Beruflich Dokumente

Kultur Dokumente

Aquarium Plumbing Basics - Reef Aquarium

Hochgeladen von

Kanashibi OgawaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Aquarium Plumbing Basics - Reef Aquarium

Hochgeladen von

Kanashibi OgawaCopyright:

Verfügbare Formate

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

HOME

YOUR GUIDE TO A THRIVING REEF

AQUARIUM PLUMBING

BASICS

13 APR 2012

POSTED BY CLIFF

49 COMMENTS

When you set out to plumb an aquarium set-up

with a sump, the more planning / thought you put

into the original set-up, the better it will be in the

long run. This is not a very hard thing to do at all,

if you focus on the basics and understand them. I

tend to think of it in flowing different steps: A)

Planning of your flow rates, B) planning the

material types and sizes, and C) installation / setup of the plumbing system. All of what you are

about to read below is based on my experiences

with various data from some North American

manufactures of plumbing products (IPEX,

Canplas, and Boshart) which is also detailed in the

American Society for Testing and Materials

(ASTM) standards.

I will explain what I mean by each step then I will

show you examples from one of my reef tanks

Note: you have to keep in mind, there may be

variation in the plumbing products available to you

based on the national building codes of the

country that you live in along with local

regulations. The below applies to almost all of

Canada and the United States. The products

available to you may vary.

A) Planning Flow Rates

With every system, you need to know how much

flow you will need. Typically this is calculated in

gallons per hour (GPH). For example, most people

feel a flow through their sumps of 10 times the

display tank volume is suitable. If you have a 120

gallon display tank, then that would mean you will

need 1200 gph of flow. But that is only a general

guideline. Your exact flow rate could be higher or

lower depending on the equipment in the sump or

what you are planning to use the sump for. Once

you have determined the flow rate you will need,

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

1 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

you will need to apply this target flow rate

differently to both your drain line and your return

line. The 10X flow rate is typically a good base to

start working from and can apply to almost all

typical salt water setups. Some people prefer

high flow through their sumps. Fresh water setups

typically use a little lower flow rates, around 4 to 6

times the display tank volume is more common.

Drain lines are the lines bring water down from

the display tank into the sump. There are many

different approaches to achieving this, but mainly

fall into one of two categories: Siphon based

systems, or a Gravity system (which involves

drilling a hole in your tank). With either set-up,

one of the bigger factors to consider is the flow

rates under extremely little to no pressure. Both

types of drains are very similar in GPH (no real

significant differences) and these types of drains

are discussed in my example here the end of the

article. Whatever choice you make, you have to

make sure the drain line can also handle the flow

you want to put through the sump.

Return lines are the pressurized lines that run

from the return pump back into the display tank.

There are three factors that are very important to

consider here: flow rates, pressure, and the types

and numbers of fittings used.

B) Planning Material Types and Sizes

With all aquarium setups (both salt water and

fresh water), you have to make sure the pipe and

fittings you use to plumb your system are both

meant for potable water (can safely handle

drinking water) and is resistant to corrosion and

scaling. You can ensure those requirements are

met by using one of the below material types

ABS (Acrylonitrile Butadiene Styrene).

Typically only used for drainage in homes as it

cannot withstand much pressure or heat. This is

typically black in color. ABS is the cheapest pipe

and fittings that can be used. It is only suitable for

drain lines and should not be used for pressurized

applications.

PVC (Polyvinyl Chloride). Most commonly used

as it can handle a range of pressure and some

heat. It can be used in residential and commercial

drinking water supply (cold water supply only). It

usually is the most economical choice for almost

all aquarium setups as well as being the most

commonly used for pressurized and drain

lines.You can get it in both in flexible and rigid

pipe (flexible PVC has lower pressure ratings).

This is typically white in color.

CPVC (Chlorinated Polyvinyl Chloride). Most

commonly used in commercial and/or industrial

applications. Can handle both hot and cold

drinking water supply. This is typically a shade of

grey in color. Although this can be used in an

aquarium set-up, it is one of the more expensive

options.

PEX (Cross-Linked Polyethylene). Slowly

becoming the most used product in the

construction of new homes for both the hot and

cold drinking water supplies. Is made both in

flexible and rigid pipe while maintaining the same

pressure rating. PEX is typically a white, almost

transparent color. Although this can be used for

both pressurized and drain lines, it also is a very

expensive option as you need special tools when

connecting PEX fittings.

PVC and CPVC are also available in different

grades / thicknesses to allow for higher pressure

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

2 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

and higher heat limits on both the pipe and

fittings. This is done through using the Schedule

System. The wall thickness of the pipe and fittings

is designated with a schedule number. The

range from sch (schedule) 40 all the way up to

sch 160. Typically you will find sch 40 (regular)

and schedule 80 (extra heavy) available in most

hardware stores. Schedule 120 and 160 is not

commonly used or available in retail stores.

For PVC pipe and fittings, The general rule of

thumb is that any pressurized application that

would require your set-up to have below 2 inch

pipe can / should be completed in schedule 40.

Anything higher (ie.. 2 and 2 inch applications)

would require schedule 80. That may vary based

on exact conditions. You would not have to worry

about up-grading to sch 80 pipe unless your

system would require around 5,500 gph of flow

(or higher flow) through a single plumbing line.

For ease of identification, most manufactures

make regular PVC (sch 40) white in color while

they make sch 80 in grey. Not all manufactures

will do this. Its always best to read the markings

and labeling on the fittings or pipe just to make

sure.

The below charts summarized flow rates by: no

pressure, average pressure applications, and the

maximum pressure that the pipe and fittings can

handle in standard PVC (standard = sch 40). Once

I start to talk about an example of plumbing a

sump, I will be referring back to these charts

(GPH = Gallons Per Hour )

And just to clear up some of the terminology used,

ID = Inside Diameter while OD = Outside

Diameter.

Loss of flow

Once thing to keep in mind, when planning your

plumbing set-up the pump should be the last thing

you choose. The reason for this is that you need

to know how much loss of flow you will have from

your plumbing design. Each time you add a 90

degree elbow, or a swing check valve, you will

lose some flow because of these additions to your

plumbing line. The below list are more of a rule of

thumb with calculating flow loss of your

pressurized return line only. They may not be

100% accurate, as many other factors can effect

these calculations. They will be close enough for

you to get an accurate estimate of the flow

reduction. The below factors will become very

important when planning your set-up.

A loss of 75 to 125 GPH for each foot of height

(from the pump to the display tank return)

A loss of 50 to 75 GPH for each 90 degree elbow

A loss of 30 to 50 GPH for each 45 degree elbow

A loss of 50 to 75 GPH for each swing check

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

3 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

valve

A loss of 20 to 40 GPH for each ball valve

A loss of ~ 3 to 5 GPH for each union

I will also be referring back to this information

latter when I show how I planned the plumbing

layout of my sump.

C) Planning the set-up/Installation.

We have already discussed the typical sizes and

material available for your pipe, now it might be

best to talk about fittings, other than the more

common fittings pictured below. This will help you

when it comes time to plan each line in your

plumbing.

Below are some of the other fittings that typically

use and most likely can be used in your set-up.

PVC Unions

These are very useful fittings to have in your setup. It can allow you to quickly disconnect a part of

the system and then reconnect again without have

to worry about gluing or resealing anything. A

perfect example of this would be using a union to

connect your return pump to the system. This

way, you could quickly remove the pump from the

plumbing, clean it, then reconnect the pump with

a minimal amount of down-time. On more

complicated set-ups, it allows for building the

plumbing system in different sections before

quickly connecting it together. Using unions is also

a good idea when working in tight / small paces

as you can assemble the lines elsewhere before

connecting the system together. They come in

standard and sch 80 PVC for both socket weld and

screwed / threaded connections

Bulk-head flanges

On a set-up that uses a tank with drilled holes in

the glass, the bulk head flange attaches to this

hole allowing us to attach plumbing lines to each

side of the hole while giving us a water tight seal

to the glass that will withstand pressure. They can

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

4 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

also come in regular and sch 80 PVC for both

socket weld and screwed / threaded connections.

The most common bulk head flanges are

threaded.

Valves

There are three main types of valves that are the

most common in aquarium set-ups, swing check

valves, ball check valves, and ball valves. Each has

a different use in a plumbing setup.

Swing check valves allow for water movement in

only one direction. It has a plate / door inside the

valve which will swing open when pressure is

apply to only one side of it. It will swing shut when

pressure is applied to the other side. Many people

install check valves on the return line to their main

tank to help prevent water draining back into the

sump should the return pump stop working (ie.. if

the power goes off). There are a few different

types of check valve out there, but the swing

check valve is among the most common one used.

The better quality swing check valves are design

to work without a spring assembly but they will

restrict the flow a little. They are available in

regular and sch 80 PVC for both socket weld and

screwed / threaded connections. The diagram

below will show you how the inside of a swing

check valve works. Exact designs vary among

different manufactures

Ball check valves have the same purpose as

compared to a swing check valve. Ball check valve

are another type of very simple check valve to only

allow water to flow in one direction through the

valve. The valve uses a PVC ball and the force of

the water to work. When water is flowing through

the valve in the intended direction of flow, the

water will hold the ball up against 4 PVC rails

inside the body of the valve. These rails allow

enough spacing around the ball for water to freely

move around it. Only one of the internal rails is

shown in the below diagram.

When the direct of the flow changes to the

opposite of the intended direction of flow, the ball

will be pushed back to rest on a rubber gasket and

prevent any flow from getting past it.

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

5 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

The below is a picture of a ball check valve that I

used on a larger reef tank. The picture was taken

early on when plumbing it all together.

Please note, a ball check valve works best when

installed on a vertical line, not a horizontal line like

pictured above.

Ball valves are used to control flow and/or to shut

off flow. It is basically a ball with a hole drilled

completely through it that is also has the same

inside diameter as the pipe it is connected to.

When the handle is turned in the same direction of

the pipe, the hole lines up with the pipe and the

valve is fully open. When the handle is turned in

the opposite direction of the pipe, the hole turned

the other way and the valve is completely closed.

These are also available in regular and sch 80

PVC for both socket weld and screwed

connections.

I would refer you to the below article with some

more detialed information about valves commonly

used on sumped aqauriums

http://www.reefaquarium.com/2013/aquariumplumbing-valves/

Miscellaneous adapter / fittings

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

6 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

There are a ton of different fittings designed to be

used in certain situations that you may come

across like: reducing sizes (glued or threaded or

both), increasing sizes (glued or threaded or

both), going from threaded to glued fittings, or

going from glued to threaded fittings. Ive only

mentioned and provided pictures of a few of those

types of fittings here to give you an idea of what is

available out there.

Drilled or not drilled

One of the last things you will need to decide is if

your display tank will be drilled or not. If the tank

will be drilled, it would also be recommended that

you have a internal or external overflow for the

drain line. I always recommend a drilled tank.

Putting it all together

As previously mentioned, there are two traditional

ways of connecting your plumbing system together

when using PVC and/or ABS materials. One

method involves using a combination of threaded

fittings and solvent weld (AKA gluing), and a

second of using only solvent welded (glued)

fittings.

Using Threaded Fittings

This is a fairly easy method to use. There are

three things you have to keep in mind:

1) You will need to use thread tape. In pressurized

lines, this will fill in the small gaps between the

threads and prevent any leaks. It will also help to

keep the two fitting tight together. Just make sure

you wrap the tape around the threads very tightly

and in the opposite direction of the threads so it

will not become un-wound or bunch up in one

spot when you screw the fittings together (see

below pic).

2) Do not use / connect threaded fittings made

from different materials together. The reason

being is that different materials will have different

expansion rates when/if they are heated up or get

very cold. This will likely cause leaks even when

thread tape is applied.

3) Unless you are a skilled pipe fitter by trade, you

will need to use adapters to transition from

threaded fittings to solvent weld fittings. The

reason being is that at some point you are going

to need to have a piece of pipe cut to fit a portion

of one of your lines. Unless you can have the ends

thread to the exact length and depth of the

fittings, you going to have to use solvents and

adapter to transition between the two connection

methods.

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

7 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

Solvent Welding

This is my preferred method. When it is done

correctly the bond between the fittings will outlast

the pipe and fittings themselves. Solvent Weld is

commonly referred to as gluing even though it is

not a gluing process at all. The solvent cement

actually starts to melt or soften the outer layers of

the PVC or ABS when it is applied to the pipe and

fitting. When the fitting and pipe are then placed

together, the soften materials will now become

fused together. It will start to harden in sections,

become dry to the touch in about 10 minutes, and

will be fully cured and safe to use in 24 hours.

There is a specific type of solvent for each type

(and sch) of plastic pipe. It is extremely important

to use the correct solvent as it contains an

element of the material dissolved in chemical

called tetrahydrofuran which allows for the

material of both peaces to become fused together.

If you use the incorrect solvent, the bond between

the two fittings will fail over time assuming one

forms at all. When correctly used, the bond

between the two fittings will be unbreakable.

With certain types of plastic pipe and fittings, a

primer is also suggested for use. This mostly

applies to the thicker plastics (like sch 120 or

160), or fittings with finishes that looks like they

are highly polished with a mirror-like finish. For

PVC and ABS applications, primers would not be

required. Additionally, when joining different types

of materials (like Regular PVC and sch 80 PVC)

you will need both a primer and a solvent meant

for using both types of materials or you will not

get a bond that will last over time. These are

commonly referred to as transition cements /

glues.

I would also recommend using a solvent that has

low VOC and (in Canada and the USA) meets on

of the following ASTM standards: ASTM D2564

ASTM F656, ASTM D2235, ASTM F493, ASTM

D3138, and ASTM 2235. Those two statements

(Low VOC and one of the previously listed ASTM

standards) should appear in the bottle.

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

8 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

Below is how I put together the plumbing set-up

for my 120 gallon tank using a 55 gallon tank as

the sump. I tried to lay it out in little more detailed

steps that I took going from planning the set-up

right to installing the plumbing. Please keep in

mind, this is just one way to set-up and install

plumbing in a sump setup. There are many other

way to approach this. I am only speaking to the

way that I have done this to hopefully give you

ideas on how to approach your set-up.

Now for the first stage A) Planning the

flow rates

Step 1 : How much flow through the display

tank

I had decided that I would use the traditional rule

of thumb. I set my goal to have 10 times the

display tank volume flowing through the sump.

That flow rate is very close to the maximum

recommended flow for my skimmer and I can add

a powerhead to the live rock compartment as that

would be the only compartment which requires a

higher flow rate. As I have a 120 gallon display

tank, that would mean I need 1,200 GPH of flow.

But I am willing to settle for anything between

1,000 and 1,400 gph

Step 2: Drilled tank or not (gravity feed or

Siphon based drain line) ?

When it comes to gravity based drains, there are

two common approaches to control the air/water

mixture in order to get a silent drain. One

approach involves using two drain lines , one line

containing a valve to restrict the water flow to

match the air flow (resulting in a silent drain), and

the second is used as a backup drain should the

first main drain line become clogged. This type of

approach as a few different common names, like:

herbie overflow, bean animal, ocean to ocean

The second approach involves using a single drain

line and controlling / restricting the airflow to

create a silent drain. This is commonly referred to

as a Duriso Standpipe. This is my preferred

approach as the plumbing is easier to setup and,

in my own opinion, less likely to become clogged

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

9 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

as you are not restricting the flow of water inside

the drain.

As I purchased a new tank, I got one that was

already drilled for a return line and a drain line

with an internal overflow, I set up a duriso

standpipe. Gravity based drains are my preferred

method to set up a tank as you can calculate the

amount of water that can drain back into the sump

should your return pump stop working preventing

any water on the floor. Both of my reef tanks have

been set-up that way as we get frequent power

failures were we live. I chose gravity feed system

over a siphon based system for a few different

reasons. The least of which is that I feel I can

trust gravity feed system not to fail and a gravity

based system makes the least amount of noise

when assembled correctly.

The pic below shows a Durso stand pipe along

with one that I used on my 90 gallon reef tank

Water flows in through the 90 degree elbow at the

top and down the pipe through the bulkhead

flange and into the plumbing line to the sump. At

the very top is a air hole which allows a steady,

even flow of water. This will give you a extremely

quiet drain line. There is no real set size for the

air hole. It can be trial and error. I had made a

adjustable air hole by drilling a 5/8 inch hole

through the side of the cap and the side of the

standpipe. You adjust it by slighting turning the

cap to make the hole smaller or bigger which

controls the flow of air. Through using an

adjustable air hole, you can get the maximum flow

and keep the drain extremely quiet (pic below).

You can also use a oversized hole (such as

inch) and an air valve as well.

The one disadvantage of a Durso standpipe with a

internal overflow is that uneaten food, sludge, etc,

can accumulate in the bottom and sides of the

overflow over time. This is a minor problem, and

really not a big deal. But for this reason I

recommend using all slip fittings in the

construction of the standpipe, and not gluing the

standpipe to the bulkhead. If left unglued, when

the interior of the overflow accumulates too much

sludge, you can simply scrub around inside the

box to loosen things up and pull the standpipe out

of the bulkhead. If you choose to drill your own

tank, the below link explains the steps of that

process.

http://www.aquaticcommunity.com/aquariumforu

m/showthread.php?t=76407

Just remember you must make the hole to

inches larger than the pipe and fitting size the bulk

head flange is rated for. For example, if you want

a 1 bulk head flange you will need a 1 inch

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

10 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

hole in your tank.

The Siphon set up is a little more involved. Below

is the most common design used.

It is designed to be a non-break siphon. If the

power goes out, the tank will only drain down to

the point of the intake being out of the water and

it is said to start draining again once the return

pump comes back on the water line is above the

intake. I have never tried one so I do not know

how well they actually work. I only wanted to

mention them here as an alternative to a stand

pipe with a drilled tank. The below link can help

you build your own siphon based drain system

should you chose that type of drain.

http://www.evillabs.net/wiki/index.php/Super_Suc

king_Siphon

There are so alternate products available for a

siphon based system using pre-assembled

overflow boxes like the one in the below link.

These products are typically available in stores

that carry products for salt water aquariums. One

example is in the link below. Once again, I have

never used one of these but it is a possible option

to look into should you have a tank that cannot be

drilled.

http://www.jlaquatics.com/product/ofcs100/CPR+C-Siphon+Aquarium+Overflow++CS100+Deluxe+%28800GPH%29.html

B) Material Types and Sizes

Step 3: Choose the pipe and fittings sizes

and material types.

First I determine the size of pipe that I will need

for my return line. You can always cheat at this

step and just go with the same size of pipe and

fittings as the outtake on your return pump. But if I

did not know that, I would base my decision on a

flow rate of 1200 GPH and the fact that I want to

use flexible PVC. This leads me to choose a oneinch line. As flexible PVC has a working pressure

of 100 psi and at that pressure a 1 inch line will

give me ~2220 gph which is more than enough.

For a drain line (including the durso stand pipe) I

chose 1 inch line as the will give me about

1400 gph of flow which is a little more than I need

just to be safe. Either PVC or ABS will be good for

this application. I used PVC as I had some left

over from another sump I had set-up.

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

11 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

C) Planning the set-up/Installation.

Step 4: plan the layout.

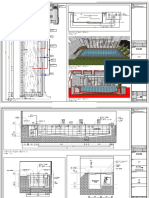

I drew a simple diagram of how I wanted to put

the plumbing together. I kept in mind how much

room I had in the stand, the size of the sump, and

where I wanted to put all of the equipment in the

sump so there would be no plumbing lines in the

way. I also did not require a swing check valve on

either the return line or drain lines as I made sure

the sump has room for all the drain-back into the

sump from the main tank should the return pump

stop working.

Step 5: Calculate the flow loss on the return

line.

Based on: 4 feet of height, three 90 degree

elbows, two unions, and one ball valve, there

would be a estimated loss of 650 gph. This would

mean that I would need a return pump with a flow

of 1650 to 2100 gph. As the drain line does not

have any significant pressure in it, any flow loss

due to only two elbows and a union would not be

significant.

Step 6: Chose a return pump

I ended up getting a pump with a 1800 gph flow

rate which results in a over flow through the sump

of 1,150 gph. This also means I do not have to upgrade the size of my pipe and fittings, or increase

the size of the. All of the other factors that go into

selecting a return pump is a topic best left for

another article.

Step 7: Assemble

After getting everything I needed, along with the

proper cements, I got started. I first measured

and cut the first few pieces of pipe and put

together the plumbing lines as I went. I did not

use any glues at this point. Once I had everything

built and place just the way I wanted it, I marked

each joint with a black marker. That way when I

took it apart to apply the cement, I just had to line

up the two marks on each connection to make

sure it was put it back together just as I had dry

fitted it together. This gives me the options to

adjust things before gluing as well as gluing some

of the plumbing system outside where I dont have

to worry as much about making a big mess

While setting the fittings together I had realized I

forgot to add a line to run a media reactor. I

added that line to the return line using a t fitting.

This will not have a significant effect on the overall

flow

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

12 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

Step 8: Test.

After letting the newly bonded fittings cure for 24

hours, I filled it up with freshwater and fired up

the return pump. I found one small leak which

was quickly fixed by tightening the bulk head

flange. I let it run for a few days until I had the air

intake adjusted so the drain line had the least

noise.

And just a few pics of the actual set-up

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

13 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

Please feel free to start a thread in the forum to

ask any questions you may have. If you are not

already a member, you will need to sign-up first.

http://www.aquaticcommunity.com/aquariumforu

m/forumdisplay.php?f=62

For more detialed information about the different

choices that you have for plumbing materials, I

would refer you to the below article here

http://www.reefaquarium.com/2013/plumbingpipe-ans-fittings/

RECOMMENDED READING:

Good Starter Fish and

Clean-up Crew Options

Buying a Used Aquarium

Common Approaches to

Filtration in Marine

Aquariums

SHARE THIS

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

14 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

WRITTEN BY CLIFF

I've been keeping tanks for over 17 years

now and have kept many different set-ups

along the way. My wife and I have really

enjoyed everything we have learned and are

looking forward to many more years of

learning and enjoying this fascinating hobby

along with the rest of our pets.

49 COMMENTS

Isaac Smith 2 YEARS AGO

(Reply)

You truly are the man Cliff very

comprehensive but still concise.

Thanks for passing on your

knowledge, its going to help me a

lot.

Dennis Stickles 2 YEARS AGO

(Reply)

Great article! Im using the siphon

method for my 125 gal freshwater

tank. Saltwater is something Ill

tackle down the road. Thank you

for taking the time to pass along

this information.

syracuse ny 2 YEARS AGO (Reply)

good article it really helped me

understand what I had been

searching for, Thank you

James labyrinth 2 YEARS AGO

(Reply)

Excellent article, it answered every

question I had! Huge thanks are in

order for the time that youve put

into this.

John L 2 YEARS AGO

(Reply)

Great article. I found this while

googling around ball check valves

for aquaria.

Question for you, Cliff, do you think

a check valve would be necessary

in a non-sump, in-line filtration

system? Specifically, I am running

a series of Lifegard tubes. The

plumbing is basically a simple overthe-lip siphon and a return pipe out

of PVC.

The only info I can find

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

15 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

recommends check valves back into

the sump. Should my pump fail, I

dont know if I would need one for

this system. The return is

submerged a bit, so it may provide

a counterbalance for the closed

loop.

Cliff Erhardt 2 YEARS AGO

(Reply)

If you are using a canister filter, you

do not need any type of check valve,

provided you have the intake and

return lines both in the tank. When

both lins are in the tank nothing will

happen when/if you unplug the filter

licensed plumber 2 YEARS AGO

(Reply)

Actually I like to seeing some

aquariums because beautiful fishs

in available this, but these types of

plumbing systems are using in

aquarium it thing is completely new

for me. Yes after reading this blog I

am understand that why plumbing

system is important on aquarium

with fish.

Bucky 2 YEARS AGO

(Reply)

Youve got to be kidding me-its so

transpaernlty clear now!

Daniel perry 2 YEARS AGO (Reply)

Hello I have a 450 litre tank with a

32mm pipe for the outlet of the

tank on the back of the tank with

just the pipe going in to tank any

help to make it flow out better

many thanks I can email pics to u

cheers dan

Cliff Erhardt 2 YEARS AGO

(Reply)

Daniel, It might be best if you were

to go to our forum and post some

pics and your questions there. It

would be a whole lot easier for me

to be able to help you with your setup that way

http://www.aquaticcommunity.com/

aquariumforum/index.php

Debbie 2 YEARS AGO

(Reply)

Thank you so much for this post.

Im setting up a 55 corner reef tank

and have only had nano cubes in

the past. My tank is older with all

non-tempered glass (I hope) and

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

16 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

understanding the many different

options for plumbing and usage of

a sump has had me overwhelmed.

I appreciate this information.

Debbie

Julie Ziroff 2 YEARS AGO

(Reply)

I found your information very very

helpful. Thank you so much. I do

have a few questions though I

am putting a sump in my

basement. This is my first time

ever doing plumbing. It would be

10 feet from the tank to the sump.

The loss of GPH would be around

1455. You said using a 1 flexable

PVC line for the return would give

you 2220 GPH. Which would make

my GPH around 765 correct? What

would be the best way to increase

this? I wanted to get around 1000

at the very least. Would increasing

the pipe size for the return line

help. maybe to 1 1/2 in? Any

suggestions would be great. The

tank size is 180 gallon and the

overflow is 1200 GPH.

Cliff Erhardt 2 YEARS AGO

(Reply)

Julie: Im afraid increasing the size

of the return line will not provide

you with the results you are looking

for. I would suggest looking into a

larger return pump. You also have

to keep in mind that after the first

few months of use, a return pumps

GPH will usually drop after the pump

break-in period is over. I would

suggest a pump in the 2000 (or

more) GPH range. You can always

plumb in a by-pass to reduce the

flow a little if it works out to be a

little more flow than what your drain

line can handle. It certainly would be

a good idea to maximize the flow

your drain line can handle, plus have

a little extra should you ever want to

add anything, such as a media

reactor or a UV.

gahwieuasa 2 YEARS AGO (Reply)

Wow, awesome blog layout!

Thanks For Your article about

Aquarium Plumbing Basics |

Saltwater Aquarium .

Matt 2 YEARS AGO

(Reply)

Great article and I have a quick

question on the loss GPH. You have

listed:

A loss of 75 to 125 GPH for each

foot of height (from the pump to

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

17 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

the display tank return)

A loss of 50 to 75 GPH for each

90 degree elbow

A loss of 30 to 50 GPH for each

45 degree elbow

A loss of 50 to 75 GPH for each

swing check valve

A loss of 20 to 40 GPH for each

ball valve

A loss of ~ 3 to 5 GPH for each

union

Do you have any idea how much a

full loop would lose per gallon? I

have off of the sump in line under

the tank a loop prior to entering the

sump. I have a feeling this is

causing sigificant slow down. The

people that installed my tank did it

to lessen the drain noise and

bubbling in the sump. I have the

same 120 you do with a Mag 12

can it feel like its slow flo.

Cliff 2 YEARS AGO

(Reply)

Matt: I would guess one complete

loop would be close to the same

effect (or a little more) as a 90

degree elbow and there is a more

gentle re-direction of the flow. That

would also depend on the length of

the hose as well. I have never found

a very credible reference for how to

calculate that, nor have I actual

calculated it myself. Just a educated

guess on my part.

What I would suggest is signing up

on our forum and starting a thread

to ask this same question. If you

post some pics of your set-up Im

sure we all can figure out how to

increase the flow to the tank.

http://www.aquaticcommunity.com/

aquariumforum/index.php

PompanoBeachPlumber

2 YEARS AGO

(Reply)

Good stuff, thank you for this. As a

contractor this really helps keep me

fresh. Thanks Again

Domenic 2 YEARS AGO

(Reply)

does any one have a design for an

automatic water changing system

David 2 YEARS AGO

(Reply)

Cliff.Help.

Ok, heres what I have cookin

55 gal tank freshwater for Discus

display.

I want to put the sump refugium in

the basement directly under the

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

18 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

aquarium above.

11-0 from return pump to tank.

My configuration will not support

one any closer as my aquarium is

place in the wall with a bar on one

side and a pantry on the back side.

Strange I knowbut I placed it in

the wall and currently use a small

fluval 330..not good.

I am constantly doing water

changes and dealing with algae

build up.

Calculations: (did this a couple

different ways but will post most

recent)

Return pump: 1 pvc 2200 GPH

Drain Line: 1 1400 GPH (using

glass holes direct drain line)

55 gal tank @ 10x = 550 GPH

Loss of flow:

@ Return line

(2) 90 degree unions at aquarium

@ 75 GPH= 150 GPH

(1) T Union overflow back to

sump @ 5 GPH= 5 GPH

(2) Unions @ pump and Aquarium

@ 5 GPH= 5 GPH

(1) Ball Valve @ 40 GPH= 40 GPH

(1) Swing Check @ aquarium @ 75

GPH= 75 GPH

11 return Average@ 100 GPH=

1,100 GPH

Total 1,650 GPH LOSS..Help!

Obviously, my Height is the major

contributing factor.. the unions, ball

valve etc. are major factors.

My Return Pump Options: (Would

like to have a ton more as my drain

line is 1000+)

Mag Drive 1800 1800-1650 = 150

GPHno good.

Are my calculations correct? Any

suggestions? Pulling my hair out

Cliff 2 YEARS AGO

(Reply)

David, you are not too far off on

your calculations as compared to

what I got. You are going to need a

serious return pump for that type of

head loss. I would suggest looking

into a external pump for that type of

flow. I would suggest a pump like

the ReeFlo Dart/Snapper. Then size

your plumbing lines accordingly. You

should need a 1.5 inch return line

for a pump that will handle more

flow even tho the head height will

reduce it. Based on the actual flow

that will get into the tank, a 1.5 inch

gravity feed drain line will be OK

http://www.reeflopumps.com/lowsp

eedhighflow.html

I would also suggest using a PVC

ball check valve and not a swing

check valve. Ball check valve are

less likely to fail when you need

them the most. Just make sure you

install it as close to your pump as

possible. You will loose about the

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

19 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

same in GPH flow as compared to

most swing check valves.

Once you have everything set-up,

make sure you complete a few

power fail tests to make sure the

sump can handle the drain back

from the tank that you will get. You

can adjust the sump compartment

sizes base on those results if

required.

David 2 YEARS AGO

(Reply)

Also using Trigger sump 36 inch

capacity of total water volume 34.5

and operating capacity of 23.4

What size return pump is my main

questionassuming I have all other

factors covered.

Maria 2 YEARS AGO

(Reply)

Such a great and informative post.

Thanks for sharing and keep

posting.

David 2 YEARS AGO

(Reply)

Thanks Cliff!

Really appreciate your quick

response and suggestions.

Ill do another run thru on my calcs

based on this info.

I have been researching info for my

setup for some time now and I

stumbled into your presentation..

Such valuable information! I

wouldve been very disappointed at

my first approach.

My kids will be excited when I get

this up and running!

Thank you, Thank you.

Water boy,

David

Wayne Morris 1 YEAR AGO (Reply)

I see you have some excellent

information and charts for flow

rates. I would like to suggest the

use of sweep 90s and 45s

wherever possible in lieu of the tight

90s used by most people. The flow

rate restrictions of tight 90s can

add up very quickly in a gravity

system but this is also true with

pumps. These restrictions can

actually be measured with an amp

meter but your pump will run

quieter and cooler with fewer

restrictions. You will be pleasantly

rewarded for your efforts.

Jason 1 YEAR AGO

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

(Reply)

20 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

I currently have a 90gal mixed reef

saltwater aquarium with a 29gal

sump. I would like to upgrade to a

larger sump and make it into a

refugium setup; when I do this I

would like to also upgrade some of

my plumbing, like adding a ball

check valve before my pump, some

pvc unions, and ball valves just to

make things neater etc. I was also

considering going to an external

pump as to eliminate some heat

from my system. I am familiar with

glueing pvc plumping and that

within a few minutes it is safe to

run water through but how

concerned should i be with my tank

inhabitants?? The last thing I want

to worry about is having some of

the pvc glue/cleaner running

through my system and wiping out

my tank!!

Also I notice on larger aquariums

most are not using power heads/

fans in their tank; is this because

they are running much more gph

flow than is necessary to get

proper flow through their return

lines that they do not need to

incorporate power heads/ fans? I

find it to be a much cleaner more

desirable look not having several

power heads/fans cluttering the

inside of the tank. I also only have

1- 3/4 return line that ends in a Y

with 2- 3 flare loc-line nozzles; so

I probably wouldnt be able to get a

tremendous amount of flow

upgrading my return pump since I

only have 1- 3/4 return line.. I

would probably need at least 1

more return line into my tank and

they would probably both need to

be at least 1 just assuming

here. If that were true that would

of course be impractical since I

would need to tear my system

apart to make changes like that :/

Thanks for your help!

Cliff 1 YEAR AGO

(Reply)

With some of the new low VOC

glues on the market today, you

should have less of a concern. Most

of them typically need around 8 to

24 hours to fully cure and be

perfectly safe for your set-up.

Follow the curing instructions listed

on the bottle of glue and you should

be fine.

The powerheads you see in others

aquariums do serve a pretty vital

purpose in a aquarium with live

rock. The below link explains that in

more detail.

http://www.reefaquarium.com/2012

/the-importance-of-water-flow-andmovement-2/

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

21 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

A 1.5 inch return line, even with the

Y fitting ending in two line-lock

should be able to handle around

2,500 gph of flow with no problems

assuming you are talk about sch 40

PVC. That would be more flow than

you would ever want in a 90 gallon

display tank so there would be no

need to change your return line. I

would be more concerned about

having a drain line (or lines) to

handle your planned increase in

flow.

I would suggest around 1300 to

1400 gph of flow in your main tank

would be a good goal to aim for.

Start by planning you sump (what

you want in it, the size of the

compartments.. and so on). Next

plan your drain lines and return

lines. You two main goals here

would be to make sure your drain

line will handle more than your

planned flow, as well as identifying

all the elements of your return line

that will restrict your flow so you

can choose the correctly sized

return pump for your set up. You

would likely want at least one 1.5

inch gravity based drain line

(minimum)

I really do like external return

pumps, but they can take up a lot of

space if your sump is going under

your display tank in your stand. Let

me know if this answeres your

questions

Matt Bosley 1 YEAR AGO

(Reply)

Is that sch 40 and tiger flex hose

that you used in 7? I love it btw,

this is exactly what I am looking to

do. I am happy someone actually

posted an exact diagram on how to

do this. I had a great idea on how

to accomplish this, but now I have

a guide ha.

Thanks for the hard work posting

this all up.

Have a good one.

Cliff 1 YEAR AGO

(Reply)

Matt, the flexible tubing used in this

article is a form of white

PolyVinylChloride (PVC). You will

commonly find it on applications like

jetted hot tubs that need a flexible

PVC tube that will work with regular

sch 40 PVC fittings.

krishikaseo1 1 YEAR AGO

(Reply)

I Gone through your Website its

really amazing.

very good information on product i

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

22 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

got know useful information thanks

for this.

Frank 12 MONTHS AGO

(Reply)

Wow, this has to be one of the best

written pieces I have read on this

topic. Spot on, it was exactly what I

was looking for to help me size my

return pump.

Thanks!

Cliff 12 MONTHS AGO

(Reply)

Thanks Frank, Im glad you found it

helpful

George 11 MONTHS AGO

(Reply)

Hi Cliff, i have recently setup a

Marine tank with Sump and Durso

drain pipe in Weir. I am

experiencing some major issues

and cannot find a solution. You

seem to be the man with the

answers so thought I should run it

past you.

I have a 32mm drain going down

into my sump (hole on top), the

return is a 25mm pipe with a D&D

H2Ocean Aquarium Pond Flow

Pump FL 3000.

The issue i am having is that the

drain is struggling hugely and it

makes a huge amount of noise.

The weir water level drops and

rises every 10-15 seconds and

makes a loud draining / sucking

noise when that happens. How do I

stop this and allow the water to

flow smoothly? At the bottom of the

drain under the tank I have 2 90

degree elbow joints before the pipe

enters the water in the sump. The

pipe is about 1-2 inches under the

water level.

When i reduce the return pump

flow to an absolute minimum it

calms down and is fine but i feel

that level of water flow is not

enough.

Anything you can recommend?

Cliff 11 MONTHS AGO

(Reply)

It sounds like you do not have have

the correct amount of air flow

getting into the standpipe, assuming

the drain (the way it currently is) is

handling the flow of the return

pump.

I would suggest getting a new cap

for it and drilling just on very very

small air hole using the smallest drill

bit you can use. Try it for a few

minutes and observe. If the duriso is

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

23 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

not draining correctly, drill a second

hole with the same drill bit and

observe for a few minutes. Repeat

until it is working the

way you want it. This approach has

always worked for me.

Let me know how that works for

you, and please keep me posted on

your progress

krishikaseo1 10 MONTHS AGO

(Reply)

I suffered your web site its very

superb.

very good data on product i got

apprehend helpful data thanks for

this.

PVC Ball Valves Manufacturer

oliver 4 MONTHS AGO

(Reply)

Exellent article this has pointed me

in the right direction to design my

system

Cliff 4 MONTHS AGO

(Reply)

Thanks Oliver, I am very glad to

read that you found this helpful

Eddie Garcia 3 MONTHS AGO (Reply)

I have an aquarium like this with,

this hole on the bottom that I would

like to plug and just go with regular

outside top Filters. Is there

something that u recommend using

or where can I find such plug or

what to do?

Cliff 3 MONTHS AGO

(Reply)

In the past, I have covered drilled

holes in aquariums by getting a

small peace of glass cut that is

about 1 inch wider than the hole and

using that almost as a patch. You

can secure it over top of the hole

using aquarium safe silicone. Just

make sure you attach the pc of glass

to the inside of the aquarium and

the pc of glass you use is as thick as

the glass used to build the

aquarium.

Darren 4 WEEKS AGO

(Reply)

cliff on a 55 gallon reef aquarium

you are saying to use a 1inch drain

correct seeing u want a 10x flow

rate

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

24 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

Darren 4 WEEKS AGO

(Reply)

cliff i would want to use a 1inch

drain on a 55 gallon reef setup

using a 20 gallon sump correct

seein u want a 10x flow rate in a

reef right or wrong

Cliff 4 WEEKS AGO

(Reply)

Using that 10X rule of thumb is just

really a starting guideline. You will

most likely be fine, but here are a

few other things to consider before

assuming that

You may need to make adjustments

deepening on what/how you are

using your sump. If it is just for your

equipment and skimmer, and the

GPH of your skimmer is around 550

GPH, then it will work out fine for

you. If not, try to match the flow

through the sump with the GHP of

your skimmer as best as you can.

That will help you get the most out

of your skimmer. If you are using

your sump for a refugium, then you

would want to match the flow going

through the sump to better match

the requirements of the algae you

are growing in there. If you are

setting up a algae scrubber on your

return line, then you may want to

consider even more flow.

As for the pipe size, 1.25 or 1.5 inch

drain line would be a little better. 1

inch would work, but I always like

having a little extra to work with, in

case I want more flow later on.

Darren 4 WEEKS AGO

(Reply)

I plan on coming in threw a sock

filter putting a protein skimmer in

the front of the sump then flowing

into refugium threw a bubble trap

then out kinda new to all this an

just want to do it right thats why I

am asking so you would suggest

1.5 drain it wont be to much thanks

for the advice

Cliff 4 WEEKS AGO

(Reply)

What is the flow rate of your

skimmer ?

Darren 4 WEEKS AGO

(Reply)

Going to use Reef Octopus Classic

110 Space Saver Protein Skimmer

rated at 92gph thank you cliff just

want to be right like i said kinda

new to all this

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

25 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

Darren 4 WEEKS AGO

(Reply)

or do i want to match this to my

return from what i understand you

want it slower threw the refugium

to build bacteria correct

Dylan 4 DAYS AGO

(Reply)

Cliff,

Article was awesome. I have had a

29 gal for about a year, but have

been only using a backpack filter. It

works, but it really doesnt keep the

tank clean. The sand gets covered

and the water less than ideal,

which has made me want a sump.

Do you have any recommendations

for a setup that can help keep my

tank clean (I hate going 2 feet

down in the water to clean the

sand), but isnt expensive (like

college budget and ingenuity).

Also, Its time for me to upgrade

my lighting. My set up now works

But I dropped it in the tank so its

running at about 30% health. My

tank is a weird size, 24 tall 24

wide 12 depth,, with a good size

anemone, some soft corals and a

few hard. Also I have a pair of

clowns, like 6 other small fish, and

shrimps and crabs. Can I get away

using this light?

http://m.ebay.com/itm/181275113

350?nav=SEARCH

If not, any recommendations

around the $100 range, I just

wanna see my corals grow!

Cliff 1 DAY AGO

(Reply)

Thanks Dylan

As far as your sump goes, make it

as big as you can. The below can

help with that as well

http://www.reefaquarium.com/2012

/some-sump-basics/

As you only have a 29 gallon tank, I

would suggest you consider finding

a new home for your anemone. All

of the anemones that will host clown

fish will get too big for your tank at

some point.

That light fixture will work fine for

your set-up

LEAVE A REPLY

Your email address will not be published. Required

fields are marked *

Name *

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

26 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

Email *

Website

Comment

You may use these HTML tags and attributes:

<a href="" title=""> <abbr title="">

<acronym title=""> <b> <blockquote

cite=""> <cite> <code> <del datetime="">

<em> <i> <q cite=""> <strike> <strong>

POST COMMENT

AUTHOR

Cliff

I've been keeping tanks for

over 17 years now and have

kept many different set-ups

along the way. My wife and I

have really enjoyed everything we have learned

and are looking forward to many more years of

learning and enjoying this fascinating hobby along

with the rest of our pets.

MENU

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

Macro Algae

Saltwater aquarium

plants

Aquarium Plumbing

Algae

Macro Algae

nuisance algae

Aquarium DIY

Chemistry

Equipment

Fish

Invertebrates

News

Reef

Corals

Corals for beginners

Reviews

Equipment review

27 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

Product review

Setting up an

aquarium

FISH PROFILE

Vampire Tang

JULY 19, 2013

Orange Shoulder Tang

JULY 19, 2013

Majestic Angelfish

APRIL 25, 2013

LATEST FORUM THREADS

... Quaranting in Adverse Conditins (?)

New garden eel

New to reef

20 Gallon Long Planning

INVERTEBRATE PROFILES

Conch Snail

APRIL 30, 2013

Turban Snail

APRIL 30, 2013

Spiny Star Astraea Snail

APRIL 30, 2013

MACRO ALGAE

Red Hair Algae

APRIL 13, 2013

Caulerpa Macro Algae

APRIL 13, 2013

Scinaia Macro Algae

APRIL 13, 2013

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

28 / 29

Aquarium Plumbing Basics - Reef Aquarium

11/11/2014

Copyright Reefaquarium.com 2012 -

http://www.reefaquarium.com/2012/aquarium-plumbing-basics/

29 / 29

Das könnte Ihnen auch gefallen

- Diy Aquaponics Plumbing Guide Part 22Dokument4 SeitenDiy Aquaponics Plumbing Guide Part 22Ching HuiNoch keine Bewertungen

- Build Your Acrylic AquariumDokument10 SeitenBuild Your Acrylic Aquariumtreasuredesigner100% (1)

- Aquaponics Plumbing ClassDokument96 SeitenAquaponics Plumbing ClassVanessa Evans100% (7)

- Freshwater Aquarium ManualDokument32 SeitenFreshwater Aquarium Manualhippong niswantoroNoch keine Bewertungen

- DIY AquariumDokument25 SeitenDIY AquariumKlause Paulino100% (2)

- Small Reef Aquarium Basics GuideDokument119 SeitenSmall Reef Aquarium Basics GuideHari Budi Surya WirawanNoch keine Bewertungen

- PetFishNet Guide AquariumDokument100 SeitenPetFishNet Guide AquariumGaurav SinghNoch keine Bewertungen

- Freshwater Aquarium - Setup and CareDokument66 SeitenFreshwater Aquarium - Setup and Carepharaonu75Noch keine Bewertungen

- Planted AquariumsDokument2 SeitenPlanted Aquariumsalexjetter100% (1)

- Healthy Auarium Fish PDFDokument68 SeitenHealthy Auarium Fish PDFKuja65Noch keine Bewertungen

- Aquaponics: Where One Plus One Equals ThreeDokument21 SeitenAquaponics: Where One Plus One Equals ThreeAquaponics100% (3)

- 02 Filters and Filter Media 2010vol1Dokument0 Seiten02 Filters and Filter Media 2010vol1cornerstone2Noch keine Bewertungen

- Build Your Own Garden Pond PDFDokument10 SeitenBuild Your Own Garden Pond PDFMwagaVumbiNoch keine Bewertungen

- Discus Care SheetDokument2 SeitenDiscus Care SheetkozokoNoch keine Bewertungen

- The Cichlids Yearbook Vol 1 PDFDokument100 SeitenThe Cichlids Yearbook Vol 1 PDFaquascapingperu100% (1)

- Beginner's Guide To Getting Started With DiscusDokument18 SeitenBeginner's Guide To Getting Started With DiscusGary HoustonNoch keine Bewertungen

- Aquarium FiltrationDokument9 SeitenAquarium Filtrationjoshua_sx1100% (3)

- Aquarium Plant GrowthDokument59 SeitenAquarium Plant Growthhoticeforu100% (1)

- Golden Grow® Aeroponic Combo System ManualDokument12 SeitenGolden Grow® Aeroponic Combo System ManualeldonperdueNoch keine Bewertungen

- BYAP Magazine Issue1Dokument35 SeitenBYAP Magazine Issue1Rigel PacisNoch keine Bewertungen

- Build Your Own Backyard PondDokument11 SeitenBuild Your Own Backyard PondSami KakarNoch keine Bewertungen

- Tropical Fish SecretsDokument129 SeitenTropical Fish Secretsnirkala100% (1)

- Planted AquariumDokument2 SeitenPlanted Aquariumadrianb7100% (1)

- The Aquarium Nitrogen Cycle GuideDokument7 SeitenThe Aquarium Nitrogen Cycle Guideharish86eceNoch keine Bewertungen

- 28 Discus PDFDokument2 Seiten28 Discus PDFEnrique Rosario SierraNoch keine Bewertungen

- Easy Scape Guide byTheCineScaper PDFDokument19 SeitenEasy Scape Guide byTheCineScaper PDFJodi PrabowoNoch keine Bewertungen

- Hydroponic & AeroponicsDokument33 SeitenHydroponic & AeroponicsSreejesh P C100% (3)

- Fish Diseases Gold FishDokument19 SeitenFish Diseases Gold FishGautam KasliwalNoch keine Bewertungen

- Welcome To Cabbage Hill Farm: Aquaponics SystemsDokument26 SeitenWelcome To Cabbage Hill Farm: Aquaponics SystemsAquaponics100% (2)

- DiscusDokument42 SeitenDiscusmaverick4300100% (1)

- Pond Owners Manual FINALDokument13 SeitenPond Owners Manual FINALaw8183100% (1)

- AquariumDokument38 SeitenAquariumHeinrichjohannes100% (1)

- Aquaponics Technical DescriptionDokument3 SeitenAquaponics Technical Descriptionrorees100% (1)

- Installation/Owner Manual: SOLARHOT Pool Heating InstallationDokument25 SeitenInstallation/Owner Manual: SOLARHOT Pool Heating InstallationAnonymous Hz5fBwKmRNoch keine Bewertungen

- Orifice Flowmeter Straight RunDokument4 SeitenOrifice Flowmeter Straight RunMuhammad ImranNoch keine Bewertungen

- Domestic Water Systems 1Dokument5 SeitenDomestic Water Systems 1Edward P. ButtsNoch keine Bewertungen

- Water Treatment For Off-The-Grid Rainwater Harvesting Systems - Water Organizing Modules (WOMS)Dokument11 SeitenWater Treatment For Off-The-Grid Rainwater Harvesting Systems - Water Organizing Modules (WOMS)Anonymous GnNuL058XSNoch keine Bewertungen

- Pipeline Analysis & Calculation Environment: Pipe SelectionDokument6 SeitenPipeline Analysis & Calculation Environment: Pipe Selectionkermech21607Noch keine Bewertungen

- Cat PHBRWPRVDokument20 SeitenCat PHBRWPRVgazwang478Noch keine Bewertungen

- PE BuildingANewPool 14 0002 006Dokument8 SeitenPE BuildingANewPool 14 0002 006dapsiduNoch keine Bewertungen

- 11 Catalog-2017Dokument29 Seiten11 Catalog-2017chetan_thakur4278Noch keine Bewertungen

- SRDA - A Guide To Siphonic Drainage - 2007Dokument18 SeitenSRDA - A Guide To Siphonic Drainage - 2007Erin Lim100% (1)

- Dynamic Characteristics Check ValvesDokument12 SeitenDynamic Characteristics Check ValvesZoran DanilovNoch keine Bewertungen

- Diy Aquaponics Plumbing Guide Part 1Dokument2 SeitenDiy Aquaponics Plumbing Guide Part 1Dye ArNoch keine Bewertungen

- Hydraulic Ram Pump ThesisDokument8 SeitenHydraulic Ram Pump ThesisProfessionalPaperWriterCanada100% (2)

- Types of Pressure Taps Used in Orifice - PIPING GUIDEDokument4 SeitenTypes of Pressure Taps Used in Orifice - PIPING GUIDEVinodKumarNoch keine Bewertungen

- DG220020Dokument8 SeitenDG220020Luis GonzalezNoch keine Bewertungen

- Series PWS10T: Pure WaterDokument4 SeitenSeries PWS10T: Pure WaterWattsNoch keine Bewertungen

- Aquaponics PlumbingDokument40 SeitenAquaponics PlumbingNik MpitNoch keine Bewertungen

- Air Distribution Systems GuideDokument3 SeitenAir Distribution Systems GuidejchuatsonNoch keine Bewertungen

- Introduction To Water Distribution Systems: What Is in This Chapter?Dokument0 SeitenIntroduction To Water Distribution Systems: What Is in This Chapter?Aob AprilNoch keine Bewertungen

- Plastic Pipe Selection GuideDokument6 SeitenPlastic Pipe Selection Guiderizviabbas2012Noch keine Bewertungen

- RODIDokument17 SeitenRODItoanancoNoch keine Bewertungen

- SRDA-The Siphonic Guide-V1-1305 PDFDokument18 SeitenSRDA-The Siphonic Guide-V1-1305 PDFYaseen MallickNoch keine Bewertungen

- Reducers For Control ValvesDokument3 SeitenReducers For Control Valveswa zaNoch keine Bewertungen

- Models OF817-8H, OF817-12H, OF1019-20H and OF1465-75H Specification SheetDokument2 SeitenModels OF817-8H, OF817-12H, OF1019-20H and OF1465-75H Specification SheetWattsNoch keine Bewertungen

- Pipings, Valves and SpecialtiesDokument22 SeitenPipings, Valves and SpecialtiesYhan SombilonNoch keine Bewertungen

- PlotDokument1 SeitePlotKanashibi OgawaNoch keine Bewertungen

- Section 610 Waterline Construction 610.3 MATERIALS: Is Changed To ReadDokument1 SeiteSection 610 Waterline Construction 610.3 MATERIALS: Is Changed To ReadKanashibi OgawaNoch keine Bewertungen

- Section 401 Traffic Control 401.4 TRAFFIC CONTROL MEASURES Is Changed To AddDokument1 SeiteSection 401 Traffic Control 401.4 TRAFFIC CONTROL MEASURES Is Changed To AddKanashibi OgawaNoch keine Bewertungen

- Concrete Curb, Gutter, Sidewalk, Sidewalk Ramps, Driveway, and Alley Entrance 340.2.1 Detectable Warnings Is Changed To AddDokument1 SeiteConcrete Curb, Gutter, Sidewalk, Sidewalk Ramps, Driveway, and Alley Entrance 340.2.1 Detectable Warnings Is Changed To AddKanashibi OgawaNoch keine Bewertungen

- Section 450: 2015 City of Chandler Supplement To MAGDokument1 SeiteSection 450: 2015 City of Chandler Supplement To MAGKanashibi OgawaNoch keine Bewertungen

- Pages From UDM - SDnSpecs-Pg5Dokument1 SeitePages From UDM - SDnSpecs-Pg5Kanashibi OgawaNoch keine Bewertungen

- Trench Excavation, Backfilling, and Compaction 601.2.9 Shoring and Sheathing: Is Changed To AddDokument1 SeiteTrench Excavation, Backfilling, and Compaction 601.2.9 Shoring and Sheathing: Is Changed To AddKanashibi OgawaNoch keine Bewertungen

- Section 450 Guided Bore Construction 450.1 DESCRIPTION:: 2015 City of Chandler Supplement To MAGDokument1 SeiteSection 450 Guided Bore Construction 450.1 DESCRIPTION:: 2015 City of Chandler Supplement To MAGKanashibi OgawaNoch keine Bewertungen

- Section 360 Telecommunications Installation 360.3 Cable InstallationDokument1 SeiteSection 360 Telecommunications Installation 360.3 Cable InstallationKanashibi OgawaNoch keine Bewertungen

- Pages From UDM - SDnSpecs-Pg4Dokument1 SeitePages From UDM - SDnSpecs-Pg4Kanashibi OgawaNoch keine Bewertungen

- Pages From UDM - SDnSpecs-Pg2Dokument1 SeitePages From UDM - SDnSpecs-Pg2Kanashibi OgawaNoch keine Bewertungen

- Pages From UDM - SDnSpecs-Pg3Dokument1 SeitePages From UDM - SDnSpecs-Pg3Kanashibi OgawaNoch keine Bewertungen

- Pages From UDM - SDnSpecs-Pg1Dokument1 SeitePages From UDM - SDnSpecs-Pg1Kanashibi OgawaNoch keine Bewertungen

- How To Use A Spare Router As A Wi-Fi Extender - How-To - PC AdvisorDokument5 SeitenHow To Use A Spare Router As A Wi-Fi Extender - How-To - PC AdvisorKanashibi OgawaNoch keine Bewertungen

- Aquarium Plumbing Guide Part I Basics of PVC&Tubing - Reefs - PGDokument1 SeiteAquarium Plumbing Guide Part I Basics of PVC&Tubing - Reefs - PGKanashibi OgawaNoch keine Bewertungen

- Aquarium Plumbing Guide Part II Basic & Advanced Plumbing S - PGDokument1 SeiteAquarium Plumbing Guide Part II Basic & Advanced Plumbing S - PGKanashibi OgawaNoch keine Bewertungen

- Aquarium Glass Thickness CalculatorDokument5 SeitenAquarium Glass Thickness CalculatorKanashibi OgawaNoch keine Bewertungen

- Aquarium Plumbing Guide Part I Basics of PVC&Tubing - Reefs - PGDokument1 SeiteAquarium Plumbing Guide Part I Basics of PVC&Tubing - Reefs - PGKanashibi OgawaNoch keine Bewertungen

- Pressure Reducing Valve ShapeDokument1 SeitePressure Reducing Valve ShapeKanashibi OgawaNoch keine Bewertungen

- 4.5 BOM CruzadoDokument2 Seiten4.5 BOM CruzadoNikolai GongoraNoch keine Bewertungen

- Technical Solution Sheet 99.02: Rainwater TanksDokument8 SeitenTechnical Solution Sheet 99.02: Rainwater TanksBarrasons Engineers TeamNoch keine Bewertungen

- Thrust Block CalcsDokument3 SeitenThrust Block CalcsThiruvasagam Subramanian0% (1)

- Water Bye Laws 2011Dokument39 SeitenWater Bye Laws 2011abc_d100% (5)

- Reece Tap Spares Inc Mixer PDFDokument16 SeitenReece Tap Spares Inc Mixer PDFtestnationNoch keine Bewertungen

- Building Design Chapter SummariesDokument5 SeitenBuilding Design Chapter SummariesKevin P MendozaNoch keine Bewertungen

- PVC-DWV and ABS-DWV Pipe and Fittings: Dimensional CatalogDokument44 SeitenPVC-DWV and ABS-DWV Pipe and Fittings: Dimensional CatalogMohamed AtefNoch keine Bewertungen

- STP Report PDFDokument128 SeitenSTP Report PDFRaviIdhayachanderNoch keine Bewertungen

- Iireview of Related Literature: This Chapter Presents TH e Related ST Udies Andlit Eratures AboDokument29 SeitenIireview of Related Literature: This Chapter Presents TH e Related ST Udies Andlit Eratures AboDranoel Yob MalinaoNoch keine Bewertungen

- Microza Membrane Guide for Water TreatmentDokument31 SeitenMicroza Membrane Guide for Water Treatmentberliana100% (2)

- Sewage Treatment Safety EssentialsDokument5 SeitenSewage Treatment Safety EssentialsMohammad Jahid AlamNoch keine Bewertungen

- COMPACT 99B Inlet Valve ManualDokument4 SeitenCOMPACT 99B Inlet Valve Manualalwill09Noch keine Bewertungen

- Impact of Networks Sectorization On Water Pressure Transient in Pipelines - Case Study of Casablanca City, MoroccoDokument20 SeitenImpact of Networks Sectorization On Water Pressure Transient in Pipelines - Case Study of Casablanca City, MoroccoBadreddine EssaidiNoch keine Bewertungen

- Etech VS4 50Hz SerieDokument38 SeitenEtech VS4 50Hz SerieMladen MuskinjaNoch keine Bewertungen

- 22 BallandneedlevalvesDokument4 Seiten22 BallandneedlevalvesmedkvNoch keine Bewertungen

- Schematic Diagram Akurana Division: National Water Supply & Drainage Board Grater Kandy Water Supply ProjectDokument1 SeiteSchematic Diagram Akurana Division: National Water Supply & Drainage Board Grater Kandy Water Supply ProjectPradeep KumaraNoch keine Bewertungen

- Pipeline Jacking Sleeve Details - Pipe RammingDokument1 SeitePipeline Jacking Sleeve Details - Pipe RammingDavaadorj 1123Noch keine Bewertungen

- Basic Vacuum TheoryDokument17 SeitenBasic Vacuum Theorypetar petarNoch keine Bewertungen

- MEP Kolam Renang Rumah WingDokument2 SeitenMEP Kolam Renang Rumah WingmisteriswantoNoch keine Bewertungen

- Water Infrastructure .................................................................... 5-1Dokument99 SeitenWater Infrastructure .................................................................... 5-1Boos yousufNoch keine Bewertungen

- Low Cost Sanitation For Rural AreasDokument11 SeitenLow Cost Sanitation For Rural AreasAshhad ShafiqueNoch keine Bewertungen

- Implementing Rules and Regulations for Water Supply Under Code of Sanitation (P.D. 856Dokument15 SeitenImplementing Rules and Regulations for Water Supply Under Code of Sanitation (P.D. 856Dianne Kristine AvilaNoch keine Bewertungen

- Hydraulic Calculations Manual (Rev 3) PDFDokument6 SeitenHydraulic Calculations Manual (Rev 3) PDFsauroNoch keine Bewertungen

- Isolation ValvesDokument12 SeitenIsolation ValvesSoham DeNoch keine Bewertungen

- Wastewater Grease and Sand StandardsDokument22 SeitenWastewater Grease and Sand StandardsNajam24Noch keine Bewertungen

- Projects Engineering Department Engineering Standard: BES-L001Dokument42 SeitenProjects Engineering Department Engineering Standard: BES-L001Fox Alpha DeltaNoch keine Bewertungen

- Salient Feature:: Right Main Canal Left Main CanalDokument4 SeitenSalient Feature:: Right Main Canal Left Main CanalSephali MoharanaNoch keine Bewertungen

- ME325 Project 2h85vf9Dokument17 SeitenME325 Project 2h85vf9christian.canaleNoch keine Bewertungen

- Domestic Waste Water Treatment PPDokument9 SeitenDomestic Waste Water Treatment PPPreetam Godbole100% (1)