Beruflich Dokumente

Kultur Dokumente

Lec 15 Highway Engineering - Asphalt Paving Mixtures

Hochgeladen von

Dr Firas AsadCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lec 15 Highway Engineering - Asphalt Paving Mixtures

Hochgeladen von

Dr Firas AsadCopyright:

Verfügbare Formate

Highway Eng.

Asphalt Paving Mixtures

14 15

Asphalt Paving Mixtures

In this lecture;

- Constitutes

- Types

- Desirable Properties

- Marshall Mix Design Method

- Volumetric Properties

Information listed in this lecture is mainly taken from Standard Specifications for

Engineering Materials and Methods of Sampling and Testing (AASHTO, 2013),

A Manual for Design of Hot Mix Asphalt with Commentary (NCHRP, Report 673,

2011), Traffic and Highway Engineering (Garber, 2009), Handbook of Highway

Engineering (Fwa, 2006), http://www.pavementinteractive.org (Accessed on 2015)

and Highways (OFlaherty, 2007).

A- Constituents of a mix

Coarse aggregates: Offer compressive and shear strength and shows good

interlocking properties. E.g. Crushed stone.

Fine aggregates: Fills the voids in the coarse aggregate and stiffens the binder. E.g.

Sand, Rock dust

Filler: Fills the voids, stiffens the binder and offers permeability. E.g. Rock dust,

cement, lime.

Binder: Fills the voids, cause particle adhesion and gluing (cementing) and offers

impermeability. E.g. Bitumen (Asphalt) and Tar.

Asphalt Concrete (Also known as hot mix asphalt, plant mix, bituminous mix,

bituminous concrete) is a combination of two primary ingredients - aggregates

(90 95)% by weight of total mixture and asphalt cement (5-10)% asphalt cement.

Lecture 15

175

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

B- Types of Asphalt Paving Mixtures

1- Hot-Mix, Hot-Laid Asphalt Mixture

Hot-mix, hot-laid asphalt mixture is produced by properly blending asphalt cement,

coarse aggregate, fine aggregate, and filler (dust) at temperatures ranging from

about 80 to 160oC depending on the type of asphalt cement used. Suitable types of

asphalt materials are those with penetration grades of 60 to 70, 85 to 100, 120 to

150, and 200 to 300.

Hot-mix, hot-laid asphalt mixture normally is used for high-type pavement

construction, and the mixture can be described as open graded, coarse-graded,

dense-graded, or fine-graded.

2- Hot-Mix, Cold-Laid Asphalt Mixture

Asphalt mixtures in this category are manufactured hot and then shipped and laid

immediately or can be stockpiled for use at a future date. Thus, they are suitable for

small jobs when it is uneconomical to set up a plant.

In this type of asphalt concrete high-penetration asphalt normally is used. The most

suitable asphalt cements is AC 200-300 penetration grade.

3- Cold-Mix, Cold-Laid Asphalt Mixture

Emulsified asphalts and low-viscosity cutback asphalts are used to produce cold-mix

asphalt mixtures. They also can be used immediately after production or stockpiled

for use at a later date. The production process is similar to that of the hot-mix

asphalts, except that the mixing is done at normal temperatures.

Examples of the types and grades of asphalt material used are MS and SS.

Lecture 15

176

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

C- Desirable Properties of Asphalt Mixtures

1- Stability

Stability is the resistance of pavement to permanent deformation caused by

sustained or moving load. It is provided by two factors:

a- Interlocking and internal friction - depend on:

1- Size and shape of aggregate;

2- Surface area and roughness;

3- Applied load.

b- Cohesion resistance - depends on:

1-rate of load application

2- loaded area;

3- viscosity of the binder.

4- Temperature.

2 - Durability

It is the ability to resist the factors of weathering; water(stripping), air(oxidation),

temperature, and abrasive action from traffic (disintegration/cracking).

Percentage of binder controls on disintegration and resistance to cracking where

brittle mixes cracks under the effect of moving loads. The brittleness is mainly

caused by: (a) low ductility asphalt and (b) low content of binder. Maximum binder

content increases durability because thick binder films do not age and harden as

rapidly as thin ones do.

Temperature causes thermal cracking at low temperature and tenderness at high

temperature.

Lecture 15

177

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

3. Flexibility

It is the ability of the pavement to bend repeatedly due to traffic loads without

cracking (fatigue resistance). To obtain the desired flexibility :

1- Using appropriate content and type of asphalt;

2- Using well graded aggregate;

3- Selected temperature of mixing and compaction.

4. Skid resistance

It depends on the roughness of surface textured aggregate , hardness of aggregate

and less asphalt content. Best skid resistance is obtained with rough-textured

aggregate in a relatively open-graded mixture.

5. Workability

Workability describes the ease with which a paving mixture can be placed and

compacted. Mixtures with good workability are easy to place and compact; those

with poor workability are difficult to place and compact.

Workability can be improved by changing

a- mix design parameters

b- aggregate source, and/or

c- gradation.

Lecture 15

178

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

D- Design of Hot-Mix Asphalt Concrete

The objective of mix designs is to adequately select and mix certain proportions of

asphalt binders and aggregates to produce HMA that performs well both

functionally and structurally . Regarding performance, the HMAC should be

durable and be able to resist pavement distresses (such as permanent deformation,

load-induced fatigue, thermal fatigue, low temperature cracking, and moistureinduced damage). From a construction standpoint, the mix should be workable

enough to place and compact with reasonable effort. Additionally, surface courses

should provide sufficient skid resistance for safety considerations.

There are several mix design methods for Hot-Mix Asphalt, Hveem (1920s), Marshall

(1930s), and Superpave (1990s) are the most common methods. In this course, only

Marshall method will be covered.

Marshall Mix Design Method

The Marshall method of mix design is intended both for

laboratory design and field control of bituminous hot-mix

dense-graded paving mixtures. Originally, it was developed by the

bituminous engineer Bruce Marshall of the Mississippi State Highway Department.

The US Army Corps of Engineers enhanced the Marshalls approach and it was then

subsequently formalized as ASTM D 1559 and AASHTO T 245 Standard Method of

Test for Resistance to Plastic Flow of Asphalt Mixtures Using Marshall Apparatus.

Lecture 15

179

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

Outline of method

The Marshall method uses standard cylindrical test specimens that are 64 mm

(2.5in) high by 102 mm (4in) diameter. These are prepared using a specified

procedure for heating, mixing and compacting the bitumenaggregate mixture. The

two principal features of the Marshall method of mix design are a density voids

analysis and a stability-flow test of the compacted test specimens. The stability of

the test specimens is the maximum load resistance, in newtons, that the standard

test specimen will develop at 60C. The flow value is the total movement or

displacement, in units of 0.25 mm, occurring in the specimen between no load and

the point of maximum load during the stability test.

Procedure

Step 1. Aggregate Evaluation

The aggregates proposed for use in the mix design should be have the desired

properties and satisfy the required specifications (See Lecture L13). If the aggregates

meet the requirements above, the aggregate specific gravity, absorption, and

gradation are determined. These will be used for determining the volumetric

properties of the mix. Last, the individual aggregate gradations are combined in

different proportions to develop trial blends.

Lecture 15

180

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

Step 2. Asphalt Cement Evaluation

The asphalt cement used in the mix design should satisfy the specifications when

running the required tests (See Lecture L14). After that, determine the mixing and

compaction temperatures based on viscosities of 170 20 and 280 30 centistokes

(cSt), respectively.

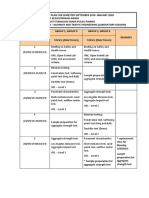

Step 3. Preparation of Marshall Specimens

Prepare the Marshall specimens in accordance to the requirements set in AASHTO

R-12. Compact three replicate specimens at five percentages of asphalt contents

(4.0, 4.5, 5.0, 5.5, 6.0 % by weight of total mix). The asphalt contents should be

selected with two asphalt contents falling above and below the optimum asphalt

content. These specimens are prepared using molds of dimension (4*2.5) and

using a hummer of 10Ib (4.5 kN) weight with 18 (457 mm) drop distance to

compact the sample with No. of blows as shown in the table below.

Three loose specimens should also be prepared for determining the maximum

theoretical specific gravity near the optimum asphalt content. Determine the bulk

specific gravity of the compacted specimens and maximum theoretical specific

gravity of the loose mix using AASHTO T166 (ASTM D2726) Standard Method of

Test for Bulk Specific Gravity of Compacted Asphalt Mixtures Using Saturated

Surface-Dry Specimens and ASHTO T209 Standard Method of Test for Theoretical

Maximum Specific Gravity and Density of Bituminous Paving Mixtures, respectively.

Step 4. Marshall Stability and Flow

Determine the Marshall stability and flow using ASTM D1559. Stability is defined as

the maximum load carried by a compacted specimen tested at 60oC at a loading rate

of 2 in./min. The two primary factors in determining the stability are the angle of

internal friction of the aggregate and the viscosity of the asphalt cement. Therefore

mixes with angular aggregates will have a higher stability than mixes with rounded

Lecture 15

181

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

aggregates. Similarly, mixes with more viscous asphalt cements will have a higher

stability than mixes with less viscous asphalt cements. The primary use of the

Marshall stability is to evaluate the effect of asphalt cement in the Marshall mix

design procedure. However, increasing the Marshall stability in the laboratory does

not automatically translate to increased stability of mixes in the field.

Flow is the vertical deformation of the sample at failure. High flow values typically

indicate a plastic mix that could be susceptible to permanent deformation. Low flow

values may indicate low air voids that may lead to premature cracking.

Step 5. Density and Void Analysis

Using the bulk specific gravity and maximum theoretical specific gravity test results

and the relevant equations, the volumetric properties of the mix can be determined.

This information is used in Step 6.

Step 6. Tabulating and Plotting Test Results

With the completion of Steps 4 and 5, the average (from three replicates) results

can be tabulated and plotted. The following plots can then be made to evaluate the

mix:

* Density (or Unit Weight) vs. Asphalt Content

* Marshall Stability vs. Asphalt Content

* Flow vs. Asphalt Content

* Air Voids vs. Asphalt Content

* VMA vs. Asphalt Content

* VFA vs. Asphalt Content

Lecture 15

182

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

The density plot typically shows a trend of increasing density until the peak is

reached. After this peak, the density begins to decrease.

The Marshall stability has a similar trend but its peak is typically at a lower asphalt

content than density. Some recycled mixes may show a decreasing stability with

increasing asphalt content with no peak.

Flow typically increases with increasing asphalt content.

The percent air voids should decrease and the VFA increase with increasing asphalt

content.

VMA is another property that increases with asphalt content until it reaches its peak

and then decreases with additional increase in asphalt content.

Step 7. Optimum Asphalt Content Determination

The criteria used to select the optimum asphalt content can vary considerably

between agencies. In the Asphalt Institute method (adopted in Iraq), the OAC is the

average of the following three asphalt contents:

* Asphalt content at maximum stability

* Asphalt content at maximum density

* Asphalt content at the mid-point of specified air void content (typically at 4%)

1

Optimum asphalt content = [ AC (Max. stability) + AC (Max. Density) + AC (Midrange of VTM) ]

Compare the proposed optimum asphalt content against the criteria in Tables

below. The proposed optimum asphalt content is selected if it meets the criteria in

the Tables. If not, the mix should be redesigned.

Lecture 15

183

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

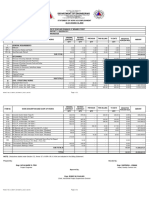

Following is the corresponding the Iraqi specifications (SCRB, 2007, Table R9/5).

The Marshall Stability of surface course for Expressway, all bridges and the

approaches to bridges for a distance of 200m on each side shall be not less than

10 KN, if directed by the Engineer.

Lecture 15

184

Dr. Firas Asad

Highway Eng.

Lecture 15

Asphalt Paving Mixtures

185

14 15

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

D- Volumetric Properties of Asphalt Mixtures

A compacted asphalt concrete mix consists primarily of aggregate, asphalt, and air.

The volumetric properties associated with the combination of these three

components are widely used for mix design and production control. Since it is

impractical to measure the volume of constituent components within a HMA mix in

the laboratory or in the field, mass volume relationships are used to convert the

measurable masses into their corresponding volumes.

The (S) letter refers to aggregate, (m) to mixture , and (b) to binder (asphalt).

Vm: volume of mix (bulk)

Mm: mass of mix

Va: volume of air

Ma: mass of air assumed to be equal to zero

Vb: volume of binder ( asphalt)

Mb: mass of binder

VFA: voids filled with asphalt (Vbe)

Mbe: mass of effective (free) binder

Vba: volume of absorbed binder

Mba: mass of absorbed binder

VMA: voids in mineral aggregate

Ms: mass of aggregates

Vbe: volume of effective asphalt

Gmb: mixture bulk specific gravity

Gb: asphalt specific gravity

Pb: binder percent by total of mix

Gsb: aggregate bulk specific gravity

Gse: aggregate effective specific gravity

Lecture 15

186

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

The mass of a constituent is directly proportional to its volume as shown in the

following equation:

M = V.G.w

where M is the mass of constituent, V is the volume of constituent, G is the specific

gravity of constituent, and w is the density of water (1.0 g/cm3).

Following are the most used mathematical formula in asphalt mix designs:

1) Specific gravities of aggregates

Mineral aggregate is porous and can absorb water and bitumen to a variable degree.

The three methods of measuring aggregate specific gravity (bulk, apparent, and

effective) take these variations into consideration. The differences between the

specific gravities arise from different definitions of aggregate volume.

The Bulk Specific Gravity (Gsb) is the ratio of the mass in air of a unit volume of a

permeable material (including both permeable and impermeable voids) at a

selected temperature to the mass in air of equal density of an equal volume of gasfree distilled water at the same selected temperature (see Figure below).

The Apparent Specific Gravity (Gsa) is the ratio of the mass in air of a unit volume of

an impermeable material at a selected temperature to the mass in air of equal

density of an equal volume of gas-free distilled water at the same temperature.

Lecture 15

187

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

The Effective Specific Gravity (Gse) is the ratio of the mass in air of a unit volume of

a permeable material (excluding voids permeable to bitumen) at a selected

temperature to the mass in air of equal density of an equal volume of gas-free

distilled water at the same selected temperature.

A - Bulk Specific Gravity of Combined Aggregate (Gsb): When the total aggregate

consists of separate fractions of coarse aggregate, fine aggregate, and mineral filler,

all having different specific gravities, the bulk specific gravity for the total aggregate

is calculated from:

where P1; P2; Pn are individual percentages by mass of aggregate and G1; G2; Gn are

individual bulk specific gravities of aggregate.

B - Effective Specific Gravity of Aggregate (Gse): The effective specific gravity of the

aggregates is normally based on the maximum theoretical specific gravity of the

paving mixture Gmm ( measured using ASTM D 2041), the effective specific gravity of

the aggregate, Gse, includes all void spaces in the aggregate particles except those

that absorb bitumen.

;

Pb + Ps=100

Where;

Pb: asphalt percent by total weight (mass) of paving mixture (100 Ps),

Ps: is the percent of the combined aggregate by total weight of mix,

100: (Pmm) is the percent by mass of total loose mix,

Gb: specific gravity of binder (asphalt).

Lecture 15

188

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

Gmm: maximum specific gravity of the paving mixture as measured using ASTM

D 2041 (AASHTO T209). The precision for the test is best when the mixture is close

to the design asphalt content.

The effective specific gravity of the aggregates Gse can be considered constant, since

varying the asphalt content in the paving mixture does not significantly vary the

asphalt absorption.

C - Maximum specific gravity of mixtures with different asphalt contents Gmm

The effective specific gravity obtained in (B) above then is used to determine the

maximum specific gravity of the paving mixtures with different asphalt cement

contents.

2) Absorbed and effective asphalt

A- Absorbed asphalt: Absorption is expressed as a percentage by weight of

aggregate rather than as a percentage by total mass of mixture. Bitumen

absorption, Pba is determined using:

where Pba = absorbed bitumen (as percentage by mass of aggregate); Gse = effective

specific gravity of aggregate; Gsb = bulk specific gravity of aggregate; and

Gb = specific gravity of bitumen.

B- Effective asphalt content of a paving mixture

The effective bitumen content, Pbe, of a paving mixture is the total bitumen content

minus the quantity of bitumen lost by absorption into the aggregate particles. As it

is the portion of the total bitumen content that remains as a coating on the outside

of the aggregate particles, it is this bitumen content which governs the performance

Lecture 15

189

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

of a bitumen paving mixture. The formula is:

where Pbe = effective bitumen content, percentage by total weight of mixture;

Pb = bitumen content, percentage by total weight of mixture; Pba = absorbed

bitumen, percentage by weight of aggregate; and Ps = aggregate content,

percentage by total weight of mixture.

3) Percent of voids in the compacted mixtures

A - Percent VMA in compacted paving mixture:

The voids in the mineral aggregate, VMA, are defined as the intergranular void space

between the aggregate particles in a compacted paving mixture. The VMA includes

the air voids and the effective bitumen content, expressed as a per cent of the total

volume (See Figure).

The VMA is calculated on the basis of the bulk specific gravity of the aggregate Gsb

and is expressed as a percentage of the bulk volume of the compacted paving

mixture. Therefore, the VMA can be calculated by subtracting the volume of the

aggregate determined by its bulk specific gravity from the bulk volume of the

compacted paving mixture. If the mix composition is determined as per cent by

mass of total mixture:

where VMA = voids in mineral aggregate, percentage of bulk volume; Gsb = bulk

specific gravity of total aggregate; Gmb = bulk specific gravity of compacted mixture

(AASHTO T 166, ASTM D 1188 or D 2726); and Ps = aggregate content, percentage by

total mass of mixture.

Lecture 15

190

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

Or, if the mix composition is determined as a per cent by mass of aggregate:

where Pb = bitumen content, percentage by mass of aggregate.

B - Percent air voids in compacted paving mixture:

The air voids, Va, is the total volume of the small pockets of air between the coated

aggregate particles throughout a compacted paving mixture, expressed as a per cent

of the bulk volume of the compacted paving mixture (Fig. 12.2). The volume

percentage of air voids in a compacted mixture can be determined using:

where Va = air voids in compacted mixture, percentage of total volume;

Gmm = maximum specific gravity of paving mixture (as determined earlier or as

measured directly for a paving mixture by ASTM D 2041); and Gmb = bulk specific

gravity of compacted mixture.

C - Percent voids filled wih bitumen in the compacted mixture:

The voids filled with bitumen, VFB, is the percentage of the intergranular void space

between the aggregate particles (VMA) that are filled with bitumen. The VFB, which

does not include the absorbed bitumen, is determined using:

where VFB= voids filled with bitumen, percentage of VMA; VMA= voids in mineral

aggregate, percentage of bulk volume; and Va = air voids in compacted mixture,

percentage of total volume.

Lecture 15

191

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

(a) Percent air voids %Va

In order to compute %Va, we should at first determine Gmm;

Hence,

= 100/((95/2.733) + (5/1.013) ) = 2.519

(f)

= 100 [(2.519 2.331) / 2.519] = 7.46%

(b) Voids in mineral aggregate %VMA

= 100 (2.331 * 5 / 2.707) = 18.2 %

(c) Voids filled with asphalt (binder) %VFA or %VFB

= 100 [ (18.2 7.46) / 18.2] = 59.01 %

In order to calculate the effective asphalt content we should firstly calculate the

absorbed asphalt content:

(e) Absorbed asphalt content

= 100

2.7332.707

2.7072.733

1.013 = 0.356%

(d) Absorbed asphalt content

= 5 [(0.356/100) 95] = 4.66 %

(f) As show above Gmm = 2.519

==================================

Lecture 15

192

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

Example: Using the information provided in the listed Table, determine the

asphalt absorption, effective asphalt binder content, VMA, air voids, and VFA of

the given asphalt mixture.

Lecture 15

193

Dr. Firas Asad

Highway Eng.

Asphalt Paving Mixtures

14 15

==================================

Lecture 15

194

Dr. Firas Asad

Das könnte Ihnen auch gefallen

- Research and Application of Hot In-Place Recycling Technology for Asphalt PavementVon EverandResearch and Application of Hot In-Place Recycling Technology for Asphalt PavementNoch keine Bewertungen

- Lec 07 Highway Engineering - Speed Change LanesDokument8 SeitenLec 07 Highway Engineering - Speed Change LanesDr Firas Asad100% (2)

- Supervising Highway Engineer: Passbooks Study GuideVon EverandSupervising Highway Engineer: Passbooks Study GuideNoch keine Bewertungen

- Lec 12 Highway Engineering - Soil StabilisationDokument8 SeitenLec 12 Highway Engineering - Soil StabilisationDr Firas Asad100% (1)

- Unbound Aggregates in RoadsVon EverandUnbound Aggregates in RoadsR.H. JonesNoch keine Bewertungen

- Lec 13 Highway Engineering - Aggregate Tests Gradation and BlendingDokument20 SeitenLec 13 Highway Engineering - Aggregate Tests Gradation and BlendingDr Firas Asad100% (6)

- Highway Materials & Mix Design Ppt. MMHDokument35 SeitenHighway Materials & Mix Design Ppt. MMHMd Mehedi HasnatNoch keine Bewertungen

- Lec 10 11 Highway Engineering - Soil Classification and CompactionDokument7 SeitenLec 10 11 Highway Engineering - Soil Classification and CompactionDr Firas Asad100% (2)

- Lecture 1 - Highway Engineering by Dr. Abdul SamiDokument44 SeitenLecture 1 - Highway Engineering by Dr. Abdul SamiDarya Memon100% (3)

- Grade Separated Intersections ﺓﺮـــــــــــــــﺴﺠﻤﻟﺍ ﺕﺎﻌﻁﺎﻘﺘﻟﺍDokument10 SeitenGrade Separated Intersections ﺓﺮـــــــــــــــﺴﺠﻤﻟﺍ ﺕﺎﻌﻁﺎﻘﺘﻟﺍDr Firas Asad100% (2)

- Lec 02 Highway Engineering - Design Parameters Turning Paths and Sight DistanceDokument15 SeitenLec 02 Highway Engineering - Design Parameters Turning Paths and Sight DistanceDr Firas Asad100% (5)

- Lec 04 Highway Engineering - Curve WideningDokument6 SeitenLec 04 Highway Engineering - Curve WideningDr Firas Asad100% (4)

- Lec 00 Highway Engineering - Opening and SyllabusDokument10 SeitenLec 00 Highway Engineering - Opening and SyllabusDr Firas Asad100% (2)

- Highway 4567 ExamDokument19 SeitenHighway 4567 Exambufalo 93100% (1)

- Lec 16 Highway Engineering - Flexible Pavemen DesignDokument25 SeitenLec 16 Highway Engineering - Flexible Pavemen DesignDr Firas Asad100% (2)

- 15cv833-Pavement DesignDokument90 Seiten15cv833-Pavement DesignMEHRAN KAPRANoch keine Bewertungen

- Lec 01 Highway Engineering - Highway ClassificationDokument10 SeitenLec 01 Highway Engineering - Highway ClassificationDr Firas Asad100% (3)

- Level of Service of Highway FacilitiesDokument43 SeitenLevel of Service of Highway FacilitiesTASHOBYA DEAN100% (2)

- Superpave Mix Design - Pavement InteractiveDokument7 SeitenSuperpave Mix Design - Pavement InteractiveHoracio Reyes de la Rosa100% (1)

- Highway Engineering JQjQ0B SampleDokument29 SeitenHighway Engineering JQjQ0B SampleHardik SolankiNoch keine Bewertungen

- Rigid Pavement DesignDokument11 SeitenRigid Pavement DesignAjit P. SinghNoch keine Bewertungen

- Factors Considered in Pavement Design and ConstructionDokument21 SeitenFactors Considered in Pavement Design and ConstructionAbinash Panda100% (4)

- Level of Service of RoadsDokument15 SeitenLevel of Service of RoadsaqilahNoch keine Bewertungen

- Structural EvaluationDokument12 SeitenStructural EvaluationSasikumar ViswanathanNoch keine Bewertungen

- Lec 03 Highway Engineering - Horizontal AlignmentDokument8 SeitenLec 03 Highway Engineering - Horizontal AlignmentDr Firas Asad100% (2)

- Superpave FundamentalsDokument163 SeitenSuperpave Fundamentalsproject list91% (11)

- Pavement DistressDokument65 SeitenPavement DistressPadma ShahiNoch keine Bewertungen

- Lec 08 Highway Engineering - Cross Section ElementsDokument15 SeitenLec 08 Highway Engineering - Cross Section ElementsDr Firas Asad81% (16)

- Highway Geometric DesignDokument40 SeitenHighway Geometric Designharikeerthan84% (19)

- Construction Method For Road-PavementDokument13 SeitenConstruction Method For Road-PavementAnonymous kuW0obtJ4pNoch keine Bewertungen

- Surface DressingDokument82 SeitenSurface Dressingluci99Noch keine Bewertungen

- Lec 17 Highway Engineering - Rigid Pavemen DesignDokument14 SeitenLec 17 Highway Engineering - Rigid Pavemen DesignDr Firas Asad80% (5)

- Geometric Design of Highway FacilitiesDokument10 SeitenGeometric Design of Highway Facilitiesanasalam100% (1)

- Geometrical Design of HighwayDokument65 SeitenGeometrical Design of Highwayjong LacNoch keine Bewertungen

- BFT 40503 Chapter 1Dokument25 SeitenBFT 40503 Chapter 1Marcelia NajaNoch keine Bewertungen

- 2014 (NCPTC) Performance History of Concrete Overlays in The United StatesDokument30 Seiten2014 (NCPTC) Performance History of Concrete Overlays in The United StatesTim LinNoch keine Bewertungen

- 7 - Flexible Pavement Design-Asphalt Institute MethodDokument68 Seiten7 - Flexible Pavement Design-Asphalt Institute MethodDaniel Mansilla100% (1)

- Surface DressingDokument34 SeitenSurface DressingNyangoe Joel100% (1)

- PAVEMENT DESIGN: Factors and ComponentsDokument18 SeitenPAVEMENT DESIGN: Factors and ComponentsMd ZeeshaanNoch keine Bewertungen

- 1 - 827 - ORN - 40 Axle Load Surveys and Traffic Counts For Traffic LoadingDokument76 Seiten1 - 827 - ORN - 40 Axle Load Surveys and Traffic Counts For Traffic LoadingHendhira Astianto100% (2)

- QA On Flexible and Rigid PavementsDokument219 SeitenQA On Flexible and Rigid PavementsRam Marathe100% (2)

- AASHTO Pavement DesignDokument6 SeitenAASHTO Pavement DesignAloysius G. LakeNoch keine Bewertungen

- Highway MaterialsDokument45 SeitenHighway Materialssyah123Noch keine Bewertungen

- Pavement Maintenance PDFDokument13 SeitenPavement Maintenance PDFKavi MaranNoch keine Bewertungen

- Pavement Deterioration and Its CausesDokument7 SeitenPavement Deterioration and Its Causesخيرالله موسى نوافNoch keine Bewertungen

- Types of Pavements Explained: Flexible vs RigidDokument17 SeitenTypes of Pavements Explained: Flexible vs RigidPereira KastroNoch keine Bewertungen

- Design of Flexible and Rigid Pavement: Parameters, Design Process and Comparison Using SoftwareDokument31 SeitenDesign of Flexible and Rigid Pavement: Parameters, Design Process and Comparison Using SoftwareSneh KhandelwalNoch keine Bewertungen

- Pothole CSIR Tech GuideDokument52 SeitenPothole CSIR Tech GuideMamphot100% (2)

- GEOMETRIC DESIGN OF ROADSDokument181 SeitenGEOMETRIC DESIGN OF ROADSAshutosh Maurya100% (2)

- Unit 7 (CONSTRUCTION OF RIGID/CONCRETE PAVEMENT)Dokument29 SeitenUnit 7 (CONSTRUCTION OF RIGID/CONCRETE PAVEMENT)Zara Nabilah76% (33)

- Bituminous Mix Design & Superpave MixesDokument53 SeitenBituminous Mix Design & Superpave Mixesjaffna100% (9)

- Tanzania Pavement & Materials Design Manual 1999 Chapter 5 - SubgradeDokument10 SeitenTanzania Pavement & Materials Design Manual 1999 Chapter 5 - SubgradeGiora Rozmarin100% (1)

- Pavement DesignDokument43 SeitenPavement DesignAbinash Mallick100% (3)

- High-Type Bituminous Pavements: Dr. Taleb M. Al-RousanDokument67 SeitenHigh-Type Bituminous Pavements: Dr. Taleb M. Al-RousanSaurav BhattacharjeeNoch keine Bewertungen

- Asphaltic MixturesDokument30 SeitenAsphaltic MixturesFlorin MatisNoch keine Bewertungen

- Hot-Mix Asphalt DesignDokument67 SeitenHot-Mix Asphalt DesignesprindiaNoch keine Bewertungen

- JSTU civil engineering student's Marshall mix design experimentDokument20 SeitenJSTU civil engineering student's Marshall mix design experimentali100% (1)

- Asphalt - Hot Mix Design - MarshallDokument61 SeitenAsphalt - Hot Mix Design - MarshallMizanul Hoque100% (1)

- Department of Civil and Environmental Engineering, School of Engineering Cedat, Makerere UniversityDokument50 SeitenDepartment of Civil and Environmental Engineering, School of Engineering Cedat, Makerere UniversityBAMSNoch keine Bewertungen

- Marshall Mix Design ReportDokument8 SeitenMarshall Mix Design ReportRana Abdelbaset BostanjiNoch keine Bewertungen

- 19-20 Lec 01 Traffic Engineering - Highway Classification and Vehicle CharacteristicsDokument34 Seiten19-20 Lec 01 Traffic Engineering - Highway Classification and Vehicle CharacteristicsDr Firas AsadNoch keine Bewertungen

- 19-20 Lec 02 Traffic Engineering - Traffic Volume StudiesDokument41 Seiten19-20 Lec 02 Traffic Engineering - Traffic Volume StudiesDr Firas Asad100% (1)

- Data and Research MethodologyDokument20 SeitenData and Research MethodologyDr Firas AsadNoch keine Bewertungen

- Lec 08 Microscopic Flow CharacteristicsDokument10 SeitenLec 08 Microscopic Flow CharacteristicsDr Firas Asad100% (1)

- Impacts of Driver's Socio-Demographic Attributes On Road Sign Cognition: Evidence From IraqDokument6 SeitenImpacts of Driver's Socio-Demographic Attributes On Road Sign Cognition: Evidence From IraqDr Firas AsadNoch keine Bewertungen

- Lec 07 Traffic Accidents PDFDokument10 SeitenLec 07 Traffic Accidents PDFDr Firas AsadNoch keine Bewertungen

- Travel Behaviour Analysis Using Scottish Household Survey Data SetDokument62 SeitenTravel Behaviour Analysis Using Scottish Household Survey Data SetDr Firas AsadNoch keine Bewertungen

- Nonlinear Regression - MS ExcelDokument9 SeitenNonlinear Regression - MS ExcelDr Firas AsadNoch keine Bewertungen

- Travel Behaviour Analysis Using Manchester City Centre Household Travel Survey DataDokument82 SeitenTravel Behaviour Analysis Using Manchester City Centre Household Travel Survey DataDr Firas AsadNoch keine Bewertungen

- Travel Pattern Analysis Using TRICS DatabaseDokument75 SeitenTravel Pattern Analysis Using TRICS DatabaseDr Firas AsadNoch keine Bewertungen

- Travel Behaviour, Regeneration and Planning PolicyDokument49 SeitenTravel Behaviour, Regeneration and Planning PolicyDr Firas AsadNoch keine Bewertungen

- City Centres Renaissance and Travel BehaviourDokument27 SeitenCity Centres Renaissance and Travel BehaviourDr Firas AsadNoch keine Bewertungen

- Grade Separated Intersections ﺓﺮـــــــــــــــﺴﺠﻤﻟﺍ ﺕﺎﻌﻁﺎﻘﺘﻟﺍDokument10 SeitenGrade Separated Intersections ﺓﺮـــــــــــــــﺴﺠﻤﻟﺍ ﺕﺎﻌﻁﺎﻘﺘﻟﺍDr Firas Asad100% (2)

- Lec 02 Intersection DesignDokument18 SeitenLec 02 Intersection DesignDr Firas Asad100% (4)

- Lec 03 Intersection ControlDokument18 SeitenLec 03 Intersection ControlDr Firas Asad100% (2)

- Lec 01 Traffic Time and Delays StudiesDokument10 SeitenLec 01 Traffic Time and Delays StudiesDr Firas Asad100% (2)

- Lec 04 Traffic Signal and CoordinationDokument17 SeitenLec 04 Traffic Signal and CoordinationDr Firas Asad100% (1)

- Lec 00 Traffic Engineering - Opening and SyllabusDokument10 SeitenLec 00 Traffic Engineering - Opening and SyllabusDr Firas Asad100% (3)

- Lec 17 Highway Engineering - Rigid Pavemen DesignDokument14 SeitenLec 17 Highway Engineering - Rigid Pavemen DesignDr Firas Asad80% (5)

- Lec 16 Highway Engineering - Flexible Pavemen DesignDokument25 SeitenLec 16 Highway Engineering - Flexible Pavemen DesignDr Firas Asad100% (2)

- Lec 09 Highway Engineering - Earthworks & Mass Haul DiagramDokument20 SeitenLec 09 Highway Engineering - Earthworks & Mass Haul DiagramDr Firas Asad92% (26)

- Lec 14 Highway Engineering - Asphalt Types Tests and SpecificationsDokument18 SeitenLec 14 Highway Engineering - Asphalt Types Tests and SpecificationsDr Firas Asad100% (2)

- Lec 10 11 Highway Engineering - Soil Classification and CompactionDokument7 SeitenLec 10 11 Highway Engineering - Soil Classification and CompactionDr Firas Asad100% (2)

- Lec 06 Highway Engineering - Vertical AlignmentDokument20 SeitenLec 06 Highway Engineering - Vertical AlignmentDr Firas Asad100% (3)

- Lec 08 Highway Engineering - Cross Section ElementsDokument15 SeitenLec 08 Highway Engineering - Cross Section ElementsDr Firas Asad81% (16)

- Transportation, Spreading, Compaction and Finishing:: Plants, Equipment and Machinery For Wet Mix MacadamDokument6 SeitenTransportation, Spreading, Compaction and Finishing:: Plants, Equipment and Machinery For Wet Mix MacadamRAMPALLI GATTAIAHNoch keine Bewertungen

- Pavement Distress: Standard Terminology Relating ToDokument3 SeitenPavement Distress: Standard Terminology Relating ToEric GozzerNoch keine Bewertungen

- TRH 21Dokument49 SeitenTRH 21AnantNoch keine Bewertungen

- Concrete pipe culvert construction detailsDokument1 SeiteConcrete pipe culvert construction detailsyetiNoch keine Bewertungen

- C 20220628 Parbhani DPR DrawingsDokument62 SeitenC 20220628 Parbhani DPR DrawingsPrabaldeep GautamNoch keine Bewertungen

- A Mini Project On Bituminous Road LayersDokument20 SeitenA Mini Project On Bituminous Road Layersapi-1988935887% (39)

- POW - Road Reconstruction Including DrainageDokument3 SeitenPOW - Road Reconstruction Including DrainageJoseph MontalesNoch keine Bewertungen

- Maintenance of Roads in Pakistan IEP CPD 170312Dokument108 SeitenMaintenance of Roads in Pakistan IEP CPD 170312MuhammadIqbalMughalNoch keine Bewertungen

- Lesson Plan - CEG552 Laboratory - Sept2019-Jan2020Dokument3 SeitenLesson Plan - CEG552 Laboratory - Sept2019-Jan2020dzikrydsNoch keine Bewertungen

- Design Tables For Flexible PavementDokument11 SeitenDesign Tables For Flexible PavementAshebirNoch keine Bewertungen

- Laporan Harian Asbuton 04 Agustus 2023 IIDokument22 SeitenLaporan Harian Asbuton 04 Agustus 2023 IItoshiba devedoNoch keine Bewertungen

- Img 0011Dokument2 SeitenImg 0011Muhammad AzriNoch keine Bewertungen

- Introduction To Pavment and Types of PavmentsDokument24 SeitenIntroduction To Pavment and Types of PavmentsMehroz BalochNoch keine Bewertungen

- 3 1 Seminar DR - Kasahara RAP-4 PDFDokument18 Seiten3 1 Seminar DR - Kasahara RAP-4 PDFAnggun PratamiNoch keine Bewertungen

- Commercial & Designer Paving BrochureDokument20 SeitenCommercial & Designer Paving BrochuredantranzNoch keine Bewertungen

- Test Results of Bitumen Content Gradation Determination of Dense Graded Bituminous MacadamDokument25 SeitenTest Results of Bitumen Content Gradation Determination of Dense Graded Bituminous MacadamabualamalNoch keine Bewertungen

- CMT Plate No. 1 BitumenDokument1 SeiteCMT Plate No. 1 Bitumenriclear ramosNoch keine Bewertungen

- Design, Construction & Maintenance of Flexible PavementDokument3 SeitenDesign, Construction & Maintenance of Flexible PavementNitish GuptaNoch keine Bewertungen

- Unit V Evaluation and Maintenance of Pavements 8Dokument7 SeitenUnit V Evaluation and Maintenance of Pavements 8Rajha RajeswaranNoch keine Bewertungen

- Cvs 02350Dokument14 SeitenCvs 02350WNoch keine Bewertungen

- Vol 2 FinalDokument434 SeitenVol 2 FinalSunil ShindekarNoch keine Bewertungen

- GROUP 6 PCI Test PROJECTDokument50 SeitenGROUP 6 PCI Test PROJECTSIDI ISKANDARNoch keine Bewertungen

- AGPT04B 14 - Guide To Pavement Technology Part 4BDokument149 SeitenAGPT04B 14 - Guide To Pavement Technology Part 4BA. S. M. Elias ShahNoch keine Bewertungen

- Hire Charge of Equipment and MachineryDokument8 SeitenHire Charge of Equipment and Machinerymohammed nusrot hossanNoch keine Bewertungen

- EAPA - Asphalt in Figures 2014Dokument9 SeitenEAPA - Asphalt in Figures 2014Xavi Planas WillisNoch keine Bewertungen

- Chapter 5 - Flexible and Composite Pavements Final (Individual Narrative Reports)Dokument30 SeitenChapter 5 - Flexible and Composite Pavements Final (Individual Narrative Reports)Frederick AgliamNoch keine Bewertungen

- MVGR College of Engineering road works abstractDokument112 SeitenMVGR College of Engineering road works abstractAnonymous ImoZI0363Noch keine Bewertungen

- Swa HPSD 10122023Dokument66 SeitenSwa HPSD 10122023ken peligrinoNoch keine Bewertungen