Beruflich Dokumente

Kultur Dokumente

Intumescent Paint

Hochgeladen von

Irshad KhanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Intumescent Paint

Hochgeladen von

Irshad KhanCopyright:

Verfügbare Formate

1.

REQUIREMENTS

1. Composition

Intumescent fire retardant paint shall comprise of vinyl acetate acrylic co-polymer emulsion,

intumescence agents and pigments. Ammonium polyphosphate, pentaerythritol, dicyndiamide

are used as intumescence agents and titanium dioxide as pigment, whereas vinyl acetate

acrylic co-polymer is used as a binder. Phosphorus content in the pigment, when examined

shall not be less than 20%.

The paint shall be suitable for application by brush or by airless spray (with 5-7% deionised

water) to provide uniform coating having thickness of 250 25 microns in single coat.

Intumescent fire retardant paint shall be water based single pack system and should be mixed

thoroughly before use. Thickness of the coat in single or two coats shall be suitable for a fire

resistance of two hours. The structural steel surfaces shall be applied with suitable primers

after surface preparation before application of intumescent paint.

2.

The paint shall also conform to requirements given in Table 1.

Table 1

Sl. No .

(1)

Characteristics (2)

Requirements (3)

1

2

Colour

Preliminary

examination

Application

properties and finish

Consistency

Drying time , minutes

(At 65% RH), max.

(a) Surface dry (b)

Hard dry

Dry film thickness,

microns

Scratch hardness, gm,

minimum(1000 g)

Flexibility and

adhesion(Bend test)

(using 25 mm

diameter mandrel)

Mass / 10 litres, kg

Percent pigment,

Minimum

Percent volatile

matter, Maximum

Fire test (a) Char

height, mm Min (b)

Flame spread Length,

mm, max c) Time

after glow,Sec

d)Time after flaming,

Sec

Keeping properties

White/Off-White

Stirring should easily produce a

smooth uniform paint suitable

for application by brush or

airless spray (with 5-7% deionised water).

Paint film shall be uniform and

free from defects

Thixotropic

4

5

6

7

8

9

10

11

12

13

Method of test

Ref. to IS: 101

Annex

Part 4/Sec 2)

Part 1/Sec 2

Part 1 /Sec 4

Part 1/Sec 2

(Part 3 / Sec 1 )

60 120

250 25

(Part3 / Sec 2)

To pass the test

Cl 3 of (Part 5/Sec 2)

To pass the test

Cl 2 of (Part 5/Sec 2)

13.7 0.3

40

(Part 1/ Sec 7 )

30

(Part 2 / Sec 2 )

30.0 127 Nil Nil

Not less than one year from

date of manufacturing

(Part 6/Sec 2)

Das könnte Ihnen auch gefallen

- Increasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionVon EverandIncreasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionNoch keine Bewertungen

- For Bis Use Only DOC:CHD 20 (1936) C: (Not To Be Reproduced Without The Permission of BIS or Used As STANDARD)Dokument7 SeitenFor Bis Use Only DOC:CHD 20 (1936) C: (Not To Be Reproduced Without The Permission of BIS or Used As STANDARD)Ajoy McNoch keine Bewertungen

- 9 Specification of Tank PaintingDokument19 Seiten9 Specification of Tank PaintingGayatri FabricatorNoch keine Bewertungen

- Technical Guideline Part 1Dokument6 SeitenTechnical Guideline Part 1Mochamad BhadawiNoch keine Bewertungen

- Scope of JobDokument6 SeitenScope of JobSHIVAM JOHRINoch keine Bewertungen

- Masterprotect 1825 TdsDokument3 SeitenMasterprotect 1825 TdsSHAIK ASIMUDDINNoch keine Bewertungen

- Jupol Silikat: TECHNICAL SHEET 03.01.14-Eng Interior Wall PaintsDokument5 SeitenJupol Silikat: TECHNICAL SHEET 03.01.14-Eng Interior Wall PaintsNikiNoch keine Bewertungen

- Method Statement For Painting WorksDokument5 SeitenMethod Statement For Painting WorksJoe_Average78% (9)

- Masterprotect 1825 TdsDokument3 SeitenMasterprotect 1825 TdsYudhaNoch keine Bewertungen

- Mastertop 1705 TdsDokument3 SeitenMastertop 1705 TdsrenandiaNoch keine Bewertungen

- Zinc Silicate (Inorganic) : Product CodeDokument5 SeitenZinc Silicate (Inorganic) : Product CodeGeorgianaNoch keine Bewertungen

- Surface Preparation & Paint Procedure (RevB)Dokument19 SeitenSurface Preparation & Paint Procedure (RevB)Mohd Taufiq IsmailNoch keine Bewertungen

- Ikote CM 50X TDS (02-April-2024) V1.3Dokument2 SeitenIkote CM 50X TDS (02-April-2024) V1.3nguyen hoang AnhNoch keine Bewertungen

- TDS - Solvent Free Epoxy STDDokument2 SeitenTDS - Solvent Free Epoxy STDRameshp PalanisamyNoch keine Bewertungen

- PaintDokument44 SeitenPaintSushil Kumar Singh100% (2)

- PresentationDokument31 SeitenPresentationisrailNoch keine Bewertungen

- Bgas PA10Dokument23 SeitenBgas PA10Ajith PayyanurNoch keine Bewertungen

- Specification GlassFiberDokument6 SeitenSpecification GlassFiberMukesh MaharjanNoch keine Bewertungen

- Work For PaymentDokument6 SeitenWork For PaymentsiamcivilengrNoch keine Bewertungen

- Sikafloor - 156: 2-Part Epoxy Primer, Levelling Mortar and Mortar ScreedDokument6 SeitenSikafloor - 156: 2-Part Epoxy Primer, Levelling Mortar and Mortar ScreedAnonymous v1blzDsEWANoch keine Bewertungen

- Roadline Paint ReflectiveDokument2 SeitenRoadline Paint ReflectiveKyaw Swar TheimNoch keine Bewertungen

- Material Integral Tamara MORARIU enDokument15 SeitenMaterial Integral Tamara MORARIU enConstantin DanNoch keine Bewertungen

- Decorative Technical ManualDokument79 SeitenDecorative Technical ManualabjnlinkNoch keine Bewertungen

- Technical Specification For Paints, Thinner and PrimerDokument3 SeitenTechnical Specification For Paints, Thinner and PrimerRadhakrishnan SreerekhaNoch keine Bewertungen

- Polyurea HB1010Dokument3 SeitenPolyurea HB1010Tox DexterNoch keine Bewertungen

- Nitocote EN901Dokument4 SeitenNitocote EN901kalidindivenkatarajuNoch keine Bewertungen

- Acrylic 5170 Wall SealerDokument2 SeitenAcrylic 5170 Wall SealerandiekaNoch keine Bewertungen

- EnamopxyDokument5 SeitenEnamopxyTawfiq ZidanNoch keine Bewertungen

- Technical Specifications - Coating and Painting Works: 11.1. GENERALDokument6 SeitenTechnical Specifications - Coating and Painting Works: 11.1. GENERALVictorVilceanuNoch keine Bewertungen

- Polyurea 1044 Standard Pure TDS ENDokument4 SeitenPolyurea 1044 Standard Pure TDS ENnsh.gnkinfraNoch keine Bewertungen

- Painting of LHB Coaches (Stainless Steel) - SKDokument41 SeitenPainting of LHB Coaches (Stainless Steel) - SKAshutoshNoch keine Bewertungen

- PAINTEX ACICO Matt 2Dokument3 SeitenPAINTEX ACICO Matt 2Osama GabrNoch keine Bewertungen

- APCS-26T HempelDokument5 SeitenAPCS-26T HempelarjunmohananNoch keine Bewertungen

- Fire Fighting & Sprinkler PipesDokument5 SeitenFire Fighting & Sprinkler Pipesareef007Noch keine Bewertungen

- Asian Paints - Prem Gloss EnamelDokument1 SeiteAsian Paints - Prem Gloss EnamelwilliumstNoch keine Bewertungen

- Nitoflor FC150Dokument4 SeitenNitoflor FC150Venkata Raju KalidindiNoch keine Bewertungen

- Industrial PolymersDokument18 SeitenIndustrial PolymersHarshitNoch keine Bewertungen

- Technical Data Sheet: Toa Roadline PaintDokument4 SeitenTechnical Data Sheet: Toa Roadline PaintSiradech SuritNoch keine Bewertungen

- IKOTE CM 31 TDS (11-Oct-2023)Dokument2 SeitenIKOTE CM 31 TDS (11-Oct-2023)nguyen hoang AnhNoch keine Bewertungen

- c400 Data SheetDokument2 Seitenc400 Data SheetJennifer BradleyNoch keine Bewertungen

- iKOTE CM 40X (TDS) 02-APRIL-2024Dokument2 SeiteniKOTE CM 40X (TDS) 02-APRIL-2024nguyen hoang AnhNoch keine Bewertungen

- Roadline Paint (Non-Reflective) : Technical Data SheetDokument2 SeitenRoadline Paint (Non-Reflective) : Technical Data SheetAiriell AZdran100% (1)

- Kerb Painting (Alkyd Type N) - Adm Standard SpecDokument3 SeitenKerb Painting (Alkyd Type N) - Adm Standard SpecRolando de GuzmanNoch keine Bewertungen

- Sp-123-2018 Rev - 2 - 0Dokument12 SeitenSp-123-2018 Rev - 2 - 0Thiruvasakan KaliyaperumalNoch keine Bewertungen

- Paint CharacterisationDokument81 SeitenPaint CharacterisationDivyansh Sisodia100% (1)

- TDS 2121 JOTUN Mur Acrylic Topcoat Euk GBDokument3 SeitenTDS 2121 JOTUN Mur Acrylic Topcoat Euk GBAnis GharsellaouiNoch keine Bewertungen

- Paint Exam Model Paper - 2Dokument6 SeitenPaint Exam Model Paper - 2Mujjamil Nakade0% (2)

- Hempel ExplanatoryNotesDokument22 SeitenHempel ExplanatoryNotesSathishkumar Ravi100% (1)

- Q & A 3 BgasDokument8 SeitenQ & A 3 BgasAbdulRahman Mohamed Hanifa100% (2)

- Tractor EmulsionDokument1 SeiteTractor EmulsionMl JainNoch keine Bewertungen

- Sikafloor 82 EpocemDokument6 SeitenSikafloor 82 Epocemthe pilotNoch keine Bewertungen

- Cssbi S8 2018Dokument3 SeitenCssbi S8 2018bpengineerNoch keine Bewertungen

- SprayStone GT Series Paint TDSDokument5 SeitenSprayStone GT Series Paint TDShilary9986Noch keine Bewertungen

- Nitocote EN901Dokument4 SeitenNitocote EN901ArieIndrawanNoch keine Bewertungen

- Bidding Documents and Invitation To Bid Part 4Dokument40 SeitenBidding Documents and Invitation To Bid Part 4Grace Mecate VillanuevaNoch keine Bewertungen

- Hempadur Mastic 45881-12170Dokument3 SeitenHempadur Mastic 45881-12170Bang OchimNoch keine Bewertungen

- Sikafloor 81 EpocemDokument6 SeitenSikafloor 81 Epocemthe pilotNoch keine Bewertungen

- MORTH 1600 2 Acrylic Elastomeric CoatingDokument4 SeitenMORTH 1600 2 Acrylic Elastomeric CoatingRameshNoch keine Bewertungen

- Barrier 90 - English (Uk) - Issued.06.12.2007Dokument3 SeitenBarrier 90 - English (Uk) - Issued.06.12.2007Mohamed FaragNoch keine Bewertungen

- KrytonDokument4 SeitenKrytonProject Manager IIT Kanpur CPWDNoch keine Bewertungen

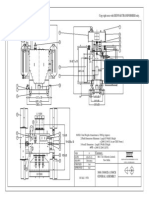

- Drawings of GIS, SEC-4, GurgaonDokument62 SeitenDrawings of GIS, SEC-4, GurgaonIrshad Khan100% (1)

- Name of Vendor: Contact Person TEL: Alif Engineers and PlannersDokument1 SeiteName of Vendor: Contact Person TEL: Alif Engineers and PlannersIrshad KhanNoch keine Bewertungen

- Are 12 PDFDokument105 SeitenAre 12 PDFIrshad KhanNoch keine Bewertungen

- New Doc 30Dokument5 SeitenNew Doc 30Irshad KhanNoch keine Bewertungen

- 1367 6 PDFDokument20 Seiten1367 6 PDFIrshad Khan100% (1)

- PortalDokument1 SeitePortalIrshad KhanNoch keine Bewertungen

- D 800 Cover 40 Bar Dia FCK 50 Fy 500 SDokument2 SeitenD 800 Cover 40 Bar Dia FCK 50 Fy 500 SIrshad KhanNoch keine Bewertungen

- Code of Conduct For Intemediaries Including Consultants / Agents / Business Partners / VendorsDokument2 SeitenCode of Conduct For Intemediaries Including Consultants / Agents / Business Partners / VendorsIrshad KhanNoch keine Bewertungen

- M.Raje Structural Consultants Pvt. LTDDokument2 SeitenM.Raje Structural Consultants Pvt. LTDIrshad KhanNoch keine Bewertungen

- Revised Foundation For 315 Mva Transformer. 28-10-09 - ModelDokument1 SeiteRevised Foundation For 315 Mva Transformer. 28-10-09 - ModelIrshad KhanNoch keine Bewertungen

- C & S 3000kVA GA DrgsDokument7 SeitenC & S 3000kVA GA DrgsIrshad Khan100% (1)

- Alif Engineers and Planners ProfileDokument5 SeitenAlif Engineers and Planners ProfileIrshad KhanNoch keine Bewertungen

- Typ. Detail of Plinth ProtectionDokument1 SeiteTyp. Detail of Plinth ProtectionIrshad KhanNoch keine Bewertungen

- Civil Specification Vol-IIIDokument266 SeitenCivil Specification Vol-IIIIrshad KhanNoch keine Bewertungen

- Owner:-North Eastern Owner: - North Eastern: Electric Power Corporation Ltd. Electric Power Corporation LTDDokument13 SeitenOwner:-North Eastern Owner: - North Eastern: Electric Power Corporation Ltd. Electric Power Corporation LTDIrshad KhanNoch keine Bewertungen

- COVER Burnt Oil PitDokument1 SeiteCOVER Burnt Oil PitIrshad KhanNoch keine Bewertungen

- Car LiftDokument4 SeitenCar LiftIrshad KhanNoch keine Bewertungen

- Ps Foundation RevisedDokument5 SeitenPs Foundation RevisedIrshad KhanNoch keine Bewertungen

- At 6 1Dokument1 SeiteAt 6 1Irshad KhanNoch keine Bewertungen

- Design of The PoleDokument5 SeitenDesign of The PoleIrshad KhanNoch keine Bewertungen

- Trafo Found DesignDokument6 SeitenTrafo Found DesignIrshad Khan100% (1)

- Toilet Details R1 A2Dokument1 SeiteToilet Details R1 A2Irshad KhanNoch keine Bewertungen

- Arizona, Utah & New Mexico: A Guide to the State & National ParksVon EverandArizona, Utah & New Mexico: A Guide to the State & National ParksBewertung: 4 von 5 Sternen4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksVon EverandNew York & New Jersey: A Guide to the State & National ParksNoch keine Bewertungen

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensVon EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNoch keine Bewertungen

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoVon EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoBewertung: 5 von 5 Sternen5/5 (1)

- The Bahamas a Taste of the Islands ExcerptVon EverandThe Bahamas a Taste of the Islands ExcerptBewertung: 4 von 5 Sternen4/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptVon EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptBewertung: 5 von 5 Sternen5/5 (1)