Beruflich Dokumente

Kultur Dokumente

Lifting Lug Calculation Rev - 1

Hochgeladen von

WijayantoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lifting Lug Calculation Rev - 1

Hochgeladen von

WijayantoCopyright:

Verfügbare Formate

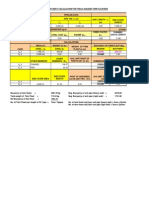

LIFTING LUG CALCULATION

Design Data :

Weight of equipments

Material of Lug A 36 / SS 400

Number of Lifting Lug

Safety Factor

Yield stress of Lug material

Allowable Load on Weld

23712.5 Kg

( 52262.40 Lb

N

Sf

Ys

=

=

=

=

4

2

268.9 Mpa

2689 kg/cm2

39000

Psi

66.19 Mpa

9600

Psi

0.39

in

25740

Psi

(

(

(

(

(

(

(

(

(

2.91

1.97

1.57

5.12

0.98

0.31

2.95

2.56

7.32

in

in

in

in

in

in

in

in

in

)

)

)

)

)

)

)

)

)

(

(

8.80

0.39

in3

in

)

)

SHEET

OF 2

tw

@

Fb

Fillet weld thickness

Angle

Bending stress , F b = 0.66 * Y s

=

=

=

=

=

kg/cm

mm

Deg

Mpa

1774.71 kg/cm

661.90

10

70

177.47

Sketch Of Lifting Lug

a

b

d

D

t

tc

R

rc

w

Z

tw

=

74

mm

=

50

mm

=

40

mm

=

130 mm

=

25

mm

=

8

mm

=

75

mm

=

65

mm

=

186 mm

= (t*w^2)/6

= 144150 mm3

= 10

mm

Force of per Lug

( 19603.91 Lb

Kg

( 16043.01 Lb

11490 Kg

( 25331.63 Lb

=

=

5.485 kg/mm2

548.46 kg/cm2

8062.37

Psi

4031.19

Psi

8670.89

Psi

2953

Psi

Pv

= (W*Sf) / N

==>

Vertical Force

8892.2 Kg

Ph

= Pv/tan @

==>

Horizontal Force

7277

Pr

= ( Pv^2 + Ph^2 )^0.5

==>

Resultan Force

Shear Stress

Ssh = Pr/[{t*(r-d/2)}+{tc*(rc-d/2)}]

Ss

548.46 kg/cm

= Satisfactory

< 0.4 * Ys

2

< 1075.6

kg/cm2

Tensile Stress in Lug

Sst = Pr/[{t*(r-d/2)*2}+{tc*(rc-d/2*4)}]

Ss

274.23 kg/cm

=

=

= Satisfactory

< 0.6 * Ys

2

< 1774.7

2.742 kg/mm2

274.23 kg/cm2

kg/cm2

Bending Stress in Lug

Sb

= Mb / Z

= ( Pr*a ) / Z

=

=

= Satisfactory

Sb < 0.6 * Ys

589.86 kg/cm

<

1774.7

5.90 kg/mm2

589.86 kg/cm2

kg/cm2

Shear Stress in welding

Fw = Pr / 2 * ( 2* b + w ) * tw

=

=

= Satisfactory

Fw < f

200.88 kg/cm

<

kg/mm2

200.88 kg/cm2

2.01

661.9

kg/cm2

SHEET

OF 2

Das könnte Ihnen auch gefallen

- Welding SymbolsDokument12 SeitenWelding SymbolsrsrtnjNoch keine Bewertungen

- A. Check For Compression: DESIGN USING ASME BTH1-2005 - Code For LiftingDokument5 SeitenA. Check For Compression: DESIGN USING ASME BTH1-2005 - Code For LiftingDhanraj VasanthNoch keine Bewertungen

- BlindDokument3 SeitenBlindSajal KulshresthaNoch keine Bewertungen

- Tail Lifting Lug Calculation MS WordDokument11 SeitenTail Lifting Lug Calculation MS WordWijayanto BekasiNoch keine Bewertungen

- Bolt Tensioning - E411 - GB PDFDokument2 SeitenBolt Tensioning - E411 - GB PDF4jawwy markme026Noch keine Bewertungen

- Horizontal Lifting LugDokument1 SeiteHorizontal Lifting LugTushar MangratiNoch keine Bewertungen

- Alloy Master LinksDokument1 SeiteAlloy Master LinksAnonymous 48jYxR1C0% (1)

- Spreaer Beam&Lifting Line Beam p5Dokument2 SeitenSpreaer Beam&Lifting Line Beam p5Sabrang LorNoch keine Bewertungen

- Comp 2Dokument9 SeitenComp 2YYo YudiNoch keine Bewertungen

- Asme Pipe Wall ThicknessDokument3 SeitenAsme Pipe Wall ThicknessYoke ShuNoch keine Bewertungen

- Application of Bellows Expansion Joints in Piping SystemDokument5 SeitenApplication of Bellows Expansion Joints in Piping Systemjlcheefei9258Noch keine Bewertungen

- Spreader Bar Calc REF.Dokument34 SeitenSpreader Bar Calc REF.Gokul AmarnathNoch keine Bewertungen

- Safe Working Load Calculation For Round BarDokument1 SeiteSafe Working Load Calculation For Round BarAdura OgunnuNoch keine Bewertungen

- 1.3 - Tubular Member Design ConsiderationsDokument27 Seiten1.3 - Tubular Member Design ConsiderationsDanNoch keine Bewertungen

- Seismic Load Calculation of The Tank As Per IS 1893Dokument1 SeiteSeismic Load Calculation of The Tank As Per IS 1893ParthibanNoch keine Bewertungen

- Marine Operations During Removal of Offshore Installations: Recommended Practice DNV-RP-H102Dokument22 SeitenMarine Operations During Removal of Offshore Installations: Recommended Practice DNV-RP-H102leelarama100% (1)

- AS4041 Pipe Wall ThicknessDokument2 SeitenAS4041 Pipe Wall Thicknessjibran42Noch keine Bewertungen

- Lug CalcionulatDokument1 SeiteLug CalcionulatkurniawanandreasNoch keine Bewertungen

- Calculation Sheet For 700mm SQ Metal FloatersDokument3 SeitenCalculation Sheet For 700mm SQ Metal FloatersAdagharaNoch keine Bewertungen

- Lift & Tail CalcsDokument3 SeitenLift & Tail Calcsnazeer_mohdNoch keine Bewertungen

- Spreader Bar3 - L.9 M-CertificationDokument10 SeitenSpreader Bar3 - L.9 M-CertificationsiagiandobahNoch keine Bewertungen

- Steel Structure ST 37Dokument11 SeitenSteel Structure ST 37aliNoch keine Bewertungen

- Lifting Lug 75 TDokument2 SeitenLifting Lug 75 Trustamriyadi0% (1)

- Pad Eye Calculation AllDokument3 SeitenPad Eye Calculation Alldsn_sarmaNoch keine Bewertungen

- Lifting Lug Calculations KodDokument2 SeitenLifting Lug Calculations Kodanu radhaNoch keine Bewertungen

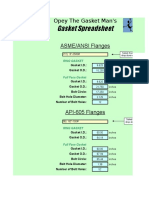

- Gasket Dimension (ASME B16.5 & B16.47)Dokument4 SeitenGasket Dimension (ASME B16.5 & B16.47)ama100% (1)

- Lifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Dokument7 SeitenLifting Lug Calculation: ITEM NO.: 521267876.xls REV. 0Steve MoonNoch keine Bewertungen

- Bolt CalculationDokument7 SeitenBolt CalculationneynaaaNoch keine Bewertungen

- DNV Structural OS C201Dokument78 SeitenDNV Structural OS C201nse mcxNoch keine Bewertungen

- Fibrelogic Flowtite Engineering Guidelines DES M-004 REFER PDFDokument122 SeitenFibrelogic Flowtite Engineering Guidelines DES M-004 REFER PDFA.Subin DasNoch keine Bewertungen

- BuoyancyDokument1 SeiteBuoyancyLcm TnlNoch keine Bewertungen

- Calculation Lifting LugDokument4 SeitenCalculation Lifting Lugelang purbayaNoch keine Bewertungen

- Deflection Calculation For Over Head PipesDokument6 SeitenDeflection Calculation For Over Head PipesRamachandran VenkateshNoch keine Bewertungen

- Piping Engineering - Tank Nozzle Loads 1Dokument1 SeitePiping Engineering - Tank Nozzle Loads 1Nasrul Adli100% (1)

- Point Load CalculationsDokument3 SeitenPoint Load Calculationskedar kavathekarNoch keine Bewertungen

- 8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQDokument3 Seiten8" (200A) SCH.80: A 106 Gr.B/EQ A 36 / EQRakeshNoch keine Bewertungen

- Strength Calculation of Skid For Indirect HeaterDokument19 SeitenStrength Calculation of Skid For Indirect HeaterDIANTORO100% (1)

- 2L5x3x1/2LLBB: #N/A #N/A #N/ADokument1 Seite2L5x3x1/2LLBB: #N/A #N/A #N/ARaza AidanNoch keine Bewertungen

- Lifting Lug DesignDokument27 SeitenLifting Lug Designmramico100% (1)

- 2276 1Dokument2 Seiten2276 1hogoyoNoch keine Bewertungen

- PMHSA R&D Forum Dent Assessment Methods & Challenges: David Chittick/Millan Sen June 24, 2009Dokument7 SeitenPMHSA R&D Forum Dent Assessment Methods & Challenges: David Chittick/Millan Sen June 24, 2009Hafizul Hisyam Maysih LuzifahNoch keine Bewertungen

- Tailing Lug - 173004-05Dokument1 SeiteTailing Lug - 173004-05shazan100% (1)

- 17 TonsDokument8 Seiten17 TonsFernando Humberto100% (1)

- Bolts,: Threaded Parts TensionDokument2 SeitenBolts,: Threaded Parts TensionMary MarasiganNoch keine Bewertungen

- Spreader BarDokument2 SeitenSpreader BarAmi PutraNoch keine Bewertungen

- Sequential Lifting of Tank Shell Used To Repair FloorsDokument4 SeitenSequential Lifting of Tank Shell Used To Repair FloorsBIPIN BALANNoch keine Bewertungen

- Mi 1Dokument9 SeitenMi 1XNoch keine Bewertungen

- Pipe StackingDokument2 SeitenPipe StackingUghojor ElohoNoch keine Bewertungen

- Skid BeamDokument2 SeitenSkid BeamYuni Ari WibowoNoch keine Bewertungen

- Lifting Lug CalcDokument4 SeitenLifting Lug CalcdharwinNoch keine Bewertungen

- Clamped Cover Plate DesignDokument7 SeitenClamped Cover Plate DesignChiedu OkonduNoch keine Bewertungen

- Blind ThicknessDokument1 SeiteBlind ThicknessRizwan Waheed KhanNoch keine Bewertungen

- Purlin Cleat 220908Dokument24 SeitenPurlin Cleat 220908kalpanaadhi100% (2)

- Verifica Giunto Secondo AsmeDokument5 SeitenVerifica Giunto Secondo AsmeFabio TemporiniNoch keine Bewertungen

- Lifting Beam DesignDokument4 SeitenLifting Beam DesignAnonymous XAqiBJ100% (4)

- Steel Design Calculation For Bridge False WorksDokument10 SeitenSteel Design Calculation For Bridge False Worksnelvar2005Noch keine Bewertungen

- Cven3302 Assignment 1: Column Loading (For The Purpose of Spacegass)Dokument11 SeitenCven3302 Assignment 1: Column Loading (For The Purpose of Spacegass)fflegendsNoch keine Bewertungen

- Pile ReportDokument14 SeitenPile ReportChen E LikNoch keine Bewertungen

- Numerical Analysis: Chapter - 6Dokument30 SeitenNumerical Analysis: Chapter - 6Pranay ReddyNoch keine Bewertungen

- Data Sheet Gas Scrubber 42 InchDokument32 SeitenData Sheet Gas Scrubber 42 InchWijayantoNoch keine Bewertungen

- Drawing Fin Fan CoolerDokument1 SeiteDrawing Fin Fan CoolerWijayantoNoch keine Bewertungen

- Pipe 12 Inch Cal Asme B 31 3 Carbon Steel Rev 1Dokument3 SeitenPipe 12 Inch Cal Asme B 31 3 Carbon Steel Rev 1WijayantoNoch keine Bewertungen

- Drawinhg Air Receiver Tank 1000 L IterDokument1 SeiteDrawinhg Air Receiver Tank 1000 L IterWijayantoNoch keine Bewertungen

- Welding Map 1Dokument1 SeiteWelding Map 1WijayantoNoch keine Bewertungen

- Ventilation WorksheetDokument14 SeitenVentilation WorksheetDeepak JoyNoch keine Bewertungen

- Skid Calculation MTRDokument3 SeitenSkid Calculation MTRWijayanto100% (1)

- Seismic Cal1Dokument4 SeitenSeismic Cal1WijayantoNoch keine Bewertungen

- Pipe CalculationDokument2 SeitenPipe CalculationWijayantoNoch keine Bewertungen

- Seismic Cal SNI 1726 - 2012Dokument2 SeitenSeismic Cal SNI 1726 - 2012WijayantoNoch keine Bewertungen