Beruflich Dokumente

Kultur Dokumente

R 390

Hochgeladen von

MiticaVladOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

R 390

Hochgeladen von

MiticaVladCopyright:

Verfügbare Formate

D.

fm Page 36 Wednesday, September 14, 2005 6:25 AM

General Turning

A

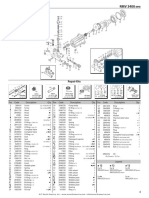

CoroMill 390

Inserts for CoroMill 390

11

Radius inserts

Parting and Grooving

MILLING

Light

Medium

Heavy

Light

Threading

Milling

Boring

Medium

Drilling

Multi-Task Machining

Heavy

Toolholding Systems

Dimensions, mm

1025

4020

4030

4040

530

1025

2030

2040

530

3040

4020

4040

H13A

1025

530

CD10

H13A

1025

2030

2040

H13A

1025

3040

4020

530

Ordering code

11 R390-11 T3 04E-PL

R390-11 T3 08E-PL

R390-11 T3 08M-PL

R390-11 T3 08E-ML

R390-11 T3 16E-ML

R390-11 T3 24E-ML

R390-11 T3 31E-ML

R390-11 T3 08E-KL

R390-11 T3 08M-KL

R390-11 T3 04E-NL

R390-11 T3 08E-NL

R390-11 T3 20E-NL

R390-11 T3 31E-NL

11 R390-11 T3 02E-PM

R390-11 T3 04M-PM

R390-11 T3 08M-PM

R390-11 T3 12E-PM

R390-11 T3 16E-PM

R390-11 T3 16M-PM

R390-11 T3 20E-PM

R390-11 T3 24E-PM

R390-11 T3 31E-PM

R390-11 T3 31M-PM

R390-11 T3 02E-MM

R390-11 T3 08M-MM

R390-11 T3 12E-MM

R390-11 T3 16E-MM

R390-11 T3 20E-MM

R390-11 T3 24E-MM

R390-11 T3 31E-MM

R390-11 T3 02E-KM

R390-11 T3 04M-KM

R390-11 T3 08M-KM

R390-11 T3 12E-KM

R390-11 T3 16E-KM

R390-11 T3 16M-KM

R390-11 T3 20E-KM

R390-11 T3 24E-KM

R390-11 T3 31E-KM

R390-11 T3 31M-KM

11 R390-11 T3 10M-PH

R390-11 T3 10M-MH

R390-11 T3 10M-KH

Polycristalline diamond

R390-11 T3 04E-P4-NL

la

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

iW

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

6.8

s

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

3.59

bs

0.9

1.5

1.2

1.5

0.8

1.02

1.02

1.02

r

0.4

0.8

0.8

0.8

1.6

2.4

3.1

0.8

0.8

0.4

0.8

2

3.1

0.2

0.4

0.8

1.2

1.6

1.6

2

2.4

3.1

3.1

0.2

0.8

1.2

1.6

2

2.4

3.1

0.2

0.4

0.8

1.2

1.6

1.6

2

2.4

3.1

3.1

1

1

1

11

6.8

3.59

0.9

0.4

1.5

1.2

0.9

1.5

0.7

0.9

1.2

0.8

0.4

0.4

0.7

1.2

0.8

0.4

0.7

0.9

1.2

0.8

0.8

0.4

0.4

Ordering example: 10 pieces R390-11 T3 04E-NL

= First choice

R390-11 T3 04 E-PL

|

E = Highest edge sharpness and precision

M = Highest edge security

I

General Information

Diamond

GC GC GC GC CT GC GC GC CT GC GC GC - GC CT CD - GC GC GC - GC GC GC CT

Light -NL

Note!

Intermediate radii and other grades

and geometry combinations are

delivered on request as engineered

inserts.

D154

MILLING CoroMill 390

D 36

D172

D2

D.fm Page 37 Wednesday, September 14, 2005 6:25 AM

MILLING

CoroMill 390

Inserts for CoroMill 390

Dimensions, mm

1025

4020

4030

4040

530

1025

2030

2040

530

3040

4020

4040

H13A

1025

530

CD10

H13A

1025

2030

2040

H13A

1025

3040

4020

530

GC GC GC GC CT GC GC GC CT GC GC GC - GC CT CD - GC GC GC - GC GC GC CT

Heavy

Medium

Light

Ordering code

17 R390-17 04 08E-PL

R390-17 04 08M-PL

R390-17 04 08E-ML

R390-17 04 08E-KL

R390-17 04 08M-KL

17 R390-17 04 04E-PM

R390-17 04 04M-PM

R390-17 04 08M-PM

R390-17 04 12E-PM

R390-17 04 16E-PM

R390-17 04 16M-PM

R390-17 04 20E-PM

R390-17 04 24E-PM

R390-17 04 31E-PM

R390-17 04 31M-PM

R390-17 04 40E-PM

R390-17 04 48E-PM

R390-17 04 50E-PM

R390-17 04 60E-PM

R390-17 04 64E-PM

R390-17 04 04E-MM

R390-17 04 08M-MM

R390-17 04 12E-MM

R390-17 04 16E-MM

R390-17 04 20E-MM

R390-17 04 24E-MM

R390-17 04 31E-MM

R390-17 04 40E-MM

R390-17 04 48E-MM

R390-17 04 50E-MM

R390-17 04 60E-MM

R390-17 04 64E-MM

R390-17 04 04E-KM

R390-17 04 04M-KM

R390-17 04 08M-KM

R390-17 04 12E-KM

R390-17 04 16E-KM

R390-17 04 16M-KM

R390-17 04 20E-KM

R390-17 04 24E-KM

R390-17 04 31E-KM

R390-17 04 31M-KM

R390-17 04 40E-KM

R390-17 04 48E-KM

R390-17 04 50E-KM

R390-17 04 60E-KM

R390-17 04 64E-KM

17 R390-17 04 08M-PH

R390-17 04 16M-PH

la

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

17

iW

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

9.6

s

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

4.76

17

9.6

4.76

bs

1.5

1.5

1.5

1.5

1.5

1

1

1.5

1.1

0.7

0.7

0.3

1

1.5

1.1

0.7

0.3

1

1

1.5

1.1

0.7

0.3

1.5

1.5

r

0.8

0.8

0.8

0.8

0.8

0.4

0.4

0.8

1.2

1.6

1.6

2

2.4

3.1

3.1

4

4.8

5

6

6.35

0.4

0.8

1.2

1.6

2

2.4

3.1

4

4.8

5

6

6.35

0.4

0.4

0.8

1.2

1.6

1.6

2

2.4

3.1

3.1

4

4.8

5

6

6.35

0.8

1.6

Threading

Diamond

Milling

Light -NL

Drilling

Heavy

Boring

Medium

Note!

Intermediate radii and other grades

and geometry combinations are

delivered on request as engineered

inserts.

Polycristalline diamond

R390-17 04 08E-P6-NL

For grade description, see page D172

R390-17 04 08 E-PL

|

E = Highest edge sharpness and precision

M = Highest edge security

0.8

Ordering example: 10 pieces R390-17 04 08E-PL 530

= First choice

Multi-Task Machining

Light

Parting and Grooving

Radius inserts

Toolholding Systems

17

General Turning

D172

D2

MILLING CoroMill 390

D 37

General Information

I

D154

D.fm Page 38 Wednesday, September 14, 2005 6:25 AM

General Turning

A

MILLING

18

Inserts for CoroMill 390

Parting and Grooving

Radius inserts

Light

Note!

Intermediate radii and other grades

and geometry combinations are

delivered on request as engineered

inserts.

Medium

Threading

Light

Milling

Medium

1025

4020

4030

4040

530

1025

2030

2040

530

3040

4020

4040

H13A

1025

530

CD10

H13A

1025

2030

2040

H13A

1025

3040

4020

530

Ordering code

18 R390-18 06 08H-KL

R390-18 06 08H-PL

R390-18 06 12H-PL

R390-18 06 16H-PL

R390-18 06 20H-PL

R390-18 06 24H-PL

R390-18 06 31H-PL

R390-18 06 40H-PL

R390-18 06 50H-PL

R390-18 06 60H-PL

R390-18 06 64H-PL

R390-18 06 08H-ML

R390-18 06 12H-ML

R390-18 06 16H-ML

R390-18 06 20H-ML

R390-18 06 24H-ML

R390-18 06 31H-ML

R390-18 06 40H-ML

R390-18 06 50H-ML

R390-18 06 60H-ML

R390-18 06 64H-ML

R390-18 06 12H-KL

R390-18 06 31H-KL

18 R390-18 06 12M-PM

R390-18 06 12M-MM

R390-18 06 12M-KM

iW

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

11

s

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.33

6.35

6.35

6.35

bs

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1.1

1.5

1.5

r

0.8

0.8

1.2

1.6

2

2.4

3.1

4

5

6

6.4

0.8

1.2

1.6

2

2.4

3.1

4

5

6

6.4

1.2

3.1

1.2

1.2

1.2

Wiper inserts for CoroMill 390

11

1)

Light

P

D154

MILLING CoroMill 390

D 38

Dc mm

12

16

20

25

32

40

H

bs

2.0

2.5

3.2

4.0

4.9

5.0

Dimensions, mm

GC GC GC GC CT GC GC GC CT GC GC GC - GC CT CD - GC GC GC - GC GC GC CT

Ordering code

11 R390-11 T3 08E-PLW

I

General Information

l

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

18.6

R390-18 06 08 H-PL

|

M = Highest edge security

H = Highest edge sharpness and higher precision

Toolholding Systems

Multi-Task Machining

la

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

15.8

Ordering example: 10 pieces R390-18 06 08H-KL 3040

= First choice

1025

4020

4030

4040

530

1025

2030

2040

530

3040

4020

4040

H13A

1025

530

CD10

H13A

1025

2030

2040

H13A

1025

3040

4020

530

Boring

Dimensions, mm

GC GC GC GC CT GC GC GC CT GC GC GC - GC CT CD - GC GC GC - GC GC GC CT

Drilling

CoroMill 390

D172

D2

la

11

l

11.8

iW

6.8

s

3.59

bs1)

0.7

r

0.8

D.fm Page 39 Wednesday, September 14, 2005 6:25 AM

CoroMill 390

MILLING

Spare parts for CoroMill 390

Square shoulder facemill

Insert size

11

Dc mm

12-20

25-80

25-32

40-125

40-200

17

18

1)

Screw

5513 020-36

5513 020-35

5513 020-37

5513 020-39

5513 020-25

Key (Torx Plus)

5680 046-01 (8IP)

5680 046-01 (8IP)

5680 046-02 (15IP)

5680 048-01 (15IP)

5680 046-02 (15IP)

Torque value Nm

1.2

1.2

3.0

3.0

3.0

Molykote

5683 010-01

5683 010-01

5683 010-01

5683 010-01

5683 010-01

Torque wrench1)

5680 100-03

5680 100-03

5680 100-06

5680 100-06

5680 100-06

Parting and Grooving

Cutter

General Turning

Ordering example: 10 pieces 5513 020-36

Accessories, must be ordered separately

Threading

CoroMill 390

Long edge milling cutter

Cutter

Insert screw *

5513 024-01

5513 020-25

Torque wrench Torx Plus

5680 100-03 (8IP)

5680 100-06

D

Dc mm

32-66

40-200

Torque value (Nm)

1.2

3.0

Molykote

5683 010-01

5683 010-01

Milling

Insert size

11

18

E

Accessories, must be ordered separately

Ordering example: 10 pieces 5513 024-01

* Note! The insert screw is unique for the CoroMill 390 long edge milling cutter. Do NOT use the screw

for the CoroMill 390 endmill.

Drilling

1)

Boring

Toolholding Systems

Multi-Task Machining

MILLING CoroMill 390

D 39

General Information

This catalogue has been split into smaller parts

to enhance downloading speeds.

If you want to view the next page

please click HERE!

(To go back to the last viewed page, use the integrated green arrows

at the bottom of the Acrobat user interface)

Das könnte Ihnen auch gefallen

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyVon EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyBewertung: 5 von 5 Sternen5/5 (1)

- High-Performance GM LS-Series Cylinder Head GuideVon EverandHigh-Performance GM LS-Series Cylinder Head GuideBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Jeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20Von EverandJeep, Dana & Chrysler Differentials: How to Rebuild the 8-1/4, 8-3/4, Dana 44 & 60 & AMC 20Noch keine Bewertungen

- Hino PartsDokument63 SeitenHino PartsCarlos0% (1)

- Bobcat S300 Parts ManualDokument400 SeitenBobcat S300 Parts ManualDobos01100% (1)

- Furuno GMDSS Installation Manual PDFDokument64 SeitenFuruno GMDSS Installation Manual PDFEric PskdNoch keine Bewertungen

- B-65160E FANUC AC SPINDLE MOTOR Parameter Manual PDFDokument419 SeitenB-65160E FANUC AC SPINDLE MOTOR Parameter Manual PDFMiticaVlad100% (4)

- Redback Operations ManualDokument11 SeitenRedback Operations ManualDon BraithwaiteNoch keine Bewertungen

- Controlled Bolt Tightening ChecklistDokument10 SeitenControlled Bolt Tightening Checklistanjangandak2932Noch keine Bewertungen

- SEVPL BrochureDokument20 SeitenSEVPL BrochureNaveen AnandNoch keine Bewertungen

- ARMSCOR PricelistDokument1 SeiteARMSCOR PricelistBuffalo Ark85% (62)

- Chumaceras DodgeDokument1.302 SeitenChumaceras DodgeMonica AquinoNoch keine Bewertungen

- Common Wire Splices and JointsDokument19 SeitenCommon Wire Splices and JointsJames Adrian Abalde Sabo100% (6)

- Catalogo de Partes Compresores de A/C.Dokument48 SeitenCatalogo de Partes Compresores de A/C.nayapepeNoch keine Bewertungen

- 86 Mould Base Series 16 & 20 Individual Plate PricesDokument21 Seiten86 Mould Base Series 16 & 20 Individual Plate PricesAmitava DattaNoch keine Bewertungen

- Kirloskar MF ManualDokument12 SeitenKirloskar MF Manualatulnalawade1980100% (1)

- FP Diesel Varios MotoresDokument18 SeitenFP Diesel Varios MotoresValeddia Beatriz Gutierrez Nina50% (2)

- 7118-0244 Ilizarov - TSF Pocket Ref ChartDokument12 Seiten7118-0244 Ilizarov - TSF Pocket Ref ChartFlorin MacarieNoch keine Bewertungen

- Harga Penawaran 22-07-2021Dokument110 SeitenHarga Penawaran 22-07-2021Maintenance Officer, PT SBSNoch keine Bewertungen

- SLP Vce 060706 PDFDokument5 SeitenSLP Vce 060706 PDFMas Inyeccion ElectronicaNoch keine Bewertungen

- Catalogo Sap Nov-11 Excel1 1Dokument953 SeitenCatalogo Sap Nov-11 Excel1 1Jorge Luis Campos Sinarahua100% (1)

- Num Orden RefaccionDokument6 SeitenNum Orden RefaccionfernandoNoch keine Bewertungen

- LHE - Master File: No Marks of Pkg's Description of Goods SpecificationDokument4 SeitenLHE - Master File: No Marks of Pkg's Description of Goods SpecificationPHAM PHI HUNGNoch keine Bewertungen

- Harga Penawaran 22-07-2021Dokument110 SeitenHarga Penawaran 22-07-2021Maintenance Officer, PT SBSNoch keine Bewertungen

- Motro 22Dokument33 SeitenMotro 22Jose cuelloNoch keine Bewertungen

- Tabel Invertoare Conforme 18Dokument7 SeitenTabel Invertoare Conforme 18octavvvianNoch keine Bewertungen

- W.O. # M/C Abv AreaDokument22 SeitenW.O. # M/C Abv AreaMahmoud HanafyNoch keine Bewertungen

- Facturas Willian 2Dokument170 SeitenFacturas Willian 2Rebeca AragónNoch keine Bewertungen

- 01 Rain Bird - Mar 2014 NoDokument9 Seiten01 Rain Bird - Mar 2014 NoAgustinus Asa Yudha UtamaNoch keine Bewertungen

- SLP Vce 060706Dokument5 SeitenSLP Vce 060706Mas Inyeccion ElectronicaNoch keine Bewertungen

- Pedido General FullDokument30 SeitenPedido General FullJuan David LopezNoch keine Bewertungen

- Pricelist Ahm Maret 02-03-2015Dokument1.155 SeitenPricelist Ahm Maret 02-03-2015momoNoch keine Bewertungen

- Reprogram Ac I OnDokument8 SeitenReprogram Ac I OnKevin Manuel IglesiasNoch keine Bewertungen

- Report View of APDokument50 SeitenReport View of APNURUL HIDAYAH BT IBRAHIM / UPMNoch keine Bewertungen

- TJ1 24122022Dokument2.006 SeitenTJ1 24122022Eduardo Moreno PalaciosNoch keine Bewertungen

- Berti Parts TBM-SB CatalogueDokument5 SeitenBerti Parts TBM-SB CataloguePatrice GuilhaumonNoch keine Bewertungen

- Painting OilingDokument4 SeitenPainting Oilingprsureshbabu7230Noch keine Bewertungen

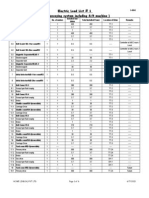

- Electric Load List # 1 (For Conveying System Including S/R Machine)Dokument6 SeitenElectric Load List # 1 (For Conveying System Including S/R Machine)Monu SharmaNoch keine Bewertungen

- Bom BelumDokument9 SeitenBom BelumTakada NamaNoch keine Bewertungen

- Rayburn Supreme-Nouvelle-355 SFW Front Plates Back Plates Base PlateDokument9 SeitenRayburn Supreme-Nouvelle-355 SFW Front Plates Back Plates Base PlateFranck PowellNoch keine Bewertungen

- Historia SupercoolDokument47 SeitenHistoria SupercoolYohannes GuðmundsdóttirNoch keine Bewertungen

- Lista de ProductosDokument138 SeitenLista de ProductoscomprasindustriaskelNoch keine Bewertungen

- Lista de Precios Motos 2015Dokument364 SeitenLista de Precios Motos 2015Tatiz Molina SarmientoNoch keine Bewertungen

- JYS Casting Replacement Parts For TrioDokument8 SeitenJYS Casting Replacement Parts For TrioborchecNoch keine Bewertungen

- Fuji ToyotaDokument27 SeitenFuji ToyotaNeftali RosalesNoch keine Bewertungen

- Work Order Trans. NBR Work Center User ID Item NumberDokument4 SeitenWork Order Trans. NBR Work Center User ID Item NumberDian ShofiyullohNoch keine Bewertungen

- Accesorios 31-05-2019Dokument30 SeitenAccesorios 31-05-2019representaciones gh 2018Noch keine Bewertungen

- 359PL 0Dokument1 Seite359PL 0Mauricio Yañez PolloniNoch keine Bewertungen

- 1 Grub Screw Allen High - Ten 16X25Mm: N.R.Agarwal Industries LTD NO Material DescriptionDokument9 Seiten1 Grub Screw Allen High - Ten 16X25Mm: N.R.Agarwal Industries LTD NO Material DescriptionPankaj PandeyNoch keine Bewertungen

- Stok 8-8Dokument12 SeitenStok 8-8Rafael JoseNoch keine Bewertungen

- DAEWOO 20a1 21a1 Ctv-21a2 DMQ-14A1 TDX-14A1 Chassis CP-330Dokument24 SeitenDAEWOO 20a1 21a1 Ctv-21a2 DMQ-14A1 TDX-14A1 Chassis CP-330Spun_GNoch keine Bewertungen

- Form Daily Report Fujiseat - SeikouDokument268 SeitenForm Daily Report Fujiseat - SeikouAku BaikNoch keine Bewertungen

- Yamada Ndp-25ba Cehnvs Bill of MaterialDokument3 SeitenYamada Ndp-25ba Cehnvs Bill of MaterialMauricio Portales MalagaNoch keine Bewertungen

- Yard Location 91 Series (59th) 1Dokument366 SeitenYard Location 91 Series (59th) 1mehedeNoch keine Bewertungen

- Main SwitchDokument13 SeitenMain Switchtrantuan4889Noch keine Bewertungen

- Take-Off and Landing Report - 894 Heca-Hesh 13jun21Dokument3 SeitenTake-Off and Landing Report - 894 Heca-Hesh 13jun21Ahmed HassanNoch keine Bewertungen

- DFVDFDokument197 SeitenDFVDFLeonardo PeñaNoch keine Bewertungen

- Relação de Frota ExcelDokument8 SeitenRelação de Frota ExcelGONZAGA SANTANANoch keine Bewertungen

- Retentores 16-02Dokument4 SeitenRetentores 16-02ulisses telmacNoch keine Bewertungen

- HD Machine Population-By Section 2014Dokument13 SeitenHD Machine Population-By Section 2014Getahun ShibiruNoch keine Bewertungen

- Toolsequipment Automotive CatalogsDokument20 SeitenToolsequipment Automotive CatalogsManuel Azabache GrandezNoch keine Bewertungen

- Kingsun HKD PDFDokument3 SeitenKingsun HKD PDFDavid MarselNoch keine Bewertungen

- OEM Manuals Service Related Product LogDokument657 SeitenOEM Manuals Service Related Product Logmatthew.polenNoch keine Bewertungen

- Mercedes Agra Up eDokument7 SeitenMercedes Agra Up eMarcio MotaNoch keine Bewertungen

- Item Site On Hand DetailDokument564 SeitenItem Site On Hand DetailMau F-Marinay BadilloNoch keine Bewertungen

- Shoulder Milling - Coromill 390: Insert Sizes 11 and 17 MMDokument7 SeitenShoulder Milling - Coromill 390: Insert Sizes 11 and 17 MMMiticaVladNoch keine Bewertungen

- Proto Max™ The Steel Cutting Specialist.: - Tool Innovations in MillingDokument38 SeitenProto Max™ The Steel Cutting Specialist.: - Tool Innovations in MillingMiticaVladNoch keine Bewertungen

- Catalog 40 Spare PartsDokument54 SeitenCatalog 40 Spare PartsMiticaVladNoch keine Bewertungen

- EasyNote TJ Series DisassemblyDokument70 SeitenEasyNote TJ Series DisassemblyBlack OnionNoch keine Bewertungen

- Impact Drill GSB 500 Re 128148 06012161f8 PDFDokument63 SeitenImpact Drill GSB 500 Re 128148 06012161f8 PDFRb SarangNoch keine Bewertungen

- L01 3way 2way WiringDokument1 SeiteL01 3way 2way Wiringshrikanth5singhNoch keine Bewertungen

- SOP of Maintenance For Ball Mill Including PolycomDokument3 SeitenSOP of Maintenance For Ball Mill Including PolycomsantoshNoch keine Bewertungen

- Welding Traceability 28-07-2019Dokument371 SeitenWelding Traceability 28-07-2019bagus handokoNoch keine Bewertungen

- FBJ BallDokument1 SeiteFBJ BallFodil DouazNoch keine Bewertungen

- Katalog KabelDokument30 SeitenKatalog KabelAdhyartha KerafNoch keine Bewertungen

- Oversized Pressure Regulator Valve Kit: Renault/Peugot AL-4, DPODokument2 SeitenOversized Pressure Regulator Valve Kit: Renault/Peugot AL-4, DPOEko hari PrasetyoNoch keine Bewertungen

- Process & Timing Calculation: Rapid ApproachDokument9 SeitenProcess & Timing Calculation: Rapid ApproachPamela GonzalesNoch keine Bewertungen

- UntitledDokument15 SeitenUntitledPrayogo Hadi SNoch keine Bewertungen

- CABEZALES HQ y HQ-UDokument2 SeitenCABEZALES HQ y HQ-UcristhiantolentinoalvarezNoch keine Bewertungen

- Catalogo Refacciones ABDickDokument201 SeitenCatalogo Refacciones ABDickAlejandra Muñoz HernandezNoch keine Bewertungen

- 98Dokument2 Seiten98StuartBohmNoch keine Bewertungen

- Dovetail Cutters: SETS - 3/8 - 1-7/8" 5 PCDokument21 SeitenDovetail Cutters: SETS - 3/8 - 1-7/8" 5 PCjl_arvizoNoch keine Bewertungen

- Manual TransmissionDokument46 SeitenManual Transmissionjrrodrigueza2Noch keine Bewertungen

- Certified RACSplitDokument16 SeitenCertified RACSplitSteven ReyesNoch keine Bewertungen

- Applications: Linear PlaningDokument4 SeitenApplications: Linear PlaningSingh KitarpNoch keine Bewertungen

- rg58b1 Manual MissionDokument8 Seitenrg58b1 Manual MissionHai Long ChenNoch keine Bewertungen

- Return SectionDokument1 SeiteReturn SectionDaniel Pouso DiosNoch keine Bewertungen

- MERCURY Tehnicheskoe Ustroystvo ReduktoraDokument139 SeitenMERCURY Tehnicheskoe Ustroystvo Reduktorafabbromauricioyahoo.com.arNoch keine Bewertungen

- Steering Column Chevrolet S10Dokument10 SeitenSteering Column Chevrolet S10Maxi SardiNoch keine Bewertungen

- RMV 3400rpm BreakdownDokument1 SeiteRMV 3400rpm BreakdownVictor FederNoch keine Bewertungen

- Grizzly G4185 Horizontal Boring Machine Instruction Manual ENDokument32 SeitenGrizzly G4185 Horizontal Boring Machine Instruction Manual ENRichard RoperNoch keine Bewertungen