Beruflich Dokumente

Kultur Dokumente

276 DK Novapress BASIC e

Hochgeladen von

Billy ZununCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

276 DK Novapress BASIC e

Hochgeladen von

Billy ZununCopyright:

Verfügbare Formate

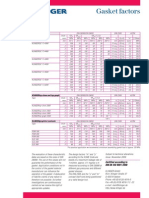

novapress BASIC

Gasket characteristics according to:

DIN 28090 part 1

(DIN E 2505 - part 2

AD - memo B 7

DIN V 2505 (1/86)

ASME-CODE

SOFT GASKET-MATERIAL

gasket material

fitting conditions

vu

thickness

novapress BASIC

internal pressure: 10 bar

internal pressure: 16 bar

internal pressure: 25 bar

internal pressure: 40 bar

(hd)

vo

50 x 90

working conditions

notes

initial load

working order

bo

in relation to:

ko x kd

k1 *

N / mm

10 x bd

mm

1,3 x bd

2,5

psi

1450

N/mm

10

vu

55 x 75

mm

1,0

N/mm

<10

N/mm

360

1,3

20C 100C 200C 300C

N/mm

360

70

45

30

1,5

11

240

1,3

240

55

35

20

2,0

12

1,3

3,0

1,0

12

11

180

120

180

120

40

30

25

15

10

5

360

70

45

30

1,5

2,0

3,0

1,0

17

15

1,5

2,0

3,0

1,0

22

22

1,5

2,0

3,0

360

1,3

1,3

15

240

1,3

240

55

35

20

17

180

120

1,3

180

120

40

30

25

15

10

5

360

70

45

30

360

1,3

1,3

20

240

1,3

240

55

35

20

22

180

120

1,3

180

120

40

30

25

15

10

5

360

70

45

30

50 x 90

bd : hd = 20 : 1

bd : hd = 13,3 : 1

11 x bd

1,3 x bd

2,5

1595

11

bd : hd = 10 : 1

12 x bd

1,3 x bd

2,5

1740

12

bd : hd = 6,7 : 1

bd : hd = 20 : 1

bd : hd = 13,3 : 1

12 x bd

11 x bd

1,3 x bd

1,3 x bd

2,5

2,5

1740

1595

12

11

15 x bd

1,3 x bd

2,5

2175

15

bd : hd = 10 : 1

17 x bd

1,3 x bd

2,5

2465

17

bd : hd = 6,7 : 1

bd : hd = 20 : 1

bd : hd = 13,3 : 1

17 x bd

15 x bd

1,3 x bd

1,3 x bd

2,5

2,5

2465

2175

17

15

20 x bd

1,3 x bd

2,5

2900

20

bd : hd = 10 : 1

22 x bd

1,3 x bd

2,5

3190

22

22 x bd

22 x bd

1,3 x bd

1,3 x bd

2,5

2,5

3190

3190

22

22

360

1,3

1,3

25

240

1,3

240

55

35

20

bd : hd = 6,7 : 1

bd : hd = 20 : 1

bd : hd = 13,3 : 1

25 x bd

1,3 x bd

2,5

3625

25

27

180

1,3

180

40

25

10

bd : hd = 10 : 1

27 x bd

1,3 x bd

2,5

3915

27

27

120

1,3

120

30

15

bd : hd = 6,7 : 1

27 x bd

1,3 x bd

2,5

3915

27

General notes regarding the m factor:

For calculating acc. To DIN V 2505 (01/86) the following can be chosen:

k1 = 1.3 x bd or m = 1.3

The values m = 1.3 to 2,5 (DIN 28090-1) take into account the different demands on

tightness classes, but not any flange irregularities.

The m- factor is a value to describe the minimum surface pressure under operating conditions sVU/L.

Up to now there is no definite test specification for it. The procedure acc. to DIN 28090-1 is controversial.

The m factor can be looked at in different ways and depends on the following:

*tightness class

*temperature

*surface pressure in the installed state

Within the Brite EuRam research project m factors of approx. 1,3 - 2,5 were found as averages for

ko x kd =

svu x bd

k1 = m x bd

fiber reinforced rubber bounded gaskets.

It is for the user to calculate with a different factor. (e.g.

m = 2)

for liquids:

bd: compressed width of gasket

calculation with 50% of

hd: thickness

svu:

the value

permeability to gas (0,1mg N2 /s*m) ( 1 ml/min) is measured on samples

with a dimension of 90 x 50 x 2 mm according to DIN 28090 part 1

Please note:

Recommended peak-to-valley height of sealing surfaces:( Rz ): 50 - 100 m.

Basis for determination for data is DIN 28090 part 1

NKO

Page 1 of 1

FRENZELIT-WERKE GmbH Co. KG Postfach/P.O.Box 11 40 95456 Bad Berneck/Germany

Phone: +49 9273 72-0 Fax: +49 9273 72-222 E-Mail: info@frenzelit.de Internet: www.frenzelit.com

March 03/V-4.0

Das könnte Ihnen auch gefallen

- Af-200 Universal AngDokument4 SeitenAf-200 Universal AngGeorgi KalchevNoch keine Bewertungen

- FTV 100Dokument7 SeitenFTV 100Sanja TadicNoch keine Bewertungen

- Klinger - Gasket FactorsDokument4 SeitenKlinger - Gasket FactorsFelip PrietoNoch keine Bewertungen

- As Stop Valve DraftDokument13 SeitenAs Stop Valve Draftpreetham brNoch keine Bewertungen

- NYYDokument4 SeitenNYYegiNoch keine Bewertungen

- Calculation PP Piping SystemDokument24 SeitenCalculation PP Piping SystemDavid FonsecaNoch keine Bewertungen

- Lecture 6 - Design of RC SlabsDokument21 SeitenLecture 6 - Design of RC SlabsTuan Jalai100% (1)

- Element Thickness 3Dokument24 SeitenElement Thickness 3Vipul GandhiNoch keine Bewertungen

- Element Thickness 2Dokument20 SeitenElement Thickness 2Vipul GandhiNoch keine Bewertungen

- MDM PROPORTIONAL PRESSURE-REDUCING VALVE TECHNICAL SPECSDokument4 SeitenMDM PROPORTIONAL PRESSURE-REDUCING VALVE TECHNICAL SPECSSilvio Roman100% (1)

- Diaphragm Seals for Food and Pharma IndustriesDokument4 SeitenDiaphragm Seals for Food and Pharma IndustriesJhon Erick Izquierdo SoteloNoch keine Bewertungen

- Summary of ASME BPVC Section VIII Div 1 (Part 3) - Welding & NDTDokument13 SeitenSummary of ASME BPVC Section VIII Div 1 (Part 3) - Welding & NDTTin Aung KyiNoch keine Bewertungen

- Bakelite PF 31Dokument3 SeitenBakelite PF 31dioguitomsolhaNoch keine Bewertungen

- Shaft analysis calculation of load capacity according to DIN 743Dokument8 SeitenShaft analysis calculation of load capacity according to DIN 743droessaert_stijnNoch keine Bewertungen

- KISSsoft, Shaft Analysis - Introduction To DIN 743, October 2000Dokument8 SeitenKISSsoft, Shaft Analysis - Introduction To DIN 743, October 2000Tomas PinheiroNoch keine Bewertungen

- Emcekrete 0 A: Routing ConcreteDokument2 SeitenEmcekrete 0 A: Routing Concretesunil kumarNoch keine Bewertungen

- Low Pressure Transmitter in Short and Compact Design: DescriptionDokument4 SeitenLow Pressure Transmitter in Short and Compact Design: DescriptionJordi AltayóNoch keine Bewertungen

- Abs (Basf Terluran Gp22)Dokument1 SeiteAbs (Basf Terluran Gp22)hakangokceNoch keine Bewertungen

- 16123010r0-NG4B - 4 ORECCH EIL v2008Dokument1 Seite16123010r0-NG4B - 4 ORECCH EIL v2008engharshNoch keine Bewertungen

- GRP Pipe Analysis - Write Up - 1Dokument8 SeitenGRP Pipe Analysis - Write Up - 1Marie SaundersNoch keine Bewertungen

- MMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagDokument13 SeitenMMU 0102, MMA 0204, MMB 0207 - Professional: Vishay BeyschlagJan KowalskiNoch keine Bewertungen

- Data Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 CompressorDokument4 SeitenData Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 Compressortutuli1990Noch keine Bewertungen

- 2 and 3 Genesis Series PD Meter SpecificationsDokument6 Seiten2 and 3 Genesis Series PD Meter Specificationsjimbo2032Noch keine Bewertungen

- HVZ adhesive anchor installation and design guideDokument13 SeitenHVZ adhesive anchor installation and design guideMihnea-Bogdan NicolaescuNoch keine Bewertungen

- SiemensMetallizedPlasticCapacitorsDataBook1978 79 TextDokument205 SeitenSiemensMetallizedPlasticCapacitorsDataBook1978 79 TextKlima UredjajNoch keine Bewertungen

- D/CRCW E3: VishayDokument8 SeitenD/CRCW E3: VishayFilipe BrendlerNoch keine Bewertungen

- D/CRCW E3: VishayDokument8 SeitenD/CRCW E3: VishayelecompinnNoch keine Bewertungen

- Tratos Flex000Dokument64 SeitenTratos Flex000twinvbooksNoch keine Bewertungen

- RivaTherm-Super gasket factorsDokument1 SeiteRivaTherm-Super gasket factorsgalici2002Noch keine Bewertungen

- Catalogo Brossard ParafusosDokument0 SeitenCatalogo Brossard ParafusosMarco ViniciusNoch keine Bewertungen

- Nor GrenDokument5 SeitenNor GrenSarlo11Noch keine Bewertungen

- DIN 7060 Curcular Sight Glass PDFDokument14 SeitenDIN 7060 Curcular Sight Glass PDFalathekoala100% (2)

- Stress Relaxation of Prestressing Steel - DIN EN 1992-1-1: Benchmark Example No. 23Dokument9 SeitenStress Relaxation of Prestressing Steel - DIN EN 1992-1-1: Benchmark Example No. 23Batuhan DerNoch keine Bewertungen

- Zn-Ni coating passivation steel corrosion protectionDokument5 SeitenZn-Ni coating passivation steel corrosion protectionPaulo Henrique NascimentoNoch keine Bewertungen

- Roof sheeting load calculation exampleDokument10 SeitenRoof sheeting load calculation examplesoareculNoch keine Bewertungen

- End Plate-Beam To Column Moment ConnectionDokument81 SeitenEnd Plate-Beam To Column Moment ConnectionHemant Ramesh Narkar50% (6)

- Ferrites and AccessoriesDokument11 SeitenFerrites and AccessoriesAdel DechirNoch keine Bewertungen

- 44 - HVZ Adhesive AnchorDokument14 Seiten44 - HVZ Adhesive AnchorHuan VoNoch keine Bewertungen

- Pressure Vessel Design ManualDokument6 SeitenPressure Vessel Design ManualJasmine Eliza EspejoNoch keine Bewertungen

- Garlock M&Y Values ExplanationDokument3 SeitenGarlock M&Y Values Explanationneha165Noch keine Bewertungen

- Torisperical - Element ThicknessDokument6 SeitenTorisperical - Element ThicknessVipul GandhiNoch keine Bewertungen

- Model Number Structure: Enclosed SwitchDokument10 SeitenModel Number Structure: Enclosed SwitchJavierNoch keine Bewertungen

- What does "COLD STRETCHING 冷拉伸"mean?Dokument10 SeitenWhat does "COLD STRETCHING 冷拉伸"mean?dhaktodesatyajitNoch keine Bewertungen

- Motor Running & Starting Capacitors GuideDokument28 SeitenMotor Running & Starting Capacitors Guidesokol_poleceNoch keine Bewertungen

- PIPE SIZING CALCULATION SHEETDokument9 SeitenPIPE SIZING CALCULATION SHEETmaxmorekNoch keine Bewertungen

- DesignDokument23 SeitenDesignscribddisantoNoch keine Bewertungen

- PP Raw Material SpecDokument1 SeitePP Raw Material SpecAnonymous eq5zSUNoch keine Bewertungen

- Specification Details of TC - 76 GasketDokument3 SeitenSpecification Details of TC - 76 GasketR P SINGHNoch keine Bewertungen

- Don3.0 Software - Proper Assembly of Flange JointDokument3 SeitenDon3.0 Software - Proper Assembly of Flange JointJoshua HobsonNoch keine Bewertungen

- Sigraflex UniversalDokument6 SeitenSigraflex UniversalJan SmitNoch keine Bewertungen

- Datasheet Sisto-Kbs Valve - KSBDokument4 SeitenDatasheet Sisto-Kbs Valve - KSBSarah PerezNoch keine Bewertungen

- TKB 00804-203 13 202308Dokument30 SeitenTKB 00804-203 13 202308Ronaldo Bandeira RodriguesNoch keine Bewertungen

- Full Bore Ball Valve - T12 Series - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsDokument2 SeitenFull Bore Ball Valve - T12 Series - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsjonnyhelluzNoch keine Bewertungen

- Din 8074 Pehd PipesDokument20 SeitenDin 8074 Pehd PipesAli MkawarNoch keine Bewertungen

- Company Name: Calculation SheetDokument4 SeitenCompany Name: Calculation SheetAlexandra DumitrescuNoch keine Bewertungen

- DTS-214 Design Doc 400kV SC GantryDokument49 SeitenDTS-214 Design Doc 400kV SC GantryanoginNoch keine Bewertungen

- Quay Walls - Combined - Wall - Buckling - TubesDokument12 SeitenQuay Walls - Combined - Wall - Buckling - TubesHugo LeiteNoch keine Bewertungen

- Honda GX200 Engine ManualDokument60 SeitenHonda GX200 Engine ManualrandtanNoch keine Bewertungen

- Repair couplings installation guideDokument2 SeitenRepair couplings installation guideBilly ZununNoch keine Bewertungen

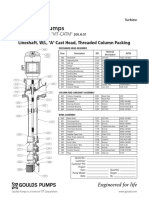

- ITT Gould PumpsDokument2 SeitenITT Gould PumpsBilly ZununNoch keine Bewertungen

- Ay20 0Dokument2 SeitenAy20 0Billy ZununNoch keine Bewertungen

- WF BeamsDokument6 SeitenWF BeamsMd. Rafique HassanNoch keine Bewertungen

- Tube and Pipe Autodesk Aplications 2Dokument7 SeitenTube and Pipe Autodesk Aplications 2Billy ZununNoch keine Bewertungen

- EN 1092-1-Flange PDFDokument18 SeitenEN 1092-1-Flange PDFSimona Adriana100% (1)

- Kuriyama Layflat HoseDokument16 SeitenKuriyama Layflat HoseBilly ZununNoch keine Bewertungen

- RISONIC Ultrasonic Transit Time Module E22 210 0067751 001Dokument6 SeitenRISONIC Ultrasonic Transit Time Module E22 210 0067751 001Billy ZununNoch keine Bewertungen

- EN 1092-1-Flange PDFDokument18 SeitenEN 1092-1-Flange PDFSimona Adriana100% (1)

- Ay4 0Dokument2 SeitenAy4 0Billy ZununNoch keine Bewertungen

- Acummulator StationDokument10 SeitenAcummulator StationBilly ZununNoch keine Bewertungen

- Autodesk Tube An Pipe Aplications 1Dokument7 SeitenAutodesk Tube An Pipe Aplications 1Billy ZununNoch keine Bewertungen

- WS1 0Dokument2 SeitenWS1 0Billy ZununNoch keine Bewertungen

- Vertical PumpsDokument1 SeiteVertical PumpsBilly ZununNoch keine Bewertungen

- WF BeamsDokument6 SeitenWF BeamsMd. Rafique HassanNoch keine Bewertungen

- Complete Joint Penetration and Partial PDFDokument3 SeitenComplete Joint Penetration and Partial PDFBudimanNoch keine Bewertungen

- WF BeamsDokument6 SeitenWF BeamsMd. Rafique HassanNoch keine Bewertungen

- Torch Head Accessories: EriesDokument1 SeiteTorch Head Accessories: EriesBilly ZununNoch keine Bewertungen

- HW-18 & HW-18R: Instructions ForDokument1 SeiteHW-18 & HW-18R: Instructions ForBilly ZununNoch keine Bewertungen

- Tutorial ETS3Dokument37 SeitenTutorial ETS3Alex KnezNoch keine Bewertungen

- Pistolas LincolnDokument1 SeitePistolas LincolnBilly ZununNoch keine Bewertungen

- XBTN - R - RT Compact Display UnitsDokument182 SeitenXBTN - R - RT Compact Display UnitsPetrovic MladenNoch keine Bewertungen

- 1066Dokument6 Seiten1066Billy ZununNoch keine Bewertungen

- Empresas Suárez, S.A. de C.V.: 8HXH-1C 1760 RPM 60 HZDokument1 SeiteEmpresas Suárez, S.A. de C.V.: 8HXH-1C 1760 RPM 60 HZBilly ZununNoch keine Bewertungen

- 276 DK Novapress BASIC eDokument1 Seite276 DK Novapress BASIC eBilly ZununNoch keine Bewertungen

- Pistolas LincolnDokument1 SeitePistolas LincolnBilly ZununNoch keine Bewertungen

- MC 13173Dokument4 SeitenMC 13173Billy ZununNoch keine Bewertungen

- Blob Serv LetDokument13 SeitenBlob Serv LetBilly ZununNoch keine Bewertungen

- Assembly123 1Dokument1 SeiteAssembly123 1Billy ZununNoch keine Bewertungen

- Learning and Reference Guide: 5265602-1EN Rev.3 (2008/08/28)Dokument340 SeitenLearning and Reference Guide: 5265602-1EN Rev.3 (2008/08/28)joseNoch keine Bewertungen

- GRADE 5 CURRICULUM PlAN FOR SOCIAL STUDIESDokument3 SeitenGRADE 5 CURRICULUM PlAN FOR SOCIAL STUDIESHesham Al-shafayNoch keine Bewertungen

- Statement of PurposeDokument3 SeitenStatement of PurposeenecheumiNoch keine Bewertungen

- Matlab HW PDFDokument3 SeitenMatlab HW PDFMohammed AbdulnaserNoch keine Bewertungen

- Marimekko's Approach to Sustainability and Global OperationsDokument3 SeitenMarimekko's Approach to Sustainability and Global OperationsHannah Van GeeresteinNoch keine Bewertungen

- Heidi With Blue Hair - Poem AnalysisDokument2 SeitenHeidi With Blue Hair - Poem AnalysisshehanitsNoch keine Bewertungen

- Module 5Dokument41 SeitenModule 5Ysabel TolentinoNoch keine Bewertungen

- Head Boy and Girl Final Application FormDokument5 SeitenHead Boy and Girl Final Application FormboobooNoch keine Bewertungen

- Geography Past PaperDokument56 SeitenGeography Past PaperNaim Mokhtar81% (27)

- Deffi Ayu Puspito Sari, PH.DDokument8 SeitenDeffi Ayu Puspito Sari, PH.DYogiNoch keine Bewertungen

- Sci-Box: Grade 7Dokument6 SeitenSci-Box: Grade 7Trinity MarieNoch keine Bewertungen

- 1.1 Introduction To Human Anatomy - 2018-2019 PDFDokument11 Seiten1.1 Introduction To Human Anatomy - 2018-2019 PDFسيف محمود شاكر حسنNoch keine Bewertungen

- IP UK Pine Needle Power Generation PDFDokument23 SeitenIP UK Pine Needle Power Generation PDFSunny DuggalNoch keine Bewertungen

- CHEN 4460 - Process Synthesis, Simulation and OptimizationDokument40 SeitenCHEN 4460 - Process Synthesis, Simulation and Optimizationmppatilmayur1679Noch keine Bewertungen

- Lecture Notes On CNCDokument125 SeitenLecture Notes On CNCniteen_mulmule48580% (5)

- Cork Physics Work Speed DistanceDokument2 SeitenCork Physics Work Speed DistanceieswaheedNoch keine Bewertungen

- METTL PERSONALITY TEST REVEALS INDIVIDUAL STRENGTHSDokument6 SeitenMETTL PERSONALITY TEST REVEALS INDIVIDUAL STRENGTHSVijeesh MNoch keine Bewertungen

- Topic: References: Materials: Value Focus: Lesson Plan in Health 6Dokument7 SeitenTopic: References: Materials: Value Focus: Lesson Plan in Health 6Kathleen Rose ReyesNoch keine Bewertungen

- Geo Lab ReportDokument12 SeitenGeo Lab ReportArivalagan Revichandran100% (1)

- The Philosophy of Behaviorism in 40 CharactersDokument17 SeitenThe Philosophy of Behaviorism in 40 CharactersEmily JamioNoch keine Bewertungen

- 5 SetDokument34 Seiten5 SetQuynh NguyenNoch keine Bewertungen

- Advantages and Disadvantages of Distance Education Power Point PresentationDokument17 SeitenAdvantages and Disadvantages of Distance Education Power Point PresentationMhimi ViduyaNoch keine Bewertungen

- Annexe PFE Ben Hamida Slimen FinalDokument113 SeitenAnnexe PFE Ben Hamida Slimen Finalyassine mestiriNoch keine Bewertungen

- Morphotectonic and Satellite Imagery Analysis For Identifying Quaternary Fault at Southern Part of Cianjur-Garut Region, West Java, IndonesiaDokument10 SeitenMorphotectonic and Satellite Imagery Analysis For Identifying Quaternary Fault at Southern Part of Cianjur-Garut Region, West Java, IndonesiaDian Ayu Lestari Alifa PutriNoch keine Bewertungen

- A Primer in Research Methodology and BiostatisticsDokument163 SeitenA Primer in Research Methodology and BiostatisticsAdriana Villarreal100% (3)

- Astrophysics Project Reaction PaperDokument2 SeitenAstrophysics Project Reaction PaperEdson DavidNoch keine Bewertungen

- Angular Dispersion and Dispersive PowerDokument6 SeitenAngular Dispersion and Dispersive PowerShivkant SinghNoch keine Bewertungen

- BHCS38523 AnomAlert Motor Anomaly Detector - R1 PDFDokument2 SeitenBHCS38523 AnomAlert Motor Anomaly Detector - R1 PDFZahid IrfanNoch keine Bewertungen

- Scheduled Oil Sampling Report: Eval CodeDokument1 SeiteScheduled Oil Sampling Report: Eval CodePutra JawaNoch keine Bewertungen

- Đề Thi Học Sinh Giỏi Thành Phố Lớp 12 TP Hải Phòng Môn Tiếng Anh Bảng Không Chuyên 2019-2020Dokument4 SeitenĐề Thi Học Sinh Giỏi Thành Phố Lớp 12 TP Hải Phòng Môn Tiếng Anh Bảng Không Chuyên 2019-2020Ý Nguyễn Thị NhưNoch keine Bewertungen