Beruflich Dokumente

Kultur Dokumente

Frictionless Compressor Technology Journal

Hochgeladen von

VishnuCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Frictionless Compressor Technology Journal

Hochgeladen von

VishnuCopyright:

Verfügbare Formate

Reprinted from HPAC Engineering January 2004 issue.

Frictionless-

Compressor

Technology

New compressor makes chillers cleaner,

quieter, and more energy-efficient

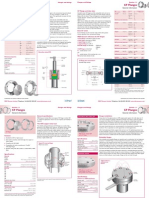

new compressor technology intro- THE BEARINGS

Traditional centrifugal compressors use roller

duced during the 2003 International

Air-Conditioning, Heating, Refrig- bearings and hydrodynamic bearings, both of

erating Exposition (AHR Expo), held last January which consume power and require oil and a lubrication system. Recently, ceramic

in Chicago, may have a significant

effect on the future of mid-range By HUGH CROWTHER, PE, roller bearings, which avoid issues

and

related to oil and reduce power conchillers and rooftop applications

EUGENE SMITHART, PE

sumption, were introduced to the

in water-cooled, evaporatively

HVAC industry. The lubrication of

cooled, and air-cooled chilledwater and direct-expansion (DX) systems. these bearings is provided by the refrigerant itself.1

Designed and optimized to take full

advantage of magnetic-bearing technology, the compressor was awarded

Touchdown

Permanent-magnet

the first AHR Expo Innovation

bearings

synchronous motor

Award in the energy category, as well

as Canadas Energy Efficiency Award

for its potential to reduce utility-genShaft and

Compressor

impellers

erated greenhouse-gas emissions. The

cooling

compressor is key to a new watercooled centrifugal-chiller design, with

Inlet-guide-vane

Magnetic bearings

Air-Conditioning and Refrigeration

assembly

and bearing sensors

Institute (ARI) tests indicating integrated part-load values (IPLVs) not

normally seen with conventional

chillers in this tonnage range.

This article describes this new The TT300 compressors onboard digital electronics manage operation

compressor technology and its first use while providing external control and Web-enabled access to a full array of

in an ARI-certified chiller design.

performance and reliability information.

Hugh Crowther, PE, is the global director of applications for McQuay International in Minneapolis. With more

than 15 years of experience in large-HVAC-system design, he has written numerous articles and application

guides related to HVAC design. Contact him at hugh.crowther@mcquay.com. Eugene (Smitty) Smithart,

PE, is vice president of sales and marketing for Turbocor in La Crosse, Wis. With nearly 30 years of experience, he

is well-known in the HVACR industry, having published numerous articles and been involved in a number of

industry-changing initiatives. A recipient of the U.S. Environmental Protection Agencys Climate Protection

Award, he can be contacted at smitty@turbocor.com.

F R I C T I O N L E S S

Magnetic-bearing technology is significantly different. A digitally controlled

magnetic-bearing system, consisting of

both permanent magnets and electromagnets, replaces conventional lubricated

bearings. The frictionless compressor

shaft is the compressors only moving

component. It rotates on a levitated

magnetic cushion (Figure 1). Magnetic

bearingstwo radial and one axial

hold the shaft in position (Figure 2).

When the magnetic bearings are energized, the motor and impellers, which

are keyed directly to the magnetic shaft,

levitate. Permanent-magnetic bearings

do the primary work, while digitally

controlled electromagnets provide the

fine positioning. Four positioning signals

per bearing hold the levitated assembly to

a tolerance of 0.00002 in. As the levitated

assembly moves from the center point,

the electromagnets intensity is adjusted

to correct the position. These adjustments

occur 6 million times a minute. The software has been designed to automatically

compensate for any out-of-balance condition in the levitated assembly.

C O M P R E S S O R S

Y-axis

position

sensor

Target sleeve

Y-axis

position

sensor

Channels

0-1

X-axis

position sensor

Channels

2-3

Channel

4

X-axis

position sensor

Impellers

Z-axis Sensor Front

position ring radial

sensor

bearing

Motor

Sensor

ring

Rear

radial

bearing

Axial bearing

FIGURE 2. A digitally controlled magnetic-bearing system consisting of two radial and

one axial bearing levitate the compressors rotor shaft and impellers during rotation.

fail, the touchdown bearings (also known

as backup bearings) are used to prevent a

compressor failure.

The compressor uses capacitors to

smooth ripples in the DC link in the

motor drive. Instantaneously after

a power failure, the motor becomes a

generator, using its angular momentum

to create electricity (sometimes known as

back EMF) and keeping the capacitors

charged during the brief coastdown

period. The capacitors, in turn, provide

SHUTDOWNS AND POWER FAILURES

enough power to maintain levitation

When the compressor is not running, during coastdown, allowing the motor

the shaft assembly rests on graphite-lined, rotor to stop and delevitate. This feature

radially located touchdown bearings. The allows the compressor to see a power

magnetic bearings normally position the outage as a normal shutdown.

rotor in the proper location, preventing

contact between the rotor and other OIL-FREE DESIGN

Oil management, particularly as it

metallic surfaces. If the magnetic bearings

pertains to the lubrication of compressor

bearings, is a critical issue in refrigerationsystem design. But with magnetic bearings, this issue is avoided. Only a very

small amount of oil is required to lubricate other system components, such as

seals and valves; often, however, experience shows that even this small amount

of oil is not needed. Avoiding oil-management systems means avoiding the

capital cost of oil pumps, sumps, heaters,

coolers, and oil separators, as well as the

labor and time required to perform oilrelated services. Reports indicate that

FIGURE 1. Electromagnetic cushions

continually change in field strength to keep for many installations, compressor-mainthe rotor shaft centrally positioned.

tenance costs have been cut by more

than 50 percent.

Most air-cooled products (including

chillers, rooftop units, and condensing

units) use DX evaporators. Most DX

systems allow oil to travel through the

refrigeration circuit and back to the

compressor oil sump. Great care must be

taken during design to provide oil return,

particularly at part load, when refrigerant

flow rates are reduced.

Water-cooled chillers often use

flooded evaporators. In a flooded evaporator, even small amounts of oil can coat

evaporator tubes and significantly diminish chiller performance. This can lead

to an elaborate oil-recovery system.

Magnetic bearings eliminate the need

for these systems and oil management in

general. In fact, the only required regular

maintenance of the compressor is the

quarterly tightening of the terminal

screws, the annual blowing off of dust

and cleaning of the boards, and the

changing of the capacitors every five

years. Complete service agreements and

extended maintenance contracts can be

provided by the manufacturer.

THE MOTOR

Most hermetic compressors use induction motors cooled by either liquid or

suction-gas refrigerant. Induction motors have copper windings that, when

alternating current is run through them,

create the magnetic fields that cause the

motor to turn. These copper windings

are bulky, adding size and weight to the

compressor.

Two-pole, 60-Hz induction motors

operate at approximately 3,600 rpm. A

higher number of revolutions per

minute can be obtained by increasing

the frequency. Compressors that require

higher shaft speeds tend to use gears.

While gears are a proven technology,

they create noise and vibration, consume

power, and require lubrication.

The magnet-bearing compressor features a synchronous permanent-magnet

brushless DC motor with a completely

integrated variable-frequency drive

(VFD). The stator windings found on

conventional induction motors are

replaced with a permanent-magnet rotor. Alternating current from the inverter energizes the armature windings.

The stator (excitation) and rotor (armature) change places. No commutator brushes are required.

The motor and key electronic

components are internally refrigerant-cooled, so no special

cooling is required for the

VFD or the motor.

The use of permanent magnets instead of rotor windings

makes the motor smaller and

lighter than induction motors. Using magnetic-bearing

technology, a 75-ton compressor weighs 265 lbabout one-fifth

the weight of a conventional compressor.

A variable-speed drive (VSD) is required for the motor to operate. The

VSD varies the frequency between 300

and 800 Hz, which provides a compressor-speed range from 18,000 to 48,000

rpm. This avoids a gear set. The VSD is

integrated into the compressor housing, avoiding long leads and allowing

key electronic components to be refrigerant-cooled. The VSD also acts as a

soft starter; as a result, the compressor

has an extremely low startup in-rush

current: less than 2 amps, compared

with 500 to 600 amps for a traditional

75-ton, 460-v screw compressor with a

cross-the-line starter.

F R I C T I O N L E S S

C O M P R E S S O R S

With the integration of the motor,

VSD, and magnetic-bearing system,

the capacitors required for the motor

and drive can be used as a backup

power source for the bearings

in the event of a power outage or emergency shutdown.

ment projects are expanding the range

and duty of the compressor wheels and

promise to offer even greater efficiency

for water-cooled and air-cooled duties

and different capacities.

CAPACITY AND EFFICIENCY

Among the key parameters affecting

performance are capacity (tons) and efficiency (kilowatts per ton). The compressors capacity ranges from 60 to 90 tons,

depending on the operating conditions.

Plans call for that range to be extended

to 150 tons water-cooled and 115 tons

air-cooled by the end of 2004 with the

use of R-134a refrigerant. An R-22 version is planned for retrofit applications.

Efficiency improvements stem from

a combination of the centrifugal com-

CONTROLS

The new compressor effectively is

a computer. It provides diagnostic and

performance information through Modbus to the refrigeration system, which

then communicates to the building

automation system through Modbus,

LonWorks, or BACnet.

CHILLER APPLICATION

The compressor manufacturer and a

major chiller manufacturer teamed up

to develop a line of ARI-certified watercooled chillers, which were expected to

be introduced in January 2004. The

combination of flooded-evaporator technology and an oil-free

system has allowed very close

approaches and, subsequently,

enhanced performance. The integrated VFD allows excellent

part-load performance as power

consumption drops off,

depending on the head relief,

near the cube root of the shaft

speed.

The compressor includes

wheels tuned for water-cooled

duty in the dual-compressor format,

which further enhances part-load performance. Tested in accordance with ARI

Standard 550/590-98, Water Chilling

Packages Using the Vapor Compression Cycle, a 150-ton (nominal) chiller has a fullload performance of 0.629 KW per ton

(5.6 COP) and an IPLV of 0.375 KW per

ton (9.4 COP).

All IPLVs are weighted for standard

operating conditions and the time spent

at those conditions. Specific operating

points for a 150-ton nominal-capacity

chiller are shown in Figure 3.

Magnetic-bearing compressors offer

economic,energy,and environmental

benefits,including increased energy

efficiency,the elimination of oil,and

considerably less noise and vibration.

pressor, permanent-magnet motor, and

magnetic bearings. Within the compressor, efficiency is affected by the

compressor isentropic efficiency (the

efficiency of the wheels), the motor,

and the bearings. Traditional induction

motors of this size typically are in the

92-percent efficiency range. This compressors permanent-magnet motor has

an efficiency of 96 to 97 percent.

Efficiency is further enhanced with

the use of magnetic bearings, which

avoid the friction of rubbing parts associated with traditional oiled bearings.

Conventional bearings can use as much

as 10,000 w, while magnetic bearings re- SOUND AND VIBRATION

Because the rotating assembly levitates,

quire only 180 w. That amounts to 500

times less friction loss. Current develop- there essentially is no structure-borne

F R I C T I O N L E S S

vibration. The magnetic bearings create

an air buffer that prevents the only major

moving partthe motor rotorfrom

transmitting vibration to the structure.

Similarly, sound levels are extremely

low, primarily because of refrigerant-gas

movement through the compressor and

the rest of the refrigeration system.

There are no tonal issues, such as those

found with some screw compressors,

and the noise occurs in the higher octave

bands, where it is easier to attenuate.

When two magnetic-bearing compressors were integrated into a chiller, the

sound pressure was 77 dBA at 3.3 ft under ARI Standard 575-94, Method of

Measuring Machinery Sound Within an

Equipment Space.

MODELED ENERGY SAVINGS

C O M P R E S S O R S

Location

Phoenix

Chicago

Tampa, Fla.

New York

Machines

Reciprocating vs

magnetic-bearing

Reciprocating vs

magnetic-bearing

Reciprocating vs

magnetic-bearing

Centrifugal vs.

magnetic-bearing

Building type

Three-story office

Three-story office

Three-story office

Three-story office

Square footage

58,200

69,000

67,800

69,600

Design cooling

load (tons)

150

149

150

150

Annual cooling

ton-hours

241,121

116,256

312,305

119,521

On-peak charge

6 cents per KWH

5 cents per KWH

6.4 cents per KWH 10.9 cents per KWH

Off-peak charge

6 cents per KWH

2.1 cents per KWH

4.4 cents per KWH 10.9 cents per KWH

Summer demand

$1.75 per KW

$16.41 per KW

$8.12 per KW

$20 per KW

Winter demand

$1.75 per KW

$12.85 per KW

$8.12 per KW

$20 per KW

Capital-cost

difference

$18,000

$18,000

$18,000

$12,000

Interest rate

6 percent

6 percent

6 percent

6 percent

Energy savings

$5,197

$5,035

$9,919

$4,587

Simple payback

3.46 years

3.57 years

1.81 years

2.62 years

Coefficient of performance

Chiller applications were modeled

Net present value

$96,278

$92,872

$195,914

$87,880

for Phoenix; Chicago; Tampa, Fla.; and

Internal rate

New York to estimate operating costs and

36.72 percent

35.8 percent

63.3 percent

46.27 percent

of return

payback times. The program compared

an hourly analysis of a 150-ton friction- TABLE 1. Estimated operating costs and payback times.

less chiller with that of a water-cooled

reciprocating chiller (Phoenix, Chicago, an annual energy savings of more than SUMMARY

After 10 years of development, magand Tampa) and a water-cooled centrifu- $4,500 and a two- to three-year payback

netic-bearing compressors offer ecogal chiller (New York). Each city showed (Table 1).

nomic, energy, and environmental benefits. Chief among them are increased

12

energy efficiency, the elimination of

11.1

oil and oil management, and consider10.5

ably less weight, noise, and vibration.

10

This initial mid-range package offers

centrifugal-compression efficiencies pre7.8

8

viously reserved for large-tonnage

systems only.

6

5.6

REFERENCE

1) Ivanovich, M.G. (2002, June). The

market for chillers: drives, controls,

simplicity. HPAC Engineering, pp. 11, 12,

15, 17.

25

50

Percent load

75

100

For HPAC Engineering feature articles

dating back to January 1992, visit

www.hpac.com.

FIGURE 3. According to ARI testing, a 150-ton frictionless chiller has a full-load

performance of 0.629 KW per ton (5.6 COP) and an IPLV of 0.375 KW per ton (9.4 COP).

For more information go to www.turbocor.com

Copyright 2003 by Penton Media, Inc.

Das könnte Ihnen auch gefallen

- Honda Gx200 Engine ManualDokument2 SeitenHonda Gx200 Engine Manualgomes_marina930% (1)

- Deep Drive - Customer Interface in AR - Oracle Apps EpicenterDokument38 SeitenDeep Drive - Customer Interface in AR - Oracle Apps Epicenterjeetu_87Noch keine Bewertungen

- HP4Dokument88 SeitenHP4Alexander Neyra100% (4)

- Cap Screws: Sae J429 Grade IdentificationDokument6 SeitenCap Screws: Sae J429 Grade IdentificationHomer SilvaNoch keine Bewertungen

- Understanding IBR 1950Dokument7 SeitenUnderstanding IBR 1950sammar_10Noch keine Bewertungen

- Twin Spindle Auto Drilling MachineDokument10 SeitenTwin Spindle Auto Drilling MachineSan SuryaNoch keine Bewertungen

- 2003-20 Communication Plan AttachmentDokument6 Seiten2003-20 Communication Plan Attachmentapi-3731879Noch keine Bewertungen

- Using CHEMCAD For Piping Network Design and AnalysisDokument51 SeitenUsing CHEMCAD For Piping Network Design and AnalysisRawlinsonNoch keine Bewertungen

- Design of Rocker Bogie MechanismDokument5 SeitenDesign of Rocker Bogie MechanismVinoth Rouge RockersNoch keine Bewertungen

- NPT Thread Dimensions PDFDokument1 SeiteNPT Thread Dimensions PDFRamnandan MahtoNoch keine Bewertungen

- Hypersonic Air Intake Design For High Performance and StartingDokument40 SeitenHypersonic Air Intake Design For High Performance and StartingRavi ShankarNoch keine Bewertungen

- Numerical Investigation of Fluidic Injection As A Means of Thrust ModulationDokument10 SeitenNumerical Investigation of Fluidic Injection As A Means of Thrust Modulationpeyman71Noch keine Bewertungen

- 2.design and Analysis of Connecting RodDokument52 Seiten2.design and Analysis of Connecting RodNaresh DamaNoch keine Bewertungen

- " Gasoline Direct Injection": Seminar Report OnDokument26 Seiten" Gasoline Direct Injection": Seminar Report OnSahal Babu50% (2)

- Peristaltic Pump: Seminar ReportDokument29 SeitenPeristaltic Pump: Seminar ReportAmruth SNoch keine Bewertungen

- Nitro Shock Absorber 355 Mwu469jDokument37 SeitenNitro Shock Absorber 355 Mwu469jMUHAMMED FAISALNoch keine Bewertungen

- Project Report Format KtuDokument50 SeitenProject Report Format KtuA .KNoch keine Bewertungen

- Remote Controlled Screw Jack 2014 AcDokument58 SeitenRemote Controlled Screw Jack 2014 AcChockalingam AthilingamNoch keine Bewertungen

- Vehicle Using Compressed AirDokument5 SeitenVehicle Using Compressed AirInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Chassis Design Analysis AssignmentDokument6 SeitenChassis Design Analysis AssignmentheltaherNoch keine Bewertungen

- Technical Seminar ReportDokument21 SeitenTechnical Seminar ReportManoj MNoch keine Bewertungen

- Under Wind MillDokument32 SeitenUnder Wind MillArjun DasNoch keine Bewertungen

- Motorized Ramming MachineDokument53 SeitenMotorized Ramming Machineilayaraja6100% (1)

- OrnithopterDokument4 SeitenOrnithopterShuklambari MadiwalarNoch keine Bewertungen

- Service Manual A10 & A12 ECDokument5 SeitenService Manual A10 & A12 ECLuisNoch keine Bewertungen

- 3 Axis Modern TrailerDokument24 Seiten3 Axis Modern TrailerRATHANNoch keine Bewertungen

- AMEE310 Lab5Dokument12 SeitenAMEE310 Lab5tsunaseetNoch keine Bewertungen

- Variable Copression Ratio EnginesDokument18 SeitenVariable Copression Ratio EnginesNicole LucasNoch keine Bewertungen

- Analysis of A Magnetorheological Fluid DamperDokument5 SeitenAnalysis of A Magnetorheological Fluid DamperInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- A Review of Structural and Thermal Analysis of Traction MotorsDokument11 SeitenA Review of Structural and Thermal Analysis of Traction MotorsGari PastranaNoch keine Bewertungen

- Magnetorheological Fluids and Its Application in Industrial Shock AbsorbersDokument31 SeitenMagnetorheological Fluids and Its Application in Industrial Shock AbsorbersNabeel AhamedNoch keine Bewertungen

- Design and Fabrication of Automeatic Hand Brake Release Using Pneumatic SystemDokument22 SeitenDesign and Fabrication of Automeatic Hand Brake Release Using Pneumatic Systemraghavendar ramanathan100% (1)

- Flange Coupling Lab PDFDokument25 SeitenFlange Coupling Lab PDFAli Raza MalikNoch keine Bewertungen

- Cam Operated HammerDokument52 SeitenCam Operated HammerSRL MECHNoch keine Bewertungen

- Study For Design of Magneto Rheological DamperDokument8 SeitenStudy For Design of Magneto Rheological DamperAnonymous lPvvgiQjRNoch keine Bewertungen

- Steam Turbines: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESDokument85 SeitenSteam Turbines: Prepared by Venkat Chintala Asst. Prof. S.G. Mechanical Engg. Deptt., UPESRaj NarayanNoch keine Bewertungen

- Important Points About It:: Mechanical JointsDokument13 SeitenImportant Points About It:: Mechanical JointsRajandra VermaNoch keine Bewertungen

- Hybrid Electric Vehicle: Presented By: Nikhil V Dhote Guided By: Prof C. R. Patil SirDokument24 SeitenHybrid Electric Vehicle: Presented By: Nikhil V Dhote Guided By: Prof C. R. Patil SirRushikesh TajneNoch keine Bewertungen

- Gearless TransmissionDokument16 SeitenGearless TransmissionAnAnd ThaWait100% (1)

- Fabrication of A Fuel Theft Preventor in Two Wheeler Using SolenoidDokument44 SeitenFabrication of A Fuel Theft Preventor in Two Wheeler Using SolenoidSTAR PRINTINGNoch keine Bewertungen

- Short ReportDokument2 SeitenShort ReportRaj MandloiNoch keine Bewertungen

- Design of Intake Manifold (CEVIZ) PDFDokument6 SeitenDesign of Intake Manifold (CEVIZ) PDFPaulo Wey Costa0% (1)

- Pnumatic Ramming and Punching Machine ReportDokument28 SeitenPnumatic Ramming and Punching Machine ReportSun SriNoch keine Bewertungen

- ABB - General Purpose Motors Cast Iron - GB 092003Dokument49 SeitenABB - General Purpose Motors Cast Iron - GB 092003ivanjaviergutierrezoNoch keine Bewertungen

- Design and Analysis of Drum Brake: Dr. Kodathalapalli SudheerDokument15 SeitenDesign and Analysis of Drum Brake: Dr. Kodathalapalli SudheerThalari VijayarajNoch keine Bewertungen

- A Mini Project Report On-1Dokument28 SeitenA Mini Project Report On-1suraj nayakNoch keine Bewertungen

- Accident Alert in Modern Traffic System With CameraDokument12 SeitenAccident Alert in Modern Traffic System With CameraLeander Lawrence100% (1)

- Fabrication of Hydraulic Dual Brake Single Lever System: SynopsisDokument4 SeitenFabrication of Hydraulic Dual Brake Single Lever System: SynopsissiddharthNoch keine Bewertungen

- Automatic Pneumatic High Speed Sheet Cutting MachineDokument5 SeitenAutomatic Pneumatic High Speed Sheet Cutting MachineIyappanNoch keine Bewertungen

- 62235-mt - Thermal Power PlantsDokument2 Seiten62235-mt - Thermal Power PlantsSRINIVASA RAO GANTANoch keine Bewertungen

- 4 - Rotating - Machines - Intro PDFDokument107 Seiten4 - Rotating - Machines - Intro PDFSantiago Sanchez SotoNoch keine Bewertungen

- Seminar Report 3C2Dokument41 SeitenSeminar Report 3C2Pritish KumarNoch keine Bewertungen

- Applied Hydraulic and Pneumatics Project FinalDokument13 SeitenApplied Hydraulic and Pneumatics Project FinalDineshkumar SNoch keine Bewertungen

- ABSTRACTDokument6 SeitenABSTRACTAkshat SharmaNoch keine Bewertungen

- Gas Dynamics LAB 02 PDFDokument16 SeitenGas Dynamics LAB 02 PDFmuhammad zia ur rehmanNoch keine Bewertungen

- Car JackDokument9 SeitenCar Jackdeepak GuptaNoch keine Bewertungen

- Automatic Tyre Pressure Inflation SystemDokument3 SeitenAutomatic Tyre Pressure Inflation SystemKarthick MNoch keine Bewertungen

- 360 Degree Load CarrierDokument28 Seiten360 Degree Load CarrierTanviNoch keine Bewertungen

- Pistonless PumpDokument21 SeitenPistonless PumpDeepuDevarajanNoch keine Bewertungen

- A Seminar Report ON "Mems Technology"Dokument32 SeitenA Seminar Report ON "Mems Technology"nikhil jhaNoch keine Bewertungen

- Automatic Tyre Pressure Inflation SystemDokument35 SeitenAutomatic Tyre Pressure Inflation SystemmujeebNoch keine Bewertungen

- Brake Failure Indicator Design: Bachelor of TechnologyDokument19 SeitenBrake Failure Indicator Design: Bachelor of TechnologyAniket KarmakarNoch keine Bewertungen

- Al Jazeera Turning Company ProfileDokument12 SeitenAl Jazeera Turning Company ProfileKaram HakoNoch keine Bewertungen

- PPE Lecture NotesDokument118 SeitenPPE Lecture NotesMITTA NARESH BABU100% (1)

- Seminar On Friction Less Compressor TechnologyDokument7 SeitenSeminar On Friction Less Compressor TechnologySwapnil Bhat0% (1)

- PandaDokument12 SeitenPandaSaroj KumarNoch keine Bewertungen

- Frictionlesscompressor 220104160727Dokument16 SeitenFrictionlesscompressor 22010416072715, Sweekar ChougaleNoch keine Bewertungen

- HSE FRM 32 Final Incident ReportDokument6 SeitenHSE FRM 32 Final Incident ReportDilshad aliNoch keine Bewertungen

- Resun Price List Solar Panel-20211227Dokument1 SeiteResun Price List Solar Panel-20211227Nemesu LorentNoch keine Bewertungen

- 10 Famous Shipping Canals of The WorldDokument7 Seiten10 Famous Shipping Canals of The Worldparth_upadhyay_1Noch keine Bewertungen

- FTNV-B FINAL - CatalogueDokument8 SeitenFTNV-B FINAL - CatalogueAmodu Usman AdeyinkaNoch keine Bewertungen

- Data Structures and Algorithms: (CS210/ESO207/ESO211)Dokument23 SeitenData Structures and Algorithms: (CS210/ESO207/ESO211)Moazzam HussainNoch keine Bewertungen

- K 1020189523hfjfjDokument3 SeitenK 1020189523hfjfjCarlos Angel Vilcapaza CaceresNoch keine Bewertungen

- ETABS 19.0.0-Report ViewerDokument207 SeitenETABS 19.0.0-Report ViewerDaniel Pesca SilvaNoch keine Bewertungen

- Superior Tuffy Valves: 290 Series LPD Globe Line ValvesDokument1 SeiteSuperior Tuffy Valves: 290 Series LPD Globe Line ValvesR M Abdullah WakeelNoch keine Bewertungen

- MS XLSXDokument290 SeitenMS XLSXAlvaro S. AcejoNoch keine Bewertungen

- Powershell Import Update Users Groups From CSV FileDokument2 SeitenPowershell Import Update Users Groups From CSV FilecrakchakibNoch keine Bewertungen

- Hanro Tools Incorporation Delhi IndiaDokument10 SeitenHanro Tools Incorporation Delhi IndiaHanro Tools IncorporationNoch keine Bewertungen

- Grade 11 Electricity W.sheetDokument6 SeitenGrade 11 Electricity W.sheetUsman AmeenNoch keine Bewertungen

- Sec1 1 1Dokument2 SeitenSec1 1 1rajfmc100% (1)

- Pulse Emitter EM345Dokument1 SeitePulse Emitter EM345wahid.hamraoui.2019Noch keine Bewertungen

- Project Example 1Dokument10 SeitenProject Example 1dervingameNoch keine Bewertungen

- Copeland Cr28k6 PFV Recip Compressor Technical Specifications2Dokument1 SeiteCopeland Cr28k6 PFV Recip Compressor Technical Specifications2PerezNoch keine Bewertungen

- DC Rectifier - OrionDokument12 SeitenDC Rectifier - OrionLimbagaNoch keine Bewertungen

- Altapail Ii: 20-Liter or 5-Gallon Pail MeltersDokument2 SeitenAltapail Ii: 20-Liter or 5-Gallon Pail MeltersjorgeramosvasNoch keine Bewertungen

- Ii.7.2 Alat Kedokteran 2 PDFDokument153 SeitenIi.7.2 Alat Kedokteran 2 PDFAguesBudi S TalawangNoch keine Bewertungen

- Re-Measurement Sheet FOR UNIT 148 Interconnecting Piperack M44-Pr3Dokument6 SeitenRe-Measurement Sheet FOR UNIT 148 Interconnecting Piperack M44-Pr3Vasilica BarbarasaNoch keine Bewertungen

- Administration-Guide Open Bee OCSDokument7 SeitenAdministration-Guide Open Bee OCSpeka76Noch keine Bewertungen

- Kočnice Shimano BR-M422Dokument1 SeiteKočnice Shimano BR-M422salecello2113Noch keine Bewertungen