Beruflich Dokumente

Kultur Dokumente

Weld End Preparation at Unequal Wall Thicknesses

Hochgeladen von

Desmond ChangCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Weld End Preparation at Unequal Wall Thicknesses

Hochgeladen von

Desmond ChangCopyright:

Verfügbare Formate

Weld End Preparation at Unequal Wall

Thicknesses

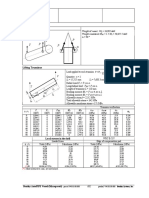

Acceptable Design in Piping components

In most piping systems there are components such as valves, castings, heavier header

sections, and equipment nozzles which are welded to the pipe.

In such instances the heavier sections are machined to match the lighter pipe wall and

the excess thickness tapered both internally and externally to form a transition zone.

Limits imposed by the various codes for this transition zone are fairly uniform.

The external surface of the heavier component is tapered at an angle of 30 maximum

for a minimum length equal to 1.1/2 times the pipe minimum wall thickness and then at

45 for a minimum of 1.1/2 times the pipe minimum wall.

Internally, either a straight bore followed by a 30 slope or a taper bore at a maximum

slope of 1 to 4 for a minimum distance of 2 times the pipe minimum wall are required.

The surface of the weld can also be tapered to accommodate differing thickness. This

taper should not exceed 30. It may be necessary to deposit weld metal to assure that

these limits are not violated.

Below some tables with acceptable design for unequal wall thicknesses acc to ASME

B31.8

Internal Offset

External Offset

Combination Offset

NOTE:

(1) No minimum when materials joined have equal specified minimum yield strengths.

Das könnte Ihnen auch gefallen

- Conversion ASME Unit ConversionDokument3 SeitenConversion ASME Unit ConversionMohdBadruddinKarimNoch keine Bewertungen

- Jacketed PipingDokument4 SeitenJacketed Pipingbinukumar100100% (1)

- Simultaneous Operations (SIMOPS)Dokument19 SeitenSimultaneous Operations (SIMOPS)Desmond Chang75% (8)

- SP-2069 Specification For Pressure VesselsDokument68 SeitenSP-2069 Specification For Pressure Vesselsarjunprasannan7Noch keine Bewertungen

- Solution: WE1 12 Nov 2008Dokument9 SeitenSolution: WE1 12 Nov 2008aauppalNoch keine Bewertungen

- Negative Feedback AmplifierDokument31 SeitenNegative Feedback AmplifierPepNoch keine Bewertungen

- A Comparison Study of Pressure Vessel Design Using Different Standards PDFDokument319 SeitenA Comparison Study of Pressure Vessel Design Using Different Standards PDFJM100% (1)

- Procedure For Visual InspectionDokument4 SeitenProcedure For Visual InspectionAkhilesh Kumar100% (4)

- Pressure Vessel Calculations ASME SectioDokument11 SeitenPressure Vessel Calculations ASME Sectioivan chirinosNoch keine Bewertungen

- Micro - Systemic Bacteriology Questions PDFDokument79 SeitenMicro - Systemic Bacteriology Questions PDFShashipriya AgressNoch keine Bewertungen

- Expansion Loops Antetsiz v2Dokument13 SeitenExpansion Loops Antetsiz v2Aan DamaiNoch keine Bewertungen

- ANSYS Modal AnalysisDokument40 SeitenANSYS Modal AnalysisDesmond Chang100% (1)

- ASME e EN STDDokument23 SeitenASME e EN STDmatteo2009Noch keine Bewertungen

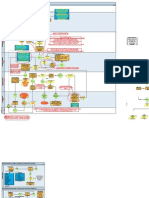

- Permit To Work Flow ChartDokument2 SeitenPermit To Work Flow ChartDesmond ChangNoch keine Bewertungen

- Piping Engineering - Tank Nozzle Loads 1Dokument1 SeitePiping Engineering - Tank Nozzle Loads 1Nasrul Adli100% (1)

- Collar Bolts: in Shell and Tube Heat ExchangersDokument2 SeitenCollar Bolts: in Shell and Tube Heat ExchangersMahdi HocineNoch keine Bewertungen

- Trunnion Stress ValidationDokument3 SeitenTrunnion Stress ValidationGaye Kanal100% (1)

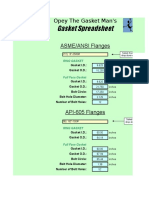

- Gasket Dimension (ASME B16.5 & B16.47)Dokument4 SeitenGasket Dimension (ASME B16.5 & B16.47)ama100% (1)

- Top Pipe MomentDokument2 SeitenTop Pipe Momentrsubramani100% (1)

- Lopa Workbook Sept 2005Dokument12 SeitenLopa Workbook Sept 2005Desmond Chang100% (1)

- Welding HabitatDokument12 SeitenWelding HabitatDesmond Chang100% (3)

- MOS - Steel StructureDokument15 SeitenMOS - Steel StructuredennisNoch keine Bewertungen

- Piping - Materials - Elbows and Bends - Reducers - PE & ROTO Lined Carbon Steel PipingDokument52 SeitenPiping - Materials - Elbows and Bends - Reducers - PE & ROTO Lined Carbon Steel PipingDesmond Chang100% (1)

- PV Elite Webinar 001Dokument23 SeitenPV Elite Webinar 001MEC_GuiNoch keine Bewertungen

- Auto PipeDokument18 SeitenAuto PipeAdi Sutardi100% (1)

- Asme Boiler and Pressure Vessel Codes: SectionsDokument68 SeitenAsme Boiler and Pressure Vessel Codes: Sectionsajay thomasNoch keine Bewertungen

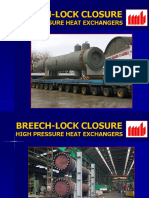

- BREECH LOCK Presentation Dec2004 Tcm24 226146Dokument24 SeitenBREECH LOCK Presentation Dec2004 Tcm24 226146Harinarayanan Samsari Kizhake VeetilNoch keine Bewertungen

- Tutorial Pressure VesselDokument19 SeitenTutorial Pressure Vesseltahseenahsan100% (1)

- Standards IndexDokument32 SeitenStandards IndexDesmond Chang100% (1)

- Hydrogen Compressor Flange Bolts FailureDokument8 SeitenHydrogen Compressor Flange Bolts FailurePablo ScottNoch keine Bewertungen

- Welding of Pressure VesselsDokument2 SeitenWelding of Pressure VesselsDvida PleasureNoch keine Bewertungen

- Heat ExchangerDokument36 SeitenHeat ExchangerUsman MansuriNoch keine Bewertungen

- List of Modern Equipment and Farm ToolsDokument15 SeitenList of Modern Equipment and Farm ToolsCarl Johnrich Quitain100% (2)

- Demo Vessel Calc SecviiiDokument51 SeitenDemo Vessel Calc SecviiihrabiecNoch keine Bewertungen

- Induction BendsDokument16 SeitenInduction BendsDesmond Chang100% (1)

- Auditory Evoked Potentials - AEPs - Underlying PrinciplesDokument19 SeitenAuditory Evoked Potentials - AEPs - Underlying PrinciplesMansi SinghNoch keine Bewertungen

- Manta To Richmond SIMOPS Risk Matrix FINALDokument1 SeiteManta To Richmond SIMOPS Risk Matrix FINALDesmond Chang50% (2)

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDokument4 SeitenLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhaleNoch keine Bewertungen

- Hassad Project Expansion Joint Data Sheet EX-P 201: Revision: A0 DATE: 28/07/2006Dokument1 SeiteHassad Project Expansion Joint Data Sheet EX-P 201: Revision: A0 DATE: 28/07/2006akilasrivatsavNoch keine Bewertungen

- API 650 Tank Nozzle Stand OutDokument5 SeitenAPI 650 Tank Nozzle Stand Outgplese0Noch keine Bewertungen

- ASME B16.5 2013 FlangeRating 1.0Dokument4 SeitenASME B16.5 2013 FlangeRating 1.0sanjaysyNoch keine Bewertungen

- Girth Flange Load Calculation Using by FEA TechniquesDokument12 SeitenGirth Flange Load Calculation Using by FEA TechniqueskingstonNoch keine Bewertungen

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Dokument10 SeitenES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsNoch keine Bewertungen

- TorquingDokument7 SeitenTorquingVicky KumarNoch keine Bewertungen

- ES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Dokument23 SeitenES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Nikki RobertsNoch keine Bewertungen

- Alvaer DNV2.7-3 PDFDokument23 SeitenAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- Foundation Load Table.Dokument1 SeiteFoundation Load Table.Lcm TnlNoch keine Bewertungen

- 16 Preiss Study en 13445 Asme ViiiDokument26 Seiten16 Preiss Study en 13445 Asme ViiiDubaiHMARNoch keine Bewertungen

- DC S3-1301 REV.0 OriginalDokument93 SeitenDC S3-1301 REV.0 OriginalPeja JusohNoch keine Bewertungen

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDokument1 SeiteRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNoch keine Bewertungen

- Flange Leakage Test As Per Asme Boiler & Pressure Vessel CodeDokument12 SeitenFlange Leakage Test As Per Asme Boiler & Pressure Vessel CoderssambhiNoch keine Bewertungen

- Welding SymbolsDokument12 SeitenWelding SymbolsrsrtnjNoch keine Bewertungen

- Pressure Vessel RT TestDokument3 SeitenPressure Vessel RT TestAriq FauzanNoch keine Bewertungen

- Fem For Inclined Pressure VesselDokument5 SeitenFem For Inclined Pressure VesselPrayas SubediNoch keine Bewertungen

- News Letter For Expansion Bellow PDFDokument4 SeitenNews Letter For Expansion Bellow PDFAsma Khan100% (1)

- Stress Analysis and Design Optimization of A Pressure Vessel Using Ansys PackageDokument12 SeitenStress Analysis and Design Optimization of A Pressure Vessel Using Ansys Packageanthony zegarra ochoaNoch keine Bewertungen

- PV Newsletter - Skirt Connections PDFDokument5 SeitenPV Newsletter - Skirt Connections PDFDivyesh PatelNoch keine Bewertungen

- Earthquake Loading Specified in GDokument3 SeitenEarthquake Loading Specified in GMas Arman TewoNoch keine Bewertungen

- WRC Check List CriteriaDokument1 SeiteWRC Check List CriteriaAlvin Smith100% (1)

- AL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCDokument5 SeitenAL-2208-6'' Pig Launcher Engineering and Fabrication - KNOCCaptainToniesNoch keine Bewertungen

- B.16.5 Interpretation PDFDokument68 SeitenB.16.5 Interpretation PDFmohdluthfiNoch keine Bewertungen

- Paulin Research Group - FE107 Experimental ValidationDokument5 SeitenPaulin Research Group - FE107 Experimental ValidationNikunj KNoch keine Bewertungen

- Asme Pipe Wall ThicknessDokument3 SeitenAsme Pipe Wall ThicknessYoke ShuNoch keine Bewertungen

- Split Tee Technical Data Sheet: NamdaranDokument1 SeiteSplit Tee Technical Data Sheet: NamdaranestudiemosNoch keine Bewertungen

- Joint Efficiency - Pressure Vessel EngineeringDokument5 SeitenJoint Efficiency - Pressure Vessel EngineeringMuthuKumar100% (1)

- Balaji S - Static Equipment Design - 7 Years - Resume - NEWDokument5 SeitenBalaji S - Static Equipment Design - 7 Years - Resume - NEWkanchanabalajiNoch keine Bewertungen

- PPSC - Product Data Sheet 3lppDokument1 SeitePPSC - Product Data Sheet 3lppjulianpirahNoch keine Bewertungen

- Nozzle Interference Error SolvingDokument2 SeitenNozzle Interference Error SolvingSakthi VelNoch keine Bewertungen

- Jun 97Dokument349 SeitenJun 97homer hullezaNoch keine Bewertungen

- Weld End Preparation at Unequal Wall Thicknesses Acceptable Design in Piping ComponentsDokument3 SeitenWeld End Preparation at Unequal Wall Thicknesses Acceptable Design in Piping ComponentsRichart SembiringNoch keine Bewertungen

- Weld End Preparation at Unequal Wall Thicknesses Acceptable Design in Piping ComponentsDokument3 SeitenWeld End Preparation at Unequal Wall Thicknesses Acceptable Design in Piping ComponentsRichart SembiringNoch keine Bewertungen

- Root Gap and Root Face For Diff Wall ThicknessDokument18 SeitenRoot Gap and Root Face For Diff Wall ThicknesspipinguserNoch keine Bewertungen

- Acoustic Properties of Miter Bends: John W. ColtmanDokument4 SeitenAcoustic Properties of Miter Bends: John W. ColtmansandbadbahriNoch keine Bewertungen

- HW D 0187Dokument2 SeitenHW D 0187Luiggi Zuñiga BarahonaNoch keine Bewertungen

- Markl SIFs & Asme ViiiDokument3 SeitenMarkl SIFs & Asme ViiiDesmond ChangNoch keine Bewertungen

- Stressman Engineering - Study - Stresses in Pipe Bends With Different Angles R2Dokument4 SeitenStressman Engineering - Study - Stresses in Pipe Bends With Different Angles R2Desmond ChangNoch keine Bewertungen

- PFD Calculation Program: #Value! #Value! #Value!Dokument4 SeitenPFD Calculation Program: #Value! #Value! #Value!Desmond ChangNoch keine Bewertungen

- Stressman Engineering - Study - Stresses in Branch Connections at Different AnglesDokument7 SeitenStressman Engineering - Study - Stresses in Branch Connections at Different AnglesDesmond ChangNoch keine Bewertungen

- SIL vs. Log (Distance) : TEMPLATE For SIL Field Lab DataDokument2 SeitenSIL vs. Log (Distance) : TEMPLATE For SIL Field Lab DataDesmond ChangNoch keine Bewertungen

- Ansys - DynamicsDokument13 SeitenAnsys - DynamicsNono_geotecNoch keine Bewertungen

- The Basics of Arc WeldingDokument35 SeitenThe Basics of Arc WeldingDesmond ChangNoch keine Bewertungen

- PDMS Update AvevaDokument21 SeitenPDMS Update AvevaDesmond ChangNoch keine Bewertungen

- Module 2Dokument7 SeitenModule 2karthik karti100% (1)

- Bustax Midtem Quiz 1 Answer Key Problem SolvingDokument2 SeitenBustax Midtem Quiz 1 Answer Key Problem Solvingralph anthony macahiligNoch keine Bewertungen

- Compact 1.8" Height Standardized Installation 9 Months To Flight Powerful and LightweightDokument2 SeitenCompact 1.8" Height Standardized Installation 9 Months To Flight Powerful and LightweightStanley Ochieng' OumaNoch keine Bewertungen

- ATS2017 ProspectusDokument13 SeitenATS2017 ProspectusGiri WakshanNoch keine Bewertungen

- FHHR 013 Red Tag Procedure PDFDokument5 SeitenFHHR 013 Red Tag Procedure PDFN3N5YNoch keine Bewertungen

- Assembly InstructionsDokument4 SeitenAssembly InstructionsAghzuiNoch keine Bewertungen

- Helipal Tbs Powercube ManualDokument29 SeitenHelipal Tbs Powercube Manualoualid zouggarNoch keine Bewertungen

- Learning TheoryDokument7 SeitenLearning Theoryapi-568999633Noch keine Bewertungen

- Remedy MidTier Guide 7-5Dokument170 SeitenRemedy MidTier Guide 7-5martin_wiedmeyerNoch keine Bewertungen

- MPT EnglishDokument5 SeitenMPT Englishkhadijaamir435Noch keine Bewertungen

- Grasa LO 915Dokument2 SeitenGrasa LO 915Angelo Carrillo VelozoNoch keine Bewertungen

- Property House Invests $1b in UAE Realty - TBW May 25 - Corporate FocusDokument1 SeiteProperty House Invests $1b in UAE Realty - TBW May 25 - Corporate FocusjiminabottleNoch keine Bewertungen

- SAED90DR Rev1 2 21.01.2011Dokument24 SeitenSAED90DR Rev1 2 21.01.2011Cherry AbhiNoch keine Bewertungen

- What Is Product Management?Dokument37 SeitenWhat Is Product Management?Jeffrey De VeraNoch keine Bewertungen

- Ward 7Dokument14 SeitenWard 7Financial NeedsNoch keine Bewertungen

- The Serious Student of HistoryDokument5 SeitenThe Serious Student of HistoryCrisanto King CortezNoch keine Bewertungen

- Essay Final ProjectDokument7 SeitenEssay Final Projectapi-740591437Noch keine Bewertungen

- Afzal ResumeDokument4 SeitenAfzal ResumeASHIQ HUSSAINNoch keine Bewertungen

- A Brief Tutorial On Interval Type-2 Fuzzy Sets and SystemsDokument10 SeitenA Brief Tutorial On Interval Type-2 Fuzzy Sets and SystemstarekeeeNoch keine Bewertungen

- Jurnal Vol. IV No.1 JANUARI 2013 - SupanjiDokument11 SeitenJurnal Vol. IV No.1 JANUARI 2013 - SupanjiIchsan SetiadiNoch keine Bewertungen

- RESEARCH 10 Module 1 Lesson 1 (WEEK 1-2)Dokument5 SeitenRESEARCH 10 Module 1 Lesson 1 (WEEK 1-2)DennisNoch keine Bewertungen

- Jones Et - Al.1994Dokument6 SeitenJones Et - Al.1994Sukanya MajumderNoch keine Bewertungen

- SRS Document Battle Royale Origins - V2Dokument36 SeitenSRS Document Battle Royale Origins - V2Talha SajjadNoch keine Bewertungen

- Thermodynamic c106Dokument120 SeitenThermodynamic c106Драгослав БјелицаNoch keine Bewertungen

- Dept & Sem: Subject Name: Course Code: Unit: Prepared byDokument75 SeitenDept & Sem: Subject Name: Course Code: Unit: Prepared by474 likithkumarreddy1Noch keine Bewertungen