Beruflich Dokumente

Kultur Dokumente

Specifications For Ss Welding Rods: Electrodes: - Description & Intended Use of Filler Material. E 209

Hochgeladen von

Vinu RaveendranOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Specifications For Ss Welding Rods: Electrodes: - Description & Intended Use of Filler Material. E 209

Hochgeladen von

Vinu RaveendranCopyright:

Verfügbare Formate

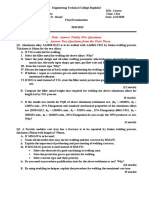

SPECIFICATIONS FOR SS WELDING RODS

1. Chromium content of weld metal deposited by these electrodes are not less than 10.5%.

2. For groove weld test assemblies:

a. Welding should be done in flat positions.

b. The test plate should not wrap more than 5 degree .If distorted more than 5deg. Then the weld plate

shall be discarded & should not be straightened.

3. For fillet weld test assemblies:

a. One edge of the Vertical plate (web) shall be machined throughout the length, so that the contact b/w

both the plate is proper.

b. When welding in the vertical position, the welding shall progress upwards.

c. After welding on one side the jt., the assembly shall be cooled upto 16oc by any means and then to be

welded on other side of the joint.

Electrodes: - Description & intended use of filler material.

E 209:

Chemical composition: 22 Cr, 11 Ni, 5.5 Mn, 2 Mo, 0.20 N.

Base metal: TYPE AISI 209.

Nitrogen strengthened austenitic stainless steel provides high strength and good

toughness over a wide range of temperatures.

Nitrogen alloying reduces the intergranular carbide precipitation in the weld area by

inhibiting carbon diffusion preventing intergranular corrosion.

Nitrogen alloying coupled with molybdenum provides superior resistance to pitting

& in service corrosion in aqueous chloride containing media.

This electrode can be used for joining dissimilar metals like Mild steel and stainless

steel. & also for direct overlay on MS.

E 219:

Chemical composition: 20 Cr, 6 Ni, 9 Mn, and 0.20 N.

Base Metal: AISI TYPE 219. Same as E 209.

1

D:\SELVA.S-Inspection\SS Electrodes(SMAW).doc

Das könnte Ihnen auch gefallen

- Fusion WeldingDokument31 SeitenFusion WeldingjaffnaNoch keine Bewertungen

- Bolted Aluminium Terminal Connectors For Substations: Material of CastingsDokument5 SeitenBolted Aluminium Terminal Connectors For Substations: Material of CastingsTravis WoodNoch keine Bewertungen

- 2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsDokument9 Seiten2062: Hot Rolled Medium and High Tensile Structural Steel - SpecificationsKapa SandeepNoch keine Bewertungen

- Knowladge Question CSWIP 3.1Dokument25 SeitenKnowladge Question CSWIP 3.1larusi100% (5)

- Question 1Dokument27 SeitenQuestion 1Rammer PakpahanNoch keine Bewertungen

- Welding Techniques and ProcedureDokument11 SeitenWelding Techniques and ProcedureDominic Apollo RoblesNoch keine Bewertungen

- Homework 2Dokument5 SeitenHomework 2NIMISHNoch keine Bewertungen

- Welding ShopDokument7 SeitenWelding Shopkartik guptaNoch keine Bewertungen

- Welding Procedure SpecificationDokument5 SeitenWelding Procedure SpecificationyazNoch keine Bewertungen

- GR 11 ReportDokument14 SeitenGR 11 ReportVanessa HadJeanxNoch keine Bewertungen

- AISE No. 7 Specifications For Ladle HooksDokument7 SeitenAISE No. 7 Specifications For Ladle HookscadyfemNoch keine Bewertungen

- Field Welding InspectionDokument13 SeitenField Welding InspectionkundanNoch keine Bewertungen

- WelderDokument20 SeitenWelderadminNoch keine Bewertungen

- Algunas Preguntas de AWS D1Dokument8 SeitenAlgunas Preguntas de AWS D1cordobaluisfNoch keine Bewertungen

- Answer Two Questions From The First ThreeDokument13 SeitenAnswer Two Questions From The First ThreeMalik AlsaadiNoch keine Bewertungen

- Cswip QbankDokument23 SeitenCswip QbankFownoon100% (1)

- General 6Dokument4 SeitenGeneral 6Solomon AttaNoch keine Bewertungen

- Welded ConnectionsDokument144 SeitenWelded ConnectionsshivaniNoch keine Bewertungen

- CSWIP Sample QuestionsDokument31 SeitenCSWIP Sample QuestionsNeo80% (5)

- Wa0084Dokument33 SeitenWa0084miteshNoch keine Bewertungen

- Laboratory Manual: Chandigarh Engineering College, Landran (Mohali)Dokument9 SeitenLaboratory Manual: Chandigarh Engineering College, Landran (Mohali)Jay PandeyNoch keine Bewertungen

- 10.9.4guided Bend Tests - 10.9.4.1transverse Face Bend, Root Bend and Side Bend Tests. The Specifications ForsomeDokument1 Seite10.9.4guided Bend Tests - 10.9.4.1transverse Face Bend, Root Bend and Side Bend Tests. The Specifications ForsomeHandri YantoNoch keine Bewertungen

- Section 5. Welding and BrazingDokument27 SeitenSection 5. Welding and BrazingrobinyNoch keine Bewertungen

- Model Question PaperDokument48 SeitenModel Question Paperselva100% (2)

- Basic WeldingDokument40 SeitenBasic WeldingAsad Bin Ala QatariNoch keine Bewertungen

- Cswip Questions and AnswersDokument8 SeitenCswip Questions and AnswersTariq Hussain100% (2)

- Technical Specifications 33 KV "V" Cross Arm, Back Clamp For "V" Cross Arm & Pole Top BracketDokument20 SeitenTechnical Specifications 33 KV "V" Cross Arm, Back Clamp For "V" Cross Arm & Pole Top BracketAnil RanaNoch keine Bewertungen

- Welding Processes Fcaw, Gmaw, Gtaw, Smaw, SawDokument2 SeitenWelding Processes Fcaw, Gmaw, Gtaw, Smaw, SawiaftNoch keine Bewertungen

- Acceptable Weld ProfilesDokument14 SeitenAcceptable Weld ProfilesMark Miano100% (1)

- 02 WeldingDokument11 Seiten02 WeldingLucky BoatNoch keine Bewertungen

- M ChoiceDokument37 SeitenM Choicevasunookesh100% (1)

- Question WI..Dokument42 SeitenQuestion WI..Indra MansyahNoch keine Bewertungen

- 3.05 A. Welding Specification of Carbon Steel & Alloy SteelDokument40 Seiten3.05 A. Welding Specification of Carbon Steel & Alloy SteelVivek Patil100% (1)

- Weld Joint PreparationDokument2 SeitenWeld Joint PreparationMurali Krishna DNoch keine Bewertungen

- Book 7Dokument21 SeitenBook 7vasuNoch keine Bewertungen

- CSWIP Test No 2Dokument3 SeitenCSWIP Test No 2stanley100% (2)

- In General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferDokument4 SeitenIn General, The MIG/MAG Mode of Transfer Best Suited For Welding Thick Sheet Is Spray TransferLe TuanNoch keine Bewertungen

- Cswip 3.1 QU MSR WI 4 05Dokument8 SeitenCswip 3.1 QU MSR WI 4 05Luan Nguyen100% (3)

- General 5Dokument3 SeitenGeneral 5Sobia KalsoomNoch keine Bewertungen

- Examen Parte CDokument7 SeitenExamen Parte CIsmael HernándezNoch keine Bewertungen

- Notes On Welding & Metal CuttingDokument69 SeitenNotes On Welding & Metal CuttingSaptarshi PalNoch keine Bewertungen

- Welding DefectsDokument122 SeitenWelding DefectsqaNoch keine Bewertungen

- Bifurcation Methodology: Basic Welding ProcedureDokument7 SeitenBifurcation Methodology: Basic Welding ProcedureNischal PokharelNoch keine Bewertungen

- Welding Questions PDFDokument42 SeitenWelding Questions PDFA. ΒρατσισταNoch keine Bewertungen

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeVon EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNoch keine Bewertungen

- Weld Like a Pro: Beginning to Advanced TechniquesVon EverandWeld Like a Pro: Beginning to Advanced TechniquesBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Spot Welding Interview Success: An Introduction to Spot WeldingVon EverandSpot Welding Interview Success: An Introduction to Spot WeldingNoch keine Bewertungen

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Von EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Noch keine Bewertungen

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopVon EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyVon EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNoch keine Bewertungen

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantVon EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantBewertung: 3.5 von 5 Sternen3.5/5 (3)

- The Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsVon EverandThe Study of Elementary Electricity and Magnetism by Experiment: Containing Two Hundred ExperimentsNoch keine Bewertungen

- Apex DSP ManualDokument20 SeitenApex DSP ManualVinu Raveendran0% (1)

- Procedure For PmiDokument5 SeitenProcedure For PmiVinu RaveendranNoch keine Bewertungen

- SurfaceProcedure Preparation-085 R3Dokument17 SeitenSurfaceProcedure Preparation-085 R3Vinu Raveendran100% (1)

- Common Pipe MaterialsDokument1 SeiteCommon Pipe MaterialsVinu RaveendranNoch keine Bewertungen

- Jacket Offshore Platform DefinitionDokument6 SeitenJacket Offshore Platform DefinitionVinu RaveendranNoch keine Bewertungen

- SurfaceProcedure Preparation-085 R3Dokument17 SeitenSurfaceProcedure Preparation-085 R3Vinu Raveendran100% (1)

- Breasting and Mooring DolphinDokument4 SeitenBreasting and Mooring DolphinVinu RaveendranNoch keine Bewertungen

- Consumption CalculationDokument1 SeiteConsumption CalculationVinu RaveendranNoch keine Bewertungen

- Duplex Ss WPSDokument8 SeitenDuplex Ss WPSVinu Raveendran100% (1)

- Electrode Classifixation FCAWDokument8 SeitenElectrode Classifixation FCAWVinu RaveendranNoch keine Bewertungen

- Mba Question Papers 2015 Part 3Dokument3 SeitenMba Question Papers 2015 Part 3Vinu RaveendranNoch keine Bewertungen

- Mba Annamali Questions Part 33Dokument4 SeitenMba Annamali Questions Part 33Vinu RaveendranNoch keine Bewertungen

- Angle ModulationDokument26 SeitenAngle ModulationAtish RanjanNoch keine Bewertungen

- PCM 2.4l Turbo 5 de 5Dokument2 SeitenPCM 2.4l Turbo 5 de 5Felix VelasquezNoch keine Bewertungen

- JCPS School Safety PlanDokument14 SeitenJCPS School Safety PlanDebbie HarbsmeierNoch keine Bewertungen

- Drilling Jigs Italiana FerramentaDokument34 SeitenDrilling Jigs Italiana FerramentaOliver Augusto Fuentes LópezNoch keine Bewertungen

- Formulae HandbookDokument60 SeitenFormulae Handbookmgvpalma100% (1)

- UntitledDokument5 SeitenUntitledapril montejoNoch keine Bewertungen

- 19 Uco 578Dokument20 Seiten19 Uco 578roshan jainNoch keine Bewertungen

- Ib Psychology - Perfect Saq Examination Answers PDFDokument2 SeitenIb Psychology - Perfect Saq Examination Answers PDFzeelaf siraj0% (2)

- T54125ADokument64 SeitenT54125ARaúl FroddenNoch keine Bewertungen

- SQL - Day 2: Structured Query LanguageDokument10 SeitenSQL - Day 2: Structured Query LanguageNight KingNoch keine Bewertungen

- HAFOMA Presentation 2022 ENGDokument9 SeitenHAFOMA Presentation 2022 ENGVeljko MilicevicNoch keine Bewertungen

- WicDokument6 SeitenWicGonzalo Humberto RojasNoch keine Bewertungen

- THE BASIC TYPES OF SPEECHES PPTDokument14 SeitenTHE BASIC TYPES OF SPEECHES PPTKevin BanezNoch keine Bewertungen

- Types of ComputersDokument7 SeitenTypes of ComputersSyed Badshah YousafzaiNoch keine Bewertungen

- ResumeDokument3 SeitenResumeAstig Kuging63% (8)

- NCRA Membership InformationDokument1 SeiteNCRA Membership Informationbkharkreader1301Noch keine Bewertungen

- Unit 1 - Plant & Eqpt. Safety Apprisal & Control Techq.Dokument147 SeitenUnit 1 - Plant & Eqpt. Safety Apprisal & Control Techq.Madhan MNoch keine Bewertungen

- Electro TechniquesDokument2 SeitenElectro TechniquesPinkk DaisyfieldNoch keine Bewertungen

- Manish Kumar: Desire To Work and Grow in The Field of MechanicalDokument4 SeitenManish Kumar: Desire To Work and Grow in The Field of MechanicalMANISHNoch keine Bewertungen

- Chapter 3 - Methods of Circuit Analysis and Circuit TheoremsDokument125 SeitenChapter 3 - Methods of Circuit Analysis and Circuit TheoremsNaim NizamNoch keine Bewertungen

- Customer Service Metrics CalculatorDokument28 SeitenCustomer Service Metrics CalculatorSelma Regita MahardiniNoch keine Bewertungen

- Ad For Guru Ned'S Enlightenment Masterclass 1 of 33Dokument33 SeitenAd For Guru Ned'S Enlightenment Masterclass 1 of 33ElliuggNoch keine Bewertungen

- Unit 13 Dialogue Writing: ObjectivesDokument8 SeitenUnit 13 Dialogue Writing: ObjectivesAkg GuptNoch keine Bewertungen

- PH-01 (KD 3.1) Filling Out Forms (PG20) - GFormDokument4 SeitenPH-01 (KD 3.1) Filling Out Forms (PG20) - GFormLahita AzizahNoch keine Bewertungen

- Slide 7 PV NewDokument74 SeitenSlide 7 PV NewPriyanshu AgrawalNoch keine Bewertungen

- Hume 100 ReviewerDokument7 SeitenHume 100 ReviewerShai GaviñoNoch keine Bewertungen

- Lub OIl Flushing Procedure PDFDokument44 SeitenLub OIl Flushing Procedure PDFSubrahmanyam100% (1)

- Swot Matrix Strengths WeaknessesDokument6 SeitenSwot Matrix Strengths Weaknessestaehyung trash100% (1)

- Perilaku Prososial Sebagai Prediktor Status Teman Sebaya Pada RemajaDokument9 SeitenPerilaku Prososial Sebagai Prediktor Status Teman Sebaya Pada RemajaMemet GoNoch keine Bewertungen

- Lab 3 Report Fins RedoDokument3 SeitenLab 3 Report Fins RedoWestley GomezNoch keine Bewertungen