Beruflich Dokumente

Kultur Dokumente

ISO 3506-2 - Mechanical Properties

Hochgeladen von

PMartinaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ISO 3506-2 - Mechanical Properties

Hochgeladen von

PMartinaCopyright:

Verfügbare Formate

ISO 3506-2:2009(E)

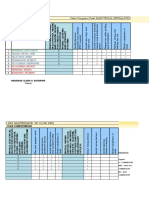

Table 1 Stainless steel grades Chemical composition

Steel

group

Austenitic

Martensitic

Ferritic

Chemical compositiona

mass fraction, %

Steel

grade

Footnotes

Si

Mn

Cr

Mo

Ni

Cu

A1

0,12

6,5

0,2

0,15 to 0,35

16 to 19

0,7

5 to 10

1,75 to 2,25

A2

0,10

0,05

0,03

15 to 20

8 to 19

A3

0,08

0,045

0,03

17 to 19

9 to 12

bcd

fg

A4

0,08

0,045

0,03

16 to 18,5

2 to 3

10 to 15

gi

A5

0,08

0,045

0,03

16 to 18,5

2 to 3

10,5 to 14

hi

C1

0,09 to 0,15

0,05

0,03

11,5 to 14

C3

0,17 to 0,25

0,04

0,03

16 to 18

1,5 to 2,5

C4

0,08 to 0,15

1,5

0,06

0,15 to 0,35

12 to 14

0,6

bi

F1

0,12

0,04

0,03

15 to 18

kl

NOTE 1 A description of the groups and grades of stainless steels also entering into their specific properties and applications is given

in Annex A.

NOTE 2 Examples of stainless steels standardized in accordance with ISO 683-13 and ISO 4954 are given in Annexes B and C,

respectively.

NOTE 3

Certain materials for specific application are given in Annex D.

Values are maximum, unless otherwise indicated.

Sulfur may be replaced by selenium.

If the nickel content is below 8 %, the minimum manganese content shall be 5 %.

There is no minimum limit to the copper content, provided that the nickel content is greater than 8 %.

Molybdenum may be present at the discretion of the manufacturer. However, if for some applications limiting of the molybdenum

content is essential, this shall be stated at the time of ordering by the purchaser.

f

If the chromium content is below 17 %, the minimum nickel content should be 12 %.

For austenitic stainless steels having a maximum carbon content of 0,03 %, nitrogen may be present to a maximum of 0,22 %.

This shall contain titanium W 5 C up to 0,8 % maximum for stabilization and be marked appropriately as specified in this table, or

shall contain niobium (columbium) and/or tantalum W 10 C up to 1,0 % maximum for stabilization and be marked appropriately as

specified in this table.

i

At the discretion of the manufacturer, the carbon content may be higher where required in order to obtain the specified mechanical

properties at larger diameters, but shall not exceed 0,12 % for austenitic steels.

j

Molybdenum may be present at the discretion of the manufacturer.

This may contain titanium W 5

This may contain niobium (columbium) and/or tantalum W 10

C up to 0,8 % maximum.

C up to 1 % maximum.

Mechanical properties

The mechanical properties of nuts in accordance with this part of ISO 3506 shall conform to the values given

in Tables 2 and 3.

For acceptance purposes, the mechanical properties given in this clause apply and shall be tested as follows:

hardness test, according to 7.1 (only steel grades C1, C3 and C4, hardened and tempered);

proof load test, according to 7.2.

NOTE

Although a great number of property classes are specified in this part of ISO 3506, this does not mean that all

classes are appropriate for all nuts. Further guidance for application of the specific property classes is given in the relevant

product standards.

ISO 2009 All rights reserved

ISO 3506-2:2009(E)

For non-standard nuts, the choice already made for similar standard nuts should be followed as closely as

possible.

Table 2 Mechanical properties for nuts Austenitic steel grades

Steel group

Property class

Steel

grade

Nuts with

Austenitic

Stress under proof load

p

min.

MPa

W 0,8

Nuts with

0,5 u 0,8

W 0,8

Nuts with

Nuts with

0,5 u 0,8

A1, A2,

50

025

500

250

A3, A4,

70

035

700

350

A5

80

040

800

400

Table 3 Mechanical properties for nuts Martensitic and ferritic steel grades

Steel

group

Steel

grade

Property class

Nuts with

Nuts with

0,5 u 0,8

W 0,8

Nuts with

0,5 u 0,8

HB

HRC

HV

50

025

500

250

147 to 209

155 to 220

70

700

209 to 314

20 to 34

220 to 330

110a

055a

1 100

550

36 to 45

350 to 440

80

040

800

400

228 to 323

21 to 35

240 to 340

50

500

147 to 209

155 to 220

70

035

700

350

209 to 314

20 to 34

220 to 330

45

020

450

200

128 to 209

135 to 220

60

030

600

300

171 to 271

180 to 285

C1

C3

C4

F1b

Nuts with

Hardened and tempered at a minimum tempering temperature of 275 C.

Nominal thread diameter u 24 mm.

7

7.1

Hardness

W 0,8

Martensitic

Ferritic

Stress under proof load

p

min.

MPa

Test methods

Hardness HB, HRC or HV

On martensitic and ferritic nuts, the hardness test shall be carried out in accordance with ISO 6506-1 (HB),

ISO 6508-1 (HRC) or ISO 6507-1 (HV). In case of doubt, the Vickers hardness test is decisive for acceptance.

The tests procedure shall be as specified in ISO 898-2 and ISO 898-6.

The hardness values shall be within the limits given in Table 3.

7.2

Proof load

The test procedure and criteria shall be in accordance with ISO 898-2 and ISO 898-6.

ISO 2009 All rights reserved

Das könnte Ihnen auch gefallen

- ISO 3506 2 Mechanical Properties PDFDokument2 SeitenISO 3506 2 Mechanical Properties PDFp2pcreep100% (1)

- Metric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityDokument4 SeitenMetric DIN 434 Square Taper Washers: Visit Our For Product AvailabilityRodrigoNoch keine Bewertungen

- Chemical Composition of Stainless Steels To BS EN 10088-2Dokument41 SeitenChemical Composition of Stainless Steels To BS EN 10088-2amit_91340% (1)

- Iso 7380Dokument1 SeiteIso 7380MarioNoch keine Bewertungen

- 06 Eurocodes Steel Workshop WALDDokument136 Seiten06 Eurocodes Steel Workshop WALDFrancisco RojasNoch keine Bewertungen

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDokument4 SeitenForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNoch keine Bewertungen

- L9 Fastening System PDFDokument6 SeitenL9 Fastening System PDFMarcel BaqueNoch keine Bewertungen

- Din 6915 PDFDokument3 SeitenDin 6915 PDFa.tabkhi1980100% (3)

- Design of Fillet Weld (As Per Bs en 1993 1 8, CL 4.5.3) : KN M KN KN M KN KN MMDokument2 SeitenDesign of Fillet Weld (As Per Bs en 1993 1 8, CL 4.5.3) : KN M KN KN M KN KN MMGiri DharanNoch keine Bewertungen

- Metric Heavy Hex Nut DimensionsDokument3 SeitenMetric Heavy Hex Nut DimensionsSenthillkumar BalasubramaniamNoch keine Bewertungen

- Voestalpine Heavy Plate TTD DUROSTAT E 10042015Dokument16 SeitenVoestalpine Heavy Plate TTD DUROSTAT E 10042015Ella Byla SaraNoch keine Bewertungen

- Technical Lamination SDokument4 SeitenTechnical Lamination SirmakNoch keine Bewertungen

- Din & IsoDokument94 SeitenDin & IsoZeinHarisHasibuan100% (5)

- BS en 20898-1-1992Dokument26 SeitenBS en 20898-1-1992consultach100% (4)

- BS en 10149-1 1996Dokument16 SeitenBS en 10149-1 1996ibson045001256100% (1)

- BS en 10279 SummaryDokument1 SeiteBS en 10279 SummaryBui Chi TamNoch keine Bewertungen

- Non Preload Assemblies BS en 15048 12Dokument4 SeitenNon Preload Assemblies BS en 15048 12AtanasKostadinov100% (1)

- Fastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Dokument3 SeitenFastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Paul OnionsNoch keine Bewertungen

- Iso 68-1-1998Dokument4 SeitenIso 68-1-1998Sirous EghlimiNoch keine Bewertungen

- BS 3410 1961 WashersDokument20 SeitenBS 3410 1961 WashersAndy TaylorNoch keine Bewertungen

- Steel Material PropertiesDokument1 SeiteSteel Material PropertiesHendra93100% (1)

- Din 7500 enDokument10 SeitenDin 7500 enCălin Bălăiţă100% (1)

- EN 10210-2 2006 Hot Finished Structural Hollow Sections of Non Alloy and Fine Grain Steels - Part 2 Tolerances Dimensions and Sectional Properties PDFDokument32 SeitenEN 10210-2 2006 Hot Finished Structural Hollow Sections of Non Alloy and Fine Grain Steels - Part 2 Tolerances Dimensions and Sectional Properties PDFJoao MendesNoch keine Bewertungen

- Timco TDS Drywall ScrewDokument2 SeitenTimco TDS Drywall ScrewNajeeb AhmedNoch keine Bewertungen

- GuidanceNotes EN131 Version2Dokument10 SeitenGuidanceNotes EN131 Version2Javier Quintero SaavedraNoch keine Bewertungen

- 1 - Din 13-20 e - 0Dokument8 Seiten1 - Din 13-20 e - 0Joaquin Alvarez100% (1)

- Din 7623Dokument2 SeitenDin 7623Racha Amel100% (1)

- BS en 10034-1993 Structural Steel I and H Sections - Tolerances On Shape and DimensionsDokument14 SeitenBS en 10034-1993 Structural Steel I and H Sections - Tolerances On Shape and Dimensionsarabsniper100% (1)

- P20 Steel Plate Tool SteelDokument4 SeitenP20 Steel Plate Tool SteelSama UmateNoch keine Bewertungen

- Types of Steel Profile and Its UsesDokument3 SeitenTypes of Steel Profile and Its UsesednavilodNoch keine Bewertungen

- HD Bolts BS - 7419Dokument5 SeitenHD Bolts BS - 7419Deana White100% (1)

- Standard GB - T1804-m & ISO 2768-1 - 2 - Advanced CeramicsDokument5 SeitenStandard GB - T1804-m & ISO 2768-1 - 2 - Advanced CeramicsMohd DanishNoch keine Bewertungen

- Ansi-Ul 94Dokument1 SeiteAnsi-Ul 94Serggie TabanaoNoch keine Bewertungen

- Din 126-2Dokument1 SeiteDin 126-2Safi Zabihullah SafiNoch keine Bewertungen

- ASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelDokument2 SeitenASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelBernice JohnsonNoch keine Bewertungen

- Ilnas-En Iso 19598:2016Dokument8 SeitenIlnas-En Iso 19598:2016Victor ParvanNoch keine Bewertungen

- Iso 8734 1997Dokument8 SeitenIso 8734 1997edNoch keine Bewertungen

- En 10029 PDFDokument5 SeitenEn 10029 PDFmanuela vilas boasNoch keine Bewertungen

- Mechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesDokument4 SeitenMechanical Properties Min. 0,2 % Yield Strength Values at Increased TemperaturesJarek CieslakNoch keine Bewertungen

- 0526 16 2004 07 en - enDokument6 Seiten0526 16 2004 07 en - envtsusr fvNoch keine Bewertungen

- Din2098 1Dokument4 SeitenDin2098 1amir8100Noch keine Bewertungen

- Dowel 2011Dokument5 SeitenDowel 2011nikhilpathak16674Noch keine Bewertungen

- Din 1025-3-1994 Eng PDFDokument4 SeitenDin 1025-3-1994 Eng PDFAnonymous gUxMsgENoch keine Bewertungen

- DIN125ADokument1 SeiteDIN125AManoj PatilNoch keine Bewertungen

- High Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)Dokument2 SeitenHigh Tensile: Hexagon Head Setscrews Fine Pitch EN ISO 8676 (DIN 961)jaison jacobNoch keine Bewertungen

- Astm A31 (1995)Dokument4 SeitenAstm A31 (1995)gsb2100% (1)

- Content Din en Iso PDFDokument244 SeitenContent Din en Iso PDFXuan Phuong HuynhNoch keine Bewertungen

- NA To Sls en 1993-1-8Dokument12 SeitenNA To Sls en 1993-1-8Shan Sandaruwan AbeywardeneNoch keine Bewertungen

- BS en 10215-1995 (1999)Dokument16 SeitenBS en 10215-1995 (1999)Federico De Martini0% (1)

- Structural Properties of Bolted JointsDokument5 SeitenStructural Properties of Bolted JointsL095244Noch keine Bewertungen

- Iso 2553Dokument8 SeitenIso 2553Eduardo TeixeiraNoch keine Bewertungen

- Equal Leg Angles To en 10056-1 1998 Dim - PropDokument2 SeitenEqual Leg Angles To en 10056-1 1998 Dim - PropJagdish Chhugani100% (1)

- Tech BS 4449 2005Dokument10 SeitenTech BS 4449 2005Syed RizwanNoch keine Bewertungen

- GP20110327Dokument36 SeitenGP20110327Artem KuznetsovNoch keine Bewertungen

- Aalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97Dokument3 SeitenAalco Metals LTD - Stainless Steel - 201 201L 202 204 200 Series - 97sgupta_192494Noch keine Bewertungen

- En 10270Dokument2 SeitenEn 10270pureroNoch keine Bewertungen

- Steel Wire, Music Spring Quality: Standard Specification ForDokument4 SeitenSteel Wire, Music Spring Quality: Standard Specification ForJosé Ramón Gutierrez100% (1)

- Stud Bolt Specification 3Dokument7 SeitenStud Bolt Specification 3santoshblonkarNoch keine Bewertungen

- Welded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser TubesDokument10 SeitenWelded Austenitic Steel Boiler, Superheater, Heat-Exchanger, and Condenser Tubesquiensabe0077Noch keine Bewertungen

- Teacher PPT - Scientific RevolutionDokument13 SeitenTeacher PPT - Scientific Revolutionapi-441776741Noch keine Bewertungen

- PUMY-P100-140YHM Technical & Service Manual (OC355revB)Dokument90 SeitenPUMY-P100-140YHM Technical & Service Manual (OC355revB)Pavle PerovicNoch keine Bewertungen

- Abnormal Labour: Perceptor: Dr. Nurul Islamy, M. Kes., Sp. OGDokument54 SeitenAbnormal Labour: Perceptor: Dr. Nurul Islamy, M. Kes., Sp. OGramadhiena destia100% (1)

- Class Progress Chart Electrical Installation and Maintenance NC Ii (196 HRS)Dokument2 SeitenClass Progress Chart Electrical Installation and Maintenance NC Ii (196 HRS)Shairrah Claire Bañares BatangueNoch keine Bewertungen

- Allen-Bradley RSLogix 500 PDFDokument6 SeitenAllen-Bradley RSLogix 500 PDFGanda PutraNoch keine Bewertungen

- Alcatel 4029 EngDokument31 SeitenAlcatel 4029 Engafsanto2000Noch keine Bewertungen

- Abb Sas GeneralDokument43 SeitenAbb Sas Generalsabill arasyidNoch keine Bewertungen

- Practical 1 PacingDokument13 SeitenPractical 1 PacingFiaz Hussain0% (1)

- A) I) Define The Term Variable Costs Variable Costs Are Costs That Change With The Quantity of Products SoldDokument2 SeitenA) I) Define The Term Variable Costs Variable Costs Are Costs That Change With The Quantity of Products SoldAleksandra LukanovskaNoch keine Bewertungen

- Troubleshooting Mechanical VentDokument15 SeitenTroubleshooting Mechanical VentIvy Jorene Roman RodriguezNoch keine Bewertungen

- A Deep Dive Into The Latest HPC SoftwareDokument38 SeitenA Deep Dive Into The Latest HPC SoftwareSundar NilNoch keine Bewertungen

- 03 VEX SpotDokument2 Seiten03 VEX SpottemamNoch keine Bewertungen

- Corirubber: Cori Engineers Private LimitedDokument1 SeiteCorirubber: Cori Engineers Private LimitedVivace SystmNoch keine Bewertungen

- ElcometerDokument228 SeitenElcometerMohammedMudassirNoch keine Bewertungen

- Owners Manual 2018Dokument49 SeitenOwners Manual 2018Marv-Vic SantosNoch keine Bewertungen

- Final Defence 2078Dokument43 SeitenFinal Defence 2078XxxNoch keine Bewertungen

- Body FluidsDokument85 SeitenBody FluidsShanta BharNoch keine Bewertungen

- D 880 - 92 R97 Rdg4mc05mli5nw - PDFDokument4 SeitenD 880 - 92 R97 Rdg4mc05mli5nw - PDFomar alvaradoNoch keine Bewertungen

- Effect of Salinity On Proteins in Some Wheat CultivarsDokument9 SeitenEffect of Salinity On Proteins in Some Wheat Cultivarsray m deraniaNoch keine Bewertungen

- Alex H.: Penguin ProjectDokument13 SeitenAlex H.: Penguin Projectapi-504550016Noch keine Bewertungen

- 12 Physics Exemplar PDFDokument130 Seiten12 Physics Exemplar PDFPRATIM SADHU100% (1)

- Biology Paper 6 NotesDokument5 SeitenBiology Paper 6 NotesbNoch keine Bewertungen

- Bearing Reliability Improvement-SKFDokument55 SeitenBearing Reliability Improvement-SKFAbdulrahman AlkhowaiterNoch keine Bewertungen

- Cj2m-Cpu, - md21 Cpu Units, Pulse I o Modules Datasheet en PDFDokument29 SeitenCj2m-Cpu, - md21 Cpu Units, Pulse I o Modules Datasheet en PDFKhairy YaakobNoch keine Bewertungen

- STR ReportDokument30 SeitenSTR ReportrahulNoch keine Bewertungen

- 07a80809 OperationsresearchDokument11 Seiten07a80809 OperationsresearchSharanya ThirichinapalliNoch keine Bewertungen

- Shear Force & Bending Moment TestDokument11 SeitenShear Force & Bending Moment TestKalaiArasanNoch keine Bewertungen

- Bohmian Mechanics Versus Madelung Quantum HydrodynamicsDokument8 SeitenBohmian Mechanics Versus Madelung Quantum HydrodynamicsregectNoch keine Bewertungen

- Form Cor Eng Pip 002 e R01Dokument1 SeiteForm Cor Eng Pip 002 e R01Uri SanchezNoch keine Bewertungen

- Color Pencil TheoryDokument2 SeitenColor Pencil Theoryapi-246017428Noch keine Bewertungen