Beruflich Dokumente

Kultur Dokumente

DP2Rementoa FMEA

Hochgeladen von

Vitor PortoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DP2Rementoa FMEA

Hochgeladen von

Vitor PortoCopyright:

Verfügbare Formate

Dynamic Positioning and Control Systems

12131 Community Rd.

Poway, CA 92064

858-679-5500 General Fax: 858-679-5501

Document Number

24005418PS-310

Document Title

Failure Modes and Effects Analysis (FMEA)

NMS6000 DP (DP Class 2) System

Remontowa 1674-09

CONTROL STATUS

Prepared by:

Robert Theisen

Approved by:

Robert Theisen

Unless over stamped MASTER or CONTROLLED in red,

this document has been provided for information only and

will not be updated.

Systems Engineer

Revision:

Date:

19-Jun-08

This document is, or contains, confidential and proprietary information of L-3 Communications. Its receipt or

possession does not convey any rights to reproduce or disclose it, or its contents, or to manufacture, use, or

sell anything it may describe or reference. Reproduction, disclosure, or use without specific written

authorization of L-3 Communications is strictly prohibited. This technical data is controlled under the Export

Administration Regulations ECCN [8E992], and may not be exported to a Foreign Person, either in the U.S.

or abroad, without the proper authorization of the U.S. Department of Commerce.

REVISION STATUS

Rev.

Date

19-Jun-08

24005418PS-310 Rev A

Description

Initial Release.

Commercial In Confidence

Page 1 of 14

Dynamic Positioning and Control Systems

Table of Contents

1. Single Point Failure Mode Analysis......................................................................................................................... 3

1.1. Purpose..................................................................................................................................................................... 3

1.2. Definition ................................................................................................................................................................... 3

1.3. Single Point Failure Assessment .......................................................................................................................... 3

1.3.1. Vessel Electrical Power Plant ................................................................................................................. 3

1.3.2. Vessel Propulsion ..................................................................................................................................... 4

1.3.3. System Architecture.................................................................................................................................. 5

1.3.4. Redundant DP Control Consoles ........................................................................................................... 5

1.3.5. Independent Backup Joystick (JS) System........................................................................................... 5

1.3.6. Control Power ............................................................................................................................................ 6

1.3.7. Redundant Programmable Logic Controllers ....................................................................................... 6

1.3.8. DP Control Network .................................................................................................................................. 7

1.3.9. DP Control Console Mode Select ........................................................................................................... 7

1.3.10. DP Control Console Automatic Backup ................................................................................................. 7

1.3.11. Signal Processor Unit ............................................................................................................................... 7

1.3.12. External Serial Sensors............................................................................................................................ 8

1.3.13. DP/Bridge/Independent JS Control Selector Switch............................................................................ 9

1.4. Conclusions .............................................................................................................................................................. 9

Appendix A

System Block Diagrams

Appendix B

Vessel FMEA

24005418PS-310 Rev A

Commercial In Confidence

Page 2 of 14

Dynamic Positioning and Control Systems

1.

Single Point Failure Mode Analysis

1.1.

Purpose

The purpose of this document is to provide a single point failure analysis for the L-3 Communications DPCS

NMS6000 Dynamic Positioning (DP) System.

The DP has been designed to meet the ABS DP Class 2 requirements.

The focus of this document is an analysis of the DP System hardware. DP System Software controlling the

communications highways is also assessed as applicable.

This review also addresses areas of possible system degradation, as contrasted with system failure, and offers

suggestions on how these problems can be alleviated.

1.2.

Definition

The definition of a single point failure is any piece of hardware (or section of software) whose loss would cause a

complete failure of the automatic positioning of the vessel. Component failures that result in system degradation,

which are not considered a system failure are also addressed to a certain extent.

It should be noted that the foregoing material assumes the Customer is familiar with the system architecture and

terminology.

1.3.

Single Point Failure Assessment

A single point failure assessment was made for the NMS6000 DP system.

summarized below.

The results are attached and

1.3.1. Vessel Electrical Power Plant

The vessel power plant is shown in Figure 1-1 below. The Remontowa 1674-09 NMS6000 software is designed for

operation in split bus modes with all Generators online.

24005418PS-310 Rev A

Commercial In Confidence

Page 3 of 14

Dynamic Positioning and Control Systems

SHAFT

GENERATOR 1

DIESEL

GENERATOR 1

DIESEL

GENERATOR 2

SHAFT

GENERATOR 2

SG1

G1

G2

SG2

MSB

-G1

-SG1

MAIN SWITCHBOARD

PORT

BUSS

-G2

-SG2

STARBOARD

BUSS

BUSS TIE BREAKER

11Q

22Q

T1

33Q

STERN

THRUSTER

SUPPLY 2

BOW

THRUSTER 1

32Q

T3

T2

STERN

THRUSTER

BOW

THRUSTER 2

Figure 1-1 Remontowa 1674-09 Propulsion System

1.3.2. Vessel Propulsion

The vessel propulsion system is shown in Figure 1-2 below.

PORT MAIN

PROPELLER (T4)

PORT

RUDDER

STERN TUNNEL

THRUSTER (T3)

STBD

RUDDER

AFT BOW

TUNNEL

THRUSTER (T2)

FORWARD BOW

TUNNEL

THRUSTER (T1)

STBD MAIN

PROPELLER (T5)

Figure 1-2 Remontowa 1674-09 Propulsion System

24005418PS-310 Rev A

Commercial In Confidence

Page 4 of 14

Dynamic Positioning and Control Systems

1.3.3. System Architecture

See the NMS6000 DP System Block Diagrams in Appendix A.

1.3.4. Redundant DP Control Consoles

The L-3 Communications DPCS NMS6000 DP System consists of dual redundant NMS6000 units. The NMS6000

units consist of two (2) primary consoles, DP1 and DP2. The operator can select which of the two consoles is the

On-Line Master Controller; the other console automatically becomes the backup, which takes over upon loss of the

Master.

A joystick for both surge and sway and a potentiometer for moment control are provided on the DP1 and DP2

control consoles. These controls only work with the Master DP control console when either the Manual Heading

mode or the Manual Position mode is selected.

1.3.5. Independent Joystick (JS) System

An NMS6000 Independent Joystick (JS) System is provided. The Independent JS unit consists of a separate

Control Console, shared Signal Processors and Control Network and is powered by a separate, dedicated Power

Source. The operator can select control from the Independent JS control by way of the 3-way Selector Switch

located at the bridge console.

A joystick for both surge and sway and a potentiometer for moment control are provided on the Independent JS

control console. These controls only work with the Selector Switch in the Independent JS position.

Although it is referenced within this document, the Independent JS is not included within the scope of the overall

FMEA, since it functions as a stand alone system.

24005418PS-310 Rev A

Commercial In Confidence

Page 5 of 14

Dynamic Positioning and Control Systems

1.3.6. Control Power

Three (3) UPSs are provided to power the DP System. UPS 1 and 2 are 24VDC UPSs. UPS 3 is a small AC UPS

which powers the Cyscan position reference system sensor.

Each NMS Control Console is provided with its own separate UPS Power. The loss of a UPS will result in the loss

of DC power to the specific items listed in the table below. Each UPS is capable of a minimum of 30 minutes of

battery back-up time at the full system load.

For redundancy, each SPU is also fed with a secondary, backup DC supply from the Ships Emergency

Switchboard, the same source that supplies the Independent Joystick system.

The UPS power is supplied to the DP System Equipment as follows:

Equipment

DP 1 (Computer, Display and

Console)

UPS1

UPS2

UPS3

(24VDC)

(24VDC)

(AC)

DC Supply

from Ships

Emergency

Switchboard

DP 2 (Computer, Display and

Console)

IND JS (Computer, Display and

Console)

SPU 1 (PLC 1)

X

X

SPU 2 (PLC 2)

X

X

DGPS 1

DGPS 2

Cyscan System

Wind Sensor 1

Wind Sensor 2

VRU (via SPU 1, +24V)

VRU (via SPU 2, +24V)

Gyro 1

Gyro 2

Alarm Printer 1 (via 24/230 inv)

Alarm Printer 2 (via 24/230 inv)

X

X

1.3.7. Programmable Logic Controllers

Two (2) Programmable Logic Controllers (Flexlogix PLC) are used in the Control Network for processing input and

output signals. They are housed in separate Signal Processing Units (SPU1 and SPU2). Furthermore, each SPU

is fed from separate UPS units.

Both PLCs run the logic routines and internal programs, each PLC has control of its data outputs. If the PLC loses

power, experiences a major fault during program execution, or has a processor failure, then it becomes inactive,

this will cause the loss of SPU where the PLC is housed, and the control to the particular thrusters (e.g. Thruster 1

and 4 or 2 and 5.)

24005418PS-310 Rev A

Commercial In Confidence

Page 6 of 14

Dynamic Positioning and Control Systems

Each SPU/PLC pair is powered from a separate UPS, with DC power backup from the emergency switchboard.

1.3.8. DP Control Network

The NMS6000 Controllers are connected to the Signal Processor Units via a peer-to-peer redundant control and

data transmission networkchannels A and B. Upon loss of channel A, channel B carries all data, and vice-versa.

1.3.9. DP Control Console Mode Select

The NMS6000 Redundancy exchange is implemented using a Dual Redundant Ethernet network on which each

node multicasts a Voting Packet on a preconfigured multicast channel. Each node reads and stores the voting

packet from the other nodes and uses this information to manage the manual and automatic Master/Backup

exchange. If node 1 is Master, then node 2 is the automatic hot backup and vice versa.

Manual mastership transfer is done by pressing the NMS Online button on the Backup Console UI.

1.3.10.

DP Control Console Automatic Backup

If a Voting Packet is timed out, the system will zero the data for that node. If the Voting packet from the Master

console is timed out, the Hot Backup will automatically take control and become the Master. The new status is

reflected in the Voting packet so when the old Master comes back up it will now become a hot backup.

1.3.11.

Signal Processor Unit

Two (2) Signal Processor Units (SPU) are provided with the NMS6000 DP System. For redundancy, the SPUs are

powered from two independent sources (L-3 24VDC UPSs and the Ship emergency DC distribution switchboard).

The SPUs perform the input/output consolidation and distribution between the field sensor control and monitoring

and the control processors located in the DP Control Consoles.

The I/O is divided between the two (2) SPUs and interfaces to the redundant ControlNet network and PLCs via the

Redundant Media Adapters (ACNRs).

1.3.11.1.

Signal Processing I/O Matrix

The I/O is divided between the SPUs to minimize the impact of the loss of an SPU or of an ACNR within an SPU.

The Thruster, Main Prop and Rudder I/O is divided between the SPUs as follows:

Thrusters/Main Props & Rudders

SPU1

Thruster 1 (Fwd Bow Tunnel

thruster)

Thruster 2 (Aft Bow Azimuth

thruster)

Thruster 3 (Stern Tunnel thruster)

Thruster 4 (Port Main Prop)

Thruster 5 (Stbd Main Prop)

Port Rudder

SPU2

X

X

Stbd Rudder

As a result of this division, the worst case effect due to the single point failure loss of an SPU or SPU-ACNR is:

SPU1-ACNR:

24005418PS-310 Rev A

Loss of interface and control of Bow Tunnel Thruster 1, Port Main Prop and Port

Rudder

Commercial In Confidence

Page 7 of 14

Dynamic Positioning and Control Systems

SPU2-ACNR:

Loss of interface and control of Bow Tunnel Thruster 2, Stbd Main Prop and Stbd

Rudder

Note: Stern Tunnel Thruster can be controlled from either SPU. The circuit is designed so that SPU1 is the primary

controller but if it should fail then control transfers to SPU2.

Other DP System analog and discrete I/O signal groups are distributed between the SPUs to provide the required

redundancy for the overall DP system.

Analog / Discrete Signals

Device / Equipment

1.3.12.

Qty

SPU1

SPU2

DP Online Signal

Independent JS Online Signal

UPS (alarms)

Vertical Reference Unit

(signal/power)

External Serial Sensors

External position, environmental and heading sensors are redundant and include:

Two (2) DGPSs. Each DGPS provides serial position data to both DP consoles and the Independent

JS console.

One (1) Cyscan System. The Cyscan System provides serial position data to both DP consoles and

the Independent JS console.

Two (2) Gyrocompasses. Each Gyrocompass provides serial heading data to both DP consoles and

the Independent JS console.

Two (2) Wind Sensors. Each Wind Sensor provides serial speed and direction data to both DP

consoles and the Independent JS console.

The serial sensors are interfaced to the NMS6000 DP System via Allen Bradley Point IO modules and the

ControlNet network. For redundancy, the serial sensors are divided between the Point IO ACNRs, with each

ACNR powered from a separate source.

The serial sensors are divided between the three (3) ACNRs as follows:

Serial Sensors

DGPS 1

Flexlogix PLC #1

Flexlogix PLC #2

Flexlogix PLC #1

Point IO ACNR 1

Point IO ACNR 2

Point IO ACNR 3

DGPS 2

Cyscan

X

X

Gyrocompass 1

Gyrocompass 2

Wind 1

X

X

Wind 2

24005418PS-310 Rev A

Commercial In Confidence

Page 8 of 14

Dynamic Positioning and Control Systems

As a result of this division, the worst case effect due to the single point failure loss of a Point I/O ACNR module is:

Point I/O ACNR1:

Loss of DGPS1, Cyscan, Wind 1

Point I/O ACNR2:

Loss of DGPS2, Gyrocompass 2, Wind 2

Point I/O ACNR3:

Loss of Gyrocompass 1

1.3.13.

DP/Bridge/Independent JS Control Selector Switch

An industrial-grade, three position DP/Bridge/Independent JS control switch is provided with the NMS6000 and

performs the following functions:

1. The switch position determines which console is in control (DP1/DP2, Bridge or the Independent JS)

2. When the switch position is DP or Independent JS, the individual thrusters, main props and rudders are

selected for DP or Independent JS control.

In the highly unlikely event of a complete failure of the DP/Bridge/JS control switch, the ability to transfer into or out

of the various control modes (Bridge, DP, Independent JS) and the ability to select the thrusters/main props and

rudders online will be affected.

Each of the contacts on the switch is electrically isolated, so an electrical failure of one contact will not affect the

others. A failure of one thruster/main prop or rudder select contact (or signal) will only affect the ability to select

that one unit for DP or Independent JS control.

There are redundant DP and Independent JS Online signals from the switch to SPU 1 and SPU 2, so the loss of

one of these contacts (or signals) will not impact the DP or Independent JS Systems.

1.4.

Conclusions

There are no known single point failures within the NMS6000 DP System that can cause loss of DP control of the

vessel.

24005418PS-310 Rev A

Commercial In Confidence

Page 9 of 14

Dynamic Positioning and Control Systems

APPENDIX A

SYSTEM BLOCK DIAGRAMS

24005418PS-310 Rev A

Commercial In Confidence

Page 10 of 14

Dynamic Positioning and Control Systems

DP #1 System

DP #2 System

Touch

Display

Independent System

Touch

Display

Touch

Display

Control

Console

Computer/CPU

Dual Redundant

Ethernet

CH: A

CH: B

Control

Console

Computer/CPU

Computer/CPU

DP 2 Control Stn.

DP 1 Control Stn.

Control

Console

Independent Control Stn.

CH: A

CH: B

Dual Redundant Co-Ax

Control Net

SPU 1

SPU 2

PLC 1

PLC 2

I/O

I/O

JS/Man/DP

Switch

To

Thruster

Interfaces

To

Thruster

Interfaces

Figure A-1, NMS6000 DP Control and Data Networks

24005418PS-310 Rev A

Commercial In Confidence

Page 11 of 14

Dynamic Positioning and Control Systems

From Customer Power Source

Display 1

GYRO 1

Control Console 1

DGPS 1

Computer/CP 1

WIND 1

= 24 VDC

PORT

Ship's Power

220 VAC

50-60Hz

UPS 1

Power

Dist.

Panel 1

DC/AC

Inverter

Alarm

Printer 1

SPU 1

PLC 1

I/O

VRU 1

From

Power Dist.

Panel 3

24 VDC

DP #1 SYSTEM

DP #2 SYSTEM

Display 2

Control Console 2

DGPS 2

Computer/CP 2

WIND 2

STBD

Ship's Power

220 VAC

50-60Hz

UPS 2

Power

Dist.

Panel 2

DC/AC

Inverter

Alarm

Printer 2

GYRO 2

SPU 2

PLC 2

I/O

VRU 2

From

Power Dist.

Panel 3

24 VDC

Figure A-2, NMS6000 Power Distribution (cont. next page)

24005418PS-310 Rev A

Commercial In Confidence

Page 12 of 14

Dynamic Positioning and Control Systems

Figure A-2, NMS6000 Power Distribution (cont.)

24005418PS-310 Rev A

Commercial In Confidence

Page 13 of 14

Dynamic Positioning and Control Systems

APPENDIX B

VESSEL DP FMEA SPREADSHEET

24005418PS-310 Rev A

Commercial In Confidence

Page 14 of 14

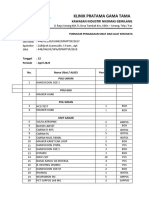

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Function

Mode of Operation

Failure Mode

Failure Cause

Failure Detection

Failure Effect

Corrective

Action

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Preventative

Actions

DP1 Subsystem

24VDC UPS Power Source

Severe ground

Alarm loss of

24 VDC UPS

fault, switchboard NMS UPS Line

battery backup

failure,

Failure on DP

will sustain power

mechanical

Stations

to DP1 subsystem

generator failure.

for 30 minutes.

220VAC from

Supplied power

main switchboard feed to NMS/DP

to NMS 24VDC

UPS 1.

220 VAC Supply to 24 VDC UPS's

Loss of Ship AC

Supply to UPS.

24VDC UPS 1

Primary 24 VDC

Charger/Rectifier Supply for the

complete DP1

Subsystem.

Includes: Touch

Display 1,

Computer/CPU1,

Control Console,

DGPS 1, VRU 1

24VDC Supply and Battery Charge

Loss of 24VDC

Battery Charger

Unit

Battery

UPS Rectifier

Charger/Rectifier Alarm on DP

Fault.

Station.

24VDC UPS 1

Batteries

24VDC Backup Supply

Loss of UPS

Battery Backup

Backup 24 VDC

Supply for the

complete DP1

Subsystem.

Includes: Touch

Display 1,

Computer/CPU1,

Control Console,

DGPS 1, VRU 1

24VDC UPS1

24VDC Power

Power Distribution Distribution for

Panel

UPS1

24005418PS-310 Rev A

24VDC Distribution and Overcurrent Loss of power to

Protection

affected

subsystem

component(s)

Repair the

affected

switchboard and

generator

components.

DP operations for No

affected DP1

subsystem will

sustain, until such

time that the UPS

batteries drain.

DP2 subsystem

will remain online

uninterrupted.

No

Repair/Replace

the Battery

Charger per

manufacturer's

specifications

DP operations for No

affected DP1

subsystem will

sustain, until such

time that the UPS

batteries drain.

DP2 subsystem

will remain online

uninterrupted.

No

Periodic

maintenance and

testing to ensure

UPS operation.

Degradation over UPS Low Voltage Affected system

time of UPS

Alarm

components will

Batteries.

deactivate below

minimum

operating voltage.

Replace UPS

Batteries per

manufacturer's

specifications

DP operations for No

affected DP1

subsystem will

sustain, until such

time that the UPS

batteries drain.

DP2 subsystem

will remain online

uninterrupted.

No

Periodic

maintenance and

testing to ensure

UPS operation.

Severe ground

fault or CB trip on

main distribution

panel

Repair/replace

shorted or faulty

equipment.

Return CB to "On"

Position.

No effect on

vessel

positioning. If

complete power

failure, system

architecture will

be substantially

reduced.

No

Loss of operating

power to affected

component(s).

Alarm is

generated on

remaining DP2

Station.

24 VDC UPS

battery backup

will sustain power

to DP1 subsystem

for 30 minutes.

In the case of

complete loss of

the DP1 operating

station, system

automatically

transfers control

to remaining DP2

control console.

Commercial In Confidence

No

Page B-1 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Function

Mode of Operation

Failure Mode

Failure Cause

Failure Detection

Computer/CPU and Console

Loss of power,

Alarm on

Loss of primary

Internal

remaining DP2

DP control from

Component

Station, "Loss of DP1. NMS DP

Failure, or

NMS1 or 2"

Alarm, monitoring

overheating of

and control

CPU.

function remains

from DP2.

DP1 CPU

DP alarm, control Automatic DP Control and

and monitoring

Coordinated Thruster Control

master central unit

Computer

Stopped

DP1

Computer Hard

Disk Drive

DP alarm, control Automatic DP Control and

and monitoring

Coordinated Thruster Control

master central unit

Failure to

Internal

read/write to hard Component

drive

Failure

Repair the

computer and put

it back online.

After start-up,

press "INITBACKUP" to

reinitialize backup

system from

Master

Alarm on

Loss of primary

Repair the

remaining DP2

DP control from

computer and put

Station, "Loss of DP1. NMS DP

it back online.

NMS1 or 2"

Alarm, monitoring After start-up,

and control

press "INITfunction remains BACKUP" to

from DP2.

reinitialize backup

system from

Master

Operator notified Loss of serial

Replace ACNR, if

of each individual sensors from that required.

serial

ACNR to DP 1,

communications DP 2, Ind JS

loss.

consoles. Other

sensors are still

available from

other console

ACNRs.

Preventative

Actions

Periodically clean

computer filters.

Automatic and

No

bumpless transfer

to remaining DP2

Station.

No

Note MTBF of

Computer HDD is

rated as 300,000

Hours.

No.

No

No

Loss of audible

alarm. Visual

flashing

unacknowledged

alarms in NMS

Replace computer No

motherboard, or

complete

computer

assembly.

No

No

Operator unable Loss of Joystick

to manually issue Control Function

control from DP1

station joystick.

Manually Transfer No

to DP2 station, or

select

Independent JS,

or select Manual

Thruster Control

levers by using

center 3-way

selector switch.

No

No

Loss of serial

communications

from that ACNR

to all consoles

Internal

Component

Failure

DP1

Workstation

Sound Card

Adapter

Alarm Annunciation

Loss of Audible

Tone.

Integrated Sound No audible tone

Card Failure

generated by

unacknowledged

alarms

Manual Joystick Control from DP1

Loss of Joystick

Control

Internal Joystick

Component

Failure or USB

Adapter Failure.

24005418PS-310 Rev A

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

No

Automatic DP Control and

Coordinated Thruster Control

DP1

3-axis Joystick

Joystick and USB Control from DP1

Adapter

Loss of DP

Control and

Monitoring

Automatic and

No

bumpless transfer

to remaining DP2

Station.

DP1

Serial Interface to

Point I/O Interface a group of the DP

Adapter (ACNR) reference and

environmental

Sensors

Audible Alarm

Tones at DP1

Failure Effect

Corrective

Action

Commercial In Confidence

Page B-2 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

DP1

Trackball

Function

Secondary User

Interface pointing

device.

Mode of Operation

Failure Cause

Blank screen, or

touch screen not

responding

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Failure Detection

Failure Effect

Mouse cursor not

tracking and/or

command objects

not selected.

Loss of video

display at the DP1

Console and/or

user interface

navigation.

Utilize

No

touchscreen if

trackball

operations fail.

Check serial

cabling to unit.

Clean trackball

roller mechanisms

as required.

No

No

Loss of power,

Mouse cursor not

Service Stopped, tracking and/or

Faulted.

command objects

not selected.

Loss of video

display at the DP1

Console and/or

user interface

navigation.

Utilize trackball if No

touchscreen

selections do not

operate. Check

power, verify

cable, check

video

transmitter/receiv

er, replace unit.

Recalibrate

Touchscreen Unit

if required.

Transfer control

to remaining DP2

control station.

No

No

User Interface, navigation and object Inability to control Loss of

control/selection.

pointing device.

Connection

and/or Faulty

Trackball.

DP1 Touchscreen Primary User

Receive video signal from DP

Interface for DP

Computer, transmit operator

alarm, control and instructions through touch screen.

monitoring system.

24005418PS-310 Rev A

Failure Mode

Corrective

Action

Commercial In Confidence

Preventative

Actions

Periodically clean

trackball

components.

Page B-3 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Function

Mode of Operation

Failure Mode

Failure Cause

Failure Detection

Failure Effect

Corrective

Action

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Preventative

Actions

DP2 Subsystem

220VAC from

Supplied power

main switchboard feed to NMS/DP

to NMS 24VDC

UPS 2.

24VDC UPS Power Source

Severe ground

Alarm loss of

24 VDC UPS

fault, switchboard NMS UPS Line

battery backup

failure,

Failure on DP

will sustain power

mechanical

Stations

to DP2 subsystem

generator failure.

for 30 minutes.

220 VAC Supply to 24 VDC UPS's

Loss of Ship AC

Supply to UPS.

24VDC UPS 2

Primary 24 VDC

24VDC Supply and Battery Charge

Charger/Rectifier Supply for the

complete DP2

Subsystem.

Includes: Touch

Display 2,

Computer/CPU2,

Control Console,

DGPS 2, GYRO 2,

WIND2, VRU 2

Loss of 24VDC

Battery Charger

Unit

Battery

UPS Rectifier

Charger/Rectifier Alarm on DP

Fault.

Station.

24VDC UPS 2

Batteries

Loss of UPS

Battery Backup

Backup 24 VDC

24VDC Backup Supply

Supply for the

complete DP2

Subsystem.

Includes: Touch

Display 2,

Computer/CPU2,

Control Console,

DGPS 2, GYRO 2,

WIND2, VRU 2

24VDC UPS 2

24VDC Power

Power Distribution Distribution for

Panel

UPS2

24VDC Distribution and Overcurrent Loss of power to

Protection

affected

subsystem

component(s)

Repair the

affected

switchboard and

generator

components.

DP operations for No

affected DP2

subsystem will

sustain, until such

time that the UPS

batteries drain.

DP1 subsystem

will remain online

uninterrupted.

No

Repair/Replace

the Battery

Charger per

manufacturer's

specifications

DP operations for No

affected DP2

subsystem will

sustain, until such

time that the UPS

batteries drain.

DP1 subsystem

will remain online

uninterrupted.

No

Periodic

maintenance and

testing to ensure

UPS operation.

Degradation over UPS Low Voltage Affected system

time of UPS

Alarm

components will

Batteries.

deactivate below

minimum

operating voltage.

Replace UPS

Batteries per

manufacturer's

specifications

DP operations for No

affected DP2

subsystem will

sustain, until such

time that the UPS

batteries drain.

DP1 subsystem

will remain online

uninterrupted.

No

Periodic

maintenance and

testing to ensure

UPS operation.

Severe ground

fault or CB trip on

main distribution

panel

Repair/replace

shorted or faulty

equipment.

Return CB to "On"

Position.

No effect on

vessel

positioning. If

complete power

failure, system

architecture will

be substantially

reduced.

No

Loss of operating

power to affected

component(s).

Alarm is

generated on

remaining DP1

Station.

24 VDC UPS

battery backup

will sustain power

to DP2 subsystem

for 30 minutes.

In the case of

complete loss of

the DP2 operating

station, system

automatically

transfers control

to remaining DP1

control console.

No

Computer/CPU and Console

24005418PS-310 Rev A

Commercial In Confidence

Page B-4 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Function

Mode of Operation

Failure Mode

Failure Cause

DP2 CPU

DP alarm, control Automatic DP Control and

and monitoring

Coordinated Thruster Control

master central unit

Computer

Stopped

DP2

Computer Hard

Disk Drive

DP alarm, control Automatic DP Control and

and monitoring

Coordinated Thruster Control

master central unit

Failure to

Internal

read/write to hard Component

drive

Failure

Loss of power,

Internal

Component

Failure, or

overheating of

CPU.

Failure Detection

Alarm on

remaining DP1

Station, "Loss of

NMS1 or 2"

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Preventative

Actions

No

Periodically clean

computer filters.

Automatic and

No

bumpless transfer

to remaining DP2

Station.

No

Note MTBF of

Computer HDD is

rated as 300,000

Hours.

No.

No

No

Loss of audible

alarm. Visual

flashing

unacknowledged

alarms in NMS

Replace computer No

motherboard, or

complete

computer

assembly.

No

No

Operator unable Loss of Joystick

to manually issue Control Function

control from DP2

station joystick.

Manually Transfer No

to DP1 station, or

select

Independent JS,

or select Manual

Thruster Control

levers by using

center 3-way

selector switch.

No

No

Loss of serial

communications

from that ACNR

to all consoles

Internal

Component

Failure

DP2

Workstation

Sound Card

Adapter

Alarm Annunciation

Loss of Audible

Tone.

Integrated Sound No audible tone

Card Failure

generated by

unacknowledged

alarms

Manual Joystick Control from DP2

Loss of Joystick

Control

Internal Joystick

Component

Failure or USB

Adapter Failure.

24005418PS-310 Rev A

Loss of DP

Control and

Monitoring

Automatic and

No

bumpless transfer

to remaining DP2

Station.

Automatic DP Control and

Coordinated Thruster Control

DP2

3-axis Joystick

Joystick and USB Control from DP2

Adapter

Loss of primary

DP control from

DP2. NMS DP

Alarm, monitoring

and control

function remains

from DP1.

Repair the

computer and put

it back online.

After start-up,

press "INITBACKUP" to

reinitialize backup

system from

Master

Alarm on

Loss of primary

Repair the

remaining DP1

DP control from

computer and put

Station, "Loss of DP2. NMS DP

it back online.

NMS1 or 2"

Alarm, monitoring After start-up,

and control

press "INITfunction remains BACKUP" to

from DP1.

reinitialize backup

system from

Master

Operator notified Loss of serial

Replace ACNR, if

of each individual sensors from that required.

serial

ACNR to DP 1,

communications DP 2, Ind JS

loss.

consoles. Other

sensors are still

available from

other console

ACNRs.

DP2

Serial Interface to

Point I/O Interface a group of the DP

Adapter (ACNR) reference and

environmental

Sensors

Audible Alarm

Tones at DP2

Failure Effect

Corrective

Action

Commercial In Confidence

Page B-5 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

DP2

Trackball

Function

Secondary User

Interface pointing

device.

Mode of Operation

Failure Cause

Blank screen, or

touch screen not

responding

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Failure Detection

Failure Effect

Mouse cursor not

tracking and/or

command objects

not selected.

Loss of video

display at the DP2

Console and/or

user interface

navigation.

Utilize

No

touchscreen if

trackball

operations fail.

Check serial

cabling to unit.

Clean trackball

roller mechanisms

as required.

No

No

Loss of power,

Mouse cursor not

Service Stopped, tracking and/or

Faulted.

command objects

not selected.

Loss of video

display at the DP2

Console and/or

user interface

navigation.

Utilize trackball if No

touchscreen

selections do not

operate. Check

power, verify

cable, check

video

transmitter/receiv

er, replace unit.

Recalibrate

Touchscreen Unit

if required.

Transfer control

to remaining DP1

control station.

No

No

User Interface, navigation and object Inability to control Loss of

control/selection.

pointing device.

Connection

and/or Faulty

Trackball.

DP2 Touchscreen Primary User

Receive video signal from DP

Interface for DP

Computer, transmit operator

alarm, control and instructions through touch screen.

monitoring system.

24005418PS-310 Rev A

Failure Mode

Corrective

Action

Commercial In Confidence

Preventative

Actions

Periodically clean

trackball

components.

Page B-6 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Function

Mode of Operation

Failure Mode

Failure Cause

Failure Detection

Failure Effect

SPU 1 PLC Communications Adapter

Loss of power,

Alarm Loss of

Internal

PLC #1

Component

Failure

Corrective

Action

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Preventative

Actions

SPU #1

Programmable

Flexlogix 1794L34 Controller

NMS Controller

SPU #1

Daughtercard

1788-CNCR

ControlNet

ControlNet connectivity

connectivity

between Point I/O

1734-ACNR, 1784PCIC, and

Flexlogix 1794-L34

Controller

Loss of sensors

data to NMS1

system

SPU #1

Module 10

1794-IB16

System IO

Channel

Failure of IO Input Loss of power,

NMS Alarms

Loss of Digital

Check power,

See Note * below No

No

Module

Internal

Module Fault

Input Signals

verify cable, verify

Component

Indication

Listed Below.

module. Replace

Failure, loss of

affected modules.

communications

with the PLC.

Loss of Thruster Ready Signal (loss of thruster). Operator Alerted.

Loss of Thruster Breaker indication. Operator alerted. No impact on DP system. The thruster will still be used by the DP system as long as the thruster ready signal is

still received.

Primary NMS Controller.

24VDC Digital Input

0 BOW TUNNEL THR (T1) READY

1 BOW TUNNEL THR (T1)

BREAKER CLSD

2

3 STERN TUNNEL THR (T3) READY

4 STERN TUNNEL THR (T3)

PRIMARY BREAKER CLSD

5 STERN TUNNEL THR (T3)

SECONDARY BREAKER CLSD

6 PORT MAIN (T4) READY

7 PORT MAIN (T4) PITCH REDUCED

8 PORT RUDDER READY

9 PORT SHAFT GEN (SG1)

BREAKER CLOSED

10 PORT GEN (G1)

BREAKER CLOSED

11 MAIN BUSS TIE BREAKER

CLOSED

12

13

24005418PS-310 Rev A

Complete PLC

failure

Loss of power,

Internal

Component

Failure, loss of

communications

with Flex Logix

PLC or Point I/O.

All alarms related

to this distributed

IO Station will

appear.

85 Check module

See Note * below No

configuration.

Replace Unit.

The system will

automatically

detect the module

is online and

restore data

communications.

Worst case effect,

loss of control

and monitoring for

NMS1

Subsystems.

Includes loss of

SPU1 IO. Loss of

thruster command

T1 and T4.

Check power,

See Note * below No

verify cable, verify

PLC (Flexlogix

1794-L34) and/or

Point I/O (1734ACNR.) Replace

effected modules.

No

No

Loss of Thruster Ready Signal (loss of thruster). Operator Alerted.

Loss of Thruster Breaker indication. Operator alerted. No impact on DP system. The thruster will still be used by the DP system as long as the thruster ready signal is

still received.

Loss of Thruster Breaker indication. Operator alerted. No impact on DP system. The thruster will still be used by the DP system as long as the thruster ready signal is

still received.

Loss of Main Ready for DP Signal. Operator Alerted.

Loss of Pitch Reduced Signal. Operator Alerted by pitch command/feedback error.

Loss of Rudder Ready Signal (loss of rudder). Operator Alerted.

Loss of Shaft Gen Breaker indication. Operator alerted. No impact on DP system. The power available for the tunnel thrusters will be limited by the loss.

Loss of Gen Breaker indication. Operator alerted. No impact on DP system. The power available for the tunnel thrusters will be limited by the loss.

Loss of Main Buss Tie Breaker indication. Operator alerted. No impact on DP system.

Commercial In Confidence

Page B-7 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Function

Mode of Operation

Failure Mode

Failure Cause

Failure Detection

Failure Effect

Corrective

Action

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Preventative

Actions

14

15

SPU #1

Module 11

1794-IB10xOB6

System IO

Channel

0

1

2

3

4

5

6

7

8

9

10

24VDC Digital Input

Failure of IO Input Loss of power,

Module

Internal

Component

Failure, loss of

communications

with the PLC.

DP ONLINE 1

IND JS ONLINE 1

UPS1 AC LINE FAIL ALM

UPS1 COMMON ALM

UPS3 AC LINE FAIL ALM

UPS3 COMMON ALM

Loss of DP Online 1. No impact on DP system due to redundant signal in SPU 2. Operator alerted if there is a mismatch.

Loss of IND JS Online 1. No impact on Ind JS system due to redundant signal in SPU 2. Operator alerted if there is a mismatch.

Loss of UPS1 AC Line Fail Alm. No impact on DP System

Loss of UPS1 Common Alm. No impact on DP System

Loss of UPS3 AC Line Fail Alm. No impact on DP System

Loss of UPS3 Common Alm. No impact on DP System

STERN TUNNEL THR (T3)

CONTROL SELECT

Loss of ability to control T3 from SPU 1, control will default to SPU 2.

24VDC Analog Input Module

Failure of IO Input Loss of power,

Module

Internal

Component

Failure, loss of

communications

with the PLC.

SPU1 24VDC SUPPLY

+10 VDC VOLTAGE MONITOR

-10 VDC VOLTAGE MONITOR

VRU1 PITCH FEEDBACK

VRU1 ROLL FEEDBACK

Loss of voltage monitor indication and alarm. Operator alerted by voltage out of range.

Loss of voltage monitor indication and alarm. Operator alerted by voltage out of range.

Loss of voltage monitor indication and alarm. Operator alerted by voltage out of range.

Loss of pitch data. Operator alerted by VRU pitch mismatch. VRU1 pitch data excluded from average.

Loss of roll data. Operator alerted by VRU roll mismatch. VRU1 roll data excluded from average.

NMS Alarms

Module Fault

Indication

Loss of Digital

Input Signals

Listed Below.

Check power,

See Note * below No

verify cable, verify

module. Replace

affected modules.

No

11

12

13

14

15

SPU #1

Module 12

1794-IE8/B

System IO

Channel

0

1

2

3

4

5

6

7

24005418PS-310 Rev A

NMS Alarms

Module Fault

Indication

Loss of Analog

Input Signals

Listed Below.

Commercial In Confidence

Check power,

See Note * below No

verify cable, verify

module. Replace

affected modules.

No

Page B-8 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

SPU #1

Module 13

1794-OF4I

SPU #1

Module 14

1794-OF4I

SPU #1

Module 15

1794-IF4I

SPU #1

Module 16

1794-IF4I

Function

System IO

Channel

System IO

Channel

System IO

Channel

System IO

Channel

Mode of Operation

24VDC Analog Output Module

0 BOW TUNNEL THR (T1) PITCH

CMD

1 PORT MAIN ENGINE (T4) PITCH

CMD

2 PORT RUDDER DIRECTION CMD

3

24VDC Analog Input Module

0 STERN TUNNEL THR (T3) PITCH

CMD

1

2

3

24VDC Analog Input Module

0 BOW TUNNEL THR (T1) PITCH

FDBK

1 PORT MAIN ENGINE (T4) PITCH

FDBK

2 PORT RUDDER DIRECTION FDBK

3

24VDC Analog Input Module

0 STERN TUNNEL THR (T3) PITCH

FDBK

1 PORT SHAFT GEN (SG1) KW

FDBK

2 PORT GEN (G1) KW FDBK

3

24005418PS-310 Rev A

Failure Mode

Failure of IO

Output Module

Failure Cause

Loss of power,

Internal

Component

Failure, loss of

communications

with the PLC.

Failure Detection

NMS Alarms

Module Fault

Indication

Failure Effect

Loss of Analog

Output Signals

Listed Below.

Corrective

Action

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Check power,

See Note * below No

verify cable, verify

module. Replace

affected modules.

Preventative

Actions

No

Loss of pitch command. Operator alerted by command/feedback comparison (See Note ** at bottom)

Loss of pitch command. Operator alerted by command/feedback comparison (See Note ** at bottom)

Loss of direction command. Operator alerted by command/feedback comparison (See Note ** at bottom)

Failure of IO Input Loss of power,

Module

Internal

Component

Failure, loss of

communications

with the PLC.

NMS Alarms

Module Fault

Indication

Loss of Analog

Input Signals

Listed Below.

Check power,

See Note * below No

verify cable, verify

module. Replace

affected modules.

No

Loss of pitch command. Operator alerted by command/feedback comparison (See Note ** at bottom)

Failure of IO Input Loss of power,

Module

Internal

Component

Failure, loss of

communications

with the PLC.

NMS Alarms

Module Fault

Indication

Loss of Analog

Input Signals

Listed Below.

Check power,

See Note * below No

verify cable, verify

module. Replace

affected modules.

No

Loss of pitch feedback. Operator alerted by command/feedback comparison. No impact on thrust cmd.

Loss of pitch feedback. Operator alerted by command/feedback comparison. No impact on pitch cmd.

Loss of direction feedback. Operator alerted by command/feedback comparison. No impact on direction cmd.

Failure of IO Input Loss of power,

NMS Alarms

Loss of Analog

Check power,

See Note * below No

Module

Internal

Module Fault

Input Signals

verify cable, verify

Component

Indication

Listed Below.

module. Replace

Failure, loss of

affected modules.

communications

with the PLC.

Loss of pitch feedback. Operator alerted by command/feedback comparison. No impact on thrust cmd.

No

Loss of SG KW feedback.

Loss of G KW feedback.

Commercial In Confidence

Page B-9 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Function

Mode of Operation

Failure Mode

Failure Cause

Failure Detection

Failure Effect

Corrective

Action

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Preventative

Actions

* The most probable cause for loss of FlexLogix PLC, Flex I/O module or ACNR (ControlNet Reundant Media Adapter) is a hardware fault in the effected component. The loss of aFlexLogix PLC will result in a loss of communications

to all Flex IO modules associated with the PLC. There is one FlexLogix PLC in each SPU1 and SPU2. Thruster, Power Plant and Environmental interfaces are split between the two SPU's for redundancy purposes, so that loss of an

SPU (or PLC) will not cause a loss of position as long as the other SPU, PLC, Flex I/O modules and ACNR are fully available. A failure of an individual module or of a single channel on a module will generate appropriate alarms.

Some operator action may be required. Singe failures are evaluated under the assumption that all other equipment is fully available.

** Loss of the ability to command a thruster (from the DP system) or a failure at the thruster (resulting in a loss of control or out of control thruster) will require the operator to take the affected thruster offline. If the thruster is not

responding to commands from the DP system then the other remaining thrusters will be commanded to compensate for the affected thruster in order to maintain position. DP system thruster commands go to zero upon failure of an

ACNR or Module (associated with the thruster commands)

24005418PS-310 Rev A

Commercial In Confidence

Page B-10 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Function

Mode of Operation

Failure Mode

Failure Cause

NMS Controller

SPU #2

Daughtercard

1788-CNCR

ControlNet

ControlNet connectivity

connectivity

between Point I/O

1734-ACNR, 1784PCIC, and

Flexlogix 1794-L34

Controller

Loss of sensors

data to NMS1

system

SPU #2

Module 20

1794-IB16

System IO

Channel

Failure of IO Input Loss of power,

Module

Internal

Component

Failure, loss of

communications

with the PLC.

24VDC Digital Input

Complete PLC

failure

Failure Effect

SPU 2 PLC Communications Adapter

Loss of power,

Alarm Loss of

Internal

PLC #2

Component

Failure

SPU #2

Programmable

Flexlogix 1794L34 Controller

Primary NMS Controller.

Failure Detection

Loss of power,

Internal

Component

Failure, loss of

communications

with Flex Logix

PLC or Point I/O.

Corrective

Action

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

85 Check module

See Note * below No

configuration.

Replace Unit.

The system will

automatically

detect the module

is online and

restore data

communications.

Preventative

Actions

No

All alarms related

to this distributed

IO Station will

appear.

Worst case effect,

loss of control

and monitoring for

NMS2

Subsystems.

Includes loss of

SPU2 IO. Loss of

thruster command

T2 and T5.

Check power,

See Note * below No

verify cable, verify

PLC (Flexlogix

1794-L34) and/or

Point I/O (1734ACNR.) Replace

effected modules.

No

NMS Alarms

Module Fault

Indication

Loss of Digital

Input Signals

Listed Below.

Check power,

See Note * below No

verify cable, verify

module. Replace

affected modules.

No

0 BOW TUNNEL THR (T2) READY

Loss of Thruster Ready Signal (loss of thruster). Operator Alerted.

1 BOW TUNNEL THR (T2) BREAKER Loss of Thruster Breaker indication. Operator alerted. No impact on DP system. The thruster will still be used by the DP system as long as the thruster ready signal is

CLSD

still received.

2

3 STERN TUNNEL THR (T3) READY

4 STERN TUNNEL THR (T3)

PRIMARY BREAKER CLSD

5 STERN TUNNEL THR (T3)

SECONDARY BREAKER CLSD

6 STBD MAIN (T5) READY

7 STBD MAIN (T5) PITCH REDUCED

8 STBD RUDDER READY

9 STBD SHAFT GEN (SG2)

BREAKER CLOSED

10 STBD GEN (G2)

BREAKER CLOSED

24005418PS-310 Rev A

Loss of Thruster Ready Signal (loss of thruster). Operator Alerted.

Loss of Thruster Breaker indication. Operator alerted. No impact on DP system. The thruster will still be used by the DP system as long as the thruster ready signal is

still received.

Loss of Thruster Breaker indication. Operator alerted. No impact on DP system. The thruster will still be used by the DP system as long as the thruster ready signal is

still received.

Loss of Main Ready for DP Signal. Operator Alerted.

Loss of Pitch Reduced Signal. Operator Alerted by pitch command/feedback error.

Loss of Rudder Ready Signal (loss of rudder). Operator Alerted.

Loss of Shaft Gen Breaker indication. Operator alerted. No impact on DP system. The power available for the tunnel thrusters will be limited by the loss.

Loss of Gen Breaker indication. Operator alerted. No impact on DP system. The power available for the tunnel thrusters will be limited by the loss.

Commercial In Confidence

Page B-11 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Function

Mode of Operation

Failure Mode

Failure Cause

Failure Detection

Failure Effect

Corrective

Action

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Preventative

Actions

11

12

13

14

15

SPU #2

Module 21

1794-IB10xOB6

System IO

Channel

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

SPU #2

Module 22

1794-IE8/B

System IO

Channel

0

1

2

3

4

5

6

7

SPU #2

Module 23

1794-OF4I

24005418PS-310 Rev A

System IO

Channel

24VDC Digital Input

Failure of IO Input Loss of power,

Module

Internal

Component

Failure, loss of

communications

with the PLC.

DP ONLINE 2

IND JS ONLINE2

UPS2 AC LINE FAIL ALM

UPS2 COMMON ALM

Loss of DP Online 2. No impact on DP system due to redundant signal in SPU 2. Operator alerted if there is a mismatch.

Loss of IND JS Online 2. No impact on Ind JS system due to redundant signal in SPU 2. Operator alerted if there is a mismatch.

Loss of UPS2 AC Line Fail Alm. No impact on DP System

Loss of UPS2 Common Alm. No impact on DP System

24VDC Analog Input Module

Failure of IO Input Loss of power,

Module

Internal

Component

Failure, loss of

communications

with the PLC.

SPU2 24VDC SUPPLY

+10 VDC VOLTAGE MONITOR

-10 VDC VOLTAGE MONITOR

VRU2 PITCH FEEDBACK

VRU2 ROLL FEEDBACK

Loss of voltage monitor indication and alarm. Operator alerted by voltage out of range.

Loss of voltage monitor indication and alarm. Operator alerted by voltage out of range.

Loss of voltage monitor indication and alarm. Operator alerted by voltage out of range.

Loss of pitch data. Operator alerted by VRU pitch mismatch. VRU1 pitch data excluded from average.

Loss of roll data. Operator alerted by VRU roll mismatch. VRU1 roll data excluded from average.

24VDC Analog Output Module

Failure of IO

Output Module

Loss of power,

Internal

Component

Failure, loss of

communications

with the PLC.

NMS Alarms

Module Fault

Indication

NMS Alarms

Module Fault

Indication

NMS Alarms

Module Fault

Indication

Loss of Digital

Input Signals

Listed Below.

Loss of Analog

Input Signals

Listed Below.

Loss of Analog

Output Signals

Listed Below.

Commercial In Confidence

Check power,

See Note * below No

verify cable, verify

module. Replace

affected modules.

Check power,

See Note * below No

verify cable, verify

module. Replace

affected modules.

Check power,

See Note * below No

verify cable, verify

module. Replace

affected modules.

No

No

No

Page B-12 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

SPU #2

Module 24

1794-OF4I

SPU #2

Module 25

1794-IF4I

SPU #2

Module 26

1794-IF4I

Function

System IO

Channel

System IO

Channel

System IO

Channel

Mode of Operation

0 BOW TUNNEL THR (T2) PITCH

CMD

1 STBD MAIN (T5) PITCH CMD

2 STBD RUDDER DIRECTION CMD

3

24VDC Analog Input Module

0 STERN TUNNEL THR (T3) PITCH

CMD

1

2

3

24VDC Analog Input Module

Failure Mode

Failure Cause

Failure Detection

Failure Effect

Corrective

Action

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Preventative

Actions

Loss of pitch command. Operator alerted by command/feedback comparison (See Note ** at bottom)

Loss of pitch command. Operator alerted by command/feedback comparison (See Note ** at bottom)

Loss of direction command. Operator alerted by command/feedback comparison (See Note ** at bottom)

Failure of IO Input Loss of power,

NMS Alarms

Loss of Analog

Check power,

See Note * below No

Module

Internal

Module Fault

Input Signals

verify cable, verify

Component

Indication

Listed Below.

module. Replace

Failure, loss of

affected modules.

communications

with the PLC.

Loss of pitch command. Operator alerted by command/feedback comparison (See Note ** at bottom)

No

Failure of IO Input Loss of power,

NMS Alarms

Loss of Analog

Check power,

See Note * below No

Module

Internal

Module Fault

Input Signals

verify cable, verify

Component

Indication

Listed Below.

module. Replace

Failure, loss of

affected modules.

communications

with the PLC.

Loss of pitch feedback. Operator alerted by command/feedback comparison. No impact on thrust cmd.

No

0 BOW TUNNEL THR (T2) PITCH

FDBK

1 STBD MAIN (T5) PITCH FDBK

Loss of pitch feedback. Operator alerted by command/feedback comparison. No impact on pitch cmd.

2 STBD RUDDER DIRECTION FDBK Loss of direction feedback. Operator alerted by command/feedback comparison. No impact on direction cmd.

3

24VDC Analog Input Module

Failure of IO Input Loss of power,

NMS Alarms

Loss of Analog

Check power,

See Note * below No

Module

Internal

Module Fault

Input Signals

verify cable, verify

Component

Indication

Listed Below.

module. Replace

Failure, loss of

affected modules.

communications

with the PLC.

0 STERN TUNNEL THR (T3) PITCH Loss of pitch feedback. Operator alerted by command/feedback comparison. No impact on thrust cmd.

FDBK

Loss of SG KW feedback.

1 STBD SHAFT GEN (SG2) KW

FDBK

Loss of G KW feedback.

2 STBD GEN (G2) KW FDBK

3

No

* The most probable cause for loss of FlexLogix PLC, Flex I/O module or ACNR (ControlNet Reundant Media Adapter) is a hardware fault in the effected component. The loss of aFlexLogix PLC will result in a loss of communications

to all Flex IO modules associated with the PLC. There is one FlexLogix PLC in each SPU1 and SPU2. Thruster, Power Plant and Environmental interfaces are split between the two SPU's for redundancy purposes, so that loss of an

SPU (or PLC) will not cause a loss of position as long as the other SPU, PLC, Flex I/O modules and ACNR are fully available. A failure of an individual module or of a single channel on a module will generate appropriate alarms.

Some operator action may be required. Singe failures are evaluated under the assumption that all other equipment is fully available.

** Loss of the ability to command a thruster (from the DP system) or a failure at the thruster (resulting in a loss of control or out of control thruster) will require the operator to take the affected thruster offline. If the thruster is not

responding to commands from the DP system then the other remaining thrusters will be commanded to compensate for the affected thruster in order to maintain position. DP system thruster commands go to zero upon failure of an

ACNR or Module (associated with the thruster commands)

24005418PS-310 Rev A

Commercial In Confidence

Page B-13 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Selector Switch

for DP Controls /

Bridge Controls /

Independent JS

Controls

Function

Mode of Operation

Selecting DP,

Three Position Switch: 1) DP

Bridge or

Control. 2) Bridge Control. 3)

Independent JS

Independent JS Control.

Control and

selecting Thrusters

for DP/JS Control

Failure Mode

Failure Cause

Failure Detection

Failure Effect

Corrective

Action

Selector Switch for DP Controls / Bridge Controls / Independent JS Controls

Mechanical,

Switch failure or Loss of DP/JS

Loss of ability to Repair/Replace

Electrical Fault

external damage Online signals or go into or out of

the switch.

Thruster Selects. DP, Bridge,

Alarm on DP or

Independent JS

Independent JS control modes or

stations.

loss of Thruster

Select Signals

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Preventative

Actions

Yes, the

possibility exists,

but only if the

redundant DP and

JS Online

contacts and/or a

majority of the

thruster select

contacts fail. This

is considered

highly unlikely as

the switch

contacts are all

electrically

isolated and the

switch is industrial

grade.

No, Ship can

revert to manual

controls at the

thrusters/main

props/rudders.

No, Ship can

revert to manual

controls at the

thrusters/main

props/rudders.

Periodic

inspection and

verification of

switch operation.

No

No

No

Periodic

verification of

proper network

communications

and no flashing

channel lights at

PLC.

Verify Ethernet

No

10BaseT cabling

and connectors

between consoles

and Ethernet

Switch.

No

No

Control and Data Networks

Control Network

Ch. A and B

Control Network Ch. A and B

Redundant control IO control network and information Single Network

Line Severed or Alarm respective No loss of DP

network between transfer between PLC's and Control Line Faulted (Ch. Mis-connected

Channel Fault on Control from

Control Stations,

Stations.

A or B)

DP1, DP2,

either station.

PLC's and IO.

Independent JS Control data

Stations

transmitted over

remaining

network channel

Ethernet

Workstation

Redundancy Data Ethernet

Network Ch. A

Communications

and B

24005418PS-310 Rev A

Redundancy Data Network

Communications

Ethernet Redundancy Data Network

Loss of Ethernet Severed Network Operator notified No loss of DP

A or B Channel

Cable

of loss of Ethernet control from either

Redundancy Data Connection,

A or B Channel. station.

problem with

Redundancy Data

Ethernet Switch

transported over

remaining

network channel.

Commercial In Confidence

Repair the

severed co-ax

connection. Reconnect

communications

line.

Page B-14 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Function

Mode of Operation

Failure Mode

Failure Cause

Failure Detection

Failure Effect

Corrective

Action

Loss of DP

Control and

Monitoring

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

Preventative

Actions

Reference Sensors

Loss DP Reference Sensors

Most probable

Operator alerted Data faulted and

cause is antenna by visual and

excluded from

shadowing,

audible alarms

blended position

scintillation, loss

estimate

of power, internal

component

failure, loss of

communications,

or loss of

differential

correction.

DGPS 1, 2

DP Position

Reference

Satellite Position Reference System Loss of sensor

data on DP 1,

DP2, Independent

JS Consoles.

Cyscan System

DP Position

Reference

Cyscan Position Reference System

Loss of sensor

data on DP

Consoles.

Most probable

cause is high

signal noise or

inteference with

target.

Operator alerted

by visual and

audible alarms

Gyro 1, 2

Heading

Reference

Gyrocompass Reference System

Loss of sensor

data on DP

Consoles.

Most probable

cause is gyro

fault, or loss of

power.

Operator alerted

by visual and

audible alarms

24005418PS-310 Rev A

If the DPGS is the

only online

position reference

system, the DP

system will

automatically go

into Dead

Reckoning

Mode". Take

sensor offline if

continued high

levels of signal

noise. Select

different

reference sensor

online.

Yes, if the only

No

reference sensor

online. No loss of

position if other

sensors are

selected online.

No

Data faulted and

excluded from

blended position

estimate

If the Cyscan is

the only online

position reference

system, the DP

system will

automatically go

into Dead

Reckoning

Mode". Take

sensor offline if

continued high

levels of signal

noise. Select

different

reference sensor

online.

Yes, if the only

No

reference sensor

online. No loss of

position of other

sensors are

selected online.

No

Data faulted and

excluded from

average heading

calculation.

Operator should

take failed gyro

offline.

No loss of

No

position. Loss of

heading, if it is the

last Gyro online.

No

Commercial In Confidence

Page B-15 of 16

Remontowa 1674-09 NMS6000 DP (Class 2) System

Component

Description

Wind 1, 2

24005418PS-310 Rev A

Function

Wind Speed and

Direction

Mode of Operation

Wind Speed and Direction

Reference System

Failure Mode

Failure Cause

Loss of impacted Most probable

Wind Sensor data cause is Wind

on DP Consoles. Sensor fault, or

loss of power.

Failure Detection

Operator alerted

by visual and

audible alarms

Failure Effect

Data faulted and

excluded from

average wind

speed and

direction

calculation.

Commercial In Confidence

Corrective

Action

Operator should

take failed Wind

Sensor offline.

Loss of DP

Control and

Monitoring

No

Loss of Steering/

Propulsion/

Navigation

Loss of Safety

No

Preventative

Actions

No

Page B-16 of 16

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Piper Lance II - Turbo Lance II-Maintenance - smv1986Dokument568 SeitenPiper Lance II - Turbo Lance II-Maintenance - smv1986willkobiNoch keine Bewertungen

- 2016 Book IrrigationAndDrainageEngineeriDokument747 Seiten2016 Book IrrigationAndDrainageEngineeriJesús Garre Ruiz100% (2)

- Hydraulic Vs Mechanical+SnubbersDokument1 SeiteHydraulic Vs Mechanical+SnubbersJordana VeigaNoch keine Bewertungen

- Dictionary of Oil Industry TerminologyDokument79 SeitenDictionary of Oil Industry Terminologyniksharris100% (22)

- International Law of The Sea: 1.1. What Is It?Dokument21 SeitenInternational Law of The Sea: 1.1. What Is It?Clark Kenntt50% (2)

- Engine Retrofit Guide v8Dokument70 SeitenEngine Retrofit Guide v8Romulo AlvarezNoch keine Bewertungen

- Free Study PDF Download from pebexam BlogDokument22 SeitenFree Study PDF Download from pebexam Blogk_jaiswalNoch keine Bewertungen

- Prediction On Miss Mamta Banerjee Honorable CM of West Bengal Much Much Before Result and Election by Indranil RayDokument24 SeitenPrediction On Miss Mamta Banerjee Honorable CM of West Bengal Much Much Before Result and Election by Indranil RayIndranil RayNoch keine Bewertungen

- Digital Bending Machine User Manual - BD SeriesDokument7 SeitenDigital Bending Machine User Manual - BD SeriesTatiane Silva BarbosaNoch keine Bewertungen

- Cognitive TheoryDokument18 SeitenCognitive TheoryshaelynNoch keine Bewertungen