Beruflich Dokumente

Kultur Dokumente

Astm A 325 PDF

Hochgeladen von

Jorge Isaac Lara Ramos0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

282 Ansichten9 SeitenOriginaltitel

ASTM-A-325.pdf

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

282 Ansichten9 SeitenAstm A 325 PDF

Hochgeladen von

Jorge Isaac Lara RamosCopyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 9

QG]) GEER) ancy asr a 325-70

Standard Specification for

American Asociion

‘State Highway an

‘Teanspratioe Ole

Standard AASHTO No. 168

HIGH-STRENGTH BOLTS FOR STRUCTURAL STEEL

JOINTS*

This standard is issued under the fixed designation A 325: the number immediately following the

adoption or, in he case of revision, the yar of last revision. A number in parentheses

yea of or

Feapprovale

designation indicates the

indiates the year of ast

‘Tus speifeaton hax been approved for use by agencies of the Department of Defense and for ising n the DOD Index of

Specifications and Standards.

1. Scope

L.1 This specification® covers the chemical

and mechanical requirements of various types

of quenched and tempered steel bolts com-

monly known as “high-strength structural

bolts,” intended for use in structural joints

that are covered under requirements of the

Specifications for Structural Joints Using

ASTM A 325 or A 490 Bolts,? {ssued by the

Research Council on Riveted and Bolted

Structural Joints of the Engineering Founda.

tion. The various types of bolts covered in this

specification are:

1.1.1 Type I—Bolts made of medivm-car-

bon steel, supplied in sizes /2 to 14/2 in.,

inclusive, in diameter

1.1.2 Type 2-Bolts made from what is

generally described as low-carbon martensite

steel, supplied in sizes "/2 to 1'/in., inclusive,

in diameter.

1.1.3 Type 3—Bolts, "2 to 1"/2 in., inclu-

sive, in diameter having atmospheric corro-

siun resistance aund weathering cua acteristics

comparable to that of the otecls covered in

Specification A 588, Specification A 242,

and Specification A'709 (these steels have

atmospheric corrosion resistance approxi

mately two times that of carbon structural

steel with copper).

1.2 When the bolt type is not specified,

either Type 1 or Type 2 may be supplied at

the option of the manufacturer. Type 3 bolts

may be supplied by the manufacturer if agreed

by the purchaser. Where elevated tempera-

tare applications ate involved, Type 1 bolts

shall be specified by the purchaser on the

order

1.3 When atmospheric corrosion resistance

is required, Type 3 bolts shall be specified by

the purchaser in any inquiry or order.

Nore 1—Bolts for general applications, includ-

ing anchor bolts, are covered by ASTM Specifica-

tion A 449, for Quenched and ‘Tempered Steel

Bolts and Studo.* Alzo refer to Gpocificetion A 449

for quenched and tempered steel bolts and studs

wath diameters greater than 1'/3 in, but with similar

mechanical proper

1.4 This specification provides that heavy

hex structural bolts shall be furnished unless

other dimensional requirements are stipulated

in the purchase inquiry and order.

1.5 When galvanized high-strength struc-

tural bolts are specified, the bolts shall be either

Type I or 2, at the manufacturer’s option,

unless otherwise ordered by the purchaser.

Bolts shall be hot-dip galvanized, or, with the

approval of the purchaser, bolts may be me-

chanically galvanized. Galvanized bolts and

nuts shall be shipped in the same container,

1.6 Suitable nuts are covered in Specifica-

ton A 363. Unless otherwise specitied, nuts

shall Le heavy hex, aud the giade and surface

finish of nut for each type of bolt shall be as,

follows:

2 This speciation ie under the jurisdiction of ASTM

Committee F-16 on Fasteners, and 1s the direct responsi-

Uy of Subeounities FIEO? on Steel Bols, Nuts, Rives,

and Washer.

‘Current edition approved May 25, 1979, Published Sep-

tember 1979. Originally published ar A 325 40°T, Last pre-

ious edition A 385 Tea,

“Por ASME Boil: and Presure Vel Coe spp.

tions see related Specification $-325 in Section Il OF that

8

* Published by American Institute of Steel Construction,

New York, N

Tanna Book of ASTM Standards, Part A

265

h

Bolt Type Nut Grade and Finish

‘Vand, plain (moncoated) plain

1 and 2 Galvanized DH, eavanized

3 3

1.6.1 Grades 2 and 2H nuts, as specified

in Specification A 194, and Grades D and

DH nuts, as specified in Specification A 563,

are acceptable altemnatives for Grade C nuts.

Grade 2H nuts, as opgcified in Specification

A 194, are acceptable alternatives for Grade

DH nuts, Type DH3 nuts are acceptable

alternatives for C3 nuts.

1,7 Suitable hardened washérs are covered

in Specification F 436. Unless otherwise spec-

ificd, galvanized washers shall be furnished

ivhen galvanized bélts are specified, and Type

3 weathering steel washers shall be furnished

when:Type 3 bolts are specified.

< Note 2A complete métric companion to Spec-

ification A 325.has been: developed-~Speciication

AJISM; therefore no metric equivalents are pre-

sented in this specification.

2/' Applicable Documents

2. ASTM Standards

‘A 183 Spécification for Zine Coating (Hot-

Dip) an Iron and Steel Haeehware’

‘AvL94 Specification’ for Carbon and Alloy

Steel Nuts for Bolts for High-Pressure

and High-Temperature Service®

‘A242 Specification for High-Strength Low-

“Alloy Structural Steal*

A370 Methods énd: Definitions for Me-

chanical Testiig-of Steel Products?

A490 Specification for Quenched and

Tempered Alloy Steel Bolts for Struc

tural Stee! Joints*

‘A563 Specification for: Carbon and Allby

‘Stet Nutst®

A SR8 Spadifivation far High-Strength Low.

Alloy Structural Steel ‘with 50.000 psi

Minimum Yield Point to 4 in. Thick*

A709 Specification for Structural Stel for

Bridges*

D454 Specification for Mechanically De-

posited Coatings of Cadmium and Zine

on Ferrous Metals*

F 436 Specification for Hardeited Steel

Washers for Use’ with. High-Strength

Bolts*

2.2. American National Stanilards:®

ANSIBL.1 Unified Screw Threads

ANSI R18.2.1 Square and Hex Bolts and

Screws

266

A325

2.3 Military Standard:

MIL-STD-10SD Sampling. Procedure and

“Tables for Inspection by Attributes

3. Ordering Information

3.1 Orders for products under this specifi-

cation shall include the following:

3.1.1 Quantity (number of pieces of bolts

‘andl aécessoties),

3.1.2 Name of products, including acves-

sories ouch as nute and washers whion desired,

3.1.3 Coating jf required (that is, hot dip

galvanized, or mechanical galvanized),

3.1.4 Dimensions including nominal ‘bolt

diameter and Jength. For bolts of dimensional

requirements other than-heavy hex structural

bolts (ee 1.4) it is normally necessary to

specify grip length,

3.1.5 Type of bolt (tliat is, Type 1,2 or 3).

Note that Type 1 and 2 bolts may be shipped

at the manufacturer’s option if type has not

been specified by the purchaser,

3.1.6 ASTM desiguation and date of isue,

and

3.1.7 Any special eéquirements

Noi 3. Two examples of ardoring descriptions

flo (7) 1000 peek Hea Hex strata bo,

ach with oie hafdened washisn, ASIM F 456 and

Gne heavy hex nut, ASTM 363 Grade C, hovdip

falvanizd, 1 by 4; ASTM A325 dated ~~ (2

Yao pees ney ae staal sole noms

wwathegs Te by 2a Type 1 ASTM A 325 dated

ocho f

4. Materials and Manufacture

4.1 Steel for bolts shall be made bythe

open-hearth, basic-oxyzen, or electric-furnace

process.

4,2. Bolts shall be heat treated by quench-

in a liquid medium from above the austen-

jug temperature aud dren tempering by

reheating to a tomperature of at least 200°P.

43. Threads of halts may he ont ar rolled

4.4 Unless otherwise specified, galvanized

bolts shall be hot-dip zinc, coated in, accord-

ance ‘with the requirements for Class C of

Specification A 153. When specified by the

purchaser to be mechanically galvanized,

lp galanin

i

Anal Book of ASTM Standards) Bart 3.

Annual Book of ASTM Standards” art 1

1 Ain Bok f ASTI Sanda, Parts, 2,3, 4,5,

ang’

innual Book of ASTM Szandards, Parts 4 and 9.

‘May be obtained from American National Standards

Insite, ng 1430 Broad New York, N.Y. 10018

“2 avaitable from Naval Publications and Forms Center,

‘8801 Tabor Ave, Phlsdelphla, Pa, 19120.

ab

bolts shall be mechanically zine coated and

the coating and coated products shall conform

to the requirements for Class 50 of Specifica-

tion B 454, or to the coating thickness, adher-

ence, and quality requirements for Class C of

Specification A 153.

4.5 If heat treatment is performed by a

subcontractor the heat-treated material shall

be returned to the manufacturer for testing,

5. Chemical Requirements

5.1 Type 1 and 2 bolts shall conform to the

requirements as to chemical composition pre~

scribed in Table 1, *

5.2 Type 3 bolts shall conform to one of

the chemical compositions prescribed in Table

2. The selection of the chemical composition,

A,B,C, D, E, or F, shall be at the option of

the bolt manufacturer

5.3 Product analyses may be made by the

purchaser from finished material representing

each lot of bolts. The chemical composition

thus determined shall conform to the require-

iments prescribed In 4.1. or 4.2

5.4 Application of heats of steel to which

bismuth, selenium, tellurium, or lead has

been intentionally added shall not be permit-

ted for bolts

6. Mechanical Requirements

6.1 Bolts shall not exceed the maximum

hardness specified in Table 3. Bolts less than

three diameters in length shall have hardness

values not less than the minimum nor more

than the maximum in hardness limits required

in Table 3, as hardness is the only require-

ment

6.2. Ralts 1a in. in diameter ar less, ather

than those excepted in 6.1, shall be tested full

size and shall conform to the tensile strength

and either the proof load or alternative proof

load requirements specified in Table 4,

6.3 Bolts larger than 1'/ in. in diameter,

other than those excepted in’6.1, shall pref-

erably be tested full size and when so tested

shall conform to the tensile strength and

either the proof load or alternative proof load

requirements specified in Table 4. When

equipment of sufficient capacity for full-size

testing is not available, or when the length of

the bolt makes full-size testing impractical,

machined specimens shall be tested and shall

conform to the requirements of Table 5. In

A325

the event that bolts are tested by both full-size

and by the machined test specimen methods,

the full-size test shall govern if a controversy

between the two methods exists.

6.4 For bolts on which hardness and ten-

sion tests are performed, acceptance based on

tensile requirements shall talze precedence in

the event that there is controversy over low

readings of hardness tests.

6.5 In addition, when galvanized bolts and

‘nuts are supplied, the bolt/nut assembly shall

be tested full size in an assembled joint as

specified in 8.5. After the tightening test, the

assembly shall show no signs of failure.

6.6 When hot-dip galvanized Type 2 bolts

are supplied, they shall be tension tested after

galvanizing in accordance with 6.2 or 6.3 de-

pending on the diameter. The number of tests

from each lot shall be in accordance with 9.2.4

or 93.4.

7. Dimensions

7.1 Bolts with hex heads shall be full-body

bolts conforming to the dimensions for heavy

hex structural bolts specified in the American

National Standard for Square and Hex Bolts

and Screws (ANSI B18.2.1).

7.2 Threads shall be the Unified Coarse

Thread Series es specified in the American

National Standard for Unified Screw Threads

(ANSI B1.1), and shall have Class 2A toler-

ances. When specified, 8 pitch thread series

may be used on bolts over 1 in. in diameter

7.3. Unless othorwise specified, bolts to be

used with nuts or tapped holes which have

been tapped oversize, in accordance with

Specification A 563, shall have Class 2A

threads before hot dip or mechanical galvan-

jing. Atter galvanizing, the maximum timit

of plich and major diamewer way exceed he

Class 2A limit by the following amount:

Diameter, in (Oversize Limit, in

Up to ig net

Over Keto Us nel

Over! 0st

4 These values ate the same & the minimum overtap-

ping required for galvanized nuts iz Specification A 563.

7.4 The gaging limit for bolts shall be

verified during manufacture or use by assem-

bly of a nut tapped as nearly as practical to

the amount oversize shown above. In case of

dispute, a calibrated thread ring gage of that

207

ib

same,size (Class X tolerance, gage tolerance

plus) is to be used. Assembly of the gage, or

the niut described above, must be possible

with hand effort following application of light

machine oil to prevent galling and damage to

the yaye. These inspections, when performed

to resolve disputes, are to be performed at the

freqnency and quality described in Table 6

8. Test Methods

8.1 ‘Tests shall be condicted in wecordarice

with Supplement HI of Methods and Defini-

tions-A 370.

8.2 For tension tests a proot load determi-

nation is preferred conducted in accordance

‘with Method 1, Length Measurement, of Sup-

plement IIT of Methods A 370.

8.3 Bolts tested in full size shall be tested

in accordance with’ the wedge test method

described in $11.1.5, Supplement II of

Methods A 370. Fracture shall be in the body

or threads of the bolt, without any fracture at

the junction of the head and body,

4 The. speed af testing as determined

with a free-running cross head shall be .a

maximum of % in,/min for the bolt proof-load

determination, and a maximum of 1 in./min

for the bolt tensile-strength determination.

8.5 The galvanized bolt shall be placed in

fa steel joint and assembled with a galvanized

washer and a galvanized nut. The joint shall

be one of more flat structural steel plates with

a total thickness, including the, washer, such

that to 5 full threads of the bolt are located

between the bearing surfaces of the bolt head

and nut..The hole in the joint shall have the

same nominal diameter: as the hole in. the

washer. The initial tightening of the nut shall

produce a load in the bolt not:less than 10:%

of the specitied proot load. After -iitial

lightening, the nut positon stl] be marked

relative to the bolt, and the rotation shown in

‘Table & shall be applied. During rotation, the.

bolt head shall be restrained from turning.

9. Quality Assurance of Mechanical Reduire-

menis

9.1 The manufacturer shall make sample

inspections of evety lot of bolts to ensure that

properties of bolts are in conforinance with

the-réqttirerients “of this specification. All

bolts shall be inspection tested ‘prior to ship-

268

i325

ment ,in accordance with one of the two

quality assurance procedures described in 9.2

and 9.3, respectively. The manufacturer shall

have the option of which procedure will. be

followed when furnishing bolts to any single

purchase order.

9.1.1 The. purpose of a lot inspection test-

ing program is ta ensure that each lot con

forms to the requirements of this specifica-

tion. For such a plan to be fully effective it is

essential that following delivery the purchaser

continue, to maintain. the identification and

integrity of cach lot until the product is in=

stalled in its service appli

9.2 Production Lot Method:

9.2.1 All bolts shall.be processed in ac-

cordance with a. lot identification-control

quality assurance plan. ‘The manufacturer

shall identify and maintain the. integrity of

each production lot of bolts from raw-material

selection. through all. processing operations

and treatments to final packing and shipment.

Each lot shall be assigned its own lot-identifi-

cation number, each lot shall be tested; and

the inspection test reports for each tot shall be

retained. ‘

9.2.2 A production lot, for purposes of

assigning an identification number and rom

which test samples shall be selected, -shall

consist of all bolts processed essentially to-

gether through all operations to the shipping

container that are of the same nominal size,

the same nominal length, and produced ftom

the same mill heat of steel

9.2.3 The mariufacturet shall make: tals

for proof load; tensile strength (wedge test);

and hardness of each lot of bolts. Altema-

tively, in aceordance with 6.3, tests may be

leiisle: stiength; yield stucigih, seduction’ uf

aréa, elongation, and hardneee

9.2.4 Frama each production lat, the minic

mum number of tests of each reqiiired prop

erty shall be as follows:

Number ot Pieces Number of

inPiodistion Lot Spectinens

+ 800 i one 1

so BOL98,000 15> er

+, 3,001 0'35,000

* 35,001 fo 150,000

"150,00 and over

‘Use of the torque’ yalue: obtained in a! Skidmore,

‘nto cul eal ey Bed in me

fib

9.2.5 Af any test specimen shows defective

machining i€ may be discarded and another

specimen substituted.

9.2.6 Bolts shall be packed in shipping

containers as soon as practicable following

final processing. Shipping containers shall be

marked with the lot identification numb

9.2.7 A copy of the inspection test report

for cach productivn Tut fig which bulls ave

cupplied to fill he requirements of a shipment

shall _he furnished to the purchaser when

specified in the order. Individual heats of steel

need not be identified on the test report.

9.3 Shipping Lot Method:

9.3.1 Ineprocess inspection during all man-

ufacturing operations and treatments and

storage of manufactured bolts shall be in

accordance with the practices of the individual

‘manufacturer.

9.3.2 Before packing bolts for shipment,

the manufacturer shall make tests of sample

bolts taken at random from each shipping lot.

A shipping lot, for purposes of selecting test

samples, is defined as that quantity of bolts of

the same nominal size and same nominal

length necessary to fill the requirements of a

single purchase order

9.3.3 The manufacturer shall make tests

for proof load, tensile strength (wedge test),

and hardness of each lot of bolts. Alterna

tively. in accordance with 6.3, tests may be

tensile strength, yield strength, reduction of

area, elongation, and hardness.

9.3.4 From each shipping lot, the mini

‘mum number of tests of each required prop-

erty shall be as follows:

Number of Peses Number of

in Shipping Lot Specimens

150and less 1

151 wo 280, 2

281 te 500 2

501 t0 1,200 5

[201 t0's,200 8

3.201 ta 10,000 ua

10,001 and over 20

9.3.5 If any test specimen shows defective

machining it may be discarded and another

specimen substituted.

9.3.6 A copy of the inspection test report

for cach shipping lot shall be furnished to the

purchaser when specified in the order. Indi-

vidual heats of steel are not identified in the

finished product.

A325

10. Marking

10.1 All bolts, Types 1, 2 and 3, shall be

marked A 325 and shall also be marked with

a symbol identifying the manufacturer

10.2 In addition Type 1 bolts may, at the

option of the manufacturer be marked with

three radial lines 120 deg apart.

10.3 In addition Type 2 bolts shall be

marked with three radial lines 60 deg apart,

10.4 In adaition Lype 3 bolts shall have

the A325 underlined, aind the sanufacture

may add other distinguishing marks indicat-

ing that the bolt is atmospheric corrosion

resistant and of a weathering type.

10.5 All markings shall be located on the

top of the bolt head and may be either raised

or depressed, at the option of the manufac-

turer

11. Visual Inspection for Head Bursts

11.1 A burst is an open break in the metal

(material). Bursts can occur on the flats or

earners of the heads af halts

11.2 A defective bolt, for the purposes of

the visual inspection for bursts, shall be any

bolt that contains a burst in the flat of the

head which extends into the top crown surface

of the head (chamfer circle) or the under-

head bearing surface. In addition, bursts oc

curring at the intersection of two wrenching

flats shall not reduce the width across corners

below the specified minimum.

A lot. for the purposes of visual in-

1, shall consist of all bults of one type

having the same nominal diameter and length

offered for inspection at one time, No lot shall

contain mote than 10 000 pieces.

11.4 From each lot of bolts, a representa-

tive sample shall be picked at random and

visually mspected for bursts. Ihe sample size

shall Le ao shiuwa in Table 7. 1 dhe nuiuber of

defective bolts found during inspection by the

manufacturer is greater than the acceptance

number given in Table 7 for the sample size,

all bolts in the lot shall be visually inspected

and all detective bolts shall be removed and

destroyed. If the mumber of defective bolts

found during inspection by the purchaser is

greater than the acceptance number given in

Table 7 for the sample size, the lot shall be

subject to rejection.

269

lb

12. Inspection

12.1 If the inspection deseribed in. 12.2 is

required by the purchaser, it shall be specified

in the inquiry and-contract or order.

12.2 The inspector representing the pur

+ chaser shall have fee ent, at all tines while

work on the contract of the purchaser is being

performed; to all-parts of the manufacturer's

works that concern, the manufacture of the

material ordered. The manufacturer shall af-

ford the inspector all reasonable. facilities to

satisfy him that the material Is being furnished

sin accordance with this specification. All tests

(except product analysis) and inspection. shall

be made at: the. place of manufacture. prior to

shipmerit, unless otherwise specified, and

A325

shall be so conducted as not to interfere

unnecessarily with the operation of the works.

13. Rejection :

13.1. Unless otherwise specified, any rejec-

tion based on tésts specified herein shall be

reported to the, manufacturer within 30 work

ing days from the receipt of samples by the

purchaser.

14, Certification

14.1 Bols—When specified on the order

the manufacturer shell furhish the testréports

described, in 9.2.7 or 9.3.6, depending on

whether the bolts are furnished by the produc-

tion lotr shipping lot method.

TARLE 1 Chemical Regolzements for Types 1 and 2

Bolts

‘Composition, %

‘Type 1 Bolts Type 2 Bolts!

Carbon:

Heat analysis.

Product analysis

laine il.

Heat analysis

: Product analysis

Phosphorus, ma:

Heat aa

Product snalyie

Suit, max

‘Heat analysis.

Produ analyls

Boro, min

‘Heat analysis

Proxluct walls

30min 0.15-0.23 5

O27 min 014025

050 070

a7 0.67

0.040 0.040

0.048 0.048

0.050 0.050

0.058, 0.038:

‘0.0005

0.0005

“Type 2 Bolts shall Be Tally Killed, He grain steel

370

{ha o25

TABLE 2 Chemical Requirements for Type 3 Bolts

Gaibon

“ect analyeie

Product analysis

Heat analysis

Product analysis

Phosphorus:

Hert aalsis

Product analysis

Sulfur

Hest analysis

Product analysis

Silicon

Heat analysis,

Product analysie

Product analysis

Nick:

Heat analysis

Product anaiysis

Chromium:

“Hest analyee

Product analysis

Heat analysis

Product analysts

Molybdenum:

Heat wnalyis

Product analysis

‘Tiaatam

Heat analysis

Product analysis

Composition, %

Type 3 Rate

033-040 038.048 0415-025 0uS-0.25 020.025 0.20-0.25

031-042 036050 0.14026 014026 0.18027 0.19-0.26

090-120 0.70-0.900.80-1.35 040-120 0.60-1.00 0,90-1.20

08-128 067-093 O.T0-139O.S6124 © —O'S8-1.08 88-124

0.040 max 0.06-0.12_ 0.035 max 0.080:mex 0.040 max 0.040 man

9.045 max 0.06-0.125 0.040 max 0.045 mex 0.085 max 0.045 max.

0.050mex 0.050 max 0.040 max 0.0S0max 0.04) max 0.040 max

0,055 max 0.085 max 0.045 max 0.055 mex 0.045 max 0,045 max

015-030 030-050 0.15-030 025-050 0.15-030 0.15-030

013-029

10% o2snss 013022 ons * 013.032

025-045 020-040 0.20-0.50, 020-040

022-048 0.17043 017-0.53, otoas

030-069 0.20-040

a.

137-068 017-043,

025-045 050-080 0.25-050

0.22-045 047-083 0.22-0.53,

045-065 050.0.75 020-050 0.50-1.00 060-090 0.45-0465.

042-068 047-083 027-053 045-1105 0155-0095 0.42-0.68

0.020 min

0.010 min

0.06 mas 0.10 aan

O.07mex O.L1max

0.05 max

© A,B, C,D, Band F ave clastes of material use for Type 3 bolts. Selection ofa class shall be at te option of the bolt

nant

TABLE 3 Hardness Requirements for Bolts

Bolt Sie, in.

Min Max Min Max

Fete ty inet 248381 ~=~«K OS

Watoits incl 22329319

mm

ab a ses

TABLE 4 Tensile Requirements for Full Se Bolts

al Son, Trop Tea Sieaga®” Prctiou* tag Alaina Bt

Inch and'Series Desig- Stress Area,*in.* ensle Stennett foot Load Length, oad,” Yield Strength,

Snes ‘in,inf” urement Moen LOX Ye Stent

Cana Con Cima Cate Cana

Ven UNC rm iro 1 of

NE oe Bin BS 2S

oune sae ot ae 35%

sure ra 840 30 Sa

Lesune osos n xo 51 0 70

teruNe oves to ioe i an

ely os ae ie a3

norte $38 on ith Sam

eau 1 1 oo ih om tao

ee unc as 12 30 8 40 93 50

Bese Ls ee is 3m

teauNe ee (30 1c 1B ow

bean en 1560 too tno a0

7 eas tela lors

A, = 0.7854 [D — (0.9743)n)?

vi

gm nr amen,

mrs deeds periek

"Loaded are bdo he aon:

Tai eg Oa cana

Ye, to T incl eee pee

Thoth Toma

TABLE 5 TwabeRegdrmens te Spcces TABLE 6 Suu Sas and Acero Num

Tintin wal Tp oo Dior isan Cave Tie

Yaad na Agee

mie sii Benge Rate toSce—Gamplesues™ ARSRIE

onsin in cig, SEED gees Sect a = ;

win, pat OfBey, tie 180 2 2

» PE 151 to 280 32 3

a a Bes 3 3

Bieta ;

i353 4

Sinwioee ae u

ootwdoer 35 a

el, Ca, aS

SSB ”

"pes bth et fhe ot is ses thn he

or

am

bases

‘TABLE 7 Sample Sizes and Acceptance Numbers for TABLE 8 Test for Galvanized Bolts

epecton of Pants Nominal Nut Rot

Tie Sang Aig Name BatLength Diamecr,in, NGM NLS

cS oe ‘Up wand incioding 4 300 fe)

T0150 A o Over 4, but not exdeeding B 360)

151 10 500 20 1 Overs 420(10)

501 01 200 32 2 a

1 201 3 200 ‘so 3

3 2011010 00080 5

4 Sample sizes and apceptance numbers are exacted

from “Single Sampling Pian Tor Normal Inspection” Teble

* inspect ll bolisin the lot if the ot size ses than the

sample sie.

The American Socey for Testing ond Materia toker no poston respecting the vlity of any patent rights exerted in

Das könnte Ihnen auch gefallen

- Proceso Det Raza Bili DadDokument6 SeitenProceso Det Raza Bili DadJorge Isaac Lara RamosNoch keine Bewertungen

- Certificado Calidad AbrasivoDokument1 SeiteCertificado Calidad AbrasivoJorge Isaac Lara RamosNoch keine Bewertungen

- Area y PerimetroDokument4 SeitenArea y PerimetroJorge Isaac Lara RamosNoch keine Bewertungen

- El Archibo Que Tonder PisoDokument1 SeiteEl Archibo Que Tonder PisoJorge Isaac Lara RamosNoch keine Bewertungen

- ASTM Statistic PDFDokument110 SeitenASTM Statistic PDFAbidi HichemNoch keine Bewertungen

- EvidenciapaginafraudulentaDokument14 SeitenEvidenciapaginafraudulentaJorge Isaac Lara RamosNoch keine Bewertungen

- Registry of Sleeve PlacementDokument10 SeitenRegistry of Sleeve PlacementJorge Isaac Lara RamosNoch keine Bewertungen

- F-CD-19 Pipe and Weld Book 26-Abr-19Dokument84 SeitenF-CD-19 Pipe and Weld Book 26-Abr-19Jorge Isaac Lara RamosNoch keine Bewertungen

- Format Otra Zabil I DadDokument4 SeitenFormat Otra Zabil I DadJorge Isaac Lara RamosNoch keine Bewertungen

- F-CD-15 Holiday Detection Coating Rev. 0Dokument4 SeitenF-CD-15 Holiday Detection Coating Rev. 0Jorge Isaac Lara Ramos100% (2)

- System 4 Epoxy Organic Zinc - Rich High Solids Solids Content Carbozinc 858 Þ Þ Þ Þ 64 + - 2 % Carbozinc 859 Þ Þ Þ Þ 66 + - 2 %Dokument2 SeitenSystem 4 Epoxy Organic Zinc - Rich High Solids Solids Content Carbozinc 858 Þ Þ Þ Þ 64 + - 2 % Carbozinc 859 Þ Þ Þ Þ 66 + - 2 %Jorge Isaac Lara RamosNoch keine Bewertungen

- TE 628 REV3 - WebDokument286 SeitenTE 628 REV3 - WebJorge Isaac Lara Ramos100% (1)

- Pyrocrete 241 PDSDokument7 SeitenPyrocrete 241 PDSJorge Isaac Lara RamosNoch keine Bewertungen

- Registry of Sleeve PlacementDokument10 SeitenRegistry of Sleeve PlacementJorge Isaac Lara RamosNoch keine Bewertungen

- Black Beauty® Iron Abrasives: Product Specification SheetDokument1 SeiteBlack Beauty® Iron Abrasives: Product Specification SheetJorge Isaac Lara RamosNoch keine Bewertungen

- Formato de Inspeccion de Prueba de Proteccion AnticorrosivaDokument3 SeitenFormato de Inspeccion de Prueba de Proteccion AnticorrosivaJorge Isaac Lara RamosNoch keine Bewertungen

- Besel VDokument2 SeitenBesel VJorge Isaac Lara RamosNoch keine Bewertungen

- Franklin Proj Quality Pers Qualif - Rev.2017-ExampleDokument8 SeitenFranklin Proj Quality Pers Qualif - Rev.2017-ExampleJorge Isaac Lara RamosNoch keine Bewertungen

- Franklin Proj Quality Pers Qualif - Rev.2017-ExampleDokument8 SeitenFranklin Proj Quality Pers Qualif - Rev.2017-ExampleJorge Isaac Lara RamosNoch keine Bewertungen

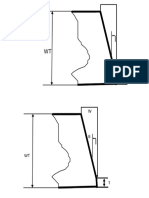

- 325DRAWINGSDokument3 Seiten325DRAWINGSJorge Isaac Lara RamosNoch keine Bewertungen

- PosiTestAT-v4 0 PDFDokument45 SeitenPosiTestAT-v4 0 PDFJorge Isaac Lara RamosNoch keine Bewertungen

- StatisticsDokument1 SeiteStatisticsJorge Isaac Lara RamosNoch keine Bewertungen

- StatisticsDokument1 SeiteStatisticsJorge Isaac Lara RamosNoch keine Bewertungen

- Untitled 1Dokument1 SeiteUntitled 1Jorge Isaac Lara RamosNoch keine Bewertungen

- 95 8723 U5015Dokument20 Seiten95 8723 U5015Jorge Isaac Lara RamosNoch keine Bewertungen

- Denso Protal 7200 Brush Application SpecDokument2 SeitenDenso Protal 7200 Brush Application SpecJorge Isaac Lara Ramos100% (1)

- R R O S A: Model ApsDokument2 SeitenR R O S A: Model ApsJorge Isaac Lara RamosNoch keine Bewertungen

- MSDS CEL375 Componente ADokument4 SeitenMSDS CEL375 Componente AJorge Isaac Lara RamosNoch keine Bewertungen

- Choride Test How To DoDokument25 SeitenChoride Test How To DoMohammad Ali Khan100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)