Beruflich Dokumente

Kultur Dokumente

Method Statement For Civil Works For Control Building

Hochgeladen von

Utku Can KılıçOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Method Statement For Civil Works For Control Building

Hochgeladen von

Utku Can KılıçCopyright:

Verfügbare Formate

Method Statement For Civil Works

For Control Building

TOTAL 26 PAGES

(Including Cover)

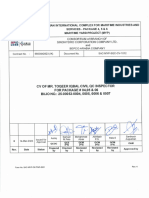

PROJECT NAME

: Khabat Thermal Power Plant Units 1&2

Purpose

DOCUMENT NO.

: KP-00+++-MQ758-V0003

For Information

TITLE

: Method Statement for Civil Works for Control

Building

OWNER

: Ministry of Electricity (MOE) of

Kurdistan Regional Government

19.09.2014

Rev.

No.

DATE

First Issue

DESCRIPTION

For Review

For Approval

For Construction

As-Built

MP

EO

AZ

TC

PREPARED

CHECKED

REVIEWED

APPROVED

GAMA POWER SYSTEMS ENG &CONTRACTING,INC.

Owner

Ministry of Electricity (MOE)

of Kurdistan Regional Government

Contractor

POSCO ENGINEERING

& CONSTRUCTION CO., LTD.

Main Subcontractor

GAMA POWER SYSTEMS

ENGINEERING & CONTRACTING,INC.

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

1/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

Khabat Thermal Power Plant Units 1&2 Project

132kV Air Insulated Switchgear

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

DOCUMENT NO: KP-00+++-MQ758-V0003

SUBCONTRACTOR: SIEMENS

GAMA REVIEW

Discipline

Superintendent

HSE Manager

QA/QC Manager

Site Manager

Name

Date

Sign

Remarks:

Any such review or consent by GAMA, shall not relieve the Subcontractor, in any case or for any reason whatsoever,

from any obligation, liability or responsibility arising out of or in connection with the Contract, including without being

limited thereto, to the responsibility for errors, omissions, discrepancies and non-compliances. Within this context, this

document shall not prevail over or amend the Contract, or relieve the Subcontractor from any of its duties, obligations,

responsibilities or liabilities under the Contract.

Anything presented herein by the Subcontractor shall in no event

i) excuse the Subcontractors non-performance under the Contract, or

ii) entitle him to a variation under the Contract or an adjustment to the Contract Price.

SUBCONTRACTOR

Rev.

No.

A

Date

Description*

19.09.2014

Civil Work for

Control

Building

Prepared

by

HSE

Manager

QA/QC

Manager

Site

Manager

Project

Manager

Mustafa

Peker

Eyyp zbay

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

2/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

DOCUMENTHISTORY:

Remarks

Rev.

No.

Date

(Reason for Revision)

19.09.2014

First Issue

*Description:

Documentissuepurpose

-

FirstIssue

ForInformation

ForReview

ForApproval(orIssuedforConstruction)

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

3/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

Contents

1.

PURPOSE .......................................................................................................................................... 5

2.

SCOPEOFWORK .............................................................................................................................. 5

3.

RESPONSIBILITIES ........................................................................................................................... 5

4.

DEFINITIONS/ABBREVIATIONS ...................................................................................................... 7

5.

PERSONNEL ..................................................................................................................................... 8

6.

MATERIALS ....................................................................................................................................... 8

7.

EQUIPMENT...................................................................................................................................... 9

8.

SUBCONTRACTORSSUBTIERCONTRACTORS .............................................................................. 9

Subcontractors.............................................................................................................................9

8.1

9.

EXECUTION .................................................................................................................................... 10

9.1

FOUNDATIONWORKS.............................................................................................................10

9.1.1.

PreparationtoExcavation.................................................................................................10

9.1.2.

SafeExcavationWorks......................................................................................................10

9.1.3.

Excavation..........................................................................................................................11

9.1.4.

BlindingandWaterproofing..............................................................................................11

9.1.5.

RebarandFormworksforBuildingFoundationandBasementShearwall......................12

9.1.6.

ConcreteWorks..................................................................................................................12

9.2

COLUMN,BEAMandSLABWORKS........................................................................................13

9.2.1.

RebarandFormworksforBuildingColumns.....................................................................13

9.2.2.

RebarandFormworksforBuildingSlabsandBeams.......................................................13

9.2.3.

ConcreteWorks..................................................................................................................14

9.2.4.

FormDismantlingandConcreteCuring............................................................................14

9.2.5. GasConcreteWallBonding .............................................................................................................. 14

PreparationofBond..................................................................................................................................... 14

WallBonding ............................................................................................................................................... 15

9.2.6. MasonryBonding............................................................................................................................. 15

9.4.

ELECTRICALANDSANITARYINSTALLATIONWORKS..........................................................16

ElectricalInstallation..............................................................................................................16

9.4.1.

9.4.2.

PlumbingandSanitaryInstallation...................................................................................17

9.5.

PLASTERINGWORKS...............................................................................................................17

9.6.

ERECTIONOFDOORSANDWINDOWS..................................................................................18

9.7.

CERAMICTILEWORKS.............................................................................................................18

9.8.

ELEVATEDFLOOR....................................................................................................................19

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

4/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

INTERNALPAINTINGWORKS..................................................................................................20

9.9.

9.10.

EXTERIORPAINTING............................................................................................................20

9.11. SUSPENDEDCEILINGWORKS.................................................................................................20

9.12.

ROOFWORKS........................................................................................................................20

10.

TIMELINEOFACTIVITIES ............................................................................................................... 21

11.

PROGRESSMEASUREMENT ........................................................................................................... 21

12.

QUALITYREQUIREMENTS ............................................................................................................. 22

13.1. PersonalProtectiveEquipment.................................................................................................22

13.2. SafetyFence...............................................................................................................................23

13.3. RelatedSafety/WarningSigns.................................................................................................23

14.

REFERENCES .................................................................................................................................. 24

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

5/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

1. PURPOSE

ThisProjectMethodStatementhasbeenproducedbySIEMENSSan.veTic.A..insupportof

clientforKhabatThermalPowerPlantUnits1&2Project.

2. SCOPEOFWORK

The method statement is prepared for Civil Works for Control Building at Khabat Thermal

PowerPlantUnits1&2Project

3. RESPONSIBILITIES

A project team has been appointed and is defined in for this project. The appointed Project

Managerwilladministerandcontroltheproject.

All personnel assigned to this project from e.g. Engineering, Quality and Planning Operations

etc.; are functionally responsible to the Project Manager, working as a team to achieve the

objectiveofcompletingtheprojecttothecustomerssatisfaction.

The Project Manager is the primary contact regarding communication between the customer

andSIEMENSSan.veTic.A...

SiteManager

ThemaindutiesoftheSiteManagerareasfollows:

Materialfollowup

Fieldarrangements

Supervisionofsubcontractor

Receiptofincomingmaterials

Executionoftheworkaccordingtothequalitystandards

Sitesafetysurveys

Providing coordination between suppliers supervisors and clientsubcontractor during site

execution

Progressreportingtotheprojectmanager

Assuringsufficientandsuitablemanpower

Participationonsitecoordinationmeetings

FollowupofQualityPlan

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

6/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

FollowupofEHSPlanincommunicationwithSiteEHSManager

Followupofsiteinspectionprogram

BuildupandhandovertheEHSandqualitydocumentation

SupervisionofsubcontractorsEHSandQualityPolicy

Providing coordination between safety officer and subcontractor team about EHS and quality

issues

Reviewandsubmittalofriskassessmentsandmethodstatementspreparedbysubcontractor

Taking necessary measures to ensure and maintain the safety of supervisors through the

executionoftheproject

SiteEHSOfficer

SiteEHSOfficerisresponsibleofimplementingandsupervisingallEHSissuesatthesite.The

majorconcernsoftheSiteEHSOfficerarelistedhereunder;

FollowupofEHSRiskAssessmentsandmethodstatementswithsubcontractor

Providingsafetyinstructions

AttendingtoEHSmeetingswithclient

SiteEHSsurveys

EnsuringandcontrollingthepracticalandeffectivedeploymentofEHSPlansbySubcontractor

CheckingofproceduresandEHSpreventionplansfortheiravailabilityatsite

Checkingqualificationofthesubcontractorsworkforce

Ensuringthesufficiencyofaccesscontroltoanyrestrictedarea

Definingandensuringprovisionofadequatepersonalprotectiveequipment(PPE)

Ensuringthereportingandevaluationofallnewriskswiththesupportofsitemanager

Requestingimmediatecorrectiveorpreventiveactionswithcorrespondingpersonsincharge

Tostopanyworkatcatastrophicorseriousriskuntilcorrectiveactionistaken

Immediatelyrecordingandreportingofalldeviationsthathavenotbeenimmediatelycorrected

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

7/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

SiteQualityEngineer

As the quality representative at site, under the authority of the Site Manager, she/he is

responsiblefor:

Thequalitycontrolfollowupatsite,whichincludes:

Checkingofthequalityofincomingmaterialsandequipmentdelivered

Followupofthesiteinspectionprogram

Ensuringcomplianceoftheholdpointsdefinedinthesiteinspectionprogrambynotifying

thecustomeroritsrepresentative

Thequalityassurancerulesfollowup,whichincludes:

Ensuring that only drawings of as acceptable status are issued to the work site for

construction

Ensuring that all drawings issued for Mark Up are returned and validated by the Site

Manageruponcompletionofthework

Ensuringcompliancewiththeprocedures

Managingandtransmittingqualitydeviationformsevents(asNonconformityReports)after

receivingvalidationfromthesitemanager

Thefollowupofthematerialsandequipmentatdeliverywhichincludes:

Qualitativecontrolofthepackaging(exteriordamage)

Quantitativecontrolofthematerials/equipmentinrelationtopackinglists

Controloftheincomingandoutgoingmaterialto/fromstorageareasandothersites

4. DEFINITIONS/ABBREVIATIONS

QEHS

QA

QC

LV

ITP

AIS

:Quality,Environmental,Health&Safety

:QualityAssurance

:QualityControl

:LowVoltage

:InspectionandTestPlan

:AirIsolatedSwitchyard

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

8/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

5. PERSONNEL

SiteManager

SiteEngineer(s)

QA/QCEngineer

QEHSSupervisor

SiteSupervisors

SiteForemen

Workers

Operators

6. MATERIALS

RebarsS420(TSE500,fyk=420N/mm)

Concrete(Type:C30/37forFoundations,C16/20forLeanConcretes)

Formworks(timberandplywood/wood)

Woodsforroof

Rooftile

Membranes

Gravelorcrushedstone

Perforateddrainagepipes

Bricks

Plasteringmaterials(roughcast,gypsumplaster)

Paints

Marble

CeramicTiles

ElevatedFloor

Rockwoolsuspendedceiling

Glasswoolforheatisolationofroof

Valleyandrainwaterpipes

PlumbingArmatures,sanitarywaresandpipes

ElectricalArmaturesandWires

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

ExteriorInsulationMaterials

Steelprofiles

DoorsandWindows

9/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

7. EQUIPMENT

Crane

Manlift

Excavator

HandTools

Rebarbendingmachine

Backhoeloader

Loader

Trucks

Scaffold

Concretevibrator

Concretemixer

Concretepump

8. SUBCONTRACTORSSUBTIERCONTRACTORS

8.1 Subcontractors

8.1.1. Subcontractor1(forCivilWorks)

CompanyName

SilopiAypanaatSan.Tic.Ltd.ti.

Address

Y.TepeMah.2.Cad.No:64

Silopi/rnak

Tel

+904865181959

Fax

+904865186900

mesut.aydin@silopiaypa.com

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

10/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

8.1.2. Subcontractor2(forPrimaryWorks,SecondaryWorksandSiteTests)

CompanyName

Address

Tel

9. EXECUTION

9.1 FOUNDATIONWORKS

9.1.1. PreparationtoExcavation

The excavation area will be defined and marked on the ground by powdered lime by the

topographeraccordingtotherelevantprojectdrawing.

Thismarkingworkwillberecordinthesurveyreport.Workingareaswillbedefinedaccording

tobelowsketchatrelatedreport.

9.1.2. SafeExcavationWorks

9.1.2.1.

Accessladdersmustbeprovidedtoallowleaveexcavationareaeasily.

9.1.2.2.

Access ladders must be secured, extend at least 1 metre above the top of the

excavationandnotbelongerthan5 meters.Toaccessexcavationsdeeper than5

meters specific access / egress means shall be in place (stairway towers, then

ladders)

9.1.2.3.

Allstoragematerialsmustbekeptatleastatadistanceof1.2metresfromtheedge

oftheexcavationunlessotherdistanceisdefinedbyanauthorisedengineer.

9.1.2.4.

Vehicle movement must be kept at a distance of 3 metres from the edge of the

excavation.

9.1.2.5.

Awarningchainmustbepresentatadistanceofatleast1.5metresfromalledges

oftheexcavationlessthan1.2metresdeep.

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

9.1.2.6.

11/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

Excavationsofmorethan1.2metresindepth,requiringanyspecificaccessmeans,

must have rigid barriers and toeboards (or any system which provides equivalent

protectionastoeboards)aroundtheoutsidetopreventpersonsandmaterialfrom

falling. Toeboards are not required when a safety distance of 1.5 metres is

maintainedbetweenedgeofexcavationandrigidbarrier.Excavationsbetween0,5

and 1,2 metres in depth must have rigid barriers around the outside to prevent

persons and material from falling, except when a safety distance of 1.5 metres is

maintainedatalltimesbyvisiblesafetychainsorflexiblemeshat1.1meterheight.

9.1.2.7.

Aprotectivesystemtopreventcollapseoftheexcavationorcavein(e.g.:sloping,

shoring and benching, shielding, support systems) must be installed when the

excavationismorethan1.2metersdeep.

9.1.2.8.

Whentheexcavationismorethan5metresindepth,theexcavationmustcomply

withthespecificationasdefinedbytheauthorizedcivilengineer(see5.1.3).

9.1.2.9.

Whenpersonsneedtocrossanexcavation,abridgingwalkwaymustbedesigned

accordingtothelocalcodeandmustbeerectedwithhandrailswhichcanwithstand

aminimumloadof1kNhorizontally.

9.1.3. Excavation

Excavation will be performed by excavator or backhoe loader in charge of topographer. The

areawillbeexcavatedtillprovidingthebottomlevelintheproject.Then,excavationpitsmust

be cleaned until provide the only ground surfaces to adherence between concrete. If there is

water in the pits, it will be drained with pumps before concrete. After final checking the

measurementsofthefoundationsbythetopographeritwillbereadytoblindingconcrete.Sizes

of the foundations will change according to equipment and pylon types. Approximately the

maximumdepthoftheexcavationwillbeonemeter.

9.1.4. BlindingandWaterproofing

Blinding concretewillbe pouredtothebottomsurfaceofthebuildingfoundationtilla10cm

height. Slump test will be performed on each concrete mixer that delivered lean concrete to

site. Slump measurements will be recorded to Concrete Pouring Cards. After the concrete

hardened,waterproofingworkswillbegin.

The waterproofing process begins by laying the waterproof membranes to the surface. The

edgeofonemembraneshalllapovertheothermembranesedgeduringthislayingoperation.

Alljointsofmembranesheetsshallbestickbymeltingbitumen,whichisthemainmaterialof

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

12/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

thesemembranesviablowtorch.Itmustbetakenintoconsiderationthatwaterproofingworks

startafterformworksandbeforerebarworks.Bituminousmembraneapplicationshallbemade

as 2 layers and after completion of application a protection concrete will be poured as 5 cm

thickness.Bituminousmembranematerialshallbeapprovedtoclientbeforeusing.

9.1.5. RebarandFormworksforBuildingFoundationandBasementShearwall

Timberssized5x10and10x10andplywoodwillbeconstitutedforconcrete.Afterhardeningand

shrinkage of lean concrete, formworks will be performed with plywood forms and supported

withtimberstoavoiddeformationformwork.Aftercompletionoffoundationformworkvertical

and horizontal rebar structures will be mounted according to the sizes in the building

foundation projects. Thereafter, foundation earthing strips will be placed according to the

foundation earthing project. When all embedded parts and formworks fixed and finished,

foundationswillbereadytopouringconcrete.

In opposition to foundation rebars, sharewall rebars shall be mounted and inspected by

engineers before applied formworks. Vertical and horizontal rebar structures will be mounted

accordingtothesizesinthebuildingprojects.Aftercompletionofinspection,sharewallforms

shallbemountedsimilarlybyusingtimbersandplywoodforms.Formworkcoordinatesshallbe

measuredbytopographersandrecordedtobeforeconcretepouringform.

9.1.6. ConcreteWorks

Air temperature shall be at range of 5 0C 32 0C for pouring of concrete. If it is necessary,

concrete will be poured with the help of the pump. To provide diffusion of the concrete,

vibrationwillbeappliedwithavibrationmachinebytheworkers.Surfacesmoothingisgoingto

be performed. After pouring concrete, surface of concrete will be supplied to its straightness.

During concrete works, samples will be taken for compressive strength test on each concrete

pouringday.6cubesampleswillbetakenforeachtest.(3for7daystest3for28daystest).If

necessaryconcreteismorethan40m3,samplingoperationwillbeperformedforeach40m3of

concretedeliveredatsite.AlsoslumptestwillbeappliedandrecordedinConcretePourCards

foreachconcretemixerbeforepour.

After hardening and providing the necessary strength of concrete, the formwork will be

dismantled. Some chemicals will be used for concrete curing at cold weather conditions.

Watering of concrete will be used for concrete curing at summer season. To provide proper

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

13/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

curing of concrete, air open surfaces of concrete shall be wrapped with curing blanket and

curingblanketshallbealwayswetbyirrigating.

9.2 COLUMN,BEAMandSLABWORKS

9.2.1. RebarandFormworksforBuildingColumns

After pouring of foundation and basement share walls, formworks will be dismantling after

required durations as defined in standards. All building construction area shall be cleaned up

fromwasteand/orreusableforms,timbersandnails.

Column rebars will be mounted rebar area and handled to building. Column rebars will be

connected to ironstones get out from foundation rebars. Tie spacers and stirrups will be

completed and column rebars shall be inspected by engineers. During mounting of rebars, if

working at high will be needed, EHS requirements shall be applied and scaffoldings shall be

usedifnecessary.

Columnsformworkwillbeconstitutedwithtimbersandplywoodforms.Plywoodformsshallbe

supported properly via timbers to avoid deformation of formwork during concrete pouring.

Formwork coordinates shall be measured by topographers and recorded to before concrete

pouringform.

9.2.2. RebarandFormworksforBuildingSlabsandBeams

Slab and beams formworks will be mounted before connection of rebars by using timber,

plywood and falsework. Firstly, forms of beam bottoms will be put between columns and

supportedwithsteelpostsproperly.Formworksofbeamsideswillbemountedandsupported

bytimbersandslabformworkscompleted.Allslabformworksshallbesupportedpropersteel

polesanddistancebetweensteelpoleswillnotbegreaterthan80cm.Forhugeslabs,horizontal

beltswillbeprovidedbetweensteelpolestostrengthen.

Whileworkingontheslabformwork,barriersshallbeprovidedtoedgeofbuildingandEHSand

working at high requirement applied. A proper ladder must be provided to access top of the

formwork.

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

14/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

After completion of slab and beam formwork vertical and horizontal rebar structures will be

mounted according to the sizes in the building slab and detailed beam projects. Thereafter,

conduits for electrical wiring and other embedded materials will be placed according to the

electrical and/or plumbing project. When all embedded materials and formworks fixed and

finished,foundationswillbereadytopouringconcrete.

9.2.3. ConcreteWorks

Airtemperatureshallbeatrangeof50C320Cforpouringofconcrete.Forcolumn,slaband

beamconcrete,concretewillbealwayspouredwiththehelpofthepump.Toprovidediffusion

oftheconcrete,vibrationwillbeappliedwithavibrationmachinebytheworkers.Surface

smoothingisgoingtobeperformed.Afterpouringconcrete,surfaceofconcretewillbesupplied

toitsstraightness.Duringconcreteworks,sampleswillbetakenforcompressivestrengthtest

oneachconcretepouringday.6cubesampleswillbetakenforeachtest.(3for7daystest3for

28daystest).Ifnecessaryconcreteismorethan40m3,samplingoperationwillbeperformed

foreach40m3ofconcretedeliveredatsite.Alsoslumptestwillbeappliedandrecordedin

ConcretePourCardsforeachconcretemixerbeforepour.

9.2.4. FormDismantlingandConcreteCuring

Afterhardeningandprovidingthenecessarystrengthofconcrete,theformworkwillbe

dismantled.Somechemicalswillbeusedforconcretecuringatcoldweatherconditions.

Wateringofconcretewillbeusedforconcretecuringatsummerseason.Toprovideproper

curingofconcrete,airopensurfacesofconcreteshallbewrappedwithcuringblanketandcuring

blanketshallbealwayswetbyirrigating.

9.2.5.GasConcreteWallBonding

PreparationofBond

GasConcreteBondwillbetransportedtositeas25kgpackages.Bondsthatarrivedtothesite

willbestockedatoneplacethatnotbeexposedtorainandsnow.

Bond mix will be prepared with added 2 unit powder bond to 1 unit water and then it will be

mixedwithhelpingofadrillingmachine.So,Bondwillbereadytouse.Bondmustbemadeas

enoughquantityandwaitedbondmustnotusewithaddingwater.

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

15/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

BondQuantitytoSpendfor1m2GasConcreteBonding

ThicknesofBlock(cm) 10 12,5 15 17,5 20

Bond(kg)

1,5 1,9

2,2 2,6

2,9

22,5

3,3

25

3,7

27,5

4,0

30

4,4

WallBonding

Materialswillbecheckedbeforestartingofwallbondingandifthereareanywetblocks,they

willbewaiteduntilbecomedrying.Packedmaterialswithnylonwillbeventilatedbyopening

onedaybeforebonding.

Beforestartingfirstrowofthewallbonding,allsurfaceswillbecleaned.

Mortarwillbeusedbetweenwallandwallsurface.Mortartobeusedwillbe34cmthickness

andwithofwall.Itisrecommendedforthismortaramixof1unitcementand1unitpowder

limeand6unitsthinsand.Afterspreadingofmortar,blockswillbeplacedbyhelpingstringand

watergage.Rubbermalletwillbeusedduringplacement.

If necessity of using blocks except standard dimensions, cutting will be made. Crushing with

troweledgeisnotallowed.

Scaffoldingwillbesetupduringwallbondingandsettingupofscaffoldingwillbeensuredthat

donebyauthorizedandtrainedpersonnel.

9.2.6. MasonryBonding

Firstly, bricks will be cleaned up from dust and if it is required it will be wetted. String and

plummet will be used to provide regularity of walls. While bricks are placed, overflowing

mortarswillbecleanedbytrowelfrombothsideofwall.AtthePlacesthatnotpossibletouse

asfullbrick,brickswillbeusedwithbreakingandperforatedsidesofbricksmustnotbeplaced

towallsurfaces.

Scaffoldingwillbesetupduringwallbondingandsettingupofscaffoldingwillbeensuredthat

donebyauthorizedandtrainedpersonnel.

Mortar that a small amount of lime added and including 250300kg cement, will be used at

masonry.Jointthicknessisonecentimeterandcontinuouslyatverticalandhorizontaldirection.

Plasteringworkswillnotstartatbothsideofwallwithoutmortarwasdried.

9.2.7. ConstructionofLintel

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

16/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

Lintelswillbeconstructedonthedoorsandwindows.Linteloverlappingdistancewillbe

accordancewithitsdrawing.Linteloverlappingdistancesaregivenbelowtable.

TypeofWall ClearSpaceMinumumOverlap(d)cm

MassiveWall

CurtainWall

(L)

cm

<135

135300

<100

100190

200300

LintelsOn

DoorandWindow

20

0,15XL

15

20

30

Lintels

Under

Window

4560

BondingofWall

9.4.

ELECTRICALANDSANITARYINSTALLATIONWORKS

9.4.1.

ElectricalInstallation

Electrical installation will be analyzed in two categories as weak current and strong current

installation.

Weak current consists of bell, antenna and fire alarm system. Strong current is relevant to

lighting and alternative power supply. Both of the systems pass through the same istallation

steps.

Firstly, the conduits, through which the cables will move on, will be installed in the concrete

slab,beamsandwallstoprotectthewires.Attheintersectionpointsoftheseconduits,junction

boxeswillbeinstalledonthebeamsand/orwallsunderplaster.Aftertheconduitinstallation,

theelectricwireswillbepassedthroughtheconduits.

Electricalwireshallbeaccordancewithelectricaldrawingsandshallbeinspectedbyengineers.

Secondstepwillbeexecutedafterplasterandpaintingworks.Inthisstage,electricalfixtures,

panelsandfuseswillbeconnectedtowiresandtheyarefixedtothepointsthatareindicatedin

the electrical installation drawings. Proper scaffolds and ladders shall be used to reach high

points.

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

17/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

Allthecablesarecollectedandcontrolledinthemainfusebox.Mainsupplywillbecomeinto

thisboxaswell.

Afterallwiringsandconnectionscompleted,electricalsystemshallbecheckedandtested.

9.4.2.

PlumbingandSanitaryInstallation

Plumbing system will be mentioned as 3 separate sections. First one is waste water system,

secondiscleanwatersystemandlastoneisinstallationofsanitarywares.

WasteWaterSystem

Waste water pipes installation will start before concrete pouring of basement shear walls. At

this stage, necessary reserved holes will be left in shear walls and when waste water pipes

startedtoinstall,theseholeswillbeusedinordertopipes,crossingbetweenroomsandoutside

of the building. After completion of lining of walls, waste water pipes will start to install

accordancewithplumbingdrawing,thanitwillbefixedtoavoidanydeformationduringscreed

pouring.Necessaryattentionshallbetakenforconnectionpoints.Opensidesofpipesmustbe

closedtoavoidcongestingofpipesbecauseofanyconstructionmaterial.

CleanWaterSystem

Clean water pipes installation will start after screed pouring and be installed accordance with

plumbing drawing. Plastic weld machine will be used to connect pipes bracket parts and tie

parts.Allconnectionsandtiepartsshallbetestedaftercompletionofallplumbingsystemby

giving pressure water into system from one point. Possible water leakage will be monitored

duringonedayandcleanwaterpipeswillbeembeddedafterthat.

InstallationofSanitaryWares

After completion of all ceramic tile and plastering work, sanitary ware installation will be

started. Armatures and sanitary fixtures will be installed by hand tools accordance with

plumbingdrawing.

9.5.

PLASTERINGWORKS

After completion of all wall lining and embedded electrical and plumbing works, plastering

workswillstartasroughcastandfinishplaster.Cement,sand,water,admixturesbondingagent

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

18/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

etc.,willbeusedforplasteringworks.Properscaffoldsshallbeusedduringplasteringworksand

itshallbeinstalledbyauthorizedandtrainedworkers.

Walls to be plastered are required that fully dry. Plaster bottom alignments will be marked

beforestartingplasteringworks.Residuesandbulgeswillberemovedfromsurface.Surfaceof

walls willbe wetted.Concretesurfacestobeplasteredwillbechippedifthey arenotenough

rough.

Verticallevelingtapeswillbepreparedatintervals2metersinordertogetplaneandplummet

surface.Roughcastmortarwillbeappliedonthesetapesbyusingsteeltrowel.Gaugestickwill

beusedtobeflattenplasteringsurfaceafterapplication.

Finishing plaster will be made after properly curing of roughcast. Roughcast surface will be

wettedwithplentyofwater.Itisrequiredthatallofscaffoldingconnectionsshouldberemoved

fromwall.

Plastering is not recommended to make neither outside of building nor inside of building,

excepttakenspecialprecautionatinsideofbuilding.

Theplasteredsurfacewillbecuredwellforaperiodof3days.

9.6. ERECTIONOFDOORSANDWINDOWS

Blindframesofdoorsandwindowswillbemountedtothewallsaftercompletionofwalllining

beforeplasteringworks.Blindframeswillbeconnectedwithweldingwithusingsteelprofiles.It

willbepaintedwithanticorrosionpaints.Afterinstallationofblindframes,deformedsurfaces

willbepaintedinplace.Blindframeswillbeconnectedtobuildingfoundationearthingsystem

byusingsteelstrips.

Doors and windows will be produced accordance with blind frames sizes and architectural

drawingofbuildinginfactory.Doorsandwindowswillbetransportedtositeaftercompletionof

insideandoutsideplasteringworks.Doorsandwindowframethatproducedatfactorywillbe

placedtomountingplacebyhelpingofplummet.Placeddoorandwindowframewillbefixed

withscrews.Installationwillbecompletedbyattachingwindowedges.Protectiontapeswillbe

removedafterinstallation.

9.7.

CERAMICTILEWORKS

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

19/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

Attheplacestobetiledwalltiling,walltilingwillbemadebeforefloortiles.

Firstly, bottom of the places that to be tiled will be cleaned. If surface is a smooth surface,

surfacemustbechippedinordertoclingoftile.

Ready mix ceramic adhesive will be used to tile ceramics. Adhesive will be applied to bottom

surfacewithtrowel.Afterthat,firstceramictilewillbeputtedtoedgeofwallorflooranditwill

becontinuedwithputtingotherceramictilestofirstceramictilealignment.

If deterioration is become at adhesive to be used, that adhesive should not be used again.

Ceramic tiles to be used for places that encountered to corners and holes will be used with

cuttingbytilecuttingtoolaftermeasuredinplace.Tilespacerwillbeusedinordertoprovide

jointbetweenceramictiles.Watergagemustbeusedtochecklevelingoftiles.

Aftercompletionoftilingworks,ceramictilewillbeleftdryingduring1dayduration.Jointing

paste will be applied after drying. Jointing paste will be applied to surface with helping of

scraper and all of joint spaces will be filled in this way. After that, surface flatness will be

providedbycleaningoffwithwettedsponge.

9.8.

ELEVATEDFLOOR

Surfacetobemadeapplicationwillbeabsolutelycleanedfromdebrisandwastemortarsthat

stickedontheconcretesurface.

After last inspections of areas which to be make installation of elevated floor, areas

measurements will be made and placement of elevated floor plates will be planned with

creatinggrids.Inthisway,jointstringwillbeused.

Afteralignedstring,elevatedfloorfootswillbedistributedtoareawithdistancebetween60cm.

Beltscrewswillbetightenwithbeltsfixingtothechannelsintopoffoots.Substructureworks

will be completed with installing of plastic seals that in the shape of star to be provide noise

isolation.

First panel of the elevated floor which is substructure system completed, will be placed at

middleoftheareaandunderthejointstring.Itwillbealignedwithwatergageandlasermeter.

Panellevelswillbealignedfromnutsundertheelevatedfloorfoots.

Afterplacementofentirepanels,panelstobecutwillbeplaced.Forthispurpose,dimensionsof

theremainingemptyspaceswillbemarkedwithmeasuring.Aftermarking,panelswillbecut

withcuttinghandtool.Elevatedfloorpanelswhicharecut,willbeplacedwithwatergage.

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

20/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

9.9. INTERNALPAINTINGWORKS

Firstly,1metersquareareawillbepaintedtodecideeasilycolortobepainted.Itisrequiredthat

ceilingpaintingsmustbepaintedbeforewallpaintings.

Primerapplicationwillbemadeallsurfacesbeforepainting.Paintingapplicationwillbestarted

afterdryingofprimer.Paintcanbethinnedasdeterminedonpackageofpaintorapplication

catalog.Connectionpointsofthewallsandedgeswillbepaintedbyfingerrollerbrushandthen

wide surfaces will be painted by big roller brush. Application should be done in the same

direction continuously. After completion of first layer, second layer will be painted after

completionofallbuildingworks.

9.10. EXTERIORPAINTING

Firstly, application surface will be cleaned and flatten. Edge profiles must be used at corners.

Exteriorpaintingworkswillbecompletedwithpainting2layersexteriorpaint.

9.11. SUSPENDEDCEILINGWORKS

Applicationareaelevationswillbemeasuredbylasergagebeforesuspendedceilingworksstart.

T24 edge profiles will be mounted on these elevations. 360cm length main carriers will be

hanged to ceiling with helping of steel dowel, suspension wire and double spring clips as

maximum 60cm distance to the wall. Similarly, second main carrier will be hanged as 120cm

distance to first main carrier. Main carrier connections will be done with spreading of main

120cm carriers at 60cm intervals. After that, obtained 60x120 sized rectangles will be divided

with60cmsecondarycarriersand60x60sizedsquareswillbeconstituted.

Suspendedceilinginstallationwillbecompletedwithplacingofrockwoolpanelsinthe60x60cm

squares.

9.12. ROOFWORKS

After completion of building concrete works, building roof should b covered as per below

section,onebyone.

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

21/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

OvertheReinforcedconcreteslab,LightweightCellularConcretewith%2slopehavetobecast.

Theslopehavetobeindirectionofrainwaterpipes.Overthislayer,AsphaltPrimerBitumen

Emulsion, have to applied. Asphalt Primer have to cover all face of concrete and have to

continue on papraphet walls up to top layer level. After Asphalt primer dried, double Layer

ModifiedbitumenWaterproofingmembranesareadheredbythermalheat.Membranehaveto

be 2+3mm. Membrane joints at two layers should not overlapped. Over this layer, Thermal

InsulationLayerExtrudedPolystrene5cmshouldbeapplied.XPSlayerhavetocoveredand

should be protected with Filter Fabric Geotextile 150 g/m2. And final layer for roof cover is

ConcretePaversLoselyLaidonPlasticSpacerSupports.

10. TIMELINEOFACTIVITIES

Approximate durations will be shown below for each section. Also each step of the work will

repeated and performed together for accelerate the work. Also working Schedule will be

followed.

ForecastedStart&FinishDatesoftheControlBuilding:01/10/201401/03/2014

11. PROGRESSMEASUREMENT

Ontimebaseprogresscurveswillbeindicatedineachmonthlyreports.

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

22/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

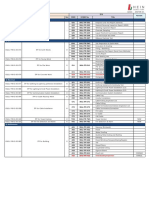

12. QUALITYREQUIREMENTS

All Electrical Erection works of the Khabat Thermal Power Plant Units 1&2 Project will be

performedaccordingtothe;(Allwillbesubmitted)

InspectionandTestPlan(ITP)ofBlockWork

InspectionandTestPlan(ITP)ofPlastering

InspectionandTestPlan(ITP)ofTiling

InspectionandTestPlan(ITP)ofPainting

InspectionandTestPlan(ITP)ofRoofConstruction

InspectionandTestPlan(ITP)ofDoorsandWindows

InspectionandTestPlan(ITP)ofPlumbing

InspectionandTestPlan(ITP)ofElectricalInstallation

InspectionandTestPlan(ITP)ofElevatedFloor

Toprovidethecontrolsafterfinishingtheworks,RelevantCheckListswillbefollowed.

SIEMENSshallbestrictlycomplywiththeProjectQA/QCPlanwhichisapprovedbyGAMA.

Method Statements, Inspection and Test Plans and Checklists will be delivered to Gama, 1

monthbeforethestartingofthesiteworksand/orfactorytests.Accordingtothecomments

of Gama, suitable changes will be applied immediately and the documentation will be

completed.

GamawillbenotifiedbySIEMENS20daysinadvanceforanytestatmanufacturerpremises

oranysiteactivitiesbyNotificationofInspectionforms.Furthermore,theinspectiondatewill

be verified by SIEMENS 3 days prior to test. For civil works, especially for concrete

inspections,notificationwillbeonedayinadvance.

Thechecklists,whicharegoingtobeapprovedbyGamaduringinspection,willstandforthe

confirmationoftheworkandbeusedassitedocumentsthoserecordthecontrol.

Incaseofoccurringnonconformitiesduringtheexecutionofwork,theywillberecordedand

reported to the related head contacts. A correction plan for the work will be prepared after

requiredsurvey.

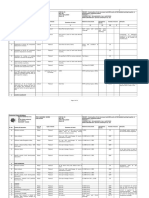

13.1. PersonalProtectiveEquipment

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

23/25

KP-00+++-MQ758V0003

Doc.No:

Date:

19.09.2014

Therequiredpersonalprotectiveequipmentforexcavationworksisdefinedinthefollowing

table.Personalprotectiveequipmentshallbereviewandredefinedwithinthecontextofthe

preparationofthetaskbasedRAMS(RiskAssessmentMethodStatement)

Related

Standard

50hz

14Kv 1dk

EN 3453466

Drainage

Works

EN 347

EN 397

EN

166175

EN

166

Teknik

EN artna

166 me

EN

149

EN

414

x4x

EN

EN 352- 352-2

413x4

1

(15

x

(30dB) Db)

Sa fety

Belt

Heat Resist.

Nomex

Clothes

Harness Belt

Safety Vest

Body Protectors

Work

Uniform

Ear Plug

Steel Netting

Gloves

Welding

Gloves

Heat Gloves

Tension

Gloves

EN

EN

420,38 EN

140,450

8

388

Ear defender

Ear

Protectors

Gloves

Filter

Cartridge

Mask

Mechanical

Work Gloves

Particle Mask

Respira tion

Protectors

Eye Wash

Protective

Glasses

Welding

Mask

Welding

Glasses

54/ 57,

50/ 54,

57/ 62

Barrettas

Plastic Boots

Footwear (for

Mech.

Works)

Insulating

Boats

PROCESS

H ea d

Protect Eye - Fa ce Protectors

ors

Foot Protectors

Footwear (for

Elect. Works)

Equipment

PERSON AL PROTECTIVE EQUIPM EN TS

EN

471

ANSI

IEC

207- EN 362

61482-1 2011

355

13.2. SafetyFence

HazardTapewillbeappliedforcoveringtheentiresiteandspecificworksthatdeterminedby

riskanalysis.

13.3. RelatedSafety/WarningSigns.

Duringtheworkatsite,therewillbewarningsignsforeachriskyworkandalsogeneralhealth

andsafetysignswillbelocatedathighlyvisiblepointstowarntheworkers.

Toprovidesafetyandcontroloftheworkingareas,therewillbespecificandlocaldemarcation

torestrictandisolatetheworkingareas.

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

24/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

14. REFERENCES

SIEMENSQualityPlan

Quality

Requirements

for

Suppliers

and

Subcontractors

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

METHOD STATEMENT FOR CIVIL WORKS FOR

CONTROL BUILDING

Page:

25/25

Doc.No:

KP-00+++-MQ758V0003

Date:

19.09.2014

Doc. No: KP-00+++-MQ758-V0003, Rev. No: A

Das könnte Ihnen auch gefallen

- Mr.Mehmet KARAMr.Mehmet KARAElectrical InstallationDokument35 SeitenMr.Mehmet KARAMr.Mehmet KARAElectrical InstallationUtku Can KılıçNoch keine Bewertungen

- QMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Dokument10 SeitenQMP-MOA-013 (Rev.1) Preparation of Method Statements (CSC)Vasilica BarbarasaNoch keine Bewertungen

- METHOD STATEMENT For INSTALLATION of PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete WallsDokument6 SeitenMETHOD STATEMENT For INSTALLATION of PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete WallsYoke Shu100% (1)

- Inspection & Test Plan for Civil and Structural SteelDokument33 SeitenInspection & Test Plan for Civil and Structural SteelAhmed Mohsin100% (1)

- Fieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Dokument4 SeitenFieid Quality Plan: DC Industrial Plant Services Pvt. Ltd. KOLKATA - 700 016Sam100% (1)

- Project Internal Audit Procedure: SheetalkumarDokument4 SeitenProject Internal Audit Procedure: SheetalkumarTwin BullsNoch keine Bewertungen

- SCC QMS MANUAL-FINAL Signed 2017 PDFDokument94 SeitenSCC QMS MANUAL-FINAL Signed 2017 PDFAlexis kabayizaNoch keine Bewertungen

- F09 - QC Monthly Report - JanuaryDokument10 SeitenF09 - QC Monthly Report - Januaryrazi khanNoch keine Bewertungen

- SLPG Q 0000 24001 019 001 4 0Dokument15 SeitenSLPG Q 0000 24001 019 001 4 0sivagnanamNoch keine Bewertungen

- Pipeline Electrical Installation Inspection MethodsDokument7 SeitenPipeline Electrical Installation Inspection Methodscherif yahyaouiNoch keine Bewertungen

- 8 Field Quality PlanDokument18 Seiten8 Field Quality Plangeorge_hem100% (1)

- Inspection Test Plan (Itp) : Mobile Fire ExtinguisherDokument4 SeitenInspection Test Plan (Itp) : Mobile Fire Extinguisher87482127Noch keine Bewertungen

- Field Installation, Inspection & Test PlanDokument2 SeitenField Installation, Inspection & Test PlanSaiful Ahda100% (1)

- A. Gis and SWGR: 1. Precast Beam and Wall Panel Erection GIS 2. Hollow Core Slab InstallationDokument4 SeitenA. Gis and SWGR: 1. Precast Beam and Wall Panel Erection GIS 2. Hollow Core Slab InstallationSyed Munawar Ali100% (1)

- 000 Itp-Itr List - r11Dokument3 Seiten000 Itp-Itr List - r11Qii BagerNoch keine Bewertungen

- Reinforcement Work Proc.Dokument5 SeitenReinforcement Work Proc.Akhilesh Kumar0% (1)

- FQP GeneralDokument21 SeitenFQP GeneralgaladrialNoch keine Bewertungen

- Itp - Electrical Second FixDokument4 SeitenItp - Electrical Second Fixirfan vpNoch keine Bewertungen

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDokument15 SeitenIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNoch keine Bewertungen

- Traffic Signage Installation ITPDokument1 SeiteTraffic Signage Installation ITPmoytabura96Noch keine Bewertungen

- Procurement Plan: FOR Epc For Constructing Pipe Line and Power Line For Sangsam Oil DevelopmentDokument9 SeitenProcurement Plan: FOR Epc For Constructing Pipe Line and Power Line For Sangsam Oil DevelopmentHaekal RamadhanNoch keine Bewertungen

- Hydrotest Check List PDFDokument1 SeiteHydrotest Check List PDFSaut Maruli Tua Samosir100% (1)

- Raceway Selection GuideDokument10 SeitenRaceway Selection GuidephilipyapNoch keine Bewertungen

- Method Statement Excavation Civil WorksDokument9 SeitenMethod Statement Excavation Civil WorksRanjith GabrielNoch keine Bewertungen

- 3 Months Look Ahead PlanDokument6 Seiten3 Months Look Ahead PlananjnaNoch keine Bewertungen

- Inspection and Test Plan Piping Works Main Deck, Service Platform, Module, EtcDokument3 SeitenInspection and Test Plan Piping Works Main Deck, Service Platform, Module, Etcaditya kokoNoch keine Bewertungen

- Field Quality Plan For LgfsDokument7 SeitenField Quality Plan For LgfsUday PratapNoch keine Bewertungen

- CV Sample - 2Dokument20 SeitenCV Sample - 2Lateef Ur REhmanNoch keine Bewertungen

- Tepng Onshore Const Itt Project Quality PlanDokument45 SeitenTepng Onshore Const Itt Project Quality PlanTrustEmmaNoch keine Bewertungen

- How To Write A Welding Procedure Specification (WPS)Dokument5 SeitenHow To Write A Welding Procedure Specification (WPS)Mohamed Atef100% (1)

- Construction Methodology - Maholiya ProjectDokument6 SeitenConstruction Methodology - Maholiya ProjectPrateek DasNoch keine Bewertungen

- ITP For Structure Steel Erection WorksDokument13 SeitenITP For Structure Steel Erection WorksShewale PravinNoch keine Bewertungen

- Project: Instrument Junction Box InstallationDokument2 SeitenProject: Instrument Junction Box InstallationAhmad DagamsehNoch keine Bewertungen

- 11.specifications For Electrical WorksDokument36 Seiten11.specifications For Electrical WorksBalamurugan ArumugamNoch keine Bewertungen

- Checklist For Transformer Yard LayoutDokument2 SeitenChecklist For Transformer Yard LayoutRahulNoch keine Bewertungen

- Quality Plan for Refinery Offsite & Utilities EPC ProjectDokument34 SeitenQuality Plan for Refinery Offsite & Utilities EPC Projectanjas_tsNoch keine Bewertungen

- Procédure MTDokument11 SeitenProcédure MTAslaouiNoch keine Bewertungen

- QC-GF-001 - Request For InspectionDokument1 SeiteQC-GF-001 - Request For InspectionDarrel Espino AranasNoch keine Bewertungen

- QA&QC-DT-FRMC-014 Mouting Structure Material RecordDokument1 SeiteQA&QC-DT-FRMC-014 Mouting Structure Material RecordTariq Ali SialNoch keine Bewertungen

- Description SLP Number Date Location Project Client Prepared by REF Attachments Machine: ConfigurationDokument1 SeiteDescription SLP Number Date Location Project Client Prepared by REF Attachments Machine: ConfigurationozchrisNoch keine Bewertungen

- MV Power Cable InstallationDokument3 SeitenMV Power Cable InstallationAhmad Dagamseh100% (1)

- Erection Method StatementDokument30 SeitenErection Method StatementmustafaNoch keine Bewertungen

- 025-ITP For Sewer & Drainage PDFDokument6 Seiten025-ITP For Sewer & Drainage PDFKöksal PatanNoch keine Bewertungen

- YAS South Infrastructure Sewer CoversDokument2 SeitenYAS South Infrastructure Sewer CoversMohamed ThowfeekNoch keine Bewertungen

- Method Statement Index NewDokument5 SeitenMethod Statement Index Newknabpsho50% (2)

- Upgrade Waste Water Systems Electrical Tie-InsDokument75 SeitenUpgrade Waste Water Systems Electrical Tie-InsHaleem Ur Rashid Bangash100% (1)

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDokument2 SeitenElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNoch keine Bewertungen

- Sop of StringingDokument7 SeitenSop of Stringingshubham shindeNoch keine Bewertungen

- Method Statement for Threaded Piping InstallationDokument17 SeitenMethod Statement for Threaded Piping InstallationsugumarNoch keine Bewertungen

- Method of Statement For GroutingDokument7 SeitenMethod of Statement For Groutingmohammad.a.d94Noch keine Bewertungen

- Quotation-Minor Civil WorksDokument2 SeitenQuotation-Minor Civil WorksAntonioNicalaNoch keine Bewertungen

- Final - Commercial & SOR-Vol IDokument86 SeitenFinal - Commercial & SOR-Vol IengharshNoch keine Bewertungen

- Structural Steel ErectionDokument7 SeitenStructural Steel Erectionzaki fadlNoch keine Bewertungen

- Wps Mig PDF FreeDokument3 SeitenWps Mig PDF Freehanz bermejoNoch keine Bewertungen

- Quality PlanDokument10 SeitenQuality PlanneerajgulabNoch keine Bewertungen

- Project: EXPO 2020 - OV016 - USA PAVILION Inspection and Test Plan (Itp)Dokument5 SeitenProject: EXPO 2020 - OV016 - USA PAVILION Inspection and Test Plan (Itp)qc_531040655Noch keine Bewertungen

- SATR-W-2007 Rev 7Dokument4 SeitenSATR-W-2007 Rev 7QA QCNoch keine Bewertungen

- DTTN Dt1 PC Rfi ST 0100Dokument1 SeiteDTTN Dt1 PC Rfi ST 0100Tariq Ali SialNoch keine Bewertungen

- KP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSDokument21 SeitenKP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSUtku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7368-Rev 0-ITP Lightning Protection PDFDokument3 SeitenKP-00+++-CQ712-B7368-Rev 0-ITP Lightning Protection PDFUtku Can KılıçNoch keine Bewertungen

- Rsae ITP QA: Document Review and Cover Sheet Company: Construction ContractorDokument5 SeitenRsae ITP QA: Document Review and Cover Sheet Company: Construction ContractorUtku Can KılıçNoch keine Bewertungen

- FRN MST PPL Pl1 011 p4 C c1Dokument18 SeitenFRN MST PPL Pl1 011 p4 C c1Utku Can Kılıç100% (1)

- Petroleum Test Questions Answers English Issue6 2016 08Dokument124 SeitenPetroleum Test Questions Answers English Issue6 2016 08Utku Can KılıçNoch keine Bewertungen

- MV&LV Switchgear Test ReportDokument4 SeitenMV&LV Switchgear Test ReportUtku Can Kılıç100% (1)

- ITP For Batteries, Chargers and UPSDokument7 SeitenITP For Batteries, Chargers and UPSUtku Can Kılıç100% (1)

- MHI Electrical 1st Comment RSAE-ITP-QA-EL-012 ITP For LV Bus DuctDokument5 SeitenMHI Electrical 1st Comment RSAE-ITP-QA-EL-012 ITP For LV Bus DuctUtku Can KılıçNoch keine Bewertungen

- Rsae-Frm-216 Rev 00 Inspection Check List LV Bus DuctDokument1 SeiteRsae-Frm-216 Rev 00 Inspection Check List LV Bus DuctUtku Can Kılıç50% (2)

- MV&LV Switchgear Test ReportDokument4 SeitenMV&LV Switchgear Test ReportUtku Can Kılıç100% (1)

- VT Test ProsedureDokument7 SeitenVT Test ProsedureUtku Can KılıçNoch keine Bewertungen

- Khabat Power Plant Auto Transformer Test ReportDokument3 SeitenKhabat Power Plant Auto Transformer Test ReportUtku Can Kılıç100% (1)

- Khabat Power Plant Test ReportDokument11 SeitenKhabat Power Plant Test ReportUtku Can Kılıç100% (2)

- VT Test ProsedureDokument7 SeitenVT Test ProsedureUtku Can KılıçNoch keine Bewertungen

- Khabat Power Plant Auto Transformer Test ReportsDokument11 SeitenKhabat Power Plant Auto Transformer Test ReportsUtku Can KılıçNoch keine Bewertungen

- Khabat TPP Electrical Panels InstallationDokument6 SeitenKhabat TPP Electrical Panels InstallationUtku Can KılıçNoch keine Bewertungen

- Post Insulator Installation ChecklistDokument1 SeitePost Insulator Installation ChecklistUtku Can KılıçNoch keine Bewertungen

- PP13 00 Bat Enl Gam 001 PDFDokument16 SeitenPP13 00 Bat Enl Gam 001 PDFUtku Can Kılıç100% (1)

- KP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSDokument21 SeitenKP-00+++-MQ758-V0008-Rev 1-METHOD OF STATEMENT FOR HV SUBSTATION BUSBAR INSTALLATION WORKSUtku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7368-Rev 0-ITP Lightning Protection PDFDokument3 SeitenKP-00+++-CQ712-B7368-Rev 0-ITP Lightning Protection PDFUtku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7907 - Rev.B - ITP For MV Switchgear Installation Cover PageDokument1 SeiteKP-00+++-CQ712-B7907 - Rev.B - ITP For MV Switchgear Installation Cover PageUtku Can KılıçNoch keine Bewertungen

- PP13 15 Ac Enl Gam 002Dokument31 SeitenPP13 15 Ac Enl Gam 002Utku Can KılıçNoch keine Bewertungen

- Lightning Protection ITPDokument3 SeitenLightning Protection ITPUtku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Dokument2 SeitenKP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Dokument1 SeiteKP-00+++-CQ712-B7907 - F01 - Rev.0 - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNoch keine Bewertungen

- IQ347 300 EL CHL 00036 Lightning ProtectionDokument1 SeiteIQ347 300 EL CHL 00036 Lightning ProtectionUtku Can KılıçNoch keine Bewertungen

- KP-00+++-CQ712-B7907 - F01 - Rev.B - MV Switchgear Installation Inspection Checklist1Dokument2 SeitenKP-00+++-CQ712-B7907 - F01 - Rev.B - MV Switchgear Installation Inspection Checklist1Utku Can KılıçNoch keine Bewertungen

- Electrical Works Grounding ITPDokument3 SeitenElectrical Works Grounding ITPUtku Can KılıçNoch keine Bewertungen

- Inspection and Test Plan For Lightning Protection InstallationDokument1 SeiteInspection and Test Plan For Lightning Protection InstallationUtku Can Kılıç100% (1)

- Check List of Lightning Protection ErectionDokument1 SeiteCheck List of Lightning Protection ErectionUtku Can KılıçNoch keine Bewertungen

- For Information For Review For Approval For Construction As-BuiltDokument21 SeitenFor Information For Review For Approval For Construction As-BuiltUtku Can KılıçNoch keine Bewertungen

- Att-2 Grounding & Lightning Protection - Tech - Specs.Dokument34 SeitenAtt-2 Grounding & Lightning Protection - Tech - Specs.Utku Can Kılıç100% (1)

- Internship ReportDokument78 SeitenInternship ReportRakesh Rake100% (1)

- Comparative Analysis of MIVAN Formwork Building and Conventional Formwork Building Based On Cost and DurationDokument4 SeitenComparative Analysis of MIVAN Formwork Building and Conventional Formwork Building Based On Cost and DurationInnovative Research PublicationsNoch keine Bewertungen

- Determining Initial Cement Setting TimeDokument15 SeitenDetermining Initial Cement Setting TimeZahim Harki100% (1)

- PandPofCC (8th Edition)Dokument629 SeitenPandPofCC (8th Edition)Carlos Alberto CaicedoNoch keine Bewertungen

- Wcms Asist 8390Dokument301 SeitenWcms Asist 8390tinashemambarizaNoch keine Bewertungen

- Construction of Surge Shaft Using Slip Form TechniqueDokument4 SeitenConstruction of Surge Shaft Using Slip Form TechniqueCharumitra Singh YadavNoch keine Bewertungen

- Project FinalDokument30 SeitenProject FinalApdy- HakimNoch keine Bewertungen

- Civil Miniproject DixitDokument65 SeitenCivil Miniproject DixitPrabhumk07Noch keine Bewertungen

- Under The Guidance of Dr. A. Mallika: Neeta Rautela 15071D2005Dokument22 SeitenUnder The Guidance of Dr. A. Mallika: Neeta Rautela 15071D2005Neeta RautelaNoch keine Bewertungen

- QOR GSP Bhopal - 006 Compliance ReportDokument3 SeitenQOR GSP Bhopal - 006 Compliance Reportfaizan aliNoch keine Bewertungen

- Material Takeoff and Project Scope DefinitionDokument26 SeitenMaterial Takeoff and Project Scope DefinitionUmar KidaNoch keine Bewertungen

- Temporary Works For Highrise ConstructionDokument41 SeitenTemporary Works For Highrise ConstructionGlen WardNoch keine Bewertungen

- EuroCode 4Dokument420 SeitenEuroCode 4Mohamed Tahar Allagui100% (3)

- BWC Constr.Dokument7 SeitenBWC Constr.venkata krishna reddy MorthlaNoch keine Bewertungen

- SLAB Cuplock With H20-01Dokument7 SeitenSLAB Cuplock With H20-01Manu MohanNoch keine Bewertungen

- Industrial Training Report at Ratnam GroupDokument38 SeitenIndustrial Training Report at Ratnam GroupvaishvikNoch keine Bewertungen

- Section 8 - Reclamation Technical SpecificationDokument42 SeitenSection 8 - Reclamation Technical SpecificationRocky Situmorang100% (1)

- CMPM Reviewer Quiz 1: It Means The Demolition of A Structure Done With Some Equipment Without The Use of Any ExplosiveDokument3 SeitenCMPM Reviewer Quiz 1: It Means The Demolition of A Structure Done With Some Equipment Without The Use of Any ExplosiveJCNoch keine Bewertungen

- Conbextra GP2 (T)Dokument4 SeitenConbextra GP2 (T)Gautam PaulNoch keine Bewertungen

- Construction Thumb Rule BrijjDokument4 SeitenConstruction Thumb Rule BrijjNaveen Bansal100% (2)

- MS For Grouting ApplicationDokument20 SeitenMS For Grouting ApplicationmarckeNoch keine Bewertungen

- MS Casting Concrete For Box Culvert 20feb2016Dokument7 SeitenMS Casting Concrete For Box Culvert 20feb2016Joel AlcantaraNoch keine Bewertungen

- Indian Standard: Method of Measurement of Building and Civil Engineering WorksDokument10 SeitenIndian Standard: Method of Measurement of Building and Civil Engineering WorksMuthusamy ArumugamNoch keine Bewertungen

- L&T Formwork Component ListDokument54 SeitenL&T Formwork Component ListShikhin Garg84% (70)

- Ancon Shear Load ConnectorDokument30 SeitenAncon Shear Load ConnectorJonathan WardropNoch keine Bewertungen

- ESTIMATE OF Brahampur ANICUT 30 MDokument12 SeitenESTIMATE OF Brahampur ANICUT 30 MRajeev MishraNoch keine Bewertungen

- 2016-17 Maharashtra PWD Schedule of RatesDokument283 Seiten2016-17 Maharashtra PWD Schedule of RatesJawed PathanNoch keine Bewertungen

- Step of Concrete SlabDokument5 SeitenStep of Concrete SlabMine MienNoch keine Bewertungen

- Gulf Precast BrochureDokument13 SeitenGulf Precast BrochureMohammad Abu-RadiNoch keine Bewertungen