Beruflich Dokumente

Kultur Dokumente

E7618M-H4 Data Sheet

Hochgeladen von

Trương ĐịnhOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

E7618M-H4 Data Sheet

Hochgeladen von

Trương ĐịnhCopyright:

Verfügbare Formate

HIGH STRENGTH BASIC ELECTRODE

Conarc 80

CLASSIFICATION

AWS A5.5

EN 757

: E11018M-H4

: E 69 5 Z B 32 H5

GENERAL DESCRIPTION

Basic all position extremely low hydrogen electrode

Weldable on AC and DC

110 - 115% recovery

Good impact values down to -51C

Meets the requirements of military specifications

Suitable for welding submarines high strength steels (UTS up to 800 N/mm2)

Also available in vacuum sealed Sahara ReadyPack(SRP): HDM< 3 ml/100g

WELDING POSITIONS

CURRENT TYPE

AC / DC +/-

ISO/ASME

PA/1G

PB/2F

PF/3Gu

PC/2G

PE/4G

PH/5Gu

APPROVALS

ABS

LR

4Y69H5

CHEMICAL COMPOSITION (W%), TYPICAL, ALL WELD METAL

C

Mn

Si

Ni

Mo

HDM

0.06

1.5

0.4

0.015

0.01

2.2

0.4

2 ml/100 g

MECHANICAL PROPERTIES, TYPICAL, ALL WELD METAL

Required: AWS A5.5

EN 757

Typical values

Condition

0.2% Proof

strength

(N/mm2)

Tensile

strength

(N/mm2)

Elongation

(%)

AW

680-760*

min. 690

750

min. 760

760-960

785

min. 20

min. 17

22

Impact ISO-V(J)

-40C

-50C

100

min. 47

80

-51C

min. 27

80

* Diam.2.5 max.795 N/mm2

SR:14h/620C

PACKAGING AND AVAILABLE SIZES

Diameter (mm)

Length (mm)

2.5

350

3.2

350

4.0

350

5.0

450

Unit: carton box

Pieces / unit

Net weight/unit (kg)

225

4.4

120

4.5

90

5.0

60

6.3

Unit: SRP

Pieces / unit

Net weight/unit (kg)

70

1.4

50

1.9

28

1.5

23

2.5

Identification

Imprint: 11018-M / CONARC 80

Tip Color: gold

All information in this data sheet is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.eu for any udpated information.

Fumes: Material Safety Data Sheets (MSDS) are available on our website.

Conarc 80: rev. EN 24

HIGH STRENGTH BASIC ELECTRODE

Conarc 80

EXAMPLES OF MATERIALS TO BE WELDED

Steel grades/Code

Type

Pipe material

API 5LX

Fine grained steels

EN 10025 part 6

X70, X75

S620, S690

Root runs and fillet welds in S890

CALCULATION DATA

Sizes

Diam. x length Current range

(mm)

(A)

2.5x350

60-80

3.2x350

80-130

4.0x350

120-180

5.0x450

160-240

Current

type

DC+

DC+

DC+

DC+

Arc time

Energy

Dep. rate

- per electrode at max. current (S)*

E(kJ)

H(kg/h)

55

99

0.8

78

261

1.1

75

356

1.6

116

627

2.3

Weight/

1000 pcs

(kg)

19.5

36.5

53.2

105.1

*Stub end 35mm

WELDING PARAMETERS, OPTIMUM FILL PASSES

Diameter

(mm)

2.5

3.2

4.0

5.0

PA/1G

75A

130A

145A

225A

PB/2F

75A

120A

145A

230A

Welding positions

PC/2G

PF/3Gup

75A

80A

135A

120A

155A

140A

210A

REMARKS / APPLICATION ADVICE

Electrodes after removal from cardboard boxes redry 2-4h 350 25C

www.lincolnelectric.eu

PE/4G

75A

115A

140A

PH/5Gup

80A

120A

140A

Electrodes/

kg weld- kg electrodes/

metal

kg weldmetal

B

1/N

82

1.61

43

1.55

30

1.59

14

1.45

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Scheduling ModelsDokument103 SeitenScheduling ModelsMCA DepartmentNoch keine Bewertungen

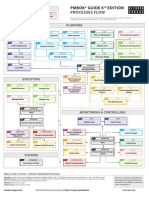

- Ricardo Vargas Simplified Pmbok Flow 6ed Color En-A3Dokument1 SeiteRicardo Vargas Simplified Pmbok Flow 6ed Color En-A3Hero Sa Mac100% (1)

- Tuyen Dung San Bay Long ThanhDokument9 SeitenTuyen Dung San Bay Long ThanhTrương ĐịnhNoch keine Bewertungen

- Welding Safety Kemp Rev909Dokument64 SeitenWelding Safety Kemp Rev909Mohammad AshpakNoch keine Bewertungen

- Sonoff Nspanel-Us Ce LVD Safety En62368 Test ReportDokument70 SeitenSonoff Nspanel-Us Ce LVD Safety En62368 Test ReportTrương ĐịnhNoch keine Bewertungen

- Franklin Steel Stock Book PDFDokument66 SeitenFranklin Steel Stock Book PDFMichael BatleyNoch keine Bewertungen

- Xintai Valve Group LTD, CO. Product CatalogueDokument79 SeitenXintai Valve Group LTD, CO. Product CatalogueTrương ĐịnhNoch keine Bewertungen

- Project Cost ManagementDokument33 SeitenProject Cost ManagementwossenNoch keine Bewertungen

- Psma62368 12017june7finDokument58 SeitenPsma62368 12017june7finTrương ĐịnhNoch keine Bewertungen

- Hot Work-Weld-Braz-Cut-L&I v1Dokument32 SeitenHot Work-Weld-Braz-Cut-L&I v1ghada gattouchNoch keine Bewertungen

- Annual Safety TrainingDokument32 SeitenAnnual Safety TrainingTrương ĐịnhNoch keine Bewertungen

- Info Iec62368-1 (Ed3.0) BDokument89 SeitenInfo Iec62368-1 (Ed3.0) BKunal RajaNoch keine Bewertungen

- PMP, Sixth EditionDokument38 SeitenPMP, Sixth EditionTrương ĐịnhNoch keine Bewertungen

- Cost ManagementDokument18 SeitenCost ManagementasdkjfNoch keine Bewertungen

- Franklin Steel Stock Book PDFDokument66 SeitenFranklin Steel Stock Book PDFMichael BatleyNoch keine Bewertungen

- Franklin Steel Stock Book PDFDokument66 SeitenFranklin Steel Stock Book PDFMichael BatleyNoch keine Bewertungen

- Project Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 4 Slide 1Dokument37 SeitenProject Management: ©ian Sommerville 2000 Software Engineering, 6th Edition. Chapter 4 Slide 1Trương ĐịnhNoch keine Bewertungen

- Wevj 09 00022Dokument13 SeitenWevj 09 00022adityaNoch keine Bewertungen

- S420MC RDokument1 SeiteS420MC RTrương ĐịnhNoch keine Bewertungen

- 7.4.20 - Aluminum Welding and Anodizing Proposal PDFDokument62 Seiten7.4.20 - Aluminum Welding and Anodizing Proposal PDFTrương ĐịnhNoch keine Bewertungen

- Q345D RDokument1 SeiteQ345D RTrương ĐịnhNoch keine Bewertungen

- Chuyen Con KienDokument25 SeitenChuyen Con KienTrương ĐịnhNoch keine Bewertungen

- S550MC RDokument1 SeiteS550MC RTrương ĐịnhNoch keine Bewertungen

- PMP Exam Formulas Summary: Earned Value Management Name Abbr. Formula NoteDokument6 SeitenPMP Exam Formulas Summary: Earned Value Management Name Abbr. Formula NoteTrương ĐịnhNoch keine Bewertungen

- G-Force Brochure PDFDokument20 SeitenG-Force Brochure PDFTrương ĐịnhNoch keine Bewertungen

- National Standards of The People's Republic of China: GB XXXXDokument25 SeitenNational Standards of The People's Republic of China: GB XXXXTrương ĐịnhNoch keine Bewertungen

- LN-25 ProDokument4 SeitenLN-25 ProTrương ĐịnhNoch keine Bewertungen

- MAESTRO ALIGNMENT PROCEDURE Take TwoDokument9 SeitenMAESTRO ALIGNMENT PROCEDURE Take TwoTrương ĐịnhNoch keine Bewertungen

- MAESTRO ALIGNMENT PROCEDURE Take TwoDokument9 SeitenMAESTRO ALIGNMENT PROCEDURE Take TwoTrương ĐịnhNoch keine Bewertungen