

372

1169.3

ON SHELL

OUTSIDE ROOT RUN

WEIGHT

CALCULATION

I/S WELDING=

C/B WELDING=

TOTAL WELDING=

CROSS SEC. AREA

1456.86

414.69

PROCESS

WELD KG

ON SHELL ON D/END

13.37

13.37

3.81

3.80

17.18

17.17

POSITION

CODE

HEATING

CODE

(Y/N)

20%

2.5

1.0

1.15

OUT SIDE BALANCE

80%

2.5

1.0

1.15

CHIP BACK WELDING

100%

2.5

1.0

1.15

TOTAL =

297503042.xls

MULTIPLICATION

FACTOR

1

1.6

1.3

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION

FACTOR

1.15

1

NOZ O/D

ELLIPSE DIMENSION

MAJOR AXIS=

MINOR AXIS=

LG. OF WELDING=

POSITION OF

WELDING

1). 1G

2). 2G

3). 3G

12/06/2015

CHIP BACK DEPTH(MM)

THK <= 30

THK > 30

RUN TIME

(min)

(Hrs)

461.4

7.7

1845.4

30.8

656.6

10.9

2963.4

49.4

6

12

NOZZLE WELD KG & RUN TIME ESTIMATION

R.F. PAD +SINGLE 'V'

NOZZLE ON SHELL/DEND) (D/S) ?

CFW= 9

INC. ANG= 35

MATERIAL (SS/STEEL)= STEEL

DENSITY= 0.00000785

PARAMETERS SETTING

PROCESS

KG/SHIFT

1). SMAW

2). SAW

3).FCAW (1.2 )

4). GTAW

INC. ANG= 5

OFF SET=

HRS/KG

3.2

14.4

6.0

1.3

2.50

0.56

1.33

6.25

0

THK= 16

R.F.PAD

5

NOZZLE O/D=

0

00

=2

D

/

DO

PA

602

THK= 20

NOZ O/D

POSITION OF

WELDING

1). 1G

2). 2G

3). 3G

MULTIPLICATION FACTOR

1

1.6

1.3

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION FACTOR

1.15

1

602

FILLET SIZE=30

ELLIPSE DIMENSION

MAJOR AXIS=

MINOR AXIS=

LG. OF WELDING=

4300

SHELL I/D=

R.F.= 2

R.G=

3

WEIGHT

CALCULATION

O/S WELDING=

C/B WELDING=

R.F.PAD WELDING=

TOTAL WELDING=

607.0

605

1903.83

ON SHELL

WELD KG

CROSS SEC. AREA ON SHELL ON D/END

554.79

8.29

8.28

56.55

0.85

0.84

450.00

22.42

22.42

31.55

31.54

CHIP BACK DEPTH(MM)

THK <= 30

THK > 30

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

OUTSIDE ROOT RUN

20%

2.5

1.0

OUT SIDE BALANCE

80%

2.5

1.0

CHIP BACK WELDING

100%

2.5

1.0

R.F.PAD WELDING

100%

2.5

1.0

TOTAL =

297503042.xls

12/06/2015

RUN TIME

(min)

(Hrs)

248.7

4.1

995.0

16.6

126.8

2.1

3362.6

56.0

1370.5

22.8

6

12

NOZZLE WELD KG & RUN TIME ESTIMATION

R.F. PAD +SINGLE 'V'

NOZZLE ON SHELL/DEND) (D/S) ?

CFW= 9

INC. ANG= 45

MATERIAL (SS/STEEL)= STEEL

1). SMAW

2). SAW

3).FCAW (1.2 )

10

INC. ANG= 5

PARAMETERS SETTING

PROCESS

KG/SHIFT

DENSITY= 0.00000785

HRS/KG

3.2

14.4

6.0

2.50

0.56

1.33

OFF SET=

330

THK= 90

R.F.PAD

10

NOZZLE O/D=

/D=

DO

A

P

0

10

345

THK= 90

NOZ O/D

POSITION OF

WELDING

1). 1G

2). 2G

3). 3G

MULTIPLICATION FACTOR

1

1.6

1.3

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION FACTOR

1.15

1

345

FILLET SIZE=40

2450

SHELL I/D=

R.F.= 2

R.G=

3

WEIGHT

CALCULATION

ELLIPSE DIMENSION o/d

I/d

O/S WELDING=

MAJOR AXIS=

381.2

331.2 R.F.PAD WELDING=

MINOR AXIS=

381.2 331.1593 TOTAL WELDING=

LG. OF WELDING=

1197.447

ON D/END

WELD KG

CROSS SEC. AREA ON SHELL ON D/END

13984.83

131.46

131.46

800.00

20.26

20.26

151.71

151.71

CHIP BACK DEPTH(MM)

THK <= 30

THK > 30

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

OUT SIDE BALANCE

100%

0.56

1.0

R.F.PAD WELDING

100%

2.50

1.3

1.15

TOTAL =

BACKING STRIPP DIMENSION

OUTER MAJOR AXIS=

386.2

OUTER MINOR AXIS=

371.0

WIDTH=

25.2

297503042.xls

12/06/2015

RUN TIME

(min)

(Hrs)

4381.9

73.0

4542.3

75.7

8924.1

148.7

6

12

NOZZLE WELD KG & RUN TIME ESTIMATION

R.F. PAD +SINGLE 'V'

NOZZLE ON SHELL/DEND) (D/S) ?

CFW= 9

MATERIAL (SS/STEEL)= STEEL

INC. ANG= 35

5

DENSITY= 0.00000785

OFF SET=

THK= 16

R.F.PAD

PARAMETERS SETTING

PROCESS

KG/SHIFT

HRS/KG

1). SMAW

2). SAW

3).FCAW (1.2 )

4). GTAW

3.2

14.4

6.0

1.3

2.50

0.56

1.33

6.25

POSITION OF

WELDING

1). 1G

2). 2G

3). 3G

MULTIPLICATION

FACTOR

1

1.6

1.3

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION

FACTOR

1.15

1

545

5

R.F.= 2

NOZZLE O/D=

407

=2

O/D

D

PA

00

THK= 17

NOZ O/D

407

4300

SHELL I/D=

FILLET SIZE=30

R.G=

3

INC. ANG=

35

ELLIPSE DIMENSION

MAJOR AXIS=

MINOR AXIS=

LG. OF WELDING=

424.7

410

1311.309

ON SHELL

WELD KG

WEIGHT

CALCULATION

CROSS SEC. AREA ON SHELL ON D/END

I/S WELDING=

129.77

0.42

1.36

C/B(O/S) WELDING=

314.68

1.01

3.30

R.F. PAD WELDING

450.00

22.42

22.42

TOTAL WELDING=

23.85

27.07

CHIP BACK DEPTH(MM)

THK <= 30

THK > 30

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

OUTSIDE ROOT RUN

20%

2.5

1.0

OUT SIDE BALANCE

80%

2.5

1.0

CHIP BACK WELDING

100%

2.5

1.0

R.F.PAD WELDING

100%

2.5

1.0

TOTAL =

297503042.xls

12/06/2015

RUN TIME

(min)

(Hrs)

12.5

0.2

50.1

0.8

151.9

2.5

3362.6

56.0

3577.2

59.6

6

12

NOZZLE WELD KG & RUN TIME ESTIMATION

297503042.xls

12/06/2015

NOZZLE WELD KG & RUN TIME ESTIMATION

R.F.PAD + DOUBLE 'V'

NOZZLE ON SHELL/DEND) (D/S) ?

CFW= 9

INC. ANG= 60

MATERIAL (SS/STEEL)= STEEL

INC. ANG= 10

10

DENSITY= 0.00000785

THK= 30

R.F.PAD

HRS/KG

1). SMAW

2). SAW

3).FCAW (1.2 )

4). GTAW

3.2

14.4

6.0

1.3

2.50

0.56

1.33

6.25

POSITION OF

WELDING

1). 1G

2). 2G

3). 3G

MULTIPLICATION

FACTOR

1

1.6

1.3

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION

FACTOR

1.15

1

OFF SET=

10

330

NOZZLE O/D=

345

40

THK= 60

=

O/D

D

PA

20

00

R.F.= 2

18

NOZ O/D

ELLIPSE DIMENSION

MAJOR AXIS=

MINOR AXIS=

LG. OF WELDING=

2450

SHELL I/D=

345

INC. ANG=

45

363.0

348

1117.086

OUTSIDE ROOT RUN

FILLET SIZE=30

R.G=

WEIGHT

CALCULATION

O/S WELDING=

C/B WELDING=

R.F. PAD WELDING

TOTAL WELDING=

WELD KG

CROSS SEC. AREA ON SHELL ON D/END

4099.95

35.95

35.19

450.00

3.95

3.86

450.00

22.42

22.42

39.90

39.05

PROCESS

ON D/END

POSITION

CODE

CHIP BACK DEPTH(MM)

THK <= 30

THK > 30

HEATING

CODE

(Y/N)

20%

0.56

1.0

OUT SIDE BALANCE

80%

2.5

1.6

1.15

CHIP BACK WELDING

100%

2.5

1.6

1.15

R.F.PAD WELDING

100%

2.5

1.0

1.15

TOTAL =

297503042.xls

PARAMETERS SETTING

PROCESS

KG/SHIFT

12/06/2015

RUN TIME

(min)

(Hrs)

234.6

3.9

7769.2

129.5

1065.9

17.8

3867.0

64.4

12936.7

215.6

6

12

NOZZLE WELD KG & RUN TIME ESTIMATION

SET ON

NOZZLE IN SHELL/DEND) (D/S) ?

50

35

NOZ I/D

MATERIAL (SS/STEEL)=

19

STEEL

DENSITY= 0.00000785

`

INC. ANG.=

15

CFW= 9

INC. ANG.= 50

3

NOZ I/D

203

NOZ O/D

3400

SHELL

I/D=

THK= 70

273

ELLIPSE DIMENSION

MAJOR AXIS=

MINOR AXIS=

LG. OF WELDING=

238.2

238

748.0

WEIGHT CALCULATION

O/S WELDING=

CROSS SEC. AREA

716.09

WELD KG

ON SHELL ON D/END

4.20

4.20

TOTAL WELDING=

ON SHELL

4.20

3.2

14.4

6.0

1.3

POSITION OF

WELDING

1). 1G

2). 2G

3). 3G

MULTIPLICATION

FACTOR

1

1.6

1.3

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION

FACTOR

1.15

1

4.20

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

OUTSIDE ROOT RUN 20%

6.25

1.0

OUT SIDE BALANCE 80%

2.5

1.0

1.15

1.15

TOTAL =

297503042.xls

HRS/KG

1). SMAW

2). SAW

3).FCAW (1.2 )

4). GTAW

2.50

0.56

1.33

6.25

OFFSET=

0

R.F.= 1

R.G.=

PARAMETERS SETTING

PROCESS

KG/SHIFT

12/06/2015

RUN TIME

(min)

(Hrs)

362.6

6.0

580.2

9.7

942.9

15.7

FILLET WELD KG & RUN TIME ESTIMATION

PARAMETERS SETTING

PROCESS

KG/SHIFT

WELD LG (CALCULATED/MANUAL) (C/M?) M

MANUAL LENGTH OF WELDING(MM)=

33615

HRS/KG

1). SMAW

2). SAW

3).FCAW (1.2 )

3.2

14.4

6.0

2.50

0.56

1.33

POSITION OF

WELDING

1). 1F/2F

2) 3F

MULTIPLICATION

FACTOR

1

1.1

PREHEATING

REQUIRED?

YES

NO

MULTIPLICATION

FACTOR

1.15

1

MATERIAL (SS/STEEL)= STEEL

DENSITY= 0.00000785

FOR CALCULATING WELD LENGTH

RADIUS OF WELDING(MM)=

0

INCLUDED ANGLE OF WELDING(DEG)=

0

CALCULATED LENGTH OF WELDING(MM)=

0.000

LENGTH OF WELDING(MM)=

WELD CALCULATION

CROSS SEC. AREA

TOTAL WELDING

18.00

FILLET WELD

297503042.xls

TOTAL WELD KG

4.75

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

2.50

33615.000

1.0

12/06/2015

(min)

712.5

712.5

RUN TIME

(Hrs)

11.9

11.9

FILLET WELD KG & RUN TIME ESTIMATION

DOUBLE SIDE FILLET JOINT

WELDING BY SINGLE OPERATOR/

DOUBLE OPERATOR(S/D)?

WELD LG (CALCULATED/AMNUAL) (C/M?) m

MANUAL LENGTH OF WELDING(MM)=

HRS/KG

1). SMAW

2). SAW

3).FCAW (1.2 )

3.2

14.4

6.0

2.50

0.56

1.33

POSITION OF

WELDING

1). 1F/2F

2) 3F

MULTIPLICATION

FACTOR

1

1.1

PREHEATING

REQUIRED?

MULTIPLICATION

FACTOR

YES

1.15

NO

1000

MATERIAL (SS/STEEL)= STEEL

13

DENSITY= 0.00000785

FOR CALCULATING WELD LENGTH

RADIUS OF WELDING(MM)=

0

INCLUDED ANGLE OF WELDING(DEG)=

0

CALCULATED LENGTH OF WELDING(MM)=

0.000

LG OF WELDING=

1000.000

13

WELD CALCULATION

FIRST SIDE WELDING

SECOND SIDE WELDING

TOTAL WELDING=

CROSS SEC. AREA

84.50

84.50

TOTAL WELD KG

0.66

0.66

169.00

1.33

DOUBLE OPERATOR

PROCESS

POSITION

CODE

HEATING

CODE

(Y/N)

FIRST SIDE

100%

2.50

1.0

SECOND SIDE SIDE

100%

2.50

1.0

1

1

TOTAL=

297503042.xls

PARAMETERS SETTING

PROCESS

KG/SHIFT

12/06/2015

(min)

99.5

99.5

99.5

RUN TIME

(Hrs)

1.7

1.7

1.7

FILLET WELD KG & RUN TIME ESTIMATION

DOUBLE SIDE FILLET JOINT

WELDING BY SINGLE OPERATOR/

DOUBLE OPERATOR(S/D)?

PARAMETERS SETTING

PROCESS

KG/SHIFT

HRS/KG

1). SMAW

2).FCAW (1.2 )

3.2

6.0

2.50

1.33

POSITION OF

WELDING

1). 1F/2F

2) 3F

MULTIPLICATION

FACTOR

1

1.1

PREHEATING

REQUIRED?

MULTIPLICATION

FACTOR

YES

1.15

NO

MATERIAL (SS/STEEL)= STEEL

SECOND SIDE

20CFW

20CFW

FIRST SIDE

WELD CALCULATION

FIRST SIDE WELDING

SECOND SIDE WELDING

TOTAL WELDING=

DENSITY= 0.00000785

O/D= 400

CROSS SEC. AREA

200.00

200.00

TOTAL WELD KG

1.94

2.01

400.00

3.95

SINGLE OPERATOR

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

FIRST SIDE

100%

2.50

1.0

SECOND SIDE SIDE

100%

2.50

1.0

1.1

1.1

TOTAL=

297503042.xls

12/06/2015

(min)

320.1

331.0

651.1

RUN TIME

(Hrs)

5.3

5.5

10.9

FILLET WELD KG & RUN TIME ESTIMATION

DOUBLE SIDE + FULL PENETATION JOINT

PARAMETERS SETTING

PROCESS

KG/SHIFT

PROCESS? (DOT/ WITH CHIP

BACK/TIG+SMAW) (D/C/T) ?

WELD LG (CALCULATED/AMNUAL) (C/M?) C

MANUAL LENGTH OF WELDING(MM)=

MATERIAL (SS/STEEL)= STEEL

20

60

10

RG=

DEG

2

2

20

10000

DENSITY= 0.00000785

FOR CALCULATING WELD LENGTH

RADIUS OF WELDING(MM)=

1000

INCLUDED ANGLE OF WELDING(DEG)=

360

CALCULATED LENGTH OF WELDING(MM)=

6283.185

LENGTH OF WELDING(MM)=

6283.185

HRS/KG

1). SMAW

2). SAW (TWIN HEAD)

3).FCAW (1.2 )

4). GTAW+SMAW

3.2

14.4

6.0

1.3

2.50

0.56

1.33

6.25

FOR TIG

POSITION OF

WELDING

1). 1F/2F

2) 3F

MULTIPLICATION

FACTOR

1

1.1

PREHEATING

REQUIRED?

MULTIPLICATION

FACTOR

YES

1.15

NO

CHIP BACK DEPTH(MM)= 6

WELD CALCULATION

FIRST SIDE WELDING

SECOND SIDE WELDING

CROSS SEC. AREA

137.59

194.14

TOTAL WELD KG

6.79

9.58

331.73

16.36

TOTAL WELDING=

WITH CHIP BACK

(INCLUDING CHIP BACK)

PROCESS

POSITION

HEATING

CODE

CODE

(Y/N)

FIRST SIDE

100%

2.63

1.0

1.1

SCOND SIDE SIDE

100%

2.63

1.0

1.1

TOTAL=

297503042.xls

12/06/2015

(min)

1175.7

1658.9

2834.7

RUN TIME

(Hrs)

19.6

27.6

47.2

OVERLAY WELD KG & RUN TIME ESTIMATION

FORGING

GASKET FACE O/LAY

O/D OF GASKET FACE O/LAY=

BORE OF FLANGE AFTER O/L=

MEAN DIA OF GASKER GROOVE=

DEPTH OF GASKET GROOVE=

WIDTH OF GROOVE AT TOP=

THK OF O/LAY=

GASKET FACE O/LAY=

BORE O/LAY

229

165

200

10

23

8

BORE OF FLANGE AFTER O/LAY=

LENGTH OF FLANGE/FORG=

THK OF O/LAY=

2.423601 KG

BORE O/LAY=

165

1234

8

42.9231 KG

BACK FACE O/LAY

O/D OF LIP =

BORE OF FORG AFTER O/L=

THK OF O/LAY=

BACK FACE O/LAY=

TOTAL O/LAY=

487

381

6

3.46862 KG

48.81532 KG

KG

PROCESS

GASKET FACE OVER LAY

2.4

2.00

1.00

BORE OVER LAY

42.9

1.14

1.15

BACK FACE (PROFILE) OVER LAY

3.5

1.33

CODE

(Y/N)

1.00

TOTAL=

297503042.xls

RUN TIME

HEATING

(min)

291

3385

277

3953.1

12/06/2015

(Hrs)

4.8

56.4

4.6

65.9

PARAMETERS SETTING

PROCESS

KG/SHIFT

1). SMAW

2).FCAW (1.2 )(M/C)

3). FCAW (MANUAL)

HRS/KG

4

7

6

2.00

1.14

1.33

PREHEATING

REQUIRED?

YES

MULTIPLICATION

FACTOR

1.15

NO

OVERLAY WELD KG & RUN TIME ESTIMATION

FLANGE

GASKET FACE O/LAY

O/D OF GASKET FACE O/LAY=

BORE OF FLANGE AFTER O/L=

DIA OF GASKER GROOVE=

DEPTH OF GASKET GROOVE=

WIDTH OF GROOVE AT TOP=

THK OF O/LAY=

BORE O/LAY

483

381

450

0

0

7

BORE OF FLANGE AFTER O/LAY=

LENGTH OF FLANGE=

THK OF O/LAY=

GASKET FACE O/LAY=

3.876072 KG

TOTAL O/LAY=

13.68025 KG

KG

BORE O/LAY=

PROCESS

HEATING

CODE

(Y/N)

GASKET FACE OVER LAY

3.9

2.00

1.00

BORE OVER LAY

9.8

1.14

1.00

9.804182 KG

RUN TIME

TOTAL=

297503042.xls

381

168

6

(min)

465

672

1137.4

12/06/2015

(Hrs)

7.8

11.2

19.0

PARAMETERS SETTING

PROCESS

KG/SHIFT

1). SMAW

2).FCAW (1.2 )(M/C)

3). FCAW (MANUAL)

PREHEATING

REQUIRED?

YES

NO

4

7

6

HRS/KG

2.00

1.14

1.33

MULTIPLICATION

FACTOR

1.15

1

OVERLAY WELD KG & RUN TIME ESTIMATION

ELBOW

I/D O/LAY

BORE OF ELBOW AFTER O/LAY=

RADIUS OF ELBOW

INCLUDED ANGLE OF ELBOW=

THK OF O/LAY=

BORE O/LAY=

448

1176

90

8

1). SMAW

2). FCAW (MANUAL)

PREHEATING

REQUIRED?

YES

NO

169.3643 KG

BORE OVER LAY

297503042.xls

PARAMETERS SETTING

PROCESS

KG/SHIFT

KG

PROCESS

HEATING

(Y/N)

169.4

CODE

1.33

1.00

12/06/2015

4

6

2.00

1.33

MULTIPLICATION

FACTOR

1.15

1

RUN TIME

(min)

13549

HRS/KG

(Hrs.)

225.8

OVERLAY WELD KG & RUN TIME ESTIMATION

PIPE

I/D O/LAY

BORE OF PIPE AFTER O/LAY=

LENGTH OF PIPE=

THK OF O/LAY=

BORE O/LAY=

381

463

6

1). SMAW

2).FCAW (1.2 )(M/C)

3). FCAW (MANUAL)

27.01986 KG

KG

BORE OVER LAY

297503042.xls

PARAMETERS SETTING

PROCESS

KG/SHIFT HRS/KG

27.0

PREHEATING

REQUIRED?

YES

NO

PROCESS

HEATING

CODE

(Y/N)

1.14

1.15

12/06/2015

4

7

6

MULTIPLICATION

FACTOR

1.15

1

RUN TIME

(min)

2131

2.00

1.14

1.33

(Hrs.)

35.5

OVERLAY WELD KG & RUN TIME ESTIMATION

CIRC. SEAM/ LONG SEAM OVERLAY

I/D OF SHELL=

THK OF O/LAY=

CLAD STRIP ANG.=

THK OF CLAD=

CALCULATION

WIDTH OF O/LAY=

R.F. WIDTH=

AREA OF O/LAY=

3400

6

45

5

THK=

I/S INC. ANG.=

I/S 'V' HEIGHT=

CLAD STRIPPING=

ROOT GAP=

LG OF CEAM=

65

78

364.5095

C/SEAM O/LAY=

PARAMETERS SETTING

PROCESS

KG/SHIFT

70

35

47

15

3

10697.12

1). SMAW

2).FCAW (1.2 )(M/C)

3). FCAW (MANUAL)

PREHEATING

REQUIRED?

YES

NO

30.60874

THK=

C/SEAM OR L/SEAM (LS/CS)?

70

47

35

5

R.G.=

3

5

15

45

O/L THK=

6

35

I/D OF SHELL= 3400

KG

CIRC. SEAM OVER LAY

297503042.xls

30.6

PROCESS

HEATING

CODE

(Y/N)

2.00

1.15

12/06/2015

RUN TIME

(min)

4224

(Hrs.)

70.4

4

7

6

HRS/KG

2.00

1.14

1.33

MULTIPLICATION

FACTOR

1.15

1

CS

SHELL ESSC OVERLAY WELD KG & RUN TIME ESTIMATION

SHELL ESSC OVERLAY

I/D OF SHELL BEFORE O/LAY=

LENGTH OF SHELL=

THK OF O/LAY=

BORE O/LAY=

PARAMETERS SETTING

PROCESS

KG/SHIFT

4500

2250

8

1) ESSC (60 WD)

2) ESSC (90WD)

3) ESSC (120 WD)

2032.133 KG

KG

PROCESS

CODE

I/D OVER LAY(WITH 2 OPERATOR)

297503042.xls

2032.1

0.18

RUN TIME

(min)

44337

12/06/2015

(Hrs.)

739.0

44

66

84

HRS/KG

0.18

0.12

0.10

Das könnte Ihnen auch gefallen

- Weld CalculationDokument34 SeitenWeld CalculationAshwani DograNoch keine Bewertungen

- Welding CalculationsDokument14 SeitenWelding Calculationsjitulpatil100% (6)

- Wrapping Material CalculationDokument1 SeiteWrapping Material CalculationBiginchNoch keine Bewertungen

- Fillet Welding CalculationDokument6 SeitenFillet Welding Calculationulul khanNoch keine Bewertungen

- Welding CalculationsDokument16 SeitenWelding Calculationsmt92606222100% (2)

- Weld Metal CalculationDokument20 SeitenWeld Metal CalculationJegan Thiyagarajan100% (1)

- Long Seam/Circ Seam Weld KG & Run Time EstimationDokument16 SeitenLong Seam/Circ Seam Weld KG & Run Time EstimationTiago FerreiraNoch keine Bewertungen

- A Guide To Estimating The Consumption of Welding Consumables-NADokument1 SeiteA Guide To Estimating The Consumption of Welding Consumables-NAManuel Antonio Santos VargasNoch keine Bewertungen

- Welding Calculations For Base PlateDokument116 SeitenWelding Calculations For Base PlateSyedZainAli100% (2)

- Welding CalculatorDokument10 SeitenWelding Calculatorneel0% (2)

- Weld WeightDokument10 SeitenWeld WeightDivyesh PatelNoch keine Bewertungen

- Electrodes CalculatorDokument2 SeitenElectrodes CalculatorAsebaho Badr100% (1)

- Weldment Strength Excel CalculationsDokument38 SeitenWeldment Strength Excel CalculationsRAMSINGH CHAUHAN100% (4)

- Weld Cost CalculationDokument27 SeitenWeld Cost Calculation-Abdul Khodir Van Java-100% (7)

- Heat Treatment Requirement Heat Treatment Requirement: o o o oDokument2 SeitenHeat Treatment Requirement Heat Treatment Requirement: o o o ofizanlaminNoch keine Bewertungen

- All Materials DocumentsDokument1 SeiteAll Materials DocumentsHarnish BariaNoch keine Bewertungen

- Weld Cost CalculationDokument15 SeitenWeld Cost CalculationMustafa KaramürselNoch keine Bewertungen

- Weld CalculatorDokument6 SeitenWeld Calculatorshahid khanNoch keine Bewertungen

- Weld Cost Calc XLDokument10 SeitenWeld Cost Calc XLSusheel ShuklaNoch keine Bewertungen

- Welding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFDokument1 SeiteWelding Cost Estimation For 12 Joints in 8 NPS SCH 80 PDFAnonymous VRspXsmNoch keine Bewertungen

- Steam DistillationDokument28 SeitenSteam Distillationami tiuNoch keine Bewertungen

- Böhler Welding CalcDokument2 SeitenBöhler Welding CalcMOHAN0% (1)

- Plumbing and Pipe Line Work PDFDokument248 SeitenPlumbing and Pipe Line Work PDFLoren ViejayNoch keine Bewertungen

- Weld Metal Calculation 1Dokument6 SeitenWeld Metal Calculation 1Nabihah NurulhudaNoch keine Bewertungen

- Welding Rod Cal (1) .Dokument7 SeitenWelding Rod Cal (1) .hakr5100% (1)

- Guide 14: SSPC: The Society For Protective CoatingsDokument4 SeitenGuide 14: SSPC: The Society For Protective CoatingsanoopkumarNoch keine Bewertungen

- Weld Metal CalculationDokument1 SeiteWeld Metal CalculationKiukStaksNoch keine Bewertungen

- Weld Cost CalculationDokument30 SeitenWeld Cost CalculationDenial BasanovicNoch keine Bewertungen

- Welding Prcesses Estimation RecordDokument5 SeitenWelding Prcesses Estimation RecorddineshshankarNoch keine Bewertungen

- Welding and Fabrication NoteDokument54 SeitenWelding and Fabrication NoteluminiousNoch keine Bewertungen

- Weld Consumable CalculatorDokument7 SeitenWeld Consumable CalculatoretienetergolinoNoch keine Bewertungen

- Double V Weld CalculationDokument8 SeitenDouble V Weld CalculationHgagselim SelimNoch keine Bewertungen

- Cone DevelopmentDokument2 SeitenCone DevelopmentpandiangvNoch keine Bewertungen

- Selection of Welding Electrodes PDFDokument1 SeiteSelection of Welding Electrodes PDFAnonymous VohpMtUSNNoch keine Bewertungen

- Cross Section Area in MM: Enter The THK-T in MM Enter The Deg-DDokument7 SeitenCross Section Area in MM: Enter The THK-T in MM Enter The Deg-DAnas MaliyekkalNoch keine Bewertungen

- Dyeing CalculationDokument4 SeitenDyeing CalculationIftakharul IslamNoch keine Bewertungen

- Skirt Support TrialDokument11 SeitenSkirt Support TrialAbhishek Nag50% (2)

- WeldkgDokument5 SeitenWeldkgalokbdasNoch keine Bewertungen

- Deposition RateDokument4 SeitenDeposition Rateahmed100% (1)

- Calculation of Electrode ConsumptionDokument4 SeitenCalculation of Electrode ConsumptionhgolestaniNoch keine Bewertungen

- The Guide To Hot Stamping and Foil Selection PDFDokument44 SeitenThe Guide To Hot Stamping and Foil Selection PDFjavisapi1100% (1)

- Weld CalculationsDokument12 SeitenWeld Calculationshakr5100% (1)

- AWSPipeWeld - American Welding SocietyDokument2 SeitenAWSPipeWeld - American Welding Societybarukomkss100% (1)

- Weld CalculationDokument7 SeitenWeld CalculationDenny Syamsuddin100% (1)

- BASF Oilfield-Solutions DrillingDokument6 SeitenBASF Oilfield-Solutions DrillingYaroslav RuizNoch keine Bewertungen

- Final Weld Strength CalnsDokument3 SeitenFinal Weld Strength CalnsSajal KulshresthaNoch keine Bewertungen

- Weld Consumable CalculatorDokument3 SeitenWeld Consumable CalculatorramausNoch keine Bewertungen

- Calculation Software of WeldingDokument1 SeiteCalculation Software of WeldinghaharameshNoch keine Bewertungen

- Lifting TrunionDokument1 SeiteLifting TrunionRUDHRA DHANASEKAR0% (1)

- How To Calculate Filler MetalDokument3 SeitenHow To Calculate Filler MetalEdgar Coavas PérezNoch keine Bewertungen

- Electrode CalculationDokument2 SeitenElectrode CalculationKenshin HimuraNoch keine Bewertungen

- Weld Deposite CalculationsDokument2 SeitenWeld Deposite CalculationsMohammad ElhedabyNoch keine Bewertungen

- 07 Piping BOQDokument54 Seiten07 Piping BOQHRK65Noch keine Bewertungen

- Result Test Panel (SUS409) HES-specDokument25 SeitenResult Test Panel (SUS409) HES-specLe Manh DungNoch keine Bewertungen

- Sheet For Calculation of Welding ElectrodesDokument4 SeitenSheet For Calculation of Welding ElectrodesthehraoNoch keine Bewertungen

- Preliminary Welding Procedure Specification (PWPS)Dokument1 SeitePreliminary Welding Procedure Specification (PWPS)AzriNoch keine Bewertungen

- S.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMDokument12 SeitenS.No SL - No Mogura Deuma Two Tee's One I Two Tee's Du. No Web TCK, MM Flange TCK, MM Width, MM Length, MMRajiv DamodarNoch keine Bewertungen

- BuoyancyDokument1 SeiteBuoyancyLcm TnlNoch keine Bewertungen

- Long Seam: Long Seam/Circ Seam Weld KG & Run Time EstimationDokument14 SeitenLong Seam: Long Seam/Circ Seam Weld KG & Run Time EstimationmhsalihNoch keine Bewertungen

- Unit-4 TG Desk Engineer'S Log BookDokument6 SeitenUnit-4 TG Desk Engineer'S Log BookJai GuptaNoch keine Bewertungen

- PSSPL Heat Load SheetDokument13 SeitenPSSPL Heat Load Sheetನವೀನ್ಕುಮಾರ್Noch keine Bewertungen

- Weld WeightDokument6 SeitenWeld WeightDesaiNoch keine Bewertungen

- Weld Weight 1Dokument2 SeitenWeld Weight 1francisco zepedaNoch keine Bewertungen

- Circ Seam: Long Seam/ Circ Seam Weld KG & Run Time EstimationDokument10 SeitenCirc Seam: Long Seam/ Circ Seam Weld KG & Run Time EstimationpelotoNoch keine Bewertungen

- Engineering Declaration Unit # 2 JindalDokument16 SeitenEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- EISA504 IMO9471886 Preliminary Test ConditionsRev2 57334319 57226253Dokument93 SeitenEISA504 IMO9471886 Preliminary Test ConditionsRev2 57334319 57226253islimaNoch keine Bewertungen

- Circ Seam: Run Time Time Required For L/Seam or C/Seam (LS/CS) CsDokument5 SeitenCirc Seam: Run Time Time Required For L/Seam or C/Seam (LS/CS) CsMina RemonNoch keine Bewertungen

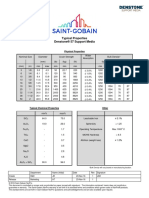

- 1 Pharma, Food & Biotech ProductsDokument4 Seiten1 Pharma, Food & Biotech ProductsDenial BasanovicNoch keine Bewertungen

- DB 650 GBDokument6 SeitenDB 650 GBDenial BasanovicNoch keine Bewertungen

- DB 698 GBDokument8 SeitenDB 698 GBDenial BasanovicNoch keine Bewertungen

- DB 658 688 GBDokument6 SeitenDB 658 688 GBDenial BasanovicNoch keine Bewertungen

- Diaphragm Valve, Metal: ConstructionDokument6 SeitenDiaphragm Valve, Metal: ConstructionDenial BasanovicNoch keine Bewertungen

- Diaphragm Valve, Metal: ConstructionDokument4 SeitenDiaphragm Valve, Metal: ConstructionDenial BasanovicNoch keine Bewertungen

- With Air Cooled Condenser: Dritec Pro 150CDokument2 SeitenWith Air Cooled Condenser: Dritec Pro 150CDenial BasanovicNoch keine Bewertungen

- VN LeafletDokument6 SeitenVN LeafletDenial BasanovicNoch keine Bewertungen

- 1 Visions and PerspectivesDokument6 Seiten1 Visions and PerspectivesDenial BasanovicNoch keine Bewertungen

- Air Treatment Image BrochureDokument8 SeitenAir Treatment Image BrochureDenial BasanovicNoch keine Bewertungen

- DryCool BrochureDokument8 SeitenDryCool BrochureDenial BasanovicNoch keine Bewertungen

- Abrechnung 0 Januar 07: Zurück Zum PlanerDokument12 SeitenAbrechnung 0 Januar 07: Zurück Zum PlanerDenial BasanovicNoch keine Bewertungen

- April D, Yyyy Week at A Gla Notes / To Do LiDokument3 SeitenApril D, Yyyy Week at A Gla Notes / To Do LiDenial BasanovicNoch keine Bewertungen

- Maintenance Schedule WorksheetDokument2 SeitenMaintenance Schedule WorksheetDenial BasanovicNoch keine Bewertungen

- ArcelorMittal NC E1.2 I-Sections ParallelDokument5 SeitenArcelorMittal NC E1.2 I-Sections ParallelMichaelNoch keine Bewertungen

- Silty Soil Stabilization Using Bituminous Emulsion - SabbaniVenkatesh-52Dokument8 SeitenSilty Soil Stabilization Using Bituminous Emulsion - SabbaniVenkatesh-5201 - HUTOMO KASPAR KURNIAWANNoch keine Bewertungen

- Final Estimation For Rate PreparationDokument5 SeitenFinal Estimation For Rate PreparationmanojNoch keine Bewertungen

- 0620 w21 Ms 62 PDFDokument8 Seiten0620 w21 Ms 62 PDFEndeavor Med TutorsNoch keine Bewertungen

- Sdarticle 18 PDFDokument8 SeitenSdarticle 18 PDFPpa Gpat AmitNoch keine Bewertungen

- Sikadur - 52: Low Viscosity Injection ResinDokument3 SeitenSikadur - 52: Low Viscosity Injection ResinSunny RohillaNoch keine Bewertungen

- IG MetalWorks-Open-Cell en AUDokument2 SeitenIG MetalWorks-Open-Cell en AUKshitij MeshramNoch keine Bewertungen

- Sikament - 600: High Range Water-Reducing Concrete AdmixtureDokument3 SeitenSikament - 600: High Range Water-Reducing Concrete Admixturedeboline mitraNoch keine Bewertungen

- Insulated Pipes - Heat Loss DiagramsDokument7 SeitenInsulated Pipes - Heat Loss DiagramsmimiNoch keine Bewertungen

- WS Grade 10 IG Chemistry 23-24 - Rate of ReactionDokument6 SeitenWS Grade 10 IG Chemistry 23-24 - Rate of ReactionSiyaNoch keine Bewertungen

- Alloy-Steel and Stainless Steel Bolting For Low-Temperature ServiceDokument8 SeitenAlloy-Steel and Stainless Steel Bolting For Low-Temperature ServiceGonzaloNoch keine Bewertungen

- Technological Advancement in FashionDokument37 SeitenTechnological Advancement in FashionMitali KapoorNoch keine Bewertungen

- AISI 4130 Alloy SteelDokument2 SeitenAISI 4130 Alloy SteelKandeepanNoch keine Bewertungen

- Manuscript - Stress Corrosion Cracking of Stainless Steel Pipes For Methyl-Methacrylate Process PlantsDokument23 SeitenManuscript - Stress Corrosion Cracking of Stainless Steel Pipes For Methyl-Methacrylate Process PlantsadammplouhNoch keine Bewertungen

- Full download Solution Manual for the Law and Business Administration in Canada Plus Companion Website Without Pearson Etext Package 14 e j e Smyth Dan Soberman Alex Easson Shelley Mcgill pdf full chapterDokument35 SeitenFull download Solution Manual for the Law and Business Administration in Canada Plus Companion Website Without Pearson Etext Package 14 e j e Smyth Dan Soberman Alex Easson Shelley Mcgill pdf full chapterimplumededgebonea3ny100% (18)

- SL - No. Unit Rate. QuantityDokument6 SeitenSL - No. Unit Rate. QuantityNaveen RevannaNoch keine Bewertungen

- B403-12 Standard Specification For Magnesium-Alloy Investment CastingsDokument4 SeitenB403-12 Standard Specification For Magnesium-Alloy Investment CastingsmithileshNoch keine Bewertungen

- A Bright Future For Copper Electrowinning: Michael Moats and Michael FreeDokument3 SeitenA Bright Future For Copper Electrowinning: Michael Moats and Michael Freealexis diazNoch keine Bewertungen

- CFT - Unit V - Chemicals and AuxiliariesDokument19 SeitenCFT - Unit V - Chemicals and AuxiliariesBalaji SureshNoch keine Bewertungen

- NullDokument1 SeiteNullwassimmahfouzNoch keine Bewertungen

- 00 IPC TM650 Contents October 2004Dokument8 Seiten00 IPC TM650 Contents October 2004Emanuel KszenicsNoch keine Bewertungen

- Denstone® 57 Support Media Typical PropertiesDokument1 SeiteDenstone® 57 Support Media Typical PropertiesJuan Victor Sulvaran ArellanoNoch keine Bewertungen

- SeraConP ARDokument5 SeitenSeraConP ARArbab SkunderNoch keine Bewertungen

- Adsorption: By: Zhraa Abas 3ed StageDokument18 SeitenAdsorption: By: Zhraa Abas 3ed Stageado cNoch keine Bewertungen