Beruflich Dokumente

Kultur Dokumente

Sihi Pompa LPG API 610

Hochgeladen von

Andry RimanovOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sihi Pompa LPG API 610

Hochgeladen von

Andry RimanovCopyright:

Verfügbare Formate

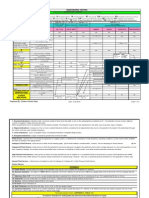

Statement

SIHI LPG pump

compare to

API 610 - pumps

API 610 is American standard mainly for refineries to handle liquid hydrocarbon, LPG in a liquefied gas and it need to be

to consider all special physical conditions of this liquid.

Special features of the liquid gas pumps:

Liquid gas is not a liquid in the usual sense, but rather a liquefied gas under pressure. This fact is especially

important for a true liquid gas pump. Even small changes in temperature can cause the formation of gas,

resulting in significant process problems and increased wear of the pump. Specially developed hydraulics for

this area of application can prevent internal out gassing and therefore increased wear from dry running.

Requirements of a real liquid gas pump:

1. High pressure rise

2. Mix flow rate

3. Gas flow rate

4. Low NPSH values

Special for LPG API 610 pumps has following disadvantages:

API 610 pumps are single stage volute casing pumps which are able to handle not more than 7% gas without

hydraulic collapses. This is not enough for real LPG pumps.

The high peripheral speed create a 3 to 4 times higher NPSHR

The single stage design is a low efficiency for low flow and high head.

24 h continue operation at 50C environment temperature is not possible, internal evaporation.

High vibration, high notice.

Sterling LPG pumps CEH, CEB, SC and UEA :

This multistage Sterling SIHI-pumps type CEH, CEB, SC and UEA are designed especially for LPG and

consider all special physical conditions. Side channel stages can handle gas up to 100%.

In CEH, CEB and SC a special for low NPSHA developed prim impeller in combination with multistage side

channel stages.

For flow rates more than 35 m3/h a combination of three different hydraulics systems, prime impeller, multistage

centrifugal stages together with a gas handling side channel stage gave all necessary characteristics for a real

LPG pump.

This pumps are used world wide more than 30 years with excellent experience in this LPG application.

The pumps are in different cases certificated to:

ATEX 94/9/EG

UL 51 U.S.

Stroomwezer Netherland

GOST Russia

Department of Explosive in India

TRB 801 Germany

( H. Mollenhauer )

LPG Market Manager

SIC / Sterling Fluid Systems- France

23.04.05

Das könnte Ihnen auch gefallen

- Pumpapi675presentation 150805065440 Lva1 App6891 PDFDokument42 SeitenPumpapi675presentation 150805065440 Lva1 App6891 PDFsanthoshkumarplNoch keine Bewertungen

- LPG Pump IOM LGL2 LGL3 PDFDokument12 SeitenLPG Pump IOM LGL2 LGL3 PDFAfani Roma A100% (1)

- Reciprocating Pumps - NDPDDokument2 SeitenReciprocating Pumps - NDPDDhanny MiharjaNoch keine Bewertungen

- 010 - Denison Control Valve 3-EN2400-ADokument15 Seiten010 - Denison Control Valve 3-EN2400-Agustavo aguilarNoch keine Bewertungen

- Circulating Pumps GuideDokument3 SeitenCirculating Pumps GuideBpNoch keine Bewertungen

- Alfa LavalDokument24 SeitenAlfa Lavaldroid11Noch keine Bewertungen

- Triplex Reciprocating Plunger Pumps Acc - API-674 (ISO-13710) : The Power of Proven TechnologyDokument4 SeitenTriplex Reciprocating Plunger Pumps Acc - API-674 (ISO-13710) : The Power of Proven Technologytahera aqeelNoch keine Bewertungen

- Gas Jet Pump Paper Oct03 Ipa03 e 059Dokument11 SeitenGas Jet Pump Paper Oct03 Ipa03 e 059kglorstadNoch keine Bewertungen

- Fives Cryogenics DELTA N BrochureDokument2 SeitenFives Cryogenics DELTA N BrochureAhmed BenjellounNoch keine Bewertungen

- Rotan Internal Gear Pumps: Desmi IncDokument14 SeitenRotan Internal Gear Pumps: Desmi IncVijay BhureNoch keine Bewertungen

- LEWA Katalog ProizvodaDokument12 SeitenLEWA Katalog ProizvodaAnonymous ItzBhUGoiNoch keine Bewertungen

- Pump Types Guide - Find the right pump for the jobDokument6 SeitenPump Types Guide - Find the right pump for the jobEnvergyProjectsNoch keine Bewertungen

- Spec For Rim Seal Fire Protection SystemDokument5 SeitenSpec For Rim Seal Fire Protection Systemshashi ranjanNoch keine Bewertungen

- Quick-Opening Closures SurveyDokument13 SeitenQuick-Opening Closures SurveyAjmi HmidaNoch keine Bewertungen

- Hlep / Vsax: High Performance Cryogenic Reciprocating PumpsDokument4 SeitenHlep / Vsax: High Performance Cryogenic Reciprocating Pumpsbarun1977Noch keine Bewertungen

- AED Design Requirements - Jockey Pumps - Mar09Dokument5 SeitenAED Design Requirements - Jockey Pumps - Mar09rogel_gana100% (1)

- Bornemann MultiphaseDokument24 SeitenBornemann MultiphaseReza Ghanavati100% (1)

- General Valve 4wayDokument12 SeitenGeneral Valve 4wayMargaret DaughertyNoch keine Bewertungen

- Check ValvesDokument17 SeitenCheck ValvesGerance Instruccion Piping100% (2)

- System OneDokument4 SeitenSystem OnerasottoNoch keine Bewertungen

- Compressor Systems Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDokument25 SeitenCompressor Systems Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignJNoch keine Bewertungen

- Mantenimiento SruDokument22 SeitenMantenimiento SruDaineris HernandezNoch keine Bewertungen

- VSD Affinity Laws and ApplicationsDokument32 SeitenVSD Affinity Laws and Applicationsram_river808100% (2)

- Safety in Oil Movement & Storage Operations: Reliance JamnagarDokument55 SeitenSafety in Oil Movement & Storage Operations: Reliance JamnagarVELNoch keine Bewertungen

- Pump DecokingDokument8 SeitenPump Decokingrohl55Noch keine Bewertungen

- BFP ARC Valve FunctionDokument6 SeitenBFP ARC Valve FunctionVenkat ShanNoch keine Bewertungen

- HPX Oh2 Api610 New enDokument8 SeitenHPX Oh2 Api610 New enAlexander RivillasNoch keine Bewertungen

- Choosing the Right Vane Pump for Your ProcessDokument25 SeitenChoosing the Right Vane Pump for Your ProcessGirlish JackieNoch keine Bewertungen

- Knife Gate ValveDokument7 SeitenKnife Gate ValveAbdul RaheemNoch keine Bewertungen

- Globe Valve Bs 1873 and Api 602: ASME B16.10Dokument7 SeitenGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNoch keine Bewertungen

- 120 Inch Fore Pump and Worm Oil Pump ADokument12 Seiten120 Inch Fore Pump and Worm Oil Pump AcarlosorizabaNoch keine Bewertungen

- Ebara Cryo BrochureDokument20 SeitenEbara Cryo BrochuremishraenggNoch keine Bewertungen

- Day2 1105 Decker Liquid-Hydrogen-Distribution-Technology LindeDokument27 SeitenDay2 1105 Decker Liquid-Hydrogen-Distribution-Technology Lindeahmed hamdyNoch keine Bewertungen

- Design Gas LiftDokument5 SeitenDesign Gas LiftRima Apriani JamilahNoch keine Bewertungen

- Guidance On The Safe Operation of Vacuum Insulated Storage Tank-BOCDokument26 SeitenGuidance On The Safe Operation of Vacuum Insulated Storage Tank-BOCchem_taNoch keine Bewertungen

- Multiphase - Pumps - Axel CalgaryDokument45 SeitenMultiphase - Pumps - Axel CalgaryAlberto Enrique De Santa Anna CampderáNoch keine Bewertungen

- Measure Flow with Orifice PlatesDokument18 SeitenMeasure Flow with Orifice PlatesJhon AlfonsoNoch keine Bewertungen

- Gas Treatment SLDokument68 SeitenGas Treatment SLwahyuriansyahNoch keine Bewertungen

- Harmony Booster Pump Operating ProcedureDokument2 SeitenHarmony Booster Pump Operating ProcedureDonNoch keine Bewertungen

- ZEO Brochure Final 3 16Dokument5 SeitenZEO Brochure Final 3 16Santiago Cabarcas L. de UrquizoNoch keine Bewertungen

- 2013 LNG FSRU FPSO Pump Considerations For Ship Motion AIChE Spring G.woodDokument15 Seiten2013 LNG FSRU FPSO Pump Considerations For Ship Motion AIChE Spring G.woodjbloggs2007Noch keine Bewertungen

- Datasheet-Process CompressorDokument1 SeiteDatasheet-Process CompressorZaw Htet WinNoch keine Bewertungen

- 10 Petalas AzizDokument7 Seiten10 Petalas AzizAnonymous f01BFKq100% (1)

- Pa 180010Dokument6 SeitenPa 180010Trịnh Đức HạnhNoch keine Bewertungen

- Pump HandbookDokument19 SeitenPump HandbookSuranga GayanNoch keine Bewertungen

- Environmental Protection TechnologiesDokument4 SeitenEnvironmental Protection TechnologiesKostyantyn DrobotNoch keine Bewertungen

- Mihir's Handbook Chapter 7Dokument10 SeitenMihir's Handbook Chapter 7heyheyNoch keine Bewertungen

- Prince Rupert Natural Gas Transmission Compressor Station Basics Factsheet TranscanadaDokument2 SeitenPrince Rupert Natural Gas Transmission Compressor Station Basics Factsheet TranscanadaShaho Abdulqader MohamedaliNoch keine Bewertungen

- High-Pressure Polymer PumpDokument5 SeitenHigh-Pressure Polymer Pumpy.s.6saputroNoch keine Bewertungen

- Blackmer Autogas HandbookDokument32 SeitenBlackmer Autogas HandbookMuhammad ImranNoch keine Bewertungen

- Datasheet Selenoid ValveDokument31 SeitenDatasheet Selenoid ValveIccank NdutNoch keine Bewertungen

- Screw Pump HC 232 - 80/2 / N: 1.0 Project DataDokument1 SeiteScrew Pump HC 232 - 80/2 / N: 1.0 Project DataBenicio Joaquín Ferrero BrebesNoch keine Bewertungen

- Vanzetti Cryogenic Pumps & Technology GuideDokument0 SeitenVanzetti Cryogenic Pumps & Technology GuidekanchanabalajiNoch keine Bewertungen

- Blackmer Positive Displacement Pump For Liquefied Gas ApplicationsDokument20 SeitenBlackmer Positive Displacement Pump For Liquefied Gas ApplicationsDaniel Leal Pintor100% (1)

- Control Valves PDFDokument6 SeitenControl Valves PDFIlham Bayu TiasmoroNoch keine Bewertungen

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryVon EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Profile of the International Pump Industry: Market Prospects to 2010Von EverandProfile of the International Pump Industry: Market Prospects to 2010Bewertung: 1 von 5 Sternen1/5 (1)

- Can KDokument12 SeitenCan KSergio RinconNoch keine Bewertungen

- Rotary PumpsDokument31 SeitenRotary PumpsalbertNoch keine Bewertungen

- Borne Man NSL HenDokument8 SeitenBorne Man NSL HensSteven Sa0% (1)

- 013-Ansi Vs API PumpsDokument6 Seiten013-Ansi Vs API Pumpsrtorabi80Noch keine Bewertungen

- API 650 & 653 Questions Closed Book With AnswersDokument7 SeitenAPI 650 & 653 Questions Closed Book With AnswersRajesh Narula100% (6)

- PR PipePatrol OilReview Africa LoResDokument2 SeitenPR PipePatrol OilReview Africa LoResAndry RimanovNoch keine Bewertungen

- Repair Leaking AST Roofs OnlineDokument6 SeitenRepair Leaking AST Roofs OnlineAndry RimanovNoch keine Bewertungen

- AB-522 Standard Pneumatic Test Procedure RequirementsDokument16 SeitenAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerNoch keine Bewertungen

- Insulating Flange Kits DatasheetDokument4 SeitenInsulating Flange Kits DatasheetAndry RimanovNoch keine Bewertungen

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Dokument2 SeitenWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- RT Acceptance CriteriaDokument3 SeitenRT Acceptance CriteriaAndry Rimanov89% (18)

- C-D Nozzle ExperimentDokument3 SeitenC-D Nozzle ExperimentKarthick MurugesanNoch keine Bewertungen

- Terminology For Mechanical PropertiesDokument75 SeitenTerminology For Mechanical PropertiesibrahimNoch keine Bewertungen

- Khomskii Physics (2009) PDFDokument8 SeitenKhomskii Physics (2009) PDFRogerNoch keine Bewertungen

- Hastelloy C 22 & C 276 Alloys in Saturated Wet ChlorineDokument2 SeitenHastelloy C 22 & C 276 Alloys in Saturated Wet ChlorinewateverwongNoch keine Bewertungen

- Lesson 5Dokument3 SeitenLesson 5Jerico Moreno FernandoNoch keine Bewertungen

- Recommended suction flow velocity for boiling fluids to prevent cavitationDokument4 SeitenRecommended suction flow velocity for boiling fluids to prevent cavitationCeyhan PolatNoch keine Bewertungen

- Reciprocating Pump Lab ExperimentDokument3 SeitenReciprocating Pump Lab ExperimentParth BisenNoch keine Bewertungen

- States of Matter - Charles GuiangDokument6 SeitenStates of Matter - Charles Guiangguiang.michaelaNoch keine Bewertungen

- 2nd AssignmentDokument1 Seite2nd AssignmentM Helmy AdityaNoch keine Bewertungen

- 3 - Fluid Kinemetics PDFDokument3 Seiten3 - Fluid Kinemetics PDFPrabhat PiyushNoch keine Bewertungen

- Excel BasedDokument24 SeitenExcel Basedelha e. maruquinNoch keine Bewertungen

- ASME Code Pressure Tests Cryogenic VesselsDokument3 SeitenASME Code Pressure Tests Cryogenic VesselsAngga100% (1)

- 2nd PU-coordination CompoundsDokument10 Seiten2nd PU-coordination CompoundsMeith DevadigaNoch keine Bewertungen

- Pressure WsDokument3 SeitenPressure WsHi everyoneNoch keine Bewertungen

- Boiler Fuel Firing SystemDokument44 SeitenBoiler Fuel Firing Systemrashm006ranjanNoch keine Bewertungen

- Atmosphere Pressure & Temperature ExplainedDokument3 SeitenAtmosphere Pressure & Temperature ExplainedPravin HandeNoch keine Bewertungen

- Water Content of High Pressure Natural GasDokument43 SeitenWater Content of High Pressure Natural Gasfarshidian100% (1)

- Process Design Basis: LPG Train-4 Project at MAA RefineryDokument42 SeitenProcess Design Basis: LPG Train-4 Project at MAA RefineryVenkat RanganNoch keine Bewertungen

- Gas Laws Homework IIDokument4 SeitenGas Laws Homework IIchpwalker100% (2)

- Liquid Ring Vacuum Pump Guide for Maximized EfficiencyDokument12 SeitenLiquid Ring Vacuum Pump Guide for Maximized EfficiencyTrần Phước TrungNoch keine Bewertungen

- Evaporation-An IntroductionDokument23 SeitenEvaporation-An IntroductionKusmakarNoch keine Bewertungen

- BP Process Safety Series - Safe Handling of Light EndsDokument100 SeitenBP Process Safety Series - Safe Handling of Light EndsLau Zam100% (11)

- Carga Refrigerante R22Dokument1 SeiteCarga Refrigerante R22FernandoNoch keine Bewertungen

- 3osons: Anc. 3ose Ensates'Dokument11 Seiten3osons: Anc. 3ose Ensates'Subhajit SarkarNoch keine Bewertungen

- SiC Epitaxy WaferDokument2 SeitenSiC Epitaxy Waferdolon royNoch keine Bewertungen

- Amada Laser Cutting Condition Tab: Material Nam File NameDokument2 SeitenAmada Laser Cutting Condition Tab: Material Nam File NameXuan Phuong HuynhNoch keine Bewertungen

- Technical Reference Guide On Steam DistributionDokument66 SeitenTechnical Reference Guide On Steam DistributionDainycious KibiwottNoch keine Bewertungen

- Fluid Friction in Steady One Dimensional FlowDokument38 SeitenFluid Friction in Steady One Dimensional FlowAlna LiviaNoch keine Bewertungen

- Hypothetical Process PathsDokument9 SeitenHypothetical Process Pathsifiok100% (1)

- Tugas 2 SINPRODokument5 SeitenTugas 2 SINPROcitra maharaniNoch keine Bewertungen