Beruflich Dokumente

Kultur Dokumente

MD Dec2015

Hochgeladen von

AbhishekNigam0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

4 Ansichten2 Seitenm j

Originaltitel

Md Dec2015

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenm j

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

4 Ansichten2 SeitenMD Dec2015

Hochgeladen von

AbhishekNigamm j

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

MECH

16-11

QP Code : 6296

~ rem] Maddine pesign- =}

Revised Course

Duration: 3 Hrs MAXIMUM MARKS : 80

* Question No. 1 is compulsory.

Attempt any THREE questions from the remaining.

* Assumption made should be clearly stated.

* Use of PSG Design Data Book is permitted.

Qu

(a) Find outer diameter of the cylinder made of GCI- FG300 using Lames 5

‘equation if the maximum intemal pressure is 30MPa, FOS is 2 and internal

diameter is 250mm.

(b) State different theories of failure and explain any two in details. s

c (©) Explain overhauling and self-Jocking of Screw. 5

(@) Derive an expression for deflection of helical spring of circular wire 5

Q.2 (@) Design a knuckle joint to withstand a tensile load of 2SKN ifthe permissible 15

"stresses are SOMPs in tensig, 40 MPa in shear and 70 MPa i& compression.

™ that y r wv is les than 50 percent.

Q3 Determine of r O i } |

: FOS=2.5 if it is subjected to tensile to

made of ¢ steel 35C8 with o):~320N/mm? and oa = 600 N/mm?

(b) Select a standard hook of trapezoidal cross section to lift « load of L1OKN 8

«and find the stress induced si critical eross section.

(©) Explain different methods to reduce sttess concentration. 4

~~ Q4 (@) A steel shaft is copported at beating A and B 750mm apart: A spur gear 16

having PCD 4(@mm is located 150mm to the right of LH bearing and a

pinion with PCD 120mm is mounted 350mm to the left of RH bearing. The

gear is drive by the pinion located vertically below, while the pinion

transmits power to another gear horizontally to the right. Using allowable

shear stress GOMPa, determine the diameter of the shaft. The shaft

transmitting 10 KW at 200 rpm. Shock and Fatigue factor in bending and

torsion are 2.0 and 1.5 respectively.

(&) Explain different types of keys with neat sketches 4

[TURN OVER

MD-Con.8403-15.

Qs @

()

©

2 QP Code : 6296

Design a Clamp coupling for mild steel shaft transmitting 40 KW at 100 rpm,

Coefficient of friction between the muff and the shaft surface is 0.3 and

number of bolts connecting two halves are six. The allowable shear stress in

the shaft and coupling bolts are 40 MPa and 70 MPa resp.

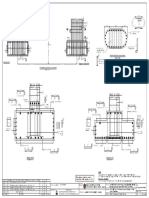

‘A Bracket is supported by means of 6 bolts of same size as shown,

Determine the diameter of the bolts if the maximum shear stress is 150MPa.

mn

yminated spring 500 mm long and 40 mm wide is held together at the

centre by a"band 85 mm wide. Ifthe thickness of each leaf is 10 mm, find the

number of leaves required to carry a load of S400N. Assume maximum

working stress of 280MPe.

If the two of the leaves extend the full length of the spring, find the deflection

of the spring. The young modulus for the spring material is 210GPa.

-———-*

MD-Con.8403-15.

10

10

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Doctor List ReportDokument18 SeitenDoctor List ReportAbhishekNigamNoch keine Bewertungen

- New Microsoft Word DocumentDokument2 SeitenNew Microsoft Word DocumentAbhishekNigamNoch keine Bewertungen

- Read MejhvhDokument6 SeitenRead MejhvhAbhishekNigamNoch keine Bewertungen

- Etk Material Curves 20121018Dokument15 SeitenEtk Material Curves 20121018ManuNoch keine Bewertungen

- ErsyerDokument3 SeitenErsyerAbhishekNigamNoch keine Bewertungen

- New Microsoft Word DocumentDokument2 SeitenNew Microsoft Word DocumentAbhishekNigamNoch keine Bewertungen

- 01 Naukri LeadsDokument20 Seiten01 Naukri LeadsAbhishekNigamNoch keine Bewertungen

- Shubham Nigam: Mechanical EngineerDokument2 SeitenShubham Nigam: Mechanical EngineerAbhishekNigamNoch keine Bewertungen

- PCC - SPJ Gammon BillDokument5 SeitenPCC - SPJ Gammon BillAbhishekNigamNoch keine Bewertungen

- AbhiDokument3 SeitenAbhiAbhishekNigamNoch keine Bewertungen

- Shubham Nigam Mechanical EngineerDokument1 SeiteShubham Nigam Mechanical EngineerAbhishekNigamNoch keine Bewertungen

- Abhishek Radheshyam Nigam: Carrier ObjectiveDokument3 SeitenAbhishek Radheshyam Nigam: Carrier ObjectiveAbhishekNigamNoch keine Bewertungen

- AbhiDokument3 SeitenAbhiAbhishekNigamNoch keine Bewertungen

- Abhishek Radheshyam Nigam: Carrier ObjectiveDokument3 SeitenAbhishek Radheshyam Nigam: Carrier ObjectiveAbhishekNigamNoch keine Bewertungen

- Shubham Nigam: Mechanical EngineerDokument2 SeitenShubham Nigam: Mechanical EngineerAbhishekNigamNoch keine Bewertungen

- Robo Remote TXDokument1 SeiteRobo Remote TXAbhishekNigamNoch keine Bewertungen

- Pier P15drg No. 06R5dtd 10-05-2016Dokument1 SeitePier P15drg No. 06R5dtd 10-05-2016AbhishekNigamNoch keine Bewertungen

- MechDokument38 SeitenMechweezyniggaNoch keine Bewertungen

- Curriculum Vitae Contact: +91-9409116973 Rajesh C Vishwakarma Career ObjectiveDokument3 SeitenCurriculum Vitae Contact: +91-9409116973 Rajesh C Vishwakarma Career ObjectiveAbhishekNigamNoch keine Bewertungen

- MechDokument38 SeitenMechweezyniggaNoch keine Bewertungen

- MechDokument38 SeitenMechweezyniggaNoch keine Bewertungen

- Brow WLReplyDokument1 SeiteBrow WLReplyAbhishekNigamNoch keine Bewertungen

- Wipro Question Paper PDFDokument86 SeitenWipro Question Paper PDFAbhishekNigamNoch keine Bewertungen

- Wipro Sample Paper With Answers.Dokument10 SeitenWipro Sample Paper With Answers.Naga Bala KrishnanNoch keine Bewertungen

- Wipro Question Paper PDFDokument86 SeitenWipro Question Paper PDFAbhishekNigamNoch keine Bewertungen

- Imp ProgramDokument1 SeiteImp ProgramAbhishekNigamNoch keine Bewertungen

- Imp ProgramDokument1 SeiteImp ProgramAbhishekNigamNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)