Beruflich Dokumente

Kultur Dokumente

Annexure - I: C. Feed Material and Operating Parameters

Hochgeladen von

HARIPRASADOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Annexure - I: C. Feed Material and Operating Parameters

Hochgeladen von

HARIPRASADCopyright:

Verfügbare Formate

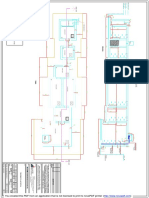

ANNEXURE - I

Page 1 of 4

C.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

FEED MATERIAL AND OPERATING PARAMETERS

FRESH SOLID FEED (NOMINAL)

TPH

FRESH SOLID FEED (MAX)

TPH

% SOLID IN FEED SLURRY (NOMINAL)

% w/w

% SOLID IN FEED SLURRY (MAX)

% w/w

D.

1

2

3

4

5

6

7

UTILITY REQUIREMENT

WASH WATER QUANTITY

WASH WATER PRESSURE

WASH WATER QUALITY

INSTRUMENT AIR QUANTITY

INSTRUMENT AIR PRESSURE

COMPRESSED AIR QUANTITY

COMPRESSED AIR PRESSURE

SG OF SOLIDS

WATER FLOW RATE (NOMINAL)

WATER FLOW RATE (MAX)

SLURRY FLOW RATE (NOMINAL)

SLURRY FLOW RATE (MAX)

SLURRY DENSITY

FEED SLURRY PRESUURE

FEED PARTICLE SIZE

SEPARATION SIZE (NOTE 1)

FEED SLURRY TEMPERATURE

m3/hr

m3/hr

m3/hr

m3/hr

t/m3

bar

micron

micron

Deg C

SLURRY pH

DESIGN FACTOR (NOTE 2)

m3/hr

mwc

Nm3/hr

bar(G)

Nm3/hr

bar(G)

211.0

240.0

30.0

30.0

4.0

492.3

560.0

545.1

620.0

1.29

Atm (gravity flow)

Refer Annexure-IA

710

Ambient

~7-8

10%

By

By

By

By

By

By

By

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Prepared by: SRM

Checked by: MBA

Approved by: MBA

Date: 07.05.2015

Date: 11.05.2015

Date: 11.05.2015

ANNEXURE - I

337962

er

rt

we

Page 2 of 4

123

222

27306

Prepared by: SRM

Checked by: MBA

Approved by: MBA

Date: 07.05.2015

Date: 11.05.2015

Date: 11.05.2015

ANNEXURE - I

F.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

G.

1

2

3

4

5

6

7

Page 3 of 4

MATERIAL OF CONSTRUCTION

SCREEN FRAME

FEED BOX

LINER FOR FEED BOX

DISTRIBUTION PLATES

LINER FOR DISTRIBUTION

PLATE

OVERFLOW DISCHARGE CHUTE

LINER FOR OVERFLOW

DISCHARGE CHUTE

UNDER PAN

LINER FOR UNDERPAN

CLUTCH

DRIP TRAY

HEAD PULLEY

TAIL PULLEY

TENSIONING PULLEY

BEND PULLEY

CLOTH ROLLER

RETURN ROLLER

SHAFTS

SCREEN CLOTH

CLUTCH TENSIONER

SPRAY BAR

SPRAY NOZZLE

SPILLAGE LAUNDER

LINER FOR SPILLAGE LAUNDER

GEAR

DRIVE BASE FRAME

FASTENERS

ELECTRICAL AND INSTRUMENTATION

DRIVE MOTOR TYPE/MAKE

FRAME SIZE

DRIVE MOTOR SPEED

RPM

DRIVE MOTOR RATED POWER

kW

DRIVE MOTOR CONSUMED

kW

POWER

POWER CONSUMPTION AT

kW

DRIVE COUPLING (MAX)

DRIVE MOTOR PROTECTION

By

By

By

By

By

By

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

By Bidder

By

By

By

By

By

By

By

By

By

By

By

By

By

By

By

By

By

By

By

By

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

Bidder

By

By

By

By

By

Bidder

Bidder

Bidder

Bidder

Bidder

By Bidder

By Bidder

Prepared by: SRM

Checked by: MBA

Approved by: MBA

Date: 07.05.2015

Date: 11.05.2015

Date: 11.05.2015

ANNEXURE - I

8

9

10

11

12

DRIVE MOTOR INSULATION

LOAD GD^2 VALUE AT MOTOR

SHAFT

NO LOAD GD^2 VALUE AT

MOTOR SHAFT

DIRECTION OF ROTATION OF

MOTOR (VIEWED FROM

COUPLING TO MOTOR)

UPS POWER REQUIREMENT

FOR INSTRUMENTATION

H.

1

2

WEIGHT DATA

TOTAL

WEIGHT

OF THEPART

EQUIPM

WEIGHT

OF HEAVIEST

OF

THE EQUIPMENT FOR

MAINTENANCE

I.

1

OTHERS

LIST OF MAKES FOR ALL

BOUGHT OUT ITEMS

ENCLOSED

By Bidder

kgf-m2

By Bidder

kgf-m2

By Bidder

Clockwise/ Counter clockwise

VA

By Bidder

Kg

By Bidder

Kg

By Bidder

Yes / No

By Bidder

NOTE:1) Bidder to size the screen area suitably to accommodate 500 microns separation size.

2) Bidder to consider suitable design factor to ensure smooth operation at rated capacity.

Page 4 of 4

Prepared by: SRM

Checked by: MBA

Approved by: MBA

Date: 07.05.2015

Date: 11.05.2015

Date: 11.05.2015

Das könnte Ihnen auch gefallen

- Annexure - I: C. Feed Material and Operating ParametersDokument4 SeitenAnnexure - I: C. Feed Material and Operating ParametersHARIPRASADNoch keine Bewertungen

- Belt Feeder: Annexure - IDokument4 SeitenBelt Feeder: Annexure - IHARIPRASADNoch keine Bewertungen

- Calculation For RingDokument4 SeitenCalculation For RingHARIPRASADNoch keine Bewertungen

- GranulatorDokument2 SeitenGranulatorNess SanchezNoch keine Bewertungen

- SBR DesignDokument2 SeitenSBR DesignHRK65100% (6)

- 102 I 8 DatasheetsDokument11 Seiten102 I 8 DatasheetschloeNoch keine Bewertungen

- Charts and TablesDokument4 SeitenCharts and TablesAbdul KharisNoch keine Bewertungen

- Control Valve Press Drop CalculationDokument3 SeitenControl Valve Press Drop CalculationAntony AbirawaNoch keine Bewertungen

- Company Profile2Dokument13 SeitenCompany Profile2clean420Noch keine Bewertungen

- Form Sand ConeDokument9 SeitenForm Sand ConeIndratama Prasetyo ChaqNoch keine Bewertungen

- Data Sheet: LG SW 4040 RDokument1 SeiteData Sheet: LG SW 4040 RAcquetech AcquetechNoch keine Bewertungen

- DBL Group TPWL Water Reuse System at Industrial ScaleDokument15 SeitenDBL Group TPWL Water Reuse System at Industrial ScaleNavid ZamanNoch keine Bewertungen

- Desozone Odor ControlDokument5 SeitenDesozone Odor Controlsolo7651Noch keine Bewertungen

- Vontronulp21 4040en1Dokument2 SeitenVontronulp21 4040en1sukiraj RasalingamNoch keine Bewertungen

- Clen RoomDokument1 SeiteClen RoomRam RajyaNoch keine Bewertungen

- Vontronfr12 8040en1Dokument2 SeitenVontronfr12 8040en1Von TronNoch keine Bewertungen

- System Design: Membrane System Design Guidelines For Commercial ElementsDokument3 SeitenSystem Design: Membrane System Design Guidelines For Commercial ElementsJose Marval RodriguezNoch keine Bewertungen

- Vontronulp31 4040en1Dokument2 SeitenVontronulp31 4040en1CAMILA ESTAY TORRESNoch keine Bewertungen

- Round The Pump Proportioner: Key Users Key FactsDokument2 SeitenRound The Pump Proportioner: Key Users Key FactsHadise NikdelNoch keine Bewertungen

- FireBall Oil Pump SpecificationsDokument1 SeiteFireBall Oil Pump SpecificationsInstruktur MesinNoch keine Bewertungen

- Simulation of Enhanced Heavy Oil Recovery: History Match of Waterflooding and Polymer Injection at Adverse Mobility RatioDokument152 SeitenSimulation of Enhanced Heavy Oil Recovery: History Match of Waterflooding and Polymer Injection at Adverse Mobility Ratiosara ahmadiNoch keine Bewertungen

- Hydraulic CalculatorDokument13 SeitenHydraulic CalculatorShady Azzam Abu HaidyNoch keine Bewertungen

- PBL Hole CleaningDokument2 SeitenPBL Hole CleaningOlgaLuciaNoch keine Bewertungen

- Vontronulp21 4021en1Dokument2 SeitenVontronulp21 4021en1sukiraj RasalingamNoch keine Bewertungen

- Dow Water & Process SolutionsDokument11 SeitenDow Water & Process SolutionsZulfikri ZulkifliNoch keine Bewertungen

- FLOW - CASE STUDIES and SELECTIONDokument32 SeitenFLOW - CASE STUDIES and SELECTIONshiva100% (1)

- TDS - Tankguard SF - Issued 04.08.2014Dokument5 SeitenTDS - Tankguard SF - Issued 04.08.2014Arya Kemal Pratama PutraNoch keine Bewertungen

- Desain BAK IPALDokument48 SeitenDesain BAK IPALBeny NainggolanNoch keine Bewertungen

- FD2000 - GEN III Rev5 FMDokument5 SeitenFD2000 - GEN III Rev5 FMJosé Alberto RodríguezNoch keine Bewertungen

- Vontronlp21 4040en1Dokument2 SeitenVontronlp21 4040en1sukiraj RasalingamNoch keine Bewertungen

- Chemical Resistance Guide GlovesDokument8 SeitenChemical Resistance Guide Glovesjitendertalwar1603Noch keine Bewertungen

- JX SW 8040 400Dokument2 SeitenJX SW 8040 400DiegoSaldañaNoch keine Bewertungen

- Relative Density Test Minimum and Maximum Density Test DataDokument1 SeiteRelative Density Test Minimum and Maximum Density Test Dataluqmanulkhakim87Noch keine Bewertungen

- Project Questionnaire - DistributedDokument4 SeitenProject Questionnaire - Distributedwacsii ccasullaNoch keine Bewertungen

- Vinayak Bindu Basic Pneumatic SysteDokument95 SeitenVinayak Bindu Basic Pneumatic SysteVinayak BinduNoch keine Bewertungen

- Survey Form For Collecting Reverse Osmosis Plant Operation DataDokument2 SeitenSurvey Form For Collecting Reverse Osmosis Plant Operation DataJendayiNoch keine Bewertungen

- Densidad Aire 1.2 kg/m3 Área 1 Densidad Alcohol 789 kg/m3 Área 2 Gravedad 9.81 m/s2Dokument26 SeitenDensidad Aire 1.2 kg/m3 Área 1 Densidad Alcohol 789 kg/m3 Área 2 Gravedad 9.81 m/s2Pablo Guzman RetamalNoch keine Bewertungen

- GOwSP - Gas Oil Water Separation PlatformDokument2 SeitenGOwSP - Gas Oil Water Separation PlatformNishant ManepalliNoch keine Bewertungen

- Epa Water Treatment Manual Primary Secondary Tertiary1Dokument131 SeitenEpa Water Treatment Manual Primary Secondary Tertiary1Pamela RichardsonNoch keine Bewertungen

- Flare Ko Drum SizingDokument5 SeitenFlare Ko Drum SizingSujith Sekar100% (2)

- 2SBR REACTOR - 1MLD - BOD Only PDFDokument7 Seiten2SBR REACTOR - 1MLD - BOD Only PDFHRK65Noch keine Bewertungen

- Doofor Brochure December2022Dokument32 SeitenDoofor Brochure December2022Ankara TurquíaNoch keine Bewertungen

- Fluid Viscosity TableDokument1 SeiteFluid Viscosity TableMihai StancescuNoch keine Bewertungen

- Datasheet LG SW 400 SR G2 ENGDokument1 SeiteDatasheet LG SW 400 SR G2 ENGMohamed MotaweaNoch keine Bewertungen

- Spesifikasi Komponen Terkait VpaDokument8 SeitenSpesifikasi Komponen Terkait VpaAgung Prasetya ChandranenaNoch keine Bewertungen

- Lab Manual Polytechnic Sul 2022Dokument32 SeitenLab Manual Polytechnic Sul 2022AramNoch keine Bewertungen

- Hoja de Calculo FP Borrador - 2Dokument14 SeitenHoja de Calculo FP Borrador - 22artNoch keine Bewertungen

- Alstom Tamuin MainDataDokument2 SeitenAlstom Tamuin MainDatarestradacarsolioNoch keine Bewertungen

- Ficha Tecnica Amberlite Ir 120 NaDokument3 SeitenFicha Tecnica Amberlite Ir 120 NaDianaNoch keine Bewertungen

- Sohar University: Oilfield Produced Water Treatment Using Membrane TechnologyDokument83 SeitenSohar University: Oilfield Produced Water Treatment Using Membrane Technologyajali1957Noch keine Bewertungen

- Hardtop Optima Alu: Technical Data SheetDokument5 SeitenHardtop Optima Alu: Technical Data SheetBiju_PottayilNoch keine Bewertungen

- Hardtop Optima Alu PDFDokument5 SeitenHardtop Optima Alu PDFBiju_PottayilNoch keine Bewertungen

- 761-V-103 (Vessel With Demister), PDFDokument1 Seite761-V-103 (Vessel With Demister), PDFAlvin SmithNoch keine Bewertungen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Roll-to-Roll Manufacturing: Process Elements and Recent AdvancesVon EverandRoll-to-Roll Manufacturing: Process Elements and Recent AdvancesJehuda GreenerNoch keine Bewertungen

- Solid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityVon EverandSolid-Liquid Filtration: A User’s Guide to Minimizing Cost and Environmental Impact, Maximizing Quality and ProductivityBewertung: 5 von 5 Sternen5/5 (2)

- Southern Marine Engineering Desk Reference: Second Edition Volume IVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INoch keine Bewertungen

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceVon EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNoch keine Bewertungen

- Gas Sweetening and Processing Field ManualVon EverandGas Sweetening and Processing Field ManualBewertung: 4 von 5 Sternen4/5 (7)

- Duty Application Iron Ore Slurry Type Slurry PumpDokument4 SeitenDuty Application Iron Ore Slurry Type Slurry PumpHARIPRASADNoch keine Bewertungen

- Design Factor-20% MM Actual Diameter of Tie Rod Considered MMDokument2 SeitenDesign Factor-20% MM Actual Diameter of Tie Rod Considered MMHARIPRASADNoch keine Bewertungen

- Design Operation ConditionDokument4 SeitenDesign Operation ConditionHARIPRASADNoch keine Bewertungen

- Duty Application Iron Ore Slurry Type Slurry PumpDokument4 SeitenDuty Application Iron Ore Slurry Type Slurry PumpHARIPRASADNoch keine Bewertungen

- DIA (M) HT (M) Dosing (LPH) KW Transfer (LPH) KWDokument1 SeiteDIA (M) HT (M) Dosing (LPH) KW Transfer (LPH) KWHARIPRASADNoch keine Bewertungen

- Data ListDokument4 SeitenData ListHARIPRASADNoch keine Bewertungen

- Truss 09Dokument2 SeitenTruss 09HARIPRASADNoch keine Bewertungen

- SOT Date Client M/S Westech Swang: EquipementDokument2 SeitenSOT Date Client M/S Westech Swang: EquipementHARIPRASADNoch keine Bewertungen

- SOT Date Client M/S Westech Swang: Equipement 1233 234332434 5665Dokument2 SeitenSOT Date Client M/S Westech Swang: Equipement 1233 234332434 5665HARIPRASADNoch keine Bewertungen

- ChemicalDokument2 SeitenChemicalHARIPRASADNoch keine Bewertungen

- Design Factor-20% MM Actual Diameter of Tie Rod Considered MMDokument2 SeitenDesign Factor-20% MM Actual Diameter of Tie Rod Considered MMHARIPRASADNoch keine Bewertungen

- Screw Conveyer CalculationDokument2 SeitenScrew Conveyer CalculationHARIPRASADNoch keine Bewertungen

- SOT Date Client M/S Westech Swang: EquipementDokument2 SeitenSOT Date Client M/S Westech Swang: EquipementHARIPRASADNoch keine Bewertungen

- OrganicDokument2 SeitenOrganicHARIPRASADNoch keine Bewertungen

- Design Factor-20% MM Actual Diameter of Tie Rod Considered MMDokument2 SeitenDesign Factor-20% MM Actual Diameter of Tie Rod Considered MMHARIPRASADNoch keine Bewertungen

- P Nue Matics 2333Dokument2 SeitenP Nue Matics 2333HARIPRASADNoch keine Bewertungen

- Annexure - I: C. Feed Material and Operating ParametersDokument4 SeitenAnnexure - I: C. Feed Material and Operating ParametersHARIPRASADNoch keine Bewertungen

- Pnuematics 1Dokument2 SeitenPnuematics 1HARIPRASADNoch keine Bewertungen

- Pump SheetDokument2 SeitenPump SheetHARIPRASADNoch keine Bewertungen

- Annexure - I: Fresh Solid Feed (Nominal)Dokument4 SeitenAnnexure - I: Fresh Solid Feed (Nominal)HARIPRASADNoch keine Bewertungen

- Specific Process Condition During Start-Up/stop/transient Pumping TempratureDokument2 SeitenSpecific Process Condition During Start-Up/stop/transient Pumping TempratureHARIPRASADNoch keine Bewertungen

- Design Coa25lDokument1 SeiteDesign Coa25lHARIPRASADNoch keine Bewertungen

- Design Operation ConditionDokument4 SeitenDesign Operation ConditionHARIPRASADNoch keine Bewertungen

- Pump Data 1Dokument2 SeitenPump Data 1HARIPRASADNoch keine Bewertungen

- Annexure - I: C. Feed Material and Operating ParametersDokument4 SeitenAnnexure - I: C. Feed Material and Operating ParametersHARIPRASADNoch keine Bewertungen

- NewDokument1 SeiteNewHARIPRASADNoch keine Bewertungen

- Linear Screen SizingDokument4 SeitenLinear Screen SizingHARIPRASADNoch keine Bewertungen

- Belt FeederDokument4 SeitenBelt FeederHARIPRASADNoch keine Bewertungen

- SL No Description 1 Planetary Gear Box 2 Motor 3 Bearing 4 Limit Switch 5 Slow Speed Switch 6 Screen ClothDokument2 SeitenSL No Description 1 Planetary Gear Box 2 Motor 3 Bearing 4 Limit Switch 5 Slow Speed Switch 6 Screen ClothHARIPRASADNoch keine Bewertungen

- tp6140 PDFDokument72 Seitentp6140 PDFjohnNoch keine Bewertungen

- C5210HP Technical DataDokument9 SeitenC5210HP Technical Data顏健軒Noch keine Bewertungen

- Softening Point TestDokument11 SeitenSoftening Point Testkadhim Ali81% (27)

- Document 1Dokument6 SeitenDocument 1LaurenceFabialaNoch keine Bewertungen

- MFC Hubli Final Bill Jan 2013Dokument12 SeitenMFC Hubli Final Bill Jan 2013Nagaraj PatilNoch keine Bewertungen

- Prestartup Check List of HRSGDokument3 SeitenPrestartup Check List of HRSGmd abNoch keine Bewertungen

- Materials Chemistry and Physics: Jure Zigon, Matja Z Pavli C, Marko Petri C, Sebastian DahleDokument12 SeitenMaterials Chemistry and Physics: Jure Zigon, Matja Z Pavli C, Marko Petri C, Sebastian DahleAromoNoch keine Bewertungen

- Popular Woodworking 213 (September-October 2014)Dokument68 SeitenPopular Woodworking 213 (September-October 2014)chrix100% (2)

- Identifying Toyota HiluxDokument4 SeitenIdentifying Toyota Hiluxtoaster es100% (1)

- 4R70W Ford Transmission Service Manual PDFDokument206 Seiten4R70W Ford Transmission Service Manual PDFFabricio Vilela100% (2)

- IRENA Biogas For Road Vehicles 2017Dokument64 SeitenIRENA Biogas For Road Vehicles 2017bulutysnNoch keine Bewertungen

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFDokument1 Seite4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- DokwegII - Auxiliary - Maintenance Compressed Air SystemDokument62 SeitenDokwegII - Auxiliary - Maintenance Compressed Air SystemCarlin BabuchasNoch keine Bewertungen

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDokument1 SeiteYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHarish Kumar MahavarNoch keine Bewertungen

- Hybrid Geosynthetic Paving Mat For Highway ApplicationsDokument4 SeitenHybrid Geosynthetic Paving Mat For Highway ApplicationsmithileshNoch keine Bewertungen

- Powder 1Dokument84 SeitenPowder 1Nyanda MadiliNoch keine Bewertungen

- Remote Control Programming GuideDokument47 SeitenRemote Control Programming GuideArslan Saleem0% (1)

- BT134WDokument7 SeitenBT134WMiloud ChouguiNoch keine Bewertungen

- Chapter 20 ProblemDokument3 SeitenChapter 20 Problemপিঁপড়া পিঁপড়াNoch keine Bewertungen

- HES Casing Accessories CatDokument23 SeitenHES Casing Accessories CatJoan Corso100% (1)

- CLASS - X CHEMISTRY Important QuestionsDokument17 SeitenCLASS - X CHEMISTRY Important Questionsvt654009Noch keine Bewertungen

- Oxygen Index Elevated-Temperature Oxygen Index: ISO 4589-2 ASTM D 2863Dokument4 SeitenOxygen Index Elevated-Temperature Oxygen Index: ISO 4589-2 ASTM D 2863p41005679Noch keine Bewertungen

- UNF Vs BSFDokument18 SeitenUNF Vs BSFJonathan GentNoch keine Bewertungen

- 01 Brosure Autoclave - Prabal-DikompresiDokument2 Seiten01 Brosure Autoclave - Prabal-DikompresiDewi NurfadilahNoch keine Bewertungen

- Pressure Vessel Exm QuestionsDokument4 SeitenPressure Vessel Exm QuestionsJithuJohn100% (1)

- M 237Dokument4 SeitenM 237Katerin Hernandez0% (1)

- Supra 644, 744, 844 Beginning With Serial# Hfy90593608 - Sunbelt ...Dokument68 SeitenSupra 644, 744, 844 Beginning With Serial# Hfy90593608 - Sunbelt ...Glacial100% (1)

- Bromine New PDFDokument1 SeiteBromine New PDFSuhasNoch keine Bewertungen

- Chapter 1 Technology and DevelopmentDokument46 SeitenChapter 1 Technology and DevelopmentKeep ThrowNoch keine Bewertungen

- Waste Water Treatment Using Electrocoagulation TechnologyDokument4 SeitenWaste Water Treatment Using Electrocoagulation TechnologyKetan V. JoshiNoch keine Bewertungen