Beruflich Dokumente

Kultur Dokumente

L 05 Analysis and Design of Two Way Slab Without Beams

Hochgeladen von

Hidayat UllahCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

L 05 Analysis and Design of Two Way Slab Without Beams

Hochgeladen von

Hidayat UllahCopyright:

Verfügbare Formate

Department of Civil Engineering, University of Engineering and Technology Peshawar

Lecture - 05

Analysis and Design of Two-way Slab

System without Beams

(Flat Plates and Flat Slabs)

By: Prof Dr. Qaisar Ali

Civil Engineering Department

UET Peshawar

www.drqaisarali.com

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Session I: Flexural Analysis of Two-Way Slab System

without Beams (Direct Design Method)

Session II: Shear Design for Two-Way Slab System

without Beams (Flat Plates and Flat Slabs)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Session I

Flexural Analysis and Design of TwoWay Slab System without Beams

(Direct Design Method)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Topics Addressed

Background

Introduction to Direct Design Method (DDM)

Frame Analysis Steps using Direct Design Method (DDM)

Example 1

Two Way Slabs (Other Requirements of ACI)

Example 2

Example 3

Summary of Direct Design Method (DDM)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Background

In previous lectures, a 90 60 Hall was analyzed as a

one-way slab system as shown below.

Option 02

Option 01

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Background

Also, in previous lecture, the slab of 100 60

commercial building was analyzed as slab with beams

using Moment coefficient method.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Background

In the same 100 60 commercial building, if there are

shallow or no beams, Moment Coefficient Method cannot

be used.

Direct Design Method (DDM) can be used for such cases.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction to DDM

Direct Design Method (DDM) is one of the method for

flexural analysis of two-way slabs with or without beams.

DDM is relatively difficult for slabs with beams or walls

therefore we will use it only for slabs without beams.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction to DDM

In DDM, frames rather than panels are analyzed.

Exterior Frame

Interior Frame

Interior Frame

Exterior Frame

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction to DDM

For complete analysis of slab system frames, are

analyzed in E-W and N-S directions.

E-W Frames

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

10

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction to DDM

For complete analysis of slab system frames, are

analyzed in E-W and N-S directions.

N-S Frames

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

11

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction to DDM

Limitations

Though DDM is useful for analysis of slabs, specially

without beams, the method is applicable with some

limitations as discussed next.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

12

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction to DDM

Limitations (ACI 13.6.1):

Uniformly distributed loading (L/D 2)

l1

2l1 /3

l1

Three or more spans

l2

Rectangular slab

panels (2 or less:1)

Prof. Dr. Qaisar Ali

Column offset

l2 /10

Reinforced Concrete Design II

13

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 01: Sizes

ACI table 9.5 (a) and (c) are used for finding the slab thickness.

Slab with Beams

Prof. Dr. Qaisar Ali

Slab without Beams

Reinforced Concrete Design II

14

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 02: Loads

The slab load is calculated in usual manner.

Prof. Dr. Qaisar Ali

15

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step I: a) Marking E-W Frame (Interior Frame)

Panel Centerline

Interior Frame

Col Centerline

Panel Centerline

l1

l2

Half width of panel

on one side

Half width of panel

on other side

According to ACI 13.6.2.3: Where the transverse span of panels on either side of the

centerline of supports varies, l2 shall be taken as the average of adjacent transverse spans.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

16

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step I: b) Marking E-W Frame (Exterior Frame)

h2/2

Exterior Frame

Half width of panel

on one side

l2

l1

l2 = Panel width/2 +h2/2

Prof. Dr. Qaisar Ali

17

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step II: a) Marking Column Strip (For Interior Frame)

b) Marking Middle Strip (For Interior Frame)

l2

Half Column strip

CS/2

CS/2

M.S/2

C.S

M.S/2

CS/2 = Least of l1/4 or l2/4

ln

l1

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

18

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step II: a) Marking Column Strip (For Interior Frame)

b) Marking Middle Strip (For Interior Frame)

l2

Half Column Strip

5

5

5

10

5

For l1 = 25 and l2 = 20, CS

and MS widths are given as

follows:

ln

CS/2 = Least of l1/4 or l2/4

l1

l2/4 = 20/4 = 5

Prof. Dr. Qaisar Ali

19

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step II: c) Marking Column Strip (For Exterior Frame)

d) Marking Middle Strip (For Exterior Frame)

h/2

CS

Min. Panel Width/4

l2

MS

CS = Min. Panel Width/4 + (Col.

Size)

MS = l2 - CS

For Given Frame:

CS and MS widths are given as

follows:

ln

l2 = (20) + (14/12) = 10.58

l1

CS = (20/4) + (14/12) = 5.58

MS = 10.58 5.58 = 5

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

20

10

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step III: Calculate Static Moment (Mo) for interior span of frame.

Span of frame

wu l2 ln2

Mo =

Mo

8

ln

Prof. Dr. Qaisar Ali

l2

Reinforced Concrete Design II

21

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step IV: Longitudinal Distribution of Static Moment (Mo).

M+

M = 0.65Mo

M + = 0.35Mo

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

22

11

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step V: Lateral Distribution to column and middle strips.

M = 0.65Mo

0.60M +

0.75M

M + = 0.35Mo

Prof. Dr. Qaisar Ali

0.75M

23

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step III: Calculate Static Moment (Mo) for exterior span of frame.

25'-0"

Mo =

25'-0"

wu l2 ln2

25'-0"

25'-0"

Span of frame

20'-0"

Mo

ln

l2

20'-0"

20'-0"

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

24

12

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step IV: Longitudinal distribution of static moment (Mo).

Mext = 0.26Mo

M ext+ = 0.52Mo

Mext

+

Mext

Mint

Mint- = 0.70Mo

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

25

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step V: Lateral Distribution to column and middle strips.

Mext- = 0.26Mo

M ext+ = 0.52Mo

1.00Mext

0.75Mint

0.60Mext

+

Mint- = 0.70Mo

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

26

13

Department of Civil Engineering, University of Engineering and Technology Peshawar

Steps In DDM

Step 03: Analysis

Step V: Lateral Distribution to column and middle strips.

Mext- = 0.26Mo

Mext+ = 0.52Mo

Mint- = 0.70Mo

0.60M+

1.00Mext

0.75Mint

0.60Mext

0.75M

0.75M

+

M- = 0.65Mo

M+ = 0.35Mo

Prof. Dr. Qaisar Ali

27

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Example 1:

Analyze the flat plate shown below using DDM. The slab supports a

live load of 144 psf. All columns are 14 square. Take fc = 4 ksi and fy

= 60 ksi.

25

25

25

25

20

20

20

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

28

14

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 01: Sizes

ACI table 9.5 (c) is used for finding flat plate and flat slab

thickness.

hmin = 5 inches (slabs without drop panels)

hmin = 4 inches (slabs with drop panels)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

29

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 01: Sizes

Exterior panel governs. Therefore,

hf = ln/30 = [{25 (2 14/2)/12}/30] 12 = 9.53 (ACI minimum

requirement)

Take hf = 10

For #6 bars: d = hf 0.75 0.75 = 8.5

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

30

15

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 02: Loads

Service Dead Load (D.L) = slabhf

= 0.15 (10/12) = 0.125 ksf

Superimposed Dead Load (SDL) = Nil

Service Live Load (L.L) = 144 psf or 0.144 ksf

Factored Load (wu) = 1.2D.L + 1.6L.L

= 1.2 0.125 + 1.6 0.144 = 0.3804 ksf

Prof. Dr. Qaisar Ali

31

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step I: Marking E-W Interior Frame.

25'-0"

25'-0"

25'-0"

25'-0"

20'-0"

Panel Centerline

Interior Frame

l2

Col Centerline

Panel Centerline

l1

20'-0"

Half width of panel

on one side

Half width of panel

on other side

20'-0"

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

32

16

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step II: Marking column and middle strips.

a) Marking Column Strip

25'-0"

25'-0"

25'-0"

25'-0"

b) Middle Strip

l2

Half Column strip

20'-0"

5

5

5

10

5

20'-0"

CS/2 = Least of l1/4 or l2/4

ln

l2/4 = 20/4 = 5

l1

20'-0"

Prof. Dr. Qaisar Ali

33

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step III: Static Moment (Mo) calculation.

25

25

25

25

Mo = wul2ln2/8

= 540 ft-kip

20

Mo = 540 ft-k

Mo = 540 ft-k

l2

20

ln =23.83

l1

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

20

34

17

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step IV: Longitudinal distribution of Static Moment (Mo).

25

Mext = 0.26Mo = 140

Mext+ = 0.52Mo = 281

Mint = 0.70Mo = 378

M = 0.65Mo = 351

M + = 0.35Mo = 189

25

25

25

20

M+

Mext+

Mext

Mint- M

M

20

20

Prof. Dr. Qaisar Ali

35

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step IV: Longitudinal distribution of Static Moment (Mo).

Mext = 0.26Mo = 140

Mext+ = 0.52Mo = 281

Mint = 0.70Mo = 378

M = 0.65Mo = 351

M + = 0.35Mo = 189

25

25

281

189

25

25

20

140

378

351

351

20

20

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

36

18

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step V: Lateral distribution to column and middle strips.

25

Mext = 0.26Mo = 140

Mext+ = 0.52Mo = 281

Mint = 0.70Mo = 378

25

25

25

20

0.75Mint 0.75M

1.00Mext

0.60Mext

0.75M

0.60M+

M = 0.65Mo = 351

M + = 0.35Mo = 189

20

20

Prof. Dr. Qaisar Ali

37

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step V: Lateral distribution to column and middle strips.

25

Mext = 0.26Mo = 140

Mext+ = 0.52Mo = 281

Mint = 0.70Mo = 378

25

0.75Mint 0.75M

140

0.75M

0.60M+

20

100 % of M ext- goes to

column strip and

remaining to middle strip

Prof. Dr. Qaisar Ali

25

20

0.60Mext

M = 0.65Mo = 351

M + = 0.35Mo = 189

25

20

Reinforced Concrete Design II

38

19

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step V: Lateral distribution to column and middle strips.

25

Mext = 0.26Mo = 140

Mext+ = 0.52Mo = 281

Mint = 0.70Mo = 378

25

25

25

20

0.75Mint 0.75M

140

169

0.75M

113

M = 0.65Mo = 351

M + = 0.35Mo = 189

20

60 % of Mext+ & M + goes

to column strip and

remaining to middle strip

20

Prof. Dr. Qaisar Ali

39

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step V: Lateral distribution to column and middle strips.

25

Mext = 0.26Mo = 140

Mext+ = 0.52Mo = 281

Mint = 0.70Mo = 378

25

25

20

284

140

168

263

263

113

M = 0.65Mo = 351

M + = 0.35Mo = 189

20

75 % of Mint- goes to

column strip and

remaining to middle strip

Prof. Dr. Qaisar Ali

25

20

Reinforced Concrete Design II

40

20

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step V: Lateral distribution to column and middle strips.

25

Mext = 0.26Mo = 140

Mext+ = 0.52Mo = 281

Mint = 0.70Mo = 378

25

25

20

0

112/2

94/2

283

140

88/2

112/2

76/2

88/2

263

263

168

M = 0.65Mo = 351

M + = 0.35Mo = 189

25

113

94/2

88/2

76/2

88/2

20

20

Prof. Dr. Qaisar Ali

41

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Interior Frame)

Step V: Lateral distribution to column and middle strips.

25

25

25

25

20

Mu (per foot width)

= M / strip width

112/2

11.2

9.4

94/2

283

28.3

140

14.0

168

16.8

88/2

8.8

76/2

7.6

8.8

88/2

5 half middle strip

263

26.3

263

26.3

11.3

113

10 column strip

5 half middle strip

20

20

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

42

21

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Exterior Frame)

Step I: Marking E-W Exterior Frame

h2/2

Exterior Frame

l2

Half width of panel

on one side

l1

l2 = Panel width/2 +h2/2

l2 = (20) + (14/12)

= 10.58

Prof. Dr. Qaisar Ali

43

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Exterior Frame)

Step II: Marking Column and Middle Strips

h/2

CS

Min. Panel Width/4

l2

MS

CS = Min. Panel Width/4 + (Col.

Size)

MS = l2 - CS

For Given Frame:

CS and MS widths are given as

follows:

l2 = (20) + (14/12) = 10.58

CS = (20/4) + (14/12) = 5.58

MS = 10.58 5.58 = 5

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

44

22

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Exterior Frame)

Step III: Calculation of static moment, Mo

25

Mo =

25

wul2ln2/8

= 285.68 ft-kip

Mo = 285.68 ft-k

25

25

Mo = 285.68 ft-k

20

l2 =10.58

ln =23.83

20

20

Prof. Dr. Qaisar Ali

45

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Exterior Frame)

Step IV: Longitudinal distribution to column and middle strips.

25

Mo = 285.68 ft-kip

Mext- = 0.26Mo = 74

Mext+ = 0.52Mo = 148

Mint- = 0.70Mo = 200

25

25

M+

Mext+

Mext

25

Mint-

20

l2 =10.58

20

M - = 0.65Mo = 186

M + = 0.35Mo = 100

20

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

46

23

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Exterior Frame)

Step IV: Longitudinal distribution to column and middle strips.

25

Mo = 285.68 ft-kip

Mext- = 0.26Mo = 74

Mext+ = 0.52Mo = 148

Mint- = 0.70Mo = 200

25

148

74

25

25

100

200

186

186

20

l2 =10.58

20

M - = 0.65Mo = 186

M + = 0.35Mo = 100

20

Prof. Dr. Qaisar Ali

47

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Exterior Frame)

Step V: Lateral distribution to column and middle strips.

25

Mo = 285.68 ft-kip

1.00Mext

0.60Mext+

25

0.75Mint

0.75M

0.60M+

25

25

0.75M

20

Mext- = 0.26Mo = 74

Mext+ = 0.52Mo = 148

Mint- = 0.70Mo = 200

l2 =10.58

20

M - = 0.65Mo = 186

M + = 0.35Mo = 100

20

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

48

24

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Exterior Frame)

Step V: Lateral distribution to column and middle strips.

25

Mo = 285.68 ft-kip

25

25

74

89

150

140

60

140

59

50

46

40

46

25

20

Mext- = 0.26Mo = 74

Mext+ = 0.52Mo = 148

Mint- = 0.70Mo = 200

l2 =10.58

20

M - = 0.65Mo = 186

M + = 0.35Mo = 100

20

Prof. Dr. Qaisar Ali

49

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Exterior Frame)

Step V: Lateral distribution to column and middle strips (per strip width)

25

Mo = 285.68 ft-kip

25

25

13.26

15.94

26.8

25.1

10.75

25.1

11.87

10

9.2

9.2

Mext- = 0.26Mo = 74

Mext+ = 0.52Mo = 148

Mint- = 0.70Mo = 200

25

CS

MS

20

l2 =10.58

20

M - = 0.65Mo = 186

M + = 0.35Mo = 100

l2 = (20) + (14/12) = 10.58

20

CS = (20/4) + (14/12) = 5.58

MS = 10.58 5.58 = 5

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

50

25

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (N-S Interior Frame)

Column Strip and Middle strip Moments

25

Mo = 421.5 ft-kip

Mext- = 0.26Mo = 110

Mext+ = 0.52Mo = 219

Mint- = 0.70Mo = 295

M - = 0.65Mo = 274

M + = 0.35Mo = 148

74/2

25

110

131

88/2

25

20

221

206

59/2

25

69/2

20

88.8

206

69/2

20

l2 =25

Prof. Dr. Qaisar Ali

51

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (N-S Interior Frame)

Column Strip and Middle strip Moments (Per Strip Width)

25

Mo = 421.5 ft-kip

Mext- = 0.26Mo = 110

Mext+ = 0.52Mo = 219

Mint- = 0.70Mo = 295

M - = 0.65Mo = 274

M + = 0.35Mo = 148

4.9

25

11.0

13.1

5.8

20

4.6

20

8.88

20.6

4.6

l2 =25

Prof. Dr. Qaisar Ali

25

22.1

20.6

3.9

25

Reinforced Concrete Design II

20

52

26

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (N-S Exterior Frame)

Column Strip and Middle strip Moments

25

Mo = 220.5 ft-kip

Mext = 0.26Mo = 58

Mext+ = 0.52Mo = 114

Mint = 0.70Mo = 154

M = 0.65Mo = 143

M + = 0.35Mo = 77

58

69

45

115.5

25

25

25

20

38.5

107.3 35.75

46.2

20

30.8

107.3 35.75

l2 =13.08

20

l2 = (25) + (14/12)

= 13.08

Prof. Dr. Qaisar Ali

53

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (N-S Exterior Frame)

Column Strip and Middle strip Moments (Per Strip Width)

25

25

25

25

Mo = 220.5 ft-kip

Mext = 0.26Mo = 58

Mext+ = 0.50Mo = 110

Mint = 0.70Mo = 154

M = 0.65Mo = 143

M + = 0.35Mo = 77

Column Strip Width

= (20/4) + (14/12)

= 5.58

MS = 13.08 5.58

= 7.5

10.4

20

12.32 6

20.69

5.13

19.2

4.76

8.27

4.12

19.2

4.76

20

20

l2 =13.08

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

54

27

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (E-W Direction Moments)

25

13.26

0

25

15.94

26.8

25.1

10.75

25.1

11.87

10

9.2

9.2

9.4

28.3

14.0

25

20

7.6

26.3

26.3

16.8

0

25

11.3

8.8

11.2

8.8

20

20

Prof. Dr. Qaisar Ali

55

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 03: Frame Analysis (N-S Direction Moments)

25

10.4

00

11.0

8.8

13.1

8.8

5.13 4.9

22.1

12.32 6

20.69

25

19.2

4.76

4.6

20.6

8.27

4.12

3.9

8.88

19.2

4.76

4.6

20.6

25

25

20

4.6

20

4.6

20

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

56

28

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 04: Design (E-W Direction)

25

13.26

0

25

15.94

26.8

25.1

10.75

25.1

11.87

10

9.2

9.2

9.4

25

20

7.6

28.3

14.0

26.3

26.3

16.8

0

25

11.3

8.8

11.2

8.8

20

20

Prof. Dr. Qaisar Ali

57

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 04: Design (E-W Direction)

25

B

25

25

C

A

A

C

C

A = #5 @ 4 c/c

B = #5 @ 8 c/c

C = #5 @ 12 c/c

Prof. Dr. Qaisar Ali

20

B

C

25

Reinforced Concrete Design II

20

20

58

29

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 1

Step 04: Design (N-S Direction)

25

B

25

4.9

3.9

25

25

20

A = #5 @ 6 c/c

B = #5 @ 9 c/c

C = #5 @ 12 c/c

D = #5 @ 15 c/c

20

20

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

59

Department of Civil Engineering, University of Engineering and Technology Peshawar

Two Way Slabs

(Other Requirements of ACI Code)

Detailing of flexural reinforcement for column supported two-way

slabs:

Maximum spacing and minimum reinforcement requirement:

Prof. Dr. Qaisar Ali

Maximum spacing (ACI 13.3.2):

smax = 2 hf in each direction.

Minimum Reinforcement (ACI 7.12.2.1):

Asmin = 0.0018 bhf for grade 60.

Asmin = 0.002 bhf for grade 40 and 50.

Reinforced Concrete Design II

60

30

Department of Civil Engineering, University of Engineering and Technology Peshawar

Two Way Slabs

(Other Requirements of ACI Code)

Detailing of flexural reinforcement for column supported two-way

slabs:

At least 3/4 cover for fire or corrosion protection.

Slab

3/4

Support

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

61

Department of Civil Engineering, University of Engineering and Technology Peshawar

Two Way Slabs

(Other Requirements of ACI Code)

Detailing of flexural reinforcement for column supported two-way

slabs:

Reinforcement placement: In case of two way slabs supported on

beams, short-direction bars are normally placed closer to the top

or bottom surface of the slab, with the larger effective depth

because of greater moment in short direction.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

62

31

Department of Civil Engineering, University of Engineering and Technology Peshawar

Two Way Slabs

(Other Requirements of ACI Code)

Detailing of flexural reinforcement for column supported two-way

slabs:

Reinforcement

placement:

However

in

the

case

of

flat

plates/slabs, the long-direction negative and positive bars, in both

middle and column strips, are placed closer to the top or bottom

surface of the slab, respectively, with the larger effective depth

because of greater moment in long direction.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

63

Department of Civil Engineering, University of Engineering and Technology Peshawar

Two Way Slabs

(Other Requirements of ACI Code)

Detailing of flexural reinforcement for column supported two-way

slabs:

Splicing: ACI 13.3.8.5 requires that all bottom bars within the

column strip in each direction be continuous or spliced with length

equal to 1.0 ld, (For development length see ACI 12.2.3 or Nelson

13th Ed, page 172 chapter 5 or mechanical or welded splices)

For #7 or larger no. of bars of fy = 60 ksi, and normal weight,

uncoated concrete of fc = 4 ksi:

Prof. Dr. Qaisar Ali

ld = 47 db

Reinforced Concrete Design II

64

32

Department of Civil Engineering, University of Engineering and Technology Peshawar

Two Way Slabs

(Other Requirements of ACI Code)

Detailing of flexural reinforcement for column supported two-way

slabs:

Continuity of bars: At least two of the column strip bars in each

direction must pass within the column core and must be anchored

at exterior supports (ACI 13.3.8.5).

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

65

Department of Civil Engineering, University of Engineering and Technology Peshawar

Two Way Slabs

(Other Requirements of ACI Code)

Detailing of flexural reinforcement for column supported two-way

slabs:

Standard Bar Cut off Points (Practical Recommendation) for column

and middle strips both.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

66

33

Department of Civil Engineering, University of Engineering and Technology Peshawar

Two Way Slabs

(Other Requirements of ACI Code)

Detailing of flexural reinforcement for

column supported two-way slabs:

Reinforcement at Exterior Corners:

Reinforcement

should

be

provided

at

exterior corners in both the bottom and top

l /5

l /5

of the slab, for a distance in each direction

from the corner equal to one-fifth the longer

span of the corner panel as shown in figure.

The positive and negative reinforcement

should be of size and spacing equivalent to

that

required

for

maximum

positive

l = longer clear span

moments (per foot of width) in the panel

(ACI 13.3.6.1)

Prof. Dr. Qaisar Ali

67

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 2

Homework: Analysis results of the slab shown below using DDM are

presented next. The slab supports a live load of 60 psf. Superimposed

dead load is equal to 40 psf. All columns are 14 square. Take fc = 3 ksi

and fy = 40 ksi.

25

25

25

25

20

20

20

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

68

34

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 2

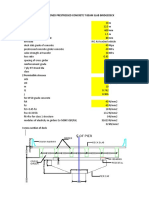

Calculation summary

Slab thickness hf = 10

Factored load (wu) = 0.294 ksf

Column strip width = 5

Prof. Dr. Qaisar Ali

69

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 2

E-W Direction Moments (units: kip-ft)

25

57.4

0

25

68.9

116

107.6

46.4

107.6

45.9

38.6

35.9

30.9

35.9

36.5

219

108.6

43.4

25

20

29.2

204

204

130

0

25

88

33.9

33.9

20

20

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

70

35

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 2

E-W Direction Moments (units: kip-ft/ft)

Moments per strip width

25

10.3

0

25

12.3

20.8

19.3

8.3

19.3

9.2

7.7

7.2

6.2

7.2

7.3

21.9

10.9

25

20

5.8

20.4

20.4

13.0

0

25

8.8

6.8

8.7

6.8

20

20

Prof. Dr. Qaisar Ali

71

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 2

N-S Direction moments (units: kip-ft)

25

44.3

53.2

89.5

84.7

35.5

101

33.9

29.8 4.9

28.5

171

83.1

27.7

35.8

23.9

83.1

27.7

00

25

159

22.8

3.9

25

20

26.5

20

68.4

159

25

26.5

20

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

72

36

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 2

N-S Direction moments (units: kip-ft/ft)

Moments per strip width

25

7.9

9.5

4.7

16.0

4.0

14.9

3.7

6.4

3.2

14.9

3.7

25

00

8.5

10.1

4.5

4.9

3.8

25

25

20

17.1

15.9

3.0

3.9

3.5

20

6.8

15.9

3.5

20

Prof. Dr. Qaisar Ali

73

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 3

Homework: Analysis results of the slab shown below using DDM are

presented next. The slab supports a live load of 60 psf. Superimposed

dead load is equal to 40 psf. All columns are 12 square. Take fc = 3 ksi

and fy = 40 ksi.

20

20

20

20

15

15

15

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

74

37

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 3

Calculation summary

Slab thickness hf = 8

Factored load (wu) = 0.264 ksf

Column strip width = 3.75

Prof. Dr. Qaisar Ali

75

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 3

E-W Direction Moments (units: kip-ft)

20

24.8

0

20

29.7

50

46.5

20

46.5

19.8

16.7

15.5

13.3

15.5

15.6

93.8

46.5

18.6

20

15

12.5

87.1

87.1

55.8

0

20

37.5

14.5

14.5

15

15

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

76

38

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 3

E-W Direction Moments (units: kip-ft/ft)

Moments per strip width

20

5.8

0

20

7.0

11.8

10.9

4.7

10.9

5.3

4.5

4.1

3.6

4.1

4.2

12.5

6.2

20

15

3.3

11.6

11.6

7.4

0

20

5.0

3.9

5.0

3.9

15

15

Prof. Dr. Qaisar Ali

77

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 3

N-S Direction moments (units: kip-ft)

20

17.7

21.2

35.7

33.6

14.1

40.4

13.5

11.9 4.9

11.3

67.9

33.1

11.0

14.3

9.5

33.1

11.0

00

20

63.1

9.1

3.9

20

15

10.5

15

27.2

63.1

20

10.5

15

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

78

39

Department of Civil Engineering, University of Engineering and Technology Peshawar

Example 3

N-S Direction moments (units: kip-ft/ft)

Moments per strip width

20

17.7

21.2

35.7

4.5

2.26

5.4

2.2

1.90 4.9

1.8

9.5

33.1

1.77

14.3

1.52

33.1

1.77

00

20

8.4

1.4

3.9

20

20

1.7

15

3.6

8.4

15

1.7

15

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

79

Department of Civil Engineering, University of Engineering and Technology Peshawar

Summary of Direct Design Method

Decide about sizes of slab and columns. The slab depth can

be calculated from ACI table 9.5 (c).

Find Load on slab (wu = 1.2DL + 1.6LL)

On given column plan of building, decide about location and

dimensions of all frames (exterior and interior)

For a particular span of frame, find static moment (Mo =

wul2ln2/8).

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

80

40

Department of Civil Engineering, University of Engineering and Technology Peshawar

Summary of Direct Design Method

Find longitudinal distribution of static moment:

Exterior span (Mext - = 0.26Mo; M ext + = 0.52Mo; Mint - = 0.70Mo)

Interior span (Mint - = 0.65Mo; M int + = 0.35Mo)

Find lateral Distribution of each longitudinal moment:

100 % of Mext goes to column strip

60 % of Mext + and Mint+ goes to column strip

75 % of Mint goes to column strip

The remaining moments goes to middle strips

Design and apply reinforcement requirements (smax = 2hf)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

81

Department of Civil Engineering, University of Engineering and Technology Peshawar

Session II

Shear Design for Two-Way Slab

System without Beams

(Flat Plates and Flat Slabs)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

82

41

Department of Civil Engineering, University of Engineering and Technology Peshawar

Topics Addressed

Introduction

Various Design Options

Design Example

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

83

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Flat Plates and Flat Slabs

These are the most common types of two-way slab system, which are commonly

used in multi-story construction.

They render low story heights and have easy construction and formwork.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

84

42

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Behavior

When two-way slabs are directly supported by columns, shear near the column

(punching shear) is of critical importance.

Therefore, in addition to flexure, flat plates shall also be designed for two way

shear (punch out shear) stresses.

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

85

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Punching Shear in Flat Plates

Punching shear occurs at column support points in flat plates and flat slabs.

Shear crack

Punch Out

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

86

43

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Critical Section for Punching Shear

Prof. Dr. Qaisar Ali

87

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Critical Section for Shear Design

In shear design of beams, the critical section is taken at a distance d

from the face of the support.

Shear

crack

Beam

d

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

88

44

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Critical Section for Shear Design

In shear design of flat plates, the critical section is an area taken at a

distance d/2 from all face of the support.

Column

Critical perimeter

Slab

Tributary Area, At

d/2

d/2

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

Slab thickness (h)

d = h cover

89

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Punching Shear: Critical Perimeter, bo

c1,S

d/2

c1,L

d/2

bo = 2(c1,S + d) + 2(c1,L + d)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

90

45

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Punching Shear: Critical Perimeter, bo

c1,S

d/2

c1,L

d/2

bo = 2(c1,S + d/2) + (c1,L + d)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

91

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Punching Shear: Critical Perimeter, bo

c1,L

d/2

c1,S

d/2

bo = (c1,S + d/2) + (c1,L + d/2)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

92

46

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Punching Shear Demand (Vu): For Square Column

Critical Perimeter, bo:

bo = 4(c + d)

Area Contributing to Load

(Excluding Area of bo), At :

l2

At = (l1 l2) (c + d)2 / 144

[l1 & l2 are in ft. units and c & d are in

inches]

l1

Punching Shear Demand:

Vu = W u At

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

93

Department of Civil Engineering, University of Engineering and Technology Peshawar

Introduction

Capacity of Slab in Punching Shear:

Vn = Vc + Vs

Vc is least of:

4 (fc)bod

(2 + 4/c) (fc)bod

{(sd/bo +2} (fc)bod

c = longer side of column/shorter side of column

s = 40 for interior column, 30 for edge column, 20 for corner columns

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

94

47

Department of Civil Engineering, University of Engineering and Technology Peshawar

Various Design Options

When Vc Vu ( = 0.75): Nothing is required.

When Vc < Vu, then we need to increase the punching shear capacity of the

slab.

Punching shear capacity of the flat plates can be increased by either of the

following ways:

i.

Increasing d ,depth of slab: This can be done by increasing the slab depth as a

whole or in the vicinity of column (Drop Panel)

ii.

Increasing bo, critical shear perimeter: This can be done by increasing column size

as a whole or by increasing size of column head (Column capital)

iii.

Increasing fc (high Strength Concrete)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

95

Department of Civil Engineering, University of Engineering and Technology Peshawar

Various Design Options

And/ or provide shear reinforcement (Vs) in the form of:

Integral beams

Bent Bars

Shear heads

Shear studs

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

96

48

Department of Civil Engineering, University of Engineering and Technology Peshawar

Various Design Options

Drop Panels (ACI 9.5.3.2 and 13.3.7):

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

97

Department of Civil Engineering, University of Engineering and Technology Peshawar

Various Design Options

Column Capital:

ACI 13.1.2 requires the column capital should be oriented no greater than 450 to the axis of the

column.

ACI 6.4.6 requires that the capital concrete be placed at the same time as the slab concrete. As a

result, the floor forming becomes considerably more complicated and expensive.

The increased perimeter can be computed by equating Vu to Vc and simplifying the resulting

equation for b0

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

98

49

Department of Civil Engineering, University of Engineering and Technology Peshawar

Various Design Options

Integral Beam and Bent Bars:

In case of integral beam or bent bar reinforcement following must be

satisfied.

ACI 11.11.3 requires the slab effective depth d to be at least 6 in., but not

less than 16 times the diameter of the shear reinforcement.

When bent bars and integral beams are to be used, ACI 11.11.3 reduces

Vc by 2

Prof. Dr. Qaisar Ali

99

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Various Design Options

Integral Beams

Integral Beams require the design of two main components:

i.

Vertical stirrups

ii. Horizontal bars radiating outward from column faces.

Vertical Stirrups

Horizontal Bars

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

100

50

Department of Civil Engineering, University of Engineering and Technology Peshawar

Various Design Options

Integral Beams (Vertical Stirrups)

Vertical stirrups are used in

conjunction with supplementary

horizontal bars radiating outward

in two perpendicular directions

from the support to form what are

termed integral beams contained

entirely within the slab thickness.

In such a way, critical perimeter

is increased

Increased

Vertical stirrups

Critical

For 4 sides, total stirrup area is 4 times

Perimeter, bo

Prof. Dr. Qaisar Ali

individual 2 legged stirrup area

101

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Various Design Options

Integral Beams (Horizontal Bars)

Critical Perimeter, bo

How much should be the length of the horizontal

bars, lv

lv can be determined using the critical perimeter

bo

(lv c/2)

Distance from the face of column to the boundary

of critical perimeter = (lv c/2)

lv

R

Prof. Dr. Qaisar Ali

X = (lv c/2)

X = (lv c/2)

Reinforced Concrete Design II

bo = 4R + 4c

102

51

Department of Civil Engineering, University of Engineering and Technology Peshawar

Various Design Options

Various Design Options

Integral Beams

Critical Perimeter,

bo

(lv c/2)

For Square Column of Size c:

bo = 4R + 4c ........ (1)

R = (X 2 + X 2 ) = (2) X

Eq (1) => bo = 4 (2) X + 4c

putting value of lv : bo = 4 (2){(3/4)(lv c1/2)} + 4c

after simplification, we get: bo = 4.24 lv + 1.88c

X = (lv c/2)

The above equation can be used for determining the

length up to which the horizontal bars should be extended

beyond the face of column.

Prof. Dr. Qaisar Ali

X = (lv c/2)

103

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Example

Step 01: Calculate Punching Shear Demand, Vu

Critical Perimeter, bo :

bo = 4(c + d)

= 4(14 + 8.5) = 90

Tributary Area (Excluding Area

of bo), At :

At = (25 20) (14 + 8.5)2 /144

20

25

= 496.5 ft2

Punching Shear Demand, Vu :

Wu = 0.3804 ksf

Vu = At Wu

= 496.5 0.3804 = 189 kips

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

104

52

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Example

Calculation of Punching shear capacity (Vc):

Checking the punching shear

capacity of concrete:

fc bo d = 4000 90 8.5 / 1000 = 48 k

20

Vc is least of:

4 fc bod = 145 k

25

(2 + 4 / c) fc bod = 216 k

{(s d/bo +2} fc bod = 208 k

Therefore,

Vc = 145 k < Vu (189 k)

Shear reinforcement is required.

Prof. Dr. Qaisar Ali

105

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Example

Design for shear (Option 01): Drop panels

In drop panels, the slab thickness in the vicinity of the columns is increased to

increase the shear capacity (Vc = 4 (fc)bod) of concrete.

The increased thickness can be computed by equating Vu to Vc

and

simplifying the resulting equation for d to calculate hTotal.

(hTotal = hSlab + hDrop Panle = hf + hDP)

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

106

53

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Example

Design for shear (Option 01): Drop panels

Equate Vu to Vc:

Vu = Vc

189 = 0.75 4 (fc) 90 d

d = 11.07

25/6 = 4.25

20/6 = 3.5

Therefore, hTotal = d +1.5 12.6

7

8.5

This gives 2.6 drop panel.

According to ACI, minimum

thickness of drop panel = hf/4 =

10/4 = 2.5, So using 2.6 thick

drop panel.

Drop Panel dimensions:

25/6 4.25; 20/6 3.5

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

107

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Example

Design for shear (Option 02): Column Capitals

Equate Vu to Vc:

Vu = Vc

189 = 0.75 4 (fc) bo 8.5

bo = 117.20

Now,

bo = 4 (c + d)

117.20 = 4(c + 8.5)

Simplification gives,

c = 20.8 21

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

108

54

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Example

Design for shear (Option 02): Column Capitals

According to ACI code, < 45o

y = 3.5/ tan

Let = 30o, then y 6.06

c = 21

For = 20o, y 9.62

3.5

capital

14

column

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

109

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Example

Design for shear (Option 03): Integral Beams (Vertical Stirrups)

Vc = 145 kips

When integral beams are to be used, ACI 11.12.3 reduces Vc by 2. Therefore

Vc = 145/2 = 72.5 kips

Using 3/8 , 2 legged (0.22 in2), 4 (side) = 4 0.22 = 0.88 in2

Spacing (s) = Avfyd/ (Vu Vc)

s = 0.75 0.88 60 8.5/ (189 72.5) = 2.89 3

Maximum spacing allowed d/2 = 8.5/2 = 4.25

Prof. Dr. Qaisar Ali

Hence spacing of 3 is within allowable limits.

Using #3, 2 legged stirrups @ 3 c/c

Reinforced Concrete Design II

110

55

Department of Civil Engineering, University of Engineering and Technology Peshawar

Design Example

Design for shear (Option 03): Integral Beams (Horizontal Bars)

Four #5 bars are to be provided in each direction to hold the stirrups. We know

minimum bo = 117.10

Using the equation bo = 4.24lv + 1.88c, we get:

lv 20

Hence the horizontal bars need to be extended beyond the center of the column up to

at least 20 (We will use 24)

First stirrup should be provided at a distance

not more than d/2 from the face of column up

to distance of d/2 from boundary of critical

perimeter.

It must be noted that integral beams along with

stirrups will shift the critical perimeter. Beams

alone cannot shift the critical perimeter.

Prof. Dr. Qaisar Ali

111

Reinforced Concrete Design II

Department of Civil Engineering, University of Engineering and Technology Peshawar

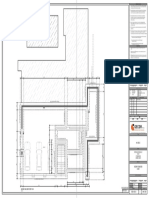

Design Example

Design for shear (Option 03): Integral Beams details.

Total length of horizontal bars is 4 in both directions.

4 #5 bars are used here to hold the vertical stirrups.

Vertical stirrups are provided up to distance of

d /2 = 8.5/2 = 4.25

d/2 from the boundary of critical perimeter.

d/2

#3 stirrups @ 3 c/c are used here.

First stirrup is provided at s/2 = 1.5 from column

d/2

face.

#3 Stirrups @ 3 c/c

2

4 #5 bars to hold stirrups

4

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

112

56

Department of Civil Engineering, University of Engineering and Technology Peshawar

References

ACI 318

Design of Concrete Structures by Nilson, Darwin and Dolan

ACI Design Handbook

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

113

Department of Civil Engineering, University of Engineering and Technology Peshawar

The End

Prof. Dr. Qaisar Ali

Reinforced Concrete Design II

114

57

Das könnte Ihnen auch gefallen

- Toyota Axio/Fielder Manual Translated in EnglishDokument377 SeitenToyota Axio/Fielder Manual Translated in EnglishHidayat Ullah86% (7)

- Strap Footing PDFDokument7 SeitenStrap Footing PDFMohammed Sumer100% (1)

- KPPSC Character Certificate FormDokument1 SeiteKPPSC Character Certificate FormHidayat UllahNoch keine Bewertungen

- Analysis & Design of Multistorey BuildingDokument124 SeitenAnalysis & Design of Multistorey Buildingriyasproject86% (36)

- Calculation of Loads For Column and Foundation DesignDokument2 SeitenCalculation of Loads For Column and Foundation DesignMandar Nadgaundi100% (1)

- Analysis Design of Multistorey BuildingDokument125 SeitenAnalysis Design of Multistorey Buildingsvivek67% (3)

- Design of a Five-Storey Reinforced Concrete Seminary Main BuildingDokument117 SeitenDesign of a Five-Storey Reinforced Concrete Seminary Main BuildingjedsclementNoch keine Bewertungen

- Lecture 1 - Curves (Simple & Compound) PDFDokument73 SeitenLecture 1 - Curves (Simple & Compound) PDFHidayat Ullah92% (164)

- 6.2.6.1 Design Criteria of Water TanksDokument17 Seiten6.2.6.1 Design Criteria of Water TanksARSENoch keine Bewertungen

- Design of Column&Wall FootingDokument20 SeitenDesign of Column&Wall FootingJo Eli MacadangdangNoch keine Bewertungen

- PPT On Design PhilosphiesDokument21 SeitenPPT On Design PhilosphiesAshish GuptaNoch keine Bewertungen

- SP 2069 Specification For Pressure Vessels 1 PDFDokument71 SeitenSP 2069 Specification For Pressure Vessels 1 PDFkart_rl100% (1)

- Design and Analysis For Wind LoadsDokument102 SeitenDesign and Analysis For Wind LoadsSabih Hashim AlzuhairyNoch keine Bewertungen

- Structural Engineering and Construction ManagementDokument42 SeitenStructural Engineering and Construction Managementakash nairNoch keine Bewertungen

- Unit III - Limit State Design For Bond, Anchorage Shear & TorsionDokument8 SeitenUnit III - Limit State Design For Bond, Anchorage Shear & TorsionManikandan0% (1)

- Example NR 2. CH 4Dokument11 SeitenExample NR 2. CH 4Tesfa Hundera100% (1)

- Steel Design Project: Laterally Supported and Unsupported Beams, Columns, Column Base Plate, ConnectionsDokument24 SeitenSteel Design Project: Laterally Supported and Unsupported Beams, Columns, Column Base Plate, Connectionsozzieastro96% (24)

- Introduction to Eurocodes DesignDokument28 SeitenIntroduction to Eurocodes DesignChamil Mahagamage100% (1)

- Staircase Design (6m)Dokument3 SeitenStaircase Design (6m)ashokpl92_227764155Noch keine Bewertungen

- Earthquake Engineering QuizDokument29 SeitenEarthquake Engineering Quizshivanandarcot0% (1)

- Introduction to Design of Building StructuresVon EverandIntroduction to Design of Building StructuresBewertung: 4 von 5 Sternen4/5 (22)

- Module 3 - Lesson 4 - Center of Mass and Center of Rigidity, and Review of Frame Analysis - CE 407-CE42S2 - Earthquake EngineeringDokument12 SeitenModule 3 - Lesson 4 - Center of Mass and Center of Rigidity, and Review of Frame Analysis - CE 407-CE42S2 - Earthquake EngineeringRich Lenard L. MagbooNoch keine Bewertungen

- Concrete Design Flowcharts 3-14-17Dokument38 SeitenConcrete Design Flowcharts 3-14-17MY NameNoch keine Bewertungen

- Strap Footing Eqns PDFDokument6 SeitenStrap Footing Eqns PDFaldert_path100% (2)

- Automotive Functional Safety Best-Practices - ISO 26262 Standard - EmbitelDokument5 SeitenAutomotive Functional Safety Best-Practices - ISO 26262 Standard - Embitelprasanna_npNoch keine Bewertungen

- Structural Design of Combined FootingsDokument6 SeitenStructural Design of Combined Footingsselina100% (1)

- Design of Slender Reinforced Concrete ColumnsDokument35 SeitenDesign of Slender Reinforced Concrete ColumnsWindi AstutiNoch keine Bewertungen

- Realism and Neo-Structural RealismDokument4 SeitenRealism and Neo-Structural RealismHidayat Ullah100% (1)

- Salary Guide: Kelly MalaysiaDokument36 SeitenSalary Guide: Kelly MalaysiaimafishNoch keine Bewertungen

- PT I Girder Design 20mDokument18 SeitenPT I Girder Design 20msamirbendre1Noch keine Bewertungen

- R.C. Design of Two-Way Slabs and BeamsDokument54 SeitenR.C. Design of Two-Way Slabs and Beamsgendadeyu552625Noch keine Bewertungen

- LOAD Computation With Water Tank ElevatorDokument27 SeitenLOAD Computation With Water Tank ElevatorJohn Paul Hilary EspejoNoch keine Bewertungen

- Reinforced Concrete Design Lecture-1-2Dokument32 SeitenReinforced Concrete Design Lecture-1-2Harold Jackson Mtyana100% (1)

- Analysis and Design of Two Way Slab With BeamsDokument63 SeitenAnalysis and Design of Two Way Slab With Beamsshahab janNoch keine Bewertungen

- Chapter 2 Member DesignDokument73 SeitenChapter 2 Member Designbsitler100% (2)

- Design and Drawing of Water TankDokument38 SeitenDesign and Drawing of Water TankSaugatoDutto67% (3)

- Design Optimization of Stiffened Composite Panels With Buckling and Damage Tolerance ConstraintsDokument14 SeitenDesign Optimization of Stiffened Composite Panels With Buckling and Damage Tolerance ConstraintslumpertNoch keine Bewertungen

- The Judicial System of PakistanDokument37 SeitenThe Judicial System of PakistanSarvinRudraNoch keine Bewertungen

- L-08 Introduction To Bridge Engineering (Coloured)Dokument41 SeitenL-08 Introduction To Bridge Engineering (Coloured)Hidayat UllahNoch keine Bewertungen

- Example Centre of Mass and Centre of Rigidity or StiffnessDokument2 SeitenExample Centre of Mass and Centre of Rigidity or StiffnessKimberly Fields50% (2)

- Reinforced C Vol II-1Dokument3 SeitenReinforced C Vol II-1pallavi gupta0% (2)

- L 02 Analysis and Design of One Way Slab System Sep 2015Dokument45 SeitenL 02 Analysis and Design of One Way Slab System Sep 2015Hidayat Ullah100% (1)

- Excel Template For Strap Footing Using ES en CodeDokument9 SeitenExcel Template For Strap Footing Using ES en CodeJim JamNoch keine Bewertungen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- L-04 Analysis and Design of Two-Way Slab With Beams (Coloured)Dokument63 SeitenL-04 Analysis and Design of Two-Way Slab With Beams (Coloured)Hidayat Ullah100% (3)

- Design of Timber JoistsDokument3 SeitenDesign of Timber JoistsDianne M. DepositarioNoch keine Bewertungen

- Direct Design Method For Two-Way Slab Analysis (PDFDrive)Dokument58 SeitenDirect Design Method For Two-Way Slab Analysis (PDFDrive)girma kebedeNoch keine Bewertungen

- Design An Interior Rib of A Concrete Joist Floor System With TheDokument4 SeitenDesign An Interior Rib of A Concrete Joist Floor System With TheChea VannaiNoch keine Bewertungen

- Slab Girder BridgeDokument42 SeitenSlab Girder BridgeAslam Saifi100% (2)

- 4.2.3 Design of Eccentric Welded Connections (IIIDokument10 Seiten4.2.3 Design of Eccentric Welded Connections (IIIyadoleNoch keine Bewertungen

- Project Report On Effect of LEACHATE On The Engineering Properties of The SoilDokument91 SeitenProject Report On Effect of LEACHATE On The Engineering Properties of The SoilShashank Singh100% (6)

- Final Exam of Structural Behavior and Analysis IDokument3 SeitenFinal Exam of Structural Behavior and Analysis INeven Ahmed HassanNoch keine Bewertungen

- Design and Analysis of Institutional Building (G+3) Using Staad ProDokument3 SeitenDesign and Analysis of Institutional Building (G+3) Using Staad Proinnovative technologies100% (1)

- Column Design for Axial Load & BendingDokument3 SeitenColumn Design for Axial Load & BendingMuhammad Farhan Gul100% (1)

- Module4 Plastictheory Rajeshsir 140806043958 Phpapp01 PDFDokument69 SeitenModule4 Plastictheory Rajeshsir 140806043958 Phpapp01 PDFEmily ShumNoch keine Bewertungen

- Design and Analysis of Prestressed Concrete-2245 PDFDokument9 SeitenDesign and Analysis of Prestressed Concrete-2245 PDFafzal taiNoch keine Bewertungen

- Dual StructureDokument21 SeitenDual StructureSauhardra OjhaNoch keine Bewertungen

- The Flexure and Shear Design of Corbel (Bracket)Dokument12 SeitenThe Flexure and Shear Design of Corbel (Bracket)Girum MindayeNoch keine Bewertungen

- Two Way Slab ExampleDokument16 SeitenTwo Way Slab ExampleJason EdwardsNoch keine Bewertungen

- Portal Method Sample Calculation AnalysisDokument2 SeitenPortal Method Sample Calculation Analysisgodofredo dumaliNoch keine Bewertungen

- Question Bank (MCQ) : Department of Civil EngineeringDokument22 SeitenQuestion Bank (MCQ) : Department of Civil Engineeringsaxenaarpita4167% (3)

- Problems (Axial-Force 2)Dokument8 SeitenProblems (Axial-Force 2)Haftom Gebreegziabiher100% (1)

- Design of 6m RC Slab BridgeDokument19 SeitenDesign of 6m RC Slab BridgenabinniraulaNoch keine Bewertungen

- Reinforced Concrete Beam Design ProblemsDokument5 SeitenReinforced Concrete Beam Design ProblemsCeyn Lumabad0% (1)

- Seismic Analysis of RC Buildings: Linear Static & Nonlinear Pushover MethodsDokument31 SeitenSeismic Analysis of RC Buildings: Linear Static & Nonlinear Pushover MethodsGaurav naddaNoch keine Bewertungen

- Slab Design DR - Zahid Ahmad SiddiqiDokument6 SeitenSlab Design DR - Zahid Ahmad SiddiqiNoor MohdNoch keine Bewertungen

- Analysis of Tension MembersDokument19 SeitenAnalysis of Tension MembersCivilEngClub100% (1)

- Slab Designer As Per IS 456-2000Dokument7 SeitenSlab Designer As Per IS 456-2000mofizahmed64% (11)

- Two-Way Concrete Slab Analysis and DesignDokument81 SeitenTwo-Way Concrete Slab Analysis and DesignBizimenyera Zenza TheonesteNoch keine Bewertungen

- Property ModifiersDokument2 SeitenProperty Modifierspido29100% (1)

- Deep BeamDokument16 SeitenDeep BeamrajasekharNoch keine Bewertungen

- Reinforced Concrete Slab DesignDokument44 SeitenReinforced Concrete Slab DesignHezb Khan100% (1)

- Lecture 09 Analysis and Design of Flat Plate SlabsDokument68 SeitenLecture 09 Analysis and Design of Flat Plate SlabsSufian Ahmad100% (1)

- RCD-II Final Term Past Papers PDFDokument5 SeitenRCD-II Final Term Past Papers PDFHidayat UllahNoch keine Bewertungen

- International Relations Notes by SIR RIAZ AHMEDDokument37 SeitenInternational Relations Notes by SIR RIAZ AHMEDHidayat Ullah100% (2)

- KPK Tehsil Municipal Officer (TMO) Syllabus 2017-2018Dokument1 SeiteKPK Tehsil Municipal Officer (TMO) Syllabus 2017-2018Hidayat UllahNoch keine Bewertungen

- Leaning Tower of Pisa v2.0Dokument22 SeitenLeaning Tower of Pisa v2.0Hidayat UllahNoch keine Bewertungen

- L-07 Introduction To Prestressed Concrete (Coloured)Dokument20 SeitenL-07 Introduction To Prestressed Concrete (Coloured)Hidayat UllahNoch keine Bewertungen

- L-06-EQ-Resistant-Design-of RCC StructuresDokument62 SeitenL-06-EQ-Resistant-Design-of RCC StructuresAbdul Hamid BhattiNoch keine Bewertungen

- L 03 Analysis and Design of One Way Slab System Part II Dec 2014Dokument37 SeitenL 03 Analysis and Design of One Way Slab System Part II Dec 2014Hidayat UllahNoch keine Bewertungen

- L 01 Introduction RCD 2Dokument31 SeitenL 01 Introduction RCD 2Hidayat UllahNoch keine Bewertungen

- SGS IND Construction Material Inspection in India A4 EN 10 PDFDokument2 SeitenSGS IND Construction Material Inspection in India A4 EN 10 PDFIndra MishraNoch keine Bewertungen

- Time Table Even Sem 18-19 (II, III and IV - PT) To WebsiteDokument42 SeitenTime Table Even Sem 18-19 (II, III and IV - PT) To WebsiteAnonymous n7zsf8w7aNoch keine Bewertungen

- Perspective: Proposed BungalowDokument1 SeitePerspective: Proposed BungalowZhey GarciaNoch keine Bewertungen

- IStrucE Detailing Manual BS8110Dokument1 SeiteIStrucE Detailing Manual BS8110Thoong Yew Chan0% (1)

- Catalogo Serie G Iec Septiembre 2005 PDFDokument59 SeitenCatalogo Serie G Iec Septiembre 2005 PDFRicardo Astocondor RabanalNoch keine Bewertungen

- VIT Campus, Jaipur: Leading Engineering College of Rajasthan/ Best Infrastructure & PlacementDokument85 SeitenVIT Campus, Jaipur: Leading Engineering College of Rajasthan/ Best Infrastructure & PlacementOnkar BagariaNoch keine Bewertungen

- 00 Basement Foundation LayoutDokument1 Seite00 Basement Foundation LayoutrendaninNoch keine Bewertungen

- Syed Sohail Hamid Zaidi: A: Technical Aspects and Areas of ExpertiseDokument13 SeitenSyed Sohail Hamid Zaidi: A: Technical Aspects and Areas of ExpertiseAfrasyab KhanNoch keine Bewertungen

- C3 - Process Selection, Design, and AnalysisDokument54 SeitenC3 - Process Selection, Design, and AnalysisMinh Thuận VõNoch keine Bewertungen

- Design of Concrete Structure II Sessional: Dhaka University of Engineering & TechnologyDokument22 SeitenDesign of Concrete Structure II Sessional: Dhaka University of Engineering & TechnologyumrumrumrNoch keine Bewertungen

- ProblemSheet - Unit 1Dokument1 SeiteProblemSheet - Unit 1Vishal VaziraniNoch keine Bewertungen

- CMP E2FW Flameproof ATEX Cable Glands For Lead Sheathed CablesDokument1 SeiteCMP E2FW Flameproof ATEX Cable Glands For Lead Sheathed CablesrocketvtNoch keine Bewertungen

- Analysis and Design of Doubly Reinforced BeamDokument1 SeiteAnalysis and Design of Doubly Reinforced BeamLouise DiazNoch keine Bewertungen

- Space RoboticsDokument9 SeitenSpace RoboticsRushikesh WareNoch keine Bewertungen

- Top Aerospace Companies & Organizations in IndiaDokument10 SeitenTop Aerospace Companies & Organizations in IndiakPrasad8Noch keine Bewertungen

- CIVI 6051-Winter 2022-OutlineDokument3 SeitenCIVI 6051-Winter 2022-OutlineMartialNoch keine Bewertungen

- Seismic Demand Evaluation For A The Northridge Earthquake 4-Story Steel Frame Structure Damaged inDokument27 SeitenSeismic Demand Evaluation For A The Northridge Earthquake 4-Story Steel Frame Structure Damaged insanh137Noch keine Bewertungen

- 02 Samss 005Dokument15 Seiten02 Samss 005Cherukunnon JubuNoch keine Bewertungen

- Resume GaneshDokument2 SeitenResume Ganeshcatchganesh86Noch keine Bewertungen

- PVPE Pneumatic Valve Packing EquipmentDokument12 SeitenPVPE Pneumatic Valve Packing EquipmentAustralian Weighing EquipmentNoch keine Bewertungen

- Gujarat Technological University: Aeronautical EngineeringDokument16 SeitenGujarat Technological University: Aeronautical EngineeringNiik StarNoch keine Bewertungen

- Updtaed CV - Y.vikas Singla-2018Dokument6 SeitenUpdtaed CV - Y.vikas Singla-2018yv singlaNoch keine Bewertungen

- 15SE202 SoftwareEP SyllabusDokument2 Seiten15SE202 SoftwareEP SyllabusAnonymous k1cZPS5xX0% (1)